The efficient functioning of a cutting tool relies heavily on the intricate assembly of its individual elements. Familiarity with these components not only aids in proper maintenance but also enhances the user’s ability to troubleshoot issues that may arise during operation. Knowing how each piece fits together creates a deeper appreciation for the technology behind the tool and ensures that it performs optimally.

Each section of the machinery plays a vital role in its overall performance. From the power unit to the cutting mechanism, every segment has been meticulously designed for specific functions. Understanding these functionalities can empower users to make informed decisions when it comes to repairs, upgrades, or replacements, ultimately extending the lifespan of the equipment.

For anyone involved in the upkeep of their cutting equipment, grasping the layout of its components is essential. This knowledge serves as a foundation for effective maintenance practices, enabling users to spot wear and tear before it leads to significant malfunctions. By delving into the specifics of the assembly, users can ensure their tools remain reliable and efficient, ready for any task that comes their way.

This section aims to provide an in-depth understanding of a popular handheld cutting tool, detailing its components and their functions. By exploring this information, users can gain insights into the assembly and operation of the device, which is essential for maintenance and troubleshooting.

Key Features and Specifications

- Engine Power: This tool typically features a robust motor, enabling efficient cutting performance.

- Weight: Lightweight construction allows for ease of handling during prolonged use.

- Bar Length: The length of the guide bar plays a crucial role in determining the type of tasks the tool can handle.

- Fuel Efficiency: An effective engine design often contributes to better fuel consumption.

Understanding the Components

Familiarity with the various components can greatly enhance the user’s ability to perform repairs and maintenance. Below are some critical parts:

- Motor: The heart of the machine, responsible for providing the necessary power.

- Guide Bar: Supports the chain, allowing for precise cutting.

- Chain: The cutting element that performs the actual sawing action.

- Air Filter: Ensures clean airflow to the engine, promoting optimal performance.

- Fuel Tank: Stores the fuel needed for operation, impacting the tool’s run time.

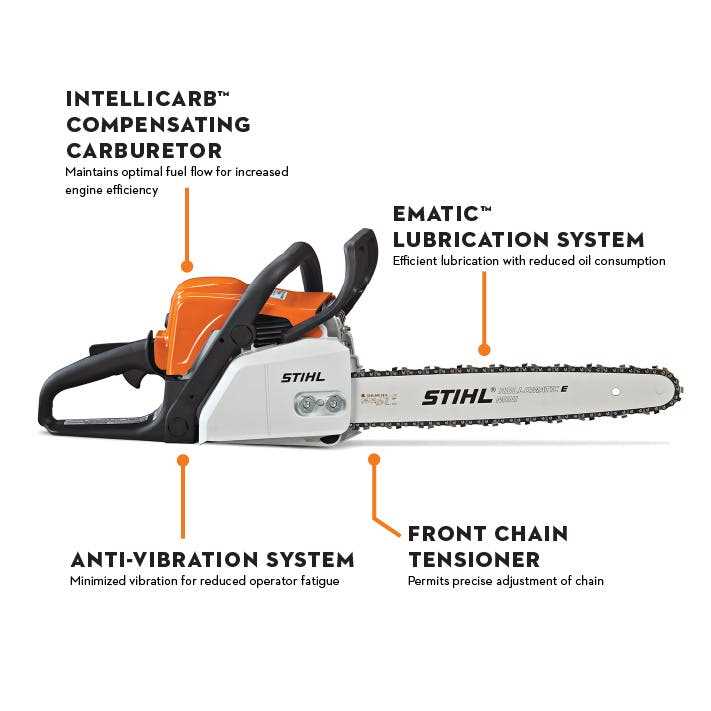

Key Features of MS 170 Model

This model stands out in the realm of outdoor power equipment due to its exceptional performance and user-friendly design. It combines innovation with practicality, making it suitable for various tasks, from light cutting to more demanding jobs.

- Lightweight Construction: Designed for ease of use, this model is lightweight, allowing for extended periods of operation without causing fatigue.

- Powerful Engine: Equipped with a robust engine that delivers reliable performance, ensuring efficient cutting even through tough materials.

