When maintaining and operating snow clearing machinery, understanding the key elements that make up the entire system is crucial for both efficiency and safety. Every machine is built with a variety of interconnected components, each serving a specific role. Proper knowledge of how these elements work together ensures optimal performance, whether for routine use or during more intensive operations.

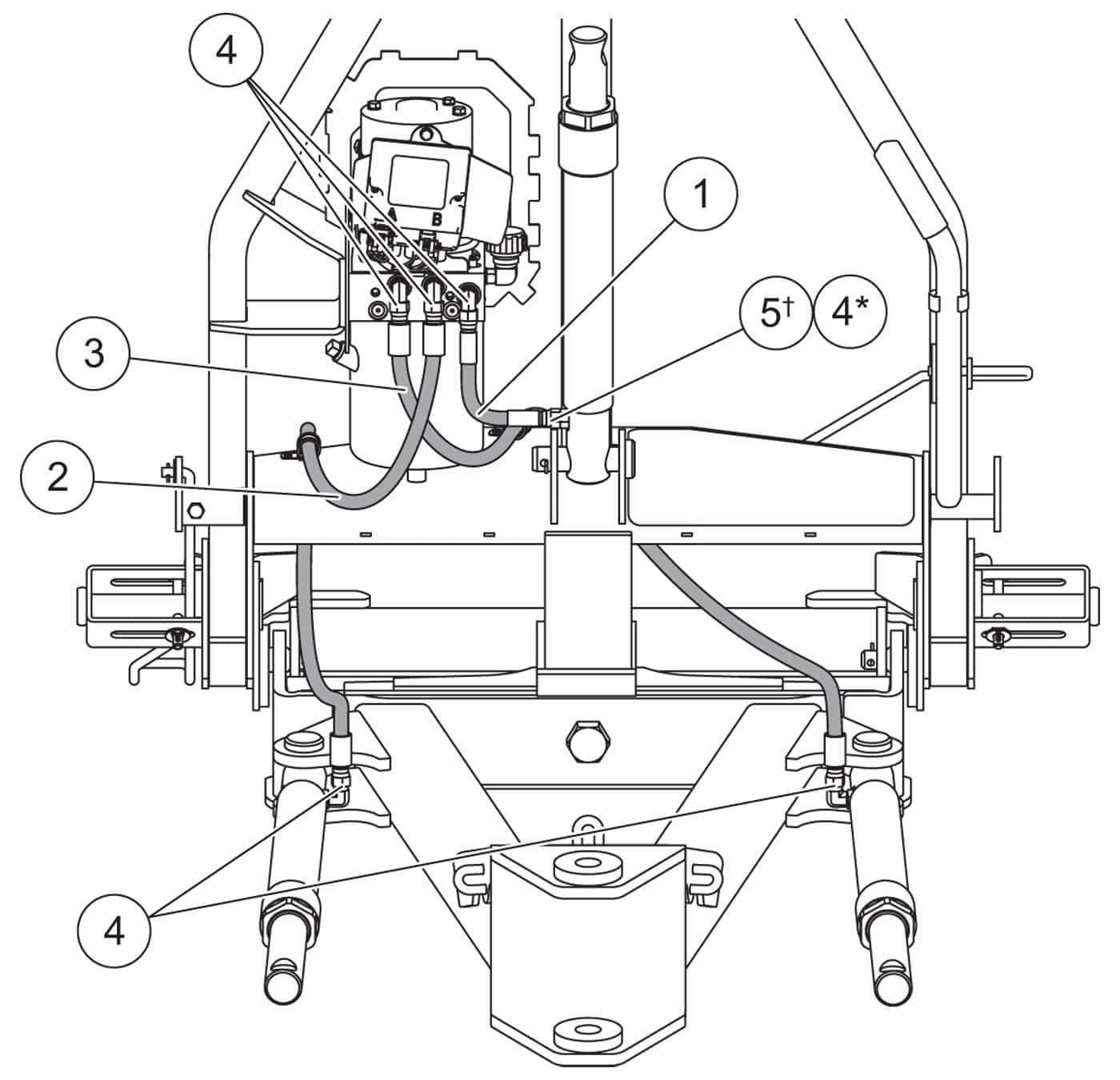

