Effective soil preparation is crucial for successful farming, and various implements play a vital role in this process. A comprehensive understanding of these tools can significantly enhance agricultural productivity. Each component of these machines serves a specific function, contributing to optimal soil cultivation.

In this section, we will explore the intricate relationships between the different elements that make up these essential farming devices. By examining their structure and functionality, we can appreciate how they work in harmony to facilitate efficient land management.

Ultimately, gaining insights into these mechanisms will empower farmers and agricultural enthusiasts to make informed decisions. This knowledge is essential for anyone looking to maximize their yield and improve their farming practices.

Moldboard Plow Overview

This section provides an insight into the essential agricultural implement designed for soil cultivation. Its innovative design allows for efficient turning and breaking of the ground, making it a staple in farming practices.

- Functionality: Primarily used for preparing fields for planting.

- Components: Comprised of several key elements that contribute to its effectiveness.

- Benefits: Enhances soil aeration and nutrient distribution.

Farmers rely on this implement for its durability and ability to handle various soil types, ensuring optimal conditions for crop growth.

- Understanding the mechanics can improve operation efficiency.

- Regular maintenance is crucial for longevity.

- Choosing the right type depends on specific agricultural needs.

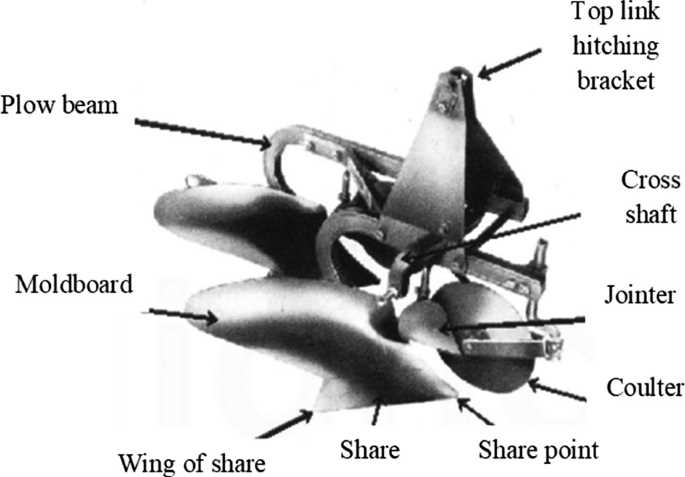

Key Components of a Moldboard Plow

This section explores the essential elements that contribute to the functionality and efficiency of agricultural tillage tools. Each component plays a vital role in soil preparation, ensuring optimal conditions for planting and crop growth.

- Frame: The backbone that supports all other elements, providing stability and strength.

- Shank: A critical piece that penetrates the ground, allowing for effective soil disruption.

- Blade: Designed to slice through the earth, turning it over and enhancing aeration.

- Furrow Wheel: Assists in guiding the implement and maintaining proper depth during operation.

- Hitch: Connects the tool to the tractor, enabling efficient movement and control.

Understanding these components is key to maximizing the performance of this essential agricultural equipment.

Functionality of Each Part

Understanding the role of each component in a soil tillage implement is essential for optimal performance and maintenance. Each element plays a specific role in the cultivation process, contributing to efficiency and effectiveness in preparing the land for planting.

The primary cutting tool is designed to slice through the soil, breaking up compacted layers and facilitating better aeration. This component ensures that the soil is adequately disturbed, promoting root growth and enhancing nutrient absorption.

The surface element helps in turning over the soil, exposing the subsoil to the air and sunlight. This action not only assists in the decomposition of organic matter but also aids in weed control, ensuring that the soil remains fertile for future crops.

The frame provides structural support, connecting all the elements together and maintaining stability during operation. A sturdy frame is crucial for handling various soil types and conditions without compromising the implement’s integrity.

The depth control mechanism allows the operator to adjust how deeply the implement penetrates the ground. This feature is vital for adapting to different soil types and agricultural practices, ensuring optimal tillage results.

Lastly, the wheels or rollers contribute to mobility, enabling the implement to be easily maneuvered across fields. They help maintain a consistent working speed, ensuring that the soil is uniformly processed.

Common Materials Used in Construction

In the realm of building and infrastructure, a variety of essential substances play crucial roles in ensuring durability and functionality. Understanding these materials is fundamental for anyone involved in the construction industry, from architects to laborers.

Concrete is one of the most widely utilized materials due to its strength and versatility. It can be molded into various shapes and provides a solid foundation for structures.

