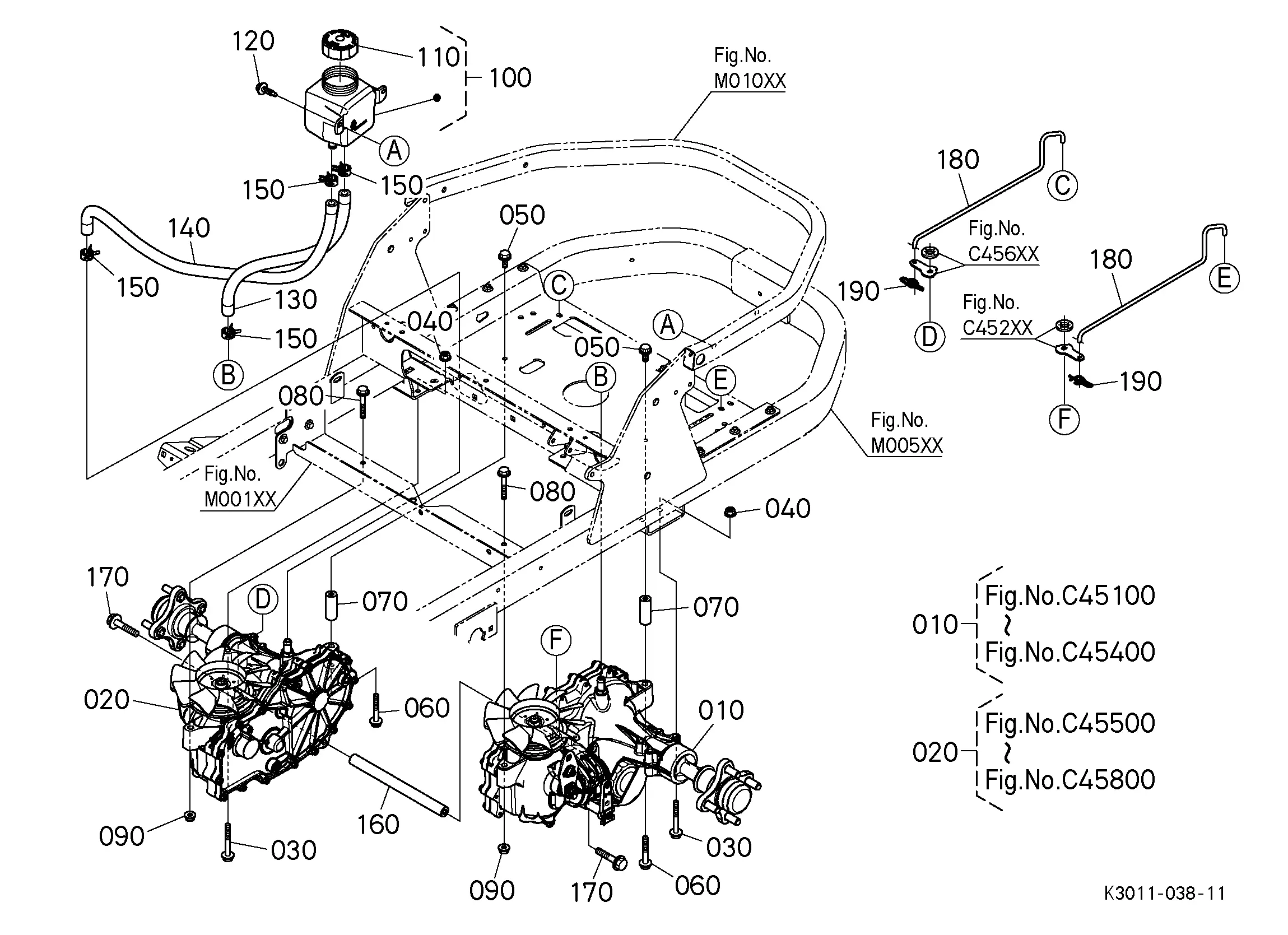

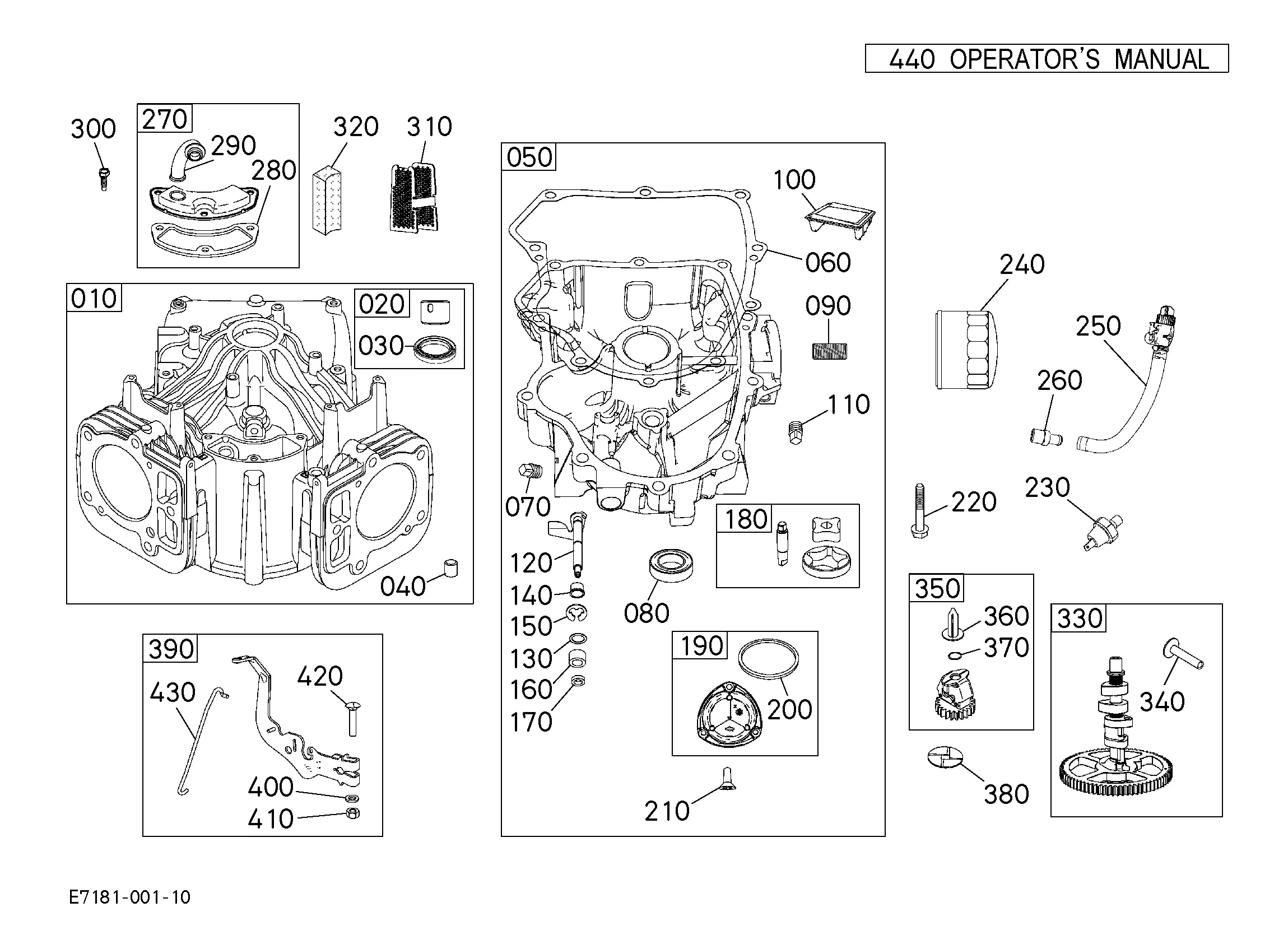

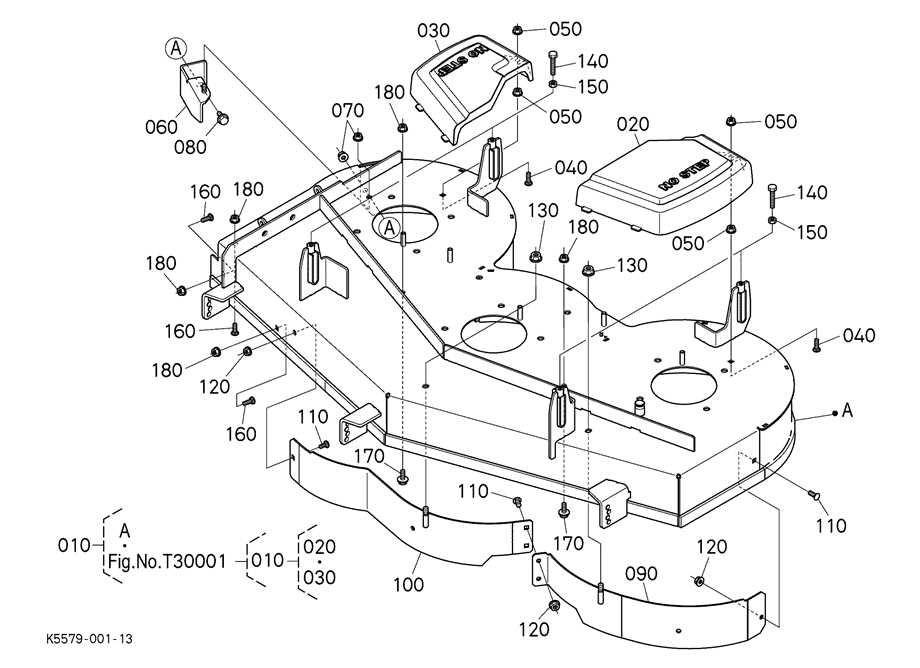

Maintaining and repairing outdoor machinery is crucial for optimal performance and longevity. A comprehensive visual representation of the various elements involved can greatly aid in this process. Whether you’re a professional or a hobbyist, knowing how these pieces fit together is essential.

In this section, we will explore an organized illustration that details the essential components of a specific model. This resource serves as a guide, helping users identify and locate each part effectively.

Diving deeper into the assembly will empower users to troubleshoot issues and execute maintenance with confidence. With a clear understanding of how everything works together, achieving peak functionality becomes the ultimate goal.

Kubota ZG124E Overview

This section provides a comprehensive overview of a popular piece of outdoor machinery designed for efficient lawn maintenance. The machine is well-regarded for its reliability and performance, making it a top choice among landscaping professionals and homeowners alike. Its design emphasizes ease of use, enabling operators to achieve a well-manicured lawn with minimal effort.

Key Features

The equipment comes equipped with several innovative features that enhance its functionality and user experience. Among these are a robust engine, ergonomic controls, and a precision cutting system. These elements work together to ensure optimal performance and versatility in various terrains.