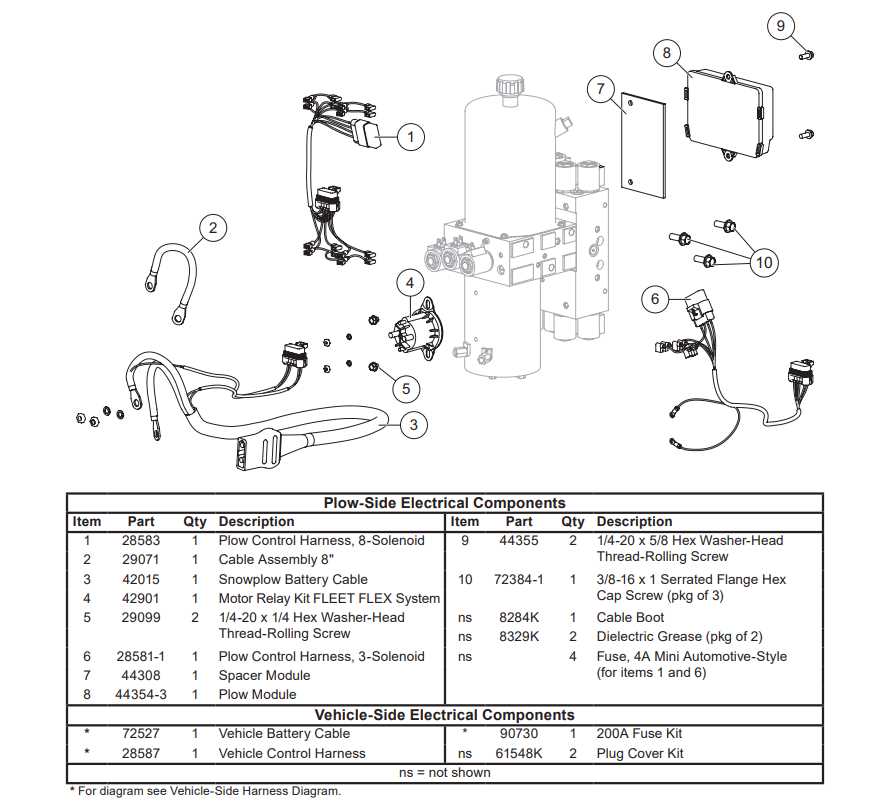

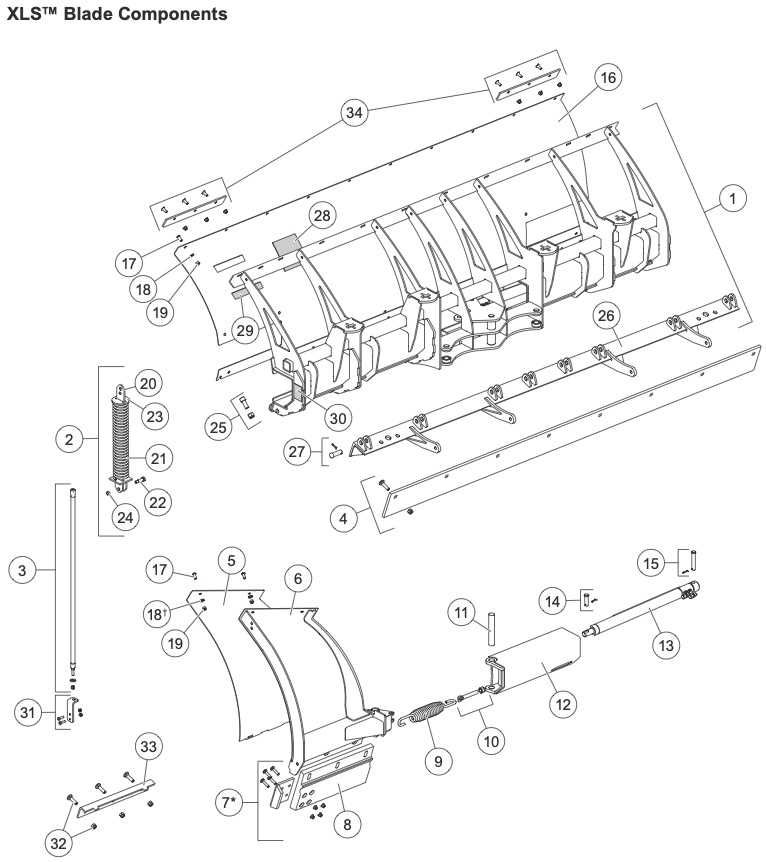

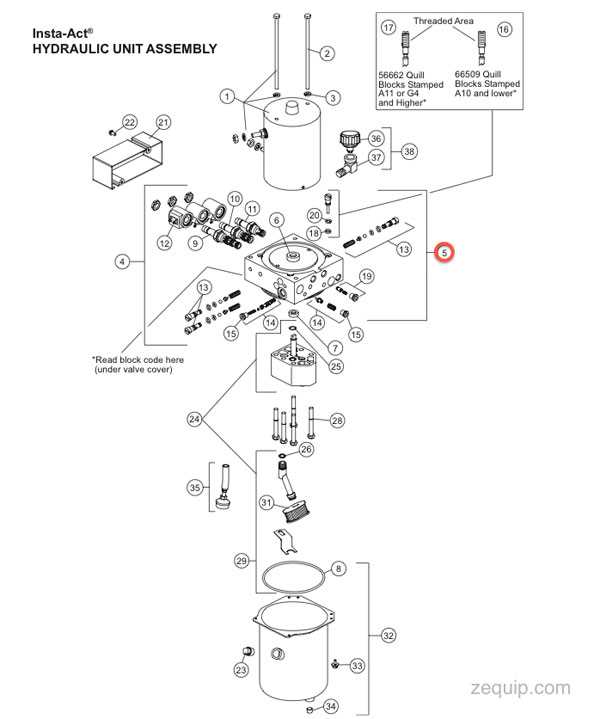

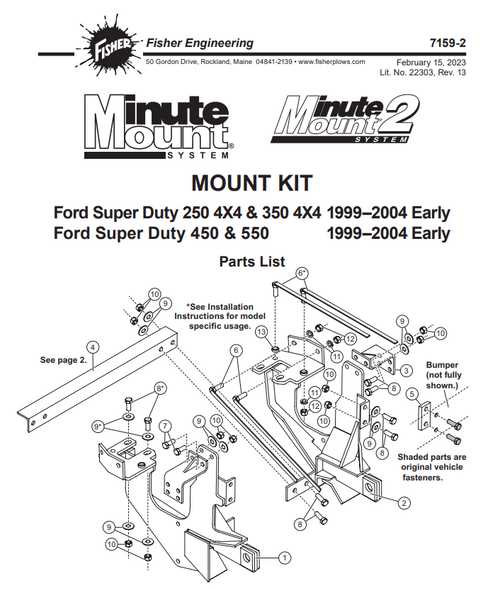

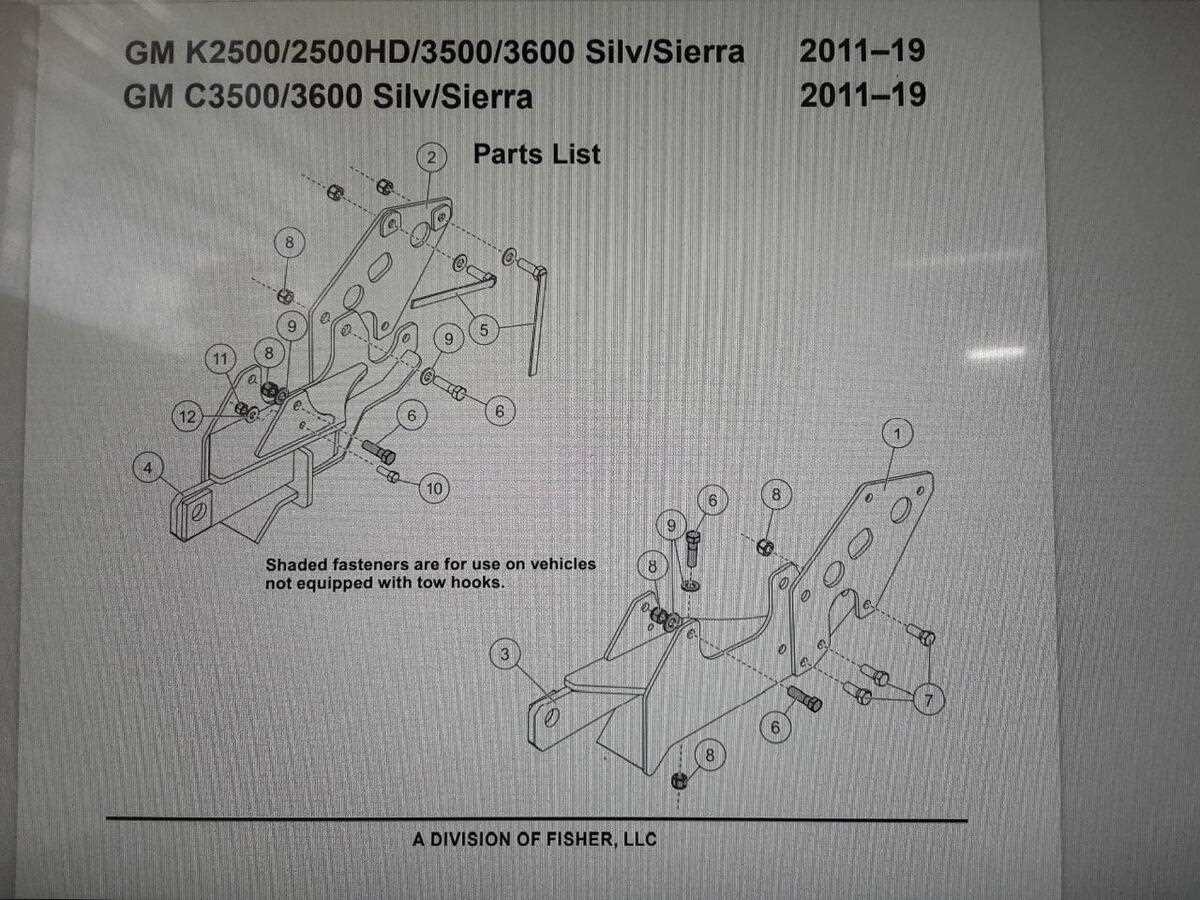