Steel is another critical element, known for its high tensile strength and ability to withstand heavy loads. This metal is often used in frameworks and reinforcements.

Wood offers a natural aesthetic and excellent insulation properties. It is frequently used in residential construction and decorative elements.

Bricks are valued for their durability and thermal mass, making them suitable for walls and facades.

Glass is essential for modern design, providing transparency and light while maintaining structural integrity.

Each of these materials serves specific purposes and contributes to the overall performance and sustainability of buildings.

Maintenance Tips for Plow Parts

Proper upkeep of agricultural equipment is essential for ensuring optimal performance and longevity. Regular attention to various components can prevent breakdowns and enhance efficiency during usage. Here are some key practices to maintain essential elements of your machinery.

1. Regular Inspection: Conduct routine checks to identify any signs of wear or damage. Look for cracks, rust, or loose fittings, which can indicate a need for repairs or replacements.

2. Lubrication: Keep moving parts well-lubricated to reduce friction and wear. Use appropriate oils and greases as specified in the manufacturer’s guidelines.

3. Cleaning: After each use, clean the surfaces to remove dirt, debris, and residues. This helps prevent corrosion and ensures smooth operation.

4. Tightening Fasteners: Periodically check and tighten all bolts and nuts. Vibrations during operation can lead to loosening, which can affect performance.

5. Seasonal Storage: If equipment will not be used for an extended period, store it in a dry place and cover it to protect against dust and moisture. This will help maintain its condition over time.

6. Follow Manufacturer’s Recommendations: Always refer to the guidelines provided by the manufacturer for specific maintenance schedules and practices. This ensures that you’re using the right techniques for your equipment.

By implementing these practices, you can enhance the functionality and lifespan of your agricultural machinery, leading to better performance during critical operations.

Choosing the Right Plow for Soil Type

Selecting the appropriate tool for tilling is crucial for optimal soil management. Different terrains demand specific designs to ensure effective cultivation and enhance productivity. Understanding the characteristics of the earth you’re working with will lead to better outcomes.

Sandy soils benefit from implements that can easily break up clumps and promote aeration. These types are generally lightweight and designed for thorough mixing. Conversely, clay soils require heavier options that can penetrate and turn the dense material without becoming bogged down.

Loamy soils provide a balance, allowing for versatile designs that cater to both tilling and maintaining structure. When assessing your land, consider moisture retention and nutrient content, as these factors will guide your choice and ultimately influence your crop yield.

History and Evolution of Plows

The development of agricultural tools has significantly shaped human civilization, enabling societies to transition from nomadic lifestyles to settled farming communities. Among these tools, the device designed for turning over soil stands out as a pivotal innovation, influencing crop production and agricultural practices throughout history.

Early Innovations

In ancient times, simple implements made from wood or stone were utilized to break up the earth, allowing for the cultivation of grains and other plants. As civilizations advanced, the introduction of metal significantly enhanced these implements, leading to more efficient designs. The use of bronze and later iron allowed for sharper edges, which improved the ability to penetrate the soil and prepare it for planting.

Modern Advancements

The industrial revolution brought about transformative changes in agricultural technology. Mechanization introduced a range of complex designs that increased efficiency and productivity. The introduction of hydraulics and other engineering advancements has led to powerful machinery capable of handling large fields, drastically changing farming practices. Today, modern variations continue to evolve, integrating technology for precision farming and sustainability.

The journey of these essential agricultural tools reflects the broader progress of human ingenuity, illustrating how innovation in farming techniques has continually adapted to meet the needs of growing populations.

Comparison with Other Tillage Equipment

Understanding the distinctions between various soil cultivation tools is essential for effective agricultural practices. Each implement serves a unique purpose, and comparing them helps farmers make informed decisions based on their specific needs and conditions. This section delves into how one particular type of implement contrasts with others in the realm of soil preparation.

Advantages of Traditional Tools

Traditional cultivation devices offer certain benefits, such as simplicity and lower cost. These implements are often easier to maintain and require less specialized knowledge for operation. They are particularly effective in specific situations where minimal disturbance to the soil is desired, making them ideal for certain crops and conditions.

Innovative Alternatives

On the other hand, modern innovations in tillage technology have introduced tools that provide enhanced efficiency and productivity. These advanced options often incorporate features designed to reduce soil compaction and improve moisture retention. However, they can be more expensive and may necessitate additional training for operators. The choice between traditional and innovative methods ultimately depends on the goals of the farmer and the characteristics of the land being cultivated.