Specifications

| Feature | Description |

|---|---|

| Engine Type | Gasoline, air-cooled |

| Cutting Width | 54 inches |

| Drive Type | Hydrostatic |

| Fuel Capacity | 4 gallons |

| Weight | 500 lbs |

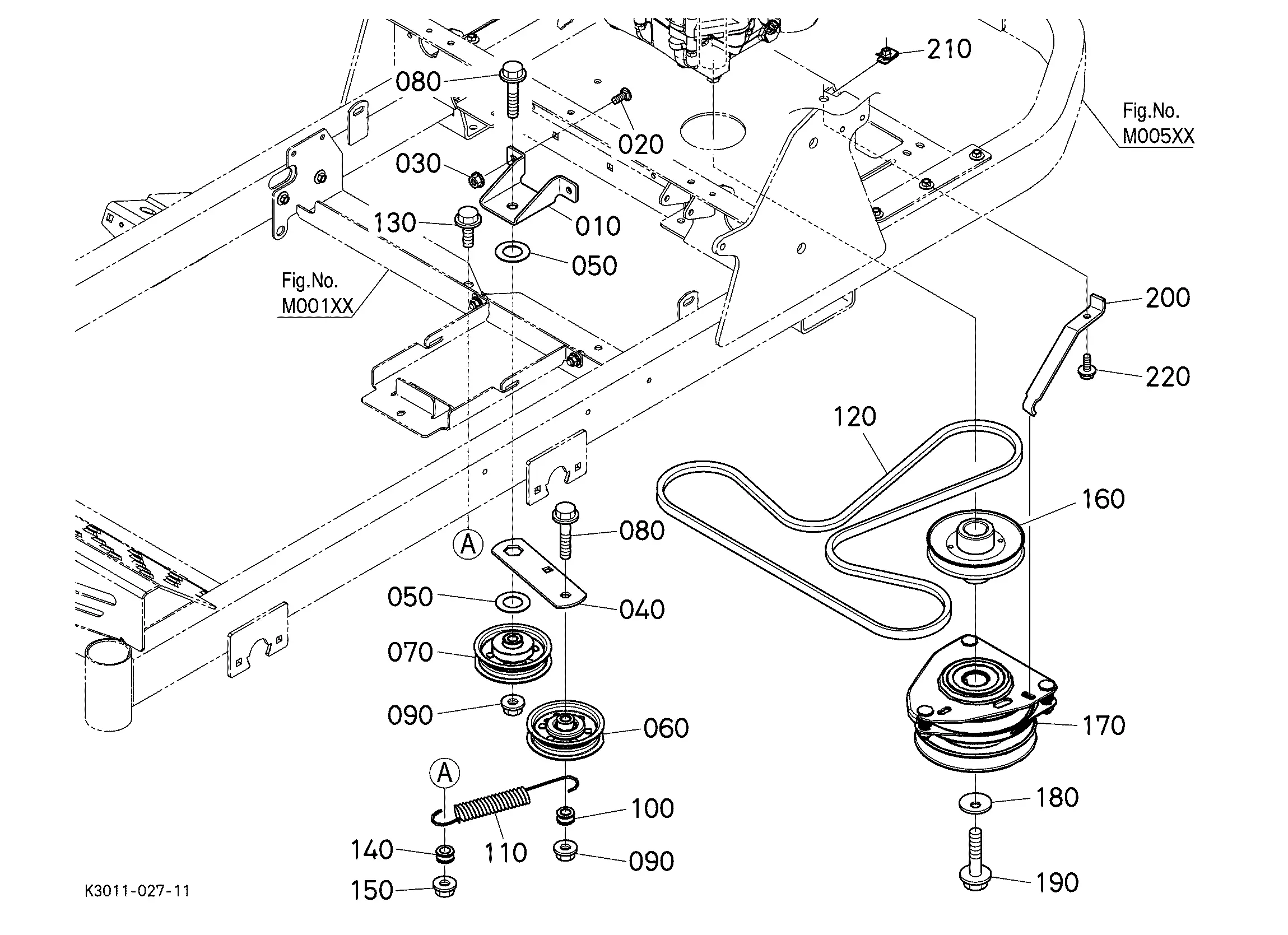

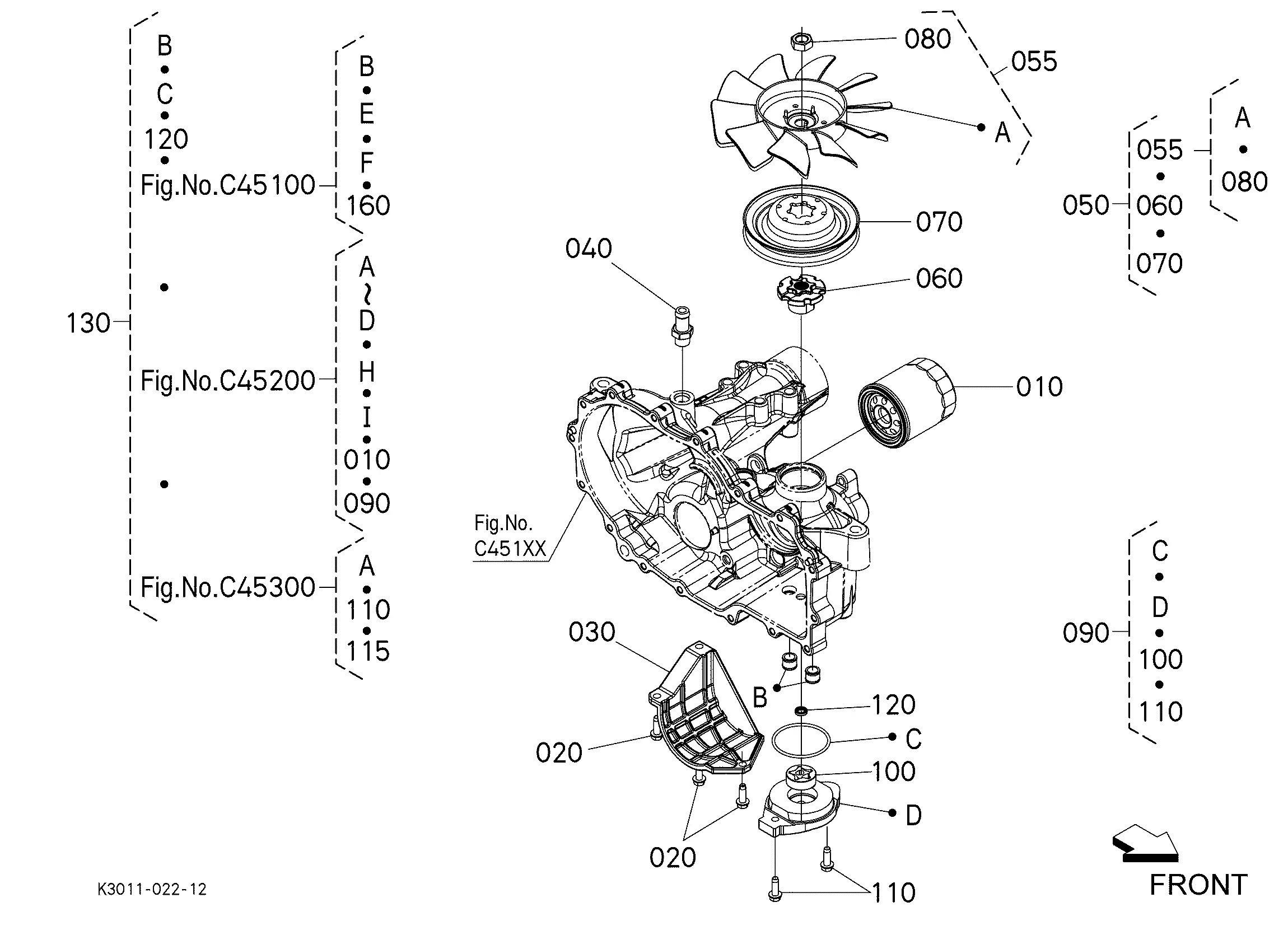

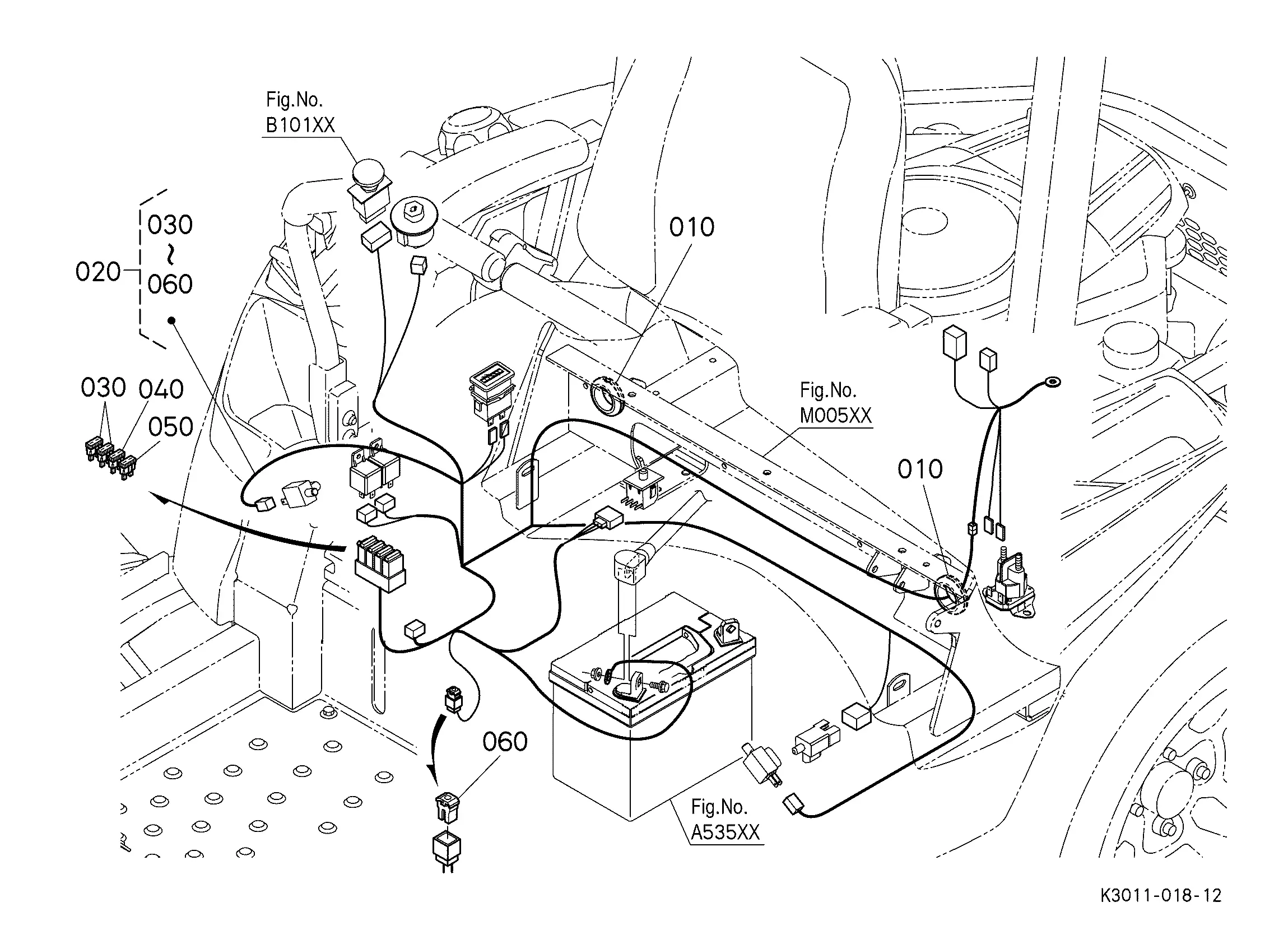

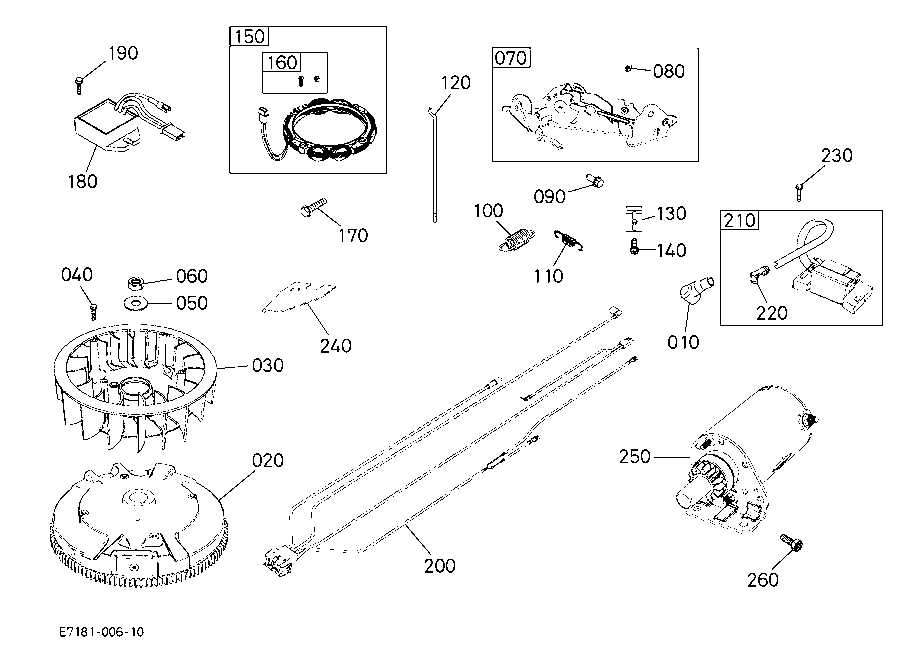

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding machinery and equipment. They provide clarity on how different elements interact, ensuring efficient maintenance and repairs. By referring to these illustrations, users can identify specific pieces and their arrangement, leading to more informed decision-making when it comes to servicing and troubleshooting.

Enhancing Understanding

- Clarifies relationships between components

- Aids in recognizing various elements

- Improves communication among technicians

Facilitating Maintenance

- Streamlines the repair process by pinpointing exact locations of parts

- Reduces downtime through efficient identification of issues

- Encourages proactive maintenance by highlighting wear-prone areas

Overall, these visual aids are invaluable tools for anyone involved in the upkeep and operation of mechanical systems, fostering both knowledge and efficiency in the field.

Common Issues with Kubota ZG124E

Owners of this particular mower often encounter several recurring problems that can affect its performance and longevity. Understanding these issues is crucial for effective maintenance and timely repairs, ensuring that the equipment operates smoothly throughout its lifespan.