- Ergonomic Handle: The handle is designed with user comfort in mind, providing a secure grip that enhances control during operation.

- Easy Start System: This feature simplifies the starting process, making it accessible for users of all skill levels.

- Efficient Fuel Consumption: The engine is engineered for fuel efficiency, minimizing operational costs and reducing environmental impact.

Overall, this model is a reliable choice for homeowners and professionals alike, offering a blend of power, comfort, and efficiency for various cutting tasks.

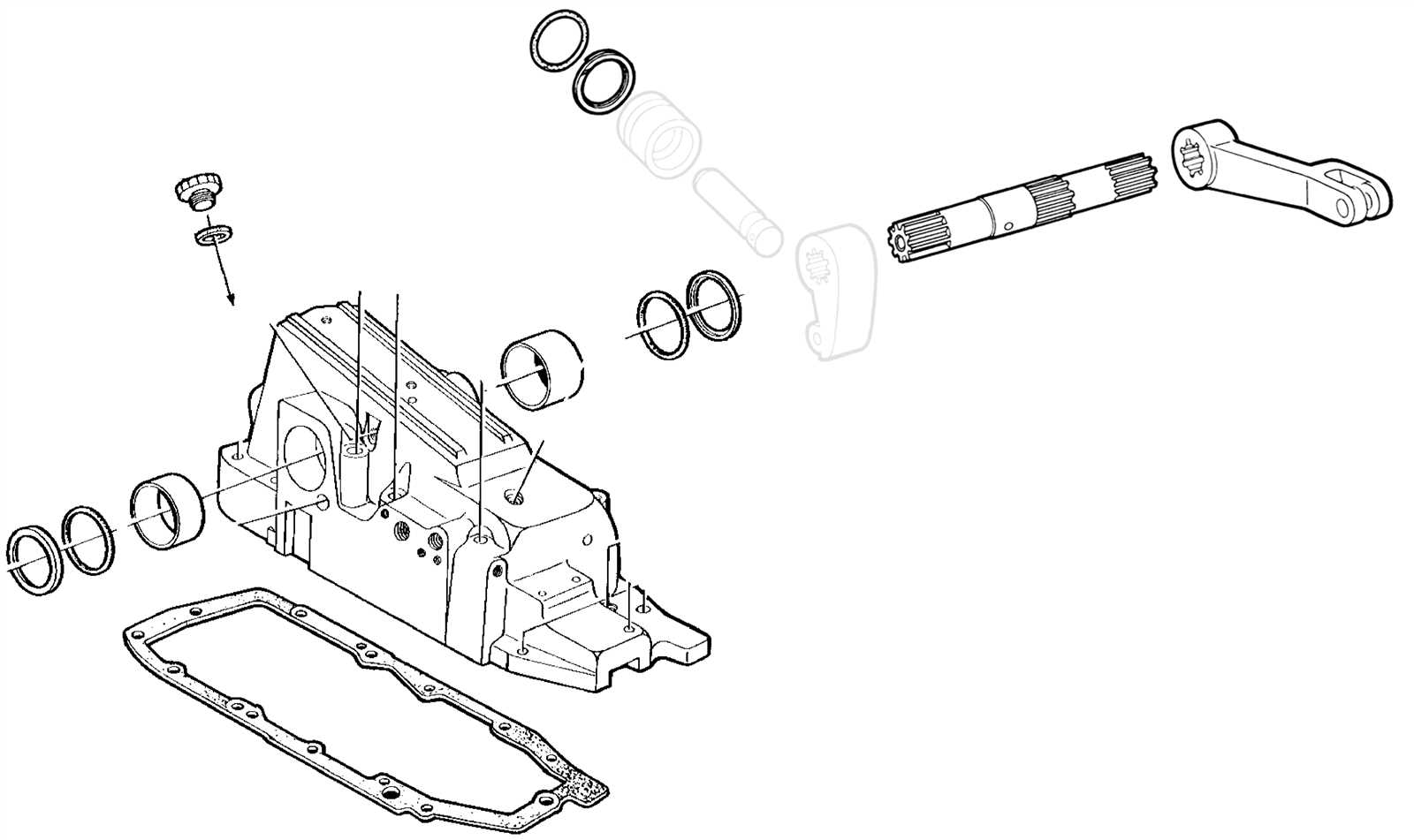

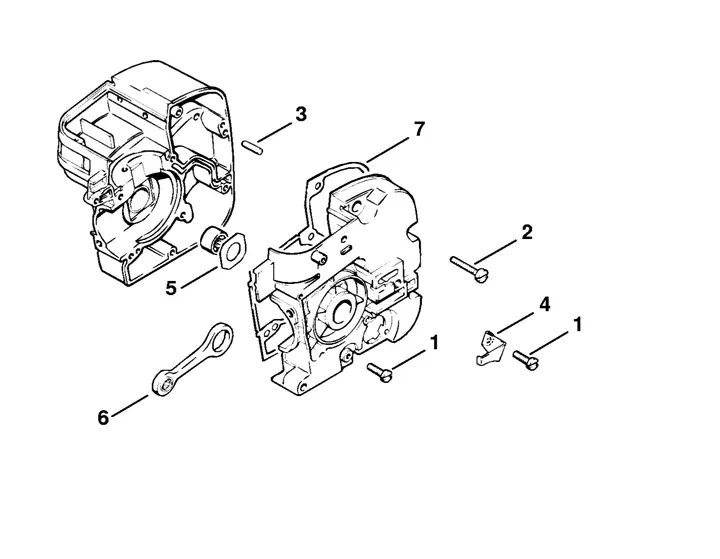

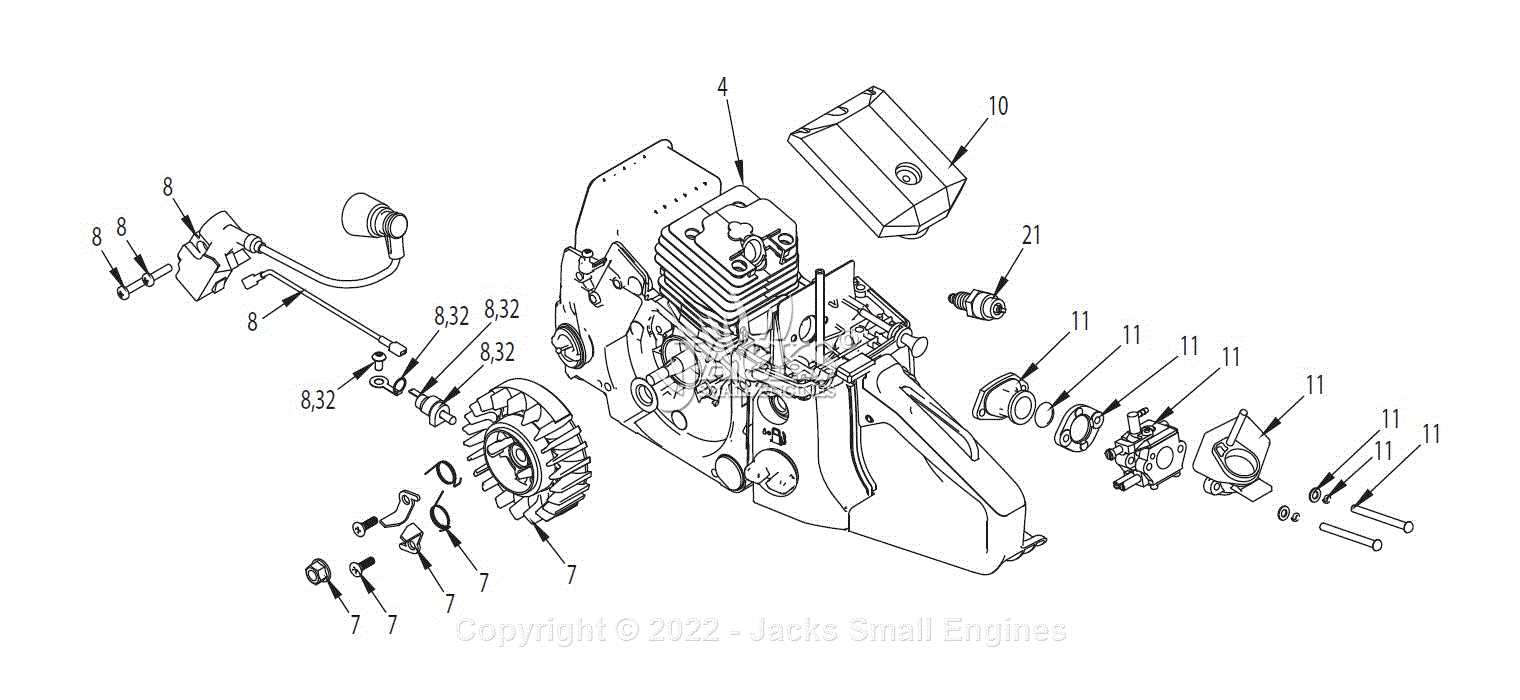

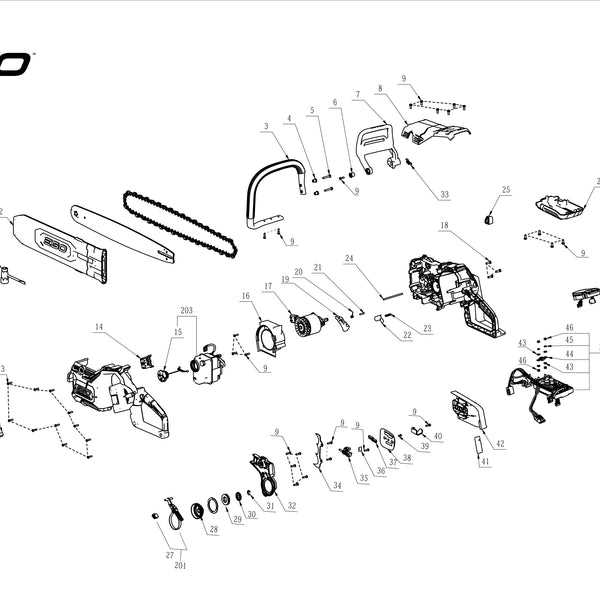

Importance of Parts Diagrams

Understanding the assembly and functionality of mechanical systems is crucial for effective maintenance and repair. Visual representations of components play a vital role in simplifying complex machinery, enabling users to grasp the relationships between various elements. Such illustrations serve as valuable resources, offering clarity and enhancing the efficiency of service procedures.

Enhanced Understanding