Engine Performance Problems

One of the primary concerns involves engine difficulties, which may manifest as reduced power or stalling. These issues can stem from clogged filters, improper fuel quality, or spark plug malfunctions, necessitating regular inspections to maintain optimal function.

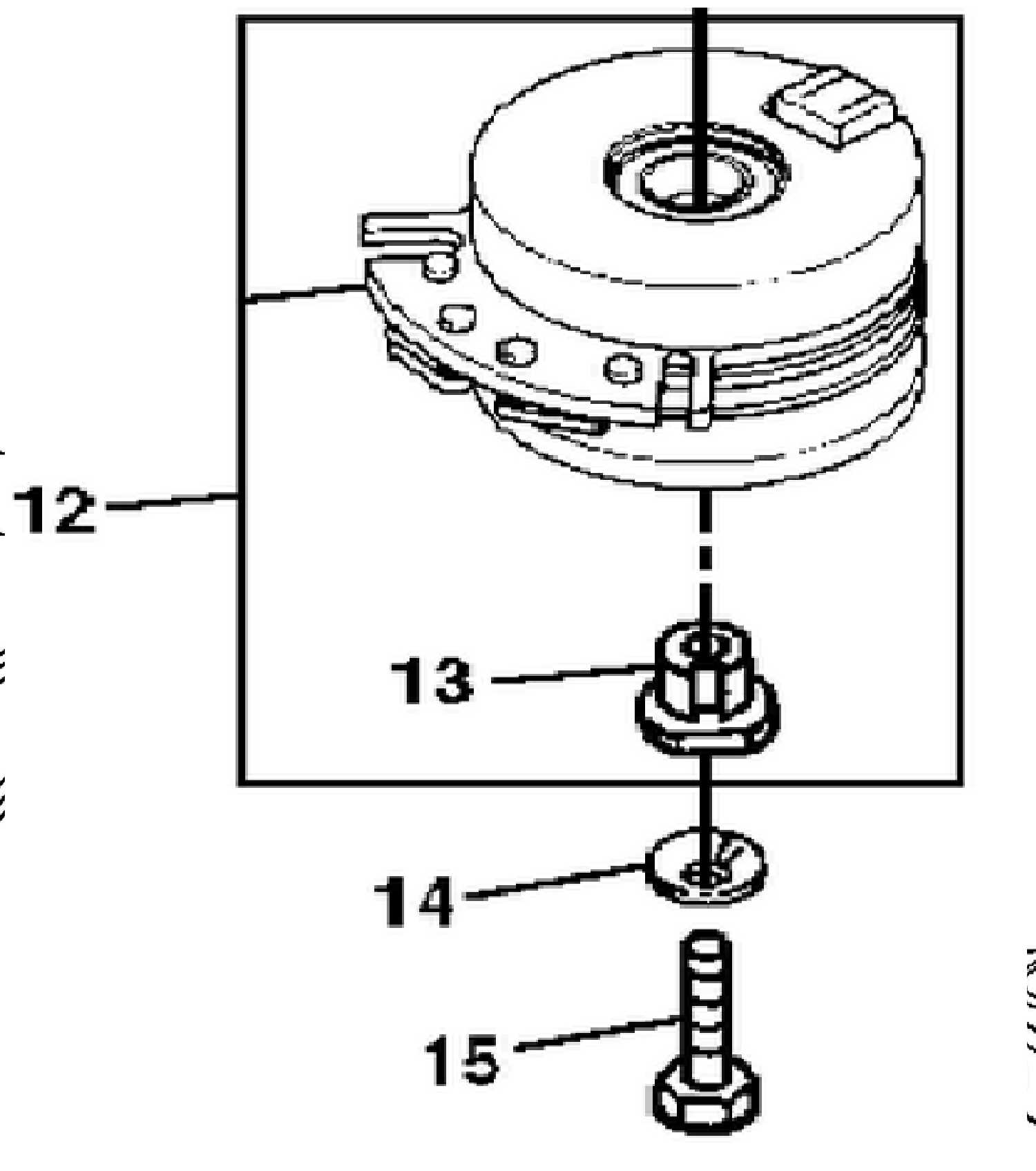

Cutting Deck Challenges

The cutting deck is another area where users frequently experience complications. Common problems include uneven cutting or blades that fail to engage properly. Such issues often arise from dull blades, buildup of grass clippings, or malfunctioning drive components, all of which should be addressed promptly to ensure a clean cut.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task, especially when faced with a myriad of options and specifications. However, with the right approach and resources, identifying the necessary items becomes a straightforward endeavor. A systematic method of searching and utilizing reliable sources can save both time and effort.

Start by consulting the manufacturer’s official resources, such as catalogs or websites, which typically provide comprehensive lists of available components. These platforms often include detailed descriptions and compatibility information, ensuring you find exactly what you need. Additionally, exploring online forums and communities can yield valuable insights, as fellow users frequently share their experiences and recommendations.

Utilizing parts suppliers that specialize in specific machinery can also streamline the process. These suppliers usually have extensive inventories and knowledgeable staff ready to assist in identifying the right components. Moreover, leveraging technology, such as mobile apps or online marketplaces, can further simplify your search, offering convenience at your fingertips.

Finally, maintaining an organized record of previous purchases and preferences will facilitate quicker future searches. By developing a clear understanding of your machinery’s requirements and utilizing available resources effectively, the task of finding replacements becomes not only manageable but efficient.

Maintenance Tips for ZG124E

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a few key practices can significantly enhance efficiency and prevent costly repairs. Below are some vital tips to keep your machine in excellent condition.

Routine Inspection

Conducting frequent checks helps identify potential issues before they escalate. Focus on the following areas:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Engine Oil | Every 25 hours | Change if dirty or low |

| Air Filter | Every 50 hours | Clean or replace as needed |

| Blades | Every use | Sharpen or replace when dull |

Seasonal Maintenance

Seasonal tasks help prepare your machine for varying weather conditions. Key actions include:

| Task | Season | Importance |

|---|---|---|

| Battery Check | Spring | Ensures reliable starts |

| Fuel System Clean | Fall | Prevents fuel issues |

| Tire Inspection | Year-round | Maintains stability and control |

Where to Buy Kubota Parts

When it comes to maintaining and repairing machinery, finding the right components is essential for ensuring optimal performance and longevity. Numerous options are available for sourcing high-quality elements, catering to both professionals and DIY enthusiasts. Understanding where to shop can greatly enhance your experience and provide peace of mind.

Authorized Dealers are often the best starting point for acquiring genuine components. These establishments typically offer a wide selection of items and can provide expert advice. Their knowledge about specific models and compatibility is invaluable, making them a reliable choice.

Online Retailers present a convenient alternative, with many websites specializing in machinery components. These platforms allow for easy comparison of prices and availability, giving you the ability to find exactly what you need from the comfort of your home. Be sure to check customer reviews to ensure you are purchasing from reputable sources.

Local Repair Shops can also be a great resource. Many of these businesses maintain inventories of essential components and may even offer installation services. Supporting local enterprises not only benefits your community but can also save you time on shipping.

Lastly, consider second-hand markets. While purchasing used items can be risky, it often presents an opportunity to find rare or discontinued components at a lower price. Just be sure to verify the condition and compatibility before making a decision.

Understanding the Parts Diagram

Grasping the intricacies of a schematic representation is essential for anyone looking to maintain or repair machinery. These visual aids serve as crucial guides, allowing users to identify various components and their interrelations, ultimately enhancing the efficiency of troubleshooting processes.

Importance of Clarity

A clear illustration not only simplifies the identification of individual elements but also facilitates a better understanding of how they function together. When examining such visuals, it’s vital to focus on the arrangement and connections between parts, as these details reveal the machine’s operational mechanics.

Decoding Symbols and Labels

Often, schematics include specific symbols and labels that denote various components. Familiarizing oneself with these can significantly expedite repair and maintenance tasks. Recognizing each symbol’s meaning allows for a more effective approach to tackling issues, ensuring that users can navigate repairs with confidence.

Benefits of Using OEM Parts

Opting for original equipment manufacturer components ensures quality and compatibility, ultimately enhancing performance and longevity. Here are some key advantages:

- Quality Assurance: OEM components are made to the same specifications as the originals, ensuring superior reliability.

- Perfect Fit: Designed specifically for your machinery, these parts guarantee an exact match and seamless integration.

- Longevity: Investing in original parts often leads to fewer replacements over time, saving both money and hassle.

- Manufacturer Support: OEM products typically come with comprehensive warranties and support from the manufacturer.

- Enhanced Performance: Using original components can significantly improve the efficiency and functionality of your equipment.