Visual aids provide an intuitive approach to comprehending the intricate layout of machinery. They facilitate a clearer understanding of how different parts interact, which is essential for troubleshooting and ensuring optimal performance. By breaking down complex systems into easily digestible segments, these representations empower users to engage more effectively with their equipment.

Streamlined Maintenance

Having access to accurate visual references can significantly expedite maintenance tasks. Users can quickly identify components that require attention, reducing the risk of errors during repairs. Furthermore, these illustrations help in locating specific parts, minimizing downtime and ensuring that machines operate smoothly for extended periods.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repairs. These visual guides provide detailed insights into the individual elements of a machine and their relationships. By grasping the structure of these illustrations, users can effectively identify and source necessary items, ensuring smooth operation of their equipment.

Identifying Components

Each element in the illustration is usually labeled with a unique identifier, which corresponds to a list of parts. Familiarizing yourself with these labels allows for quick reference when looking up specific items. Take note of any numbers or letters that accompany the visual representation, as they are crucial for precise identification.

Understanding Relationships

The layout often indicates how different components fit together, highlighting their connections and interactions. Pay attention to lines and arrows that show how parts interact with each other. This knowledge is vital for understanding the assembly process, troubleshooting issues, or performing upgrades.

By mastering the art of interpreting these illustrations, individuals can enhance their efficiency in managing repairs and replacements, ultimately prolonging the lifespan of their machinery.

Commonly Replaced Parts in MS 170

Maintaining a chainsaw involves routine checks and timely replacements of certain components to ensure optimal performance. Understanding which elements are frequently substituted can help users enhance the longevity and efficiency of their equipment. Below are some of the most commonly swapped components for effective upkeep.

Essential Components

- Chain: Regular wear and tear can dull the chain, necessitating replacement for safe and effective cutting.

- Bar: The guide bar can become worn or damaged over time, impacting cutting precision.

- Air Filter: A clogged air filter can hinder engine performance, making replacement essential for air quality and efficiency.

Additional Items to Consider

- Sprocket: A worn sprocket can lead to chain slippage and uneven wear.

- Fuel Filter: Replacing the fuel filter regularly helps prevent engine issues caused by debris.

- Spark Plug: A faulty spark plug can cause starting problems and poor engine performance, making timely replacement crucial.

Regularly checking and replacing these components will not only extend the life of the equipment but also improve its performance and safety during use. It is advisable to consult the user manual for specific recommendations on maintenance schedules.

Finding Genuine Stihl Replacement Parts

Ensuring the longevity and optimal performance of your outdoor equipment is essential for any user. When components become worn or damaged, sourcing authentic replacements is crucial. This process not only enhances the functionality of your machine but also contributes to safety and reliability during use.

The Importance of Authentic Components

Utilizing original components guarantees compatibility and maintains the integrity of your equipment. Imitation parts may appear similar but can lead to malfunction and potentially damage other vital systems. Investing in genuine items ultimately results in better performance and a longer lifespan for your machinery.

Where to Source Genuine Items

To find authentic replacements, consider authorized retailers or the manufacturer’s official website. These sources ensure you are purchasing quality components that meet rigorous standards. Additionally, reaching out to local dealers can provide insights into available stock and expert guidance on selecting the correct items.

Maintenance Tips for Stihl MS 170

Proper care and regular upkeep are essential for ensuring the longevity and performance of your chainsaw. By following a few key maintenance practices, you can enhance its efficiency and minimize the risk of breakdowns. This section outlines crucial tips to keep your equipment in optimal condition, promoting both safety and reliability.

1. Regular Cleaning: After each use, clean the exterior of the tool to remove sawdust, oil, and debris. Pay special attention to the air filter and cooling fins, as buildup can impede airflow and lead to overheating. A clean machine performs better and lasts longer.

2. Chain Maintenance: Frequently check the sharpness of the cutting chain. A dull chain requires more power and increases the risk of kickback. Sharpen the chain regularly and ensure proper tension to facilitate smooth cutting and reduce wear.

3. Lubrication: Ensure that the guide bar and chain receive adequate lubrication. Regularly check the oil reservoir and refill it with the appropriate lubricant to avoid excessive friction, which can lead to premature wear.

4. Inspect Components: Routinely inspect all components for signs of wear or damage. Look for cracks in the housing, wear on the guide bar, and any issues with the throttle or brake mechanisms. Addressing these issues promptly can prevent further damage and enhance safety.

5. Fuel Quality: Use fresh, high-quality fuel mixed with the correct ratio of oil as specified by the manufacturer. Stale fuel can lead to starting problems and poor performance. Always store fuel in a cool, dry place to maintain its quality.

6. Seasonal Storage: If you plan to store your equipment for an extended period, take steps to prepare it. Empty the fuel tank, clean the machine thoroughly, and store it in a dry location. This will prevent deterioration and ensure it’s ready for use when you need it.

By implementing these maintenance tips, you can ensure that your chainsaw operates efficiently and safely, allowing you to tackle various tasks with confidence.

Resources for Stihl MS 170 Owners

For individuals who own a specific model of outdoor power equipment, access to reliable resources is essential for maintaining and enhancing the performance of their machine. A variety of materials can aid in understanding its components, troubleshooting issues, and ensuring optimal operation. Whether you’re looking for manuals, repair guides, or community support, numerous avenues are available to help you make the most of your equipment.

| Resource Type | Description | Where to Find |

|---|---|---|

| Owner’s Manual | A comprehensive guide outlining operation, maintenance, and safety instructions. | Official website or authorized dealers |

| Repair Guides | Step-by-step instructions for troubleshooting and repairing common issues. | Online forums or repair websites |

| Video Tutorials | Visual demonstrations of maintenance tasks and repairs. | YouTube and other video-sharing platforms |

| Community Forums | A platform for sharing experiences, tips, and advice with fellow owners. | Online community boards |

| Replacement Parts Retailers | Stores that specialize in selling components and accessories for various models. | Local hardware stores and online marketplaces |