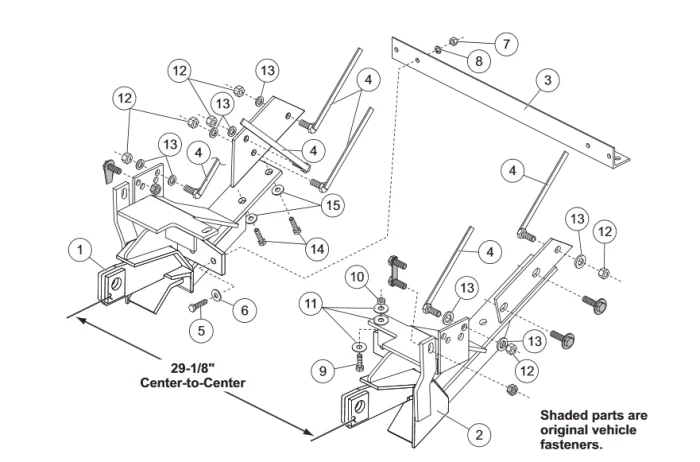

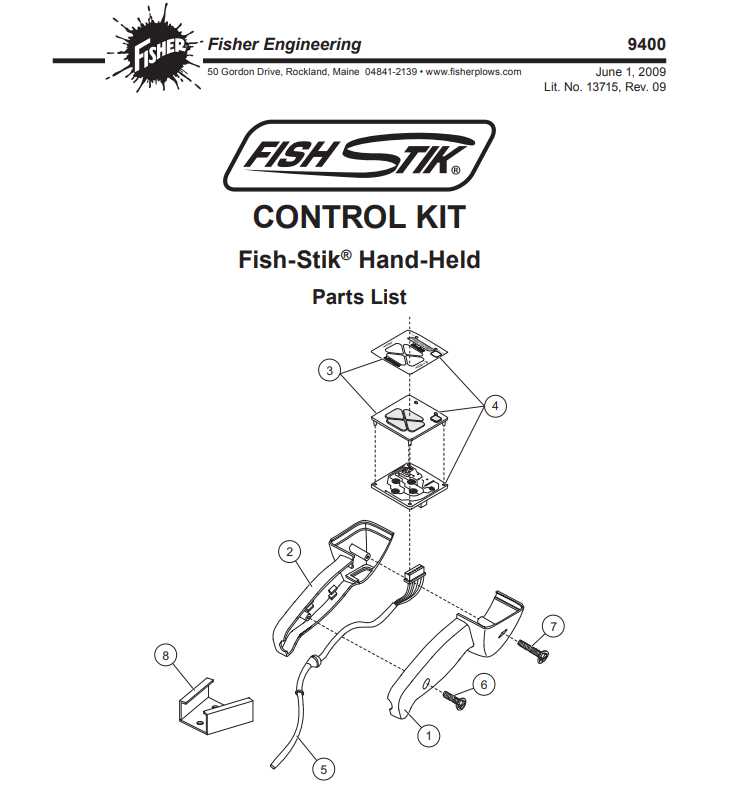

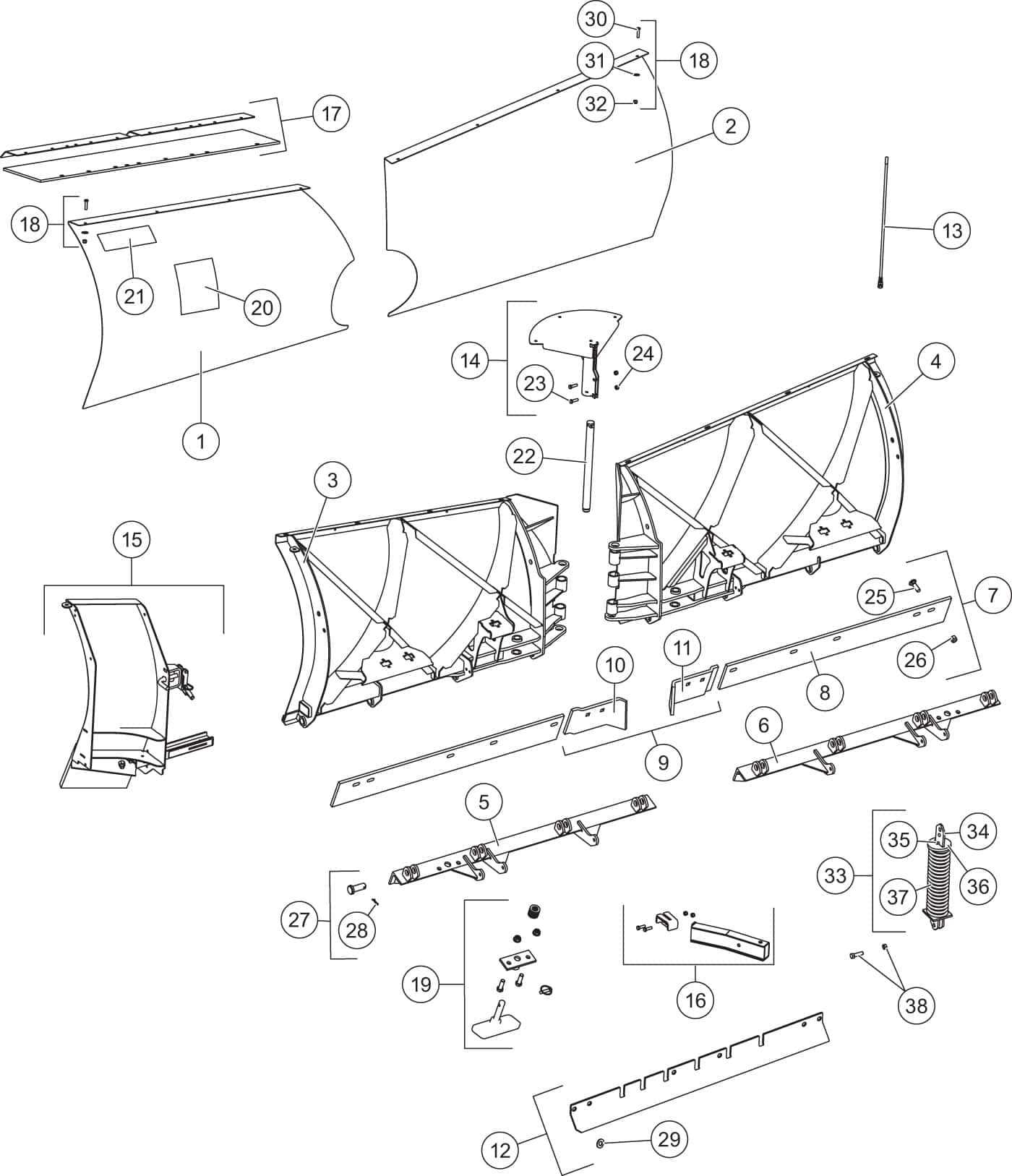

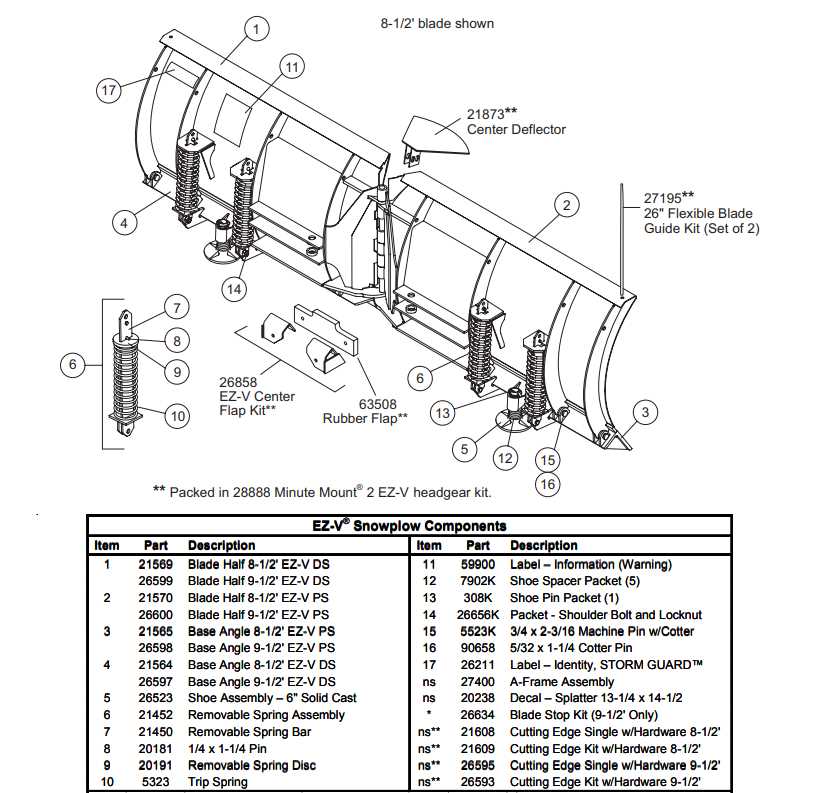

Visual guides that illustrate the layout and interaction of these components are invaluable tools for operators and technicians. By referring to these schematics, users can quickly identify any issues, make necessary repairs, or perform routine maintenance. Knowing the precise location and function of each part not only improves the operation but also reduces the chances of costly mistakes or downtime.

These guides are especially useful when dealing with complex equipment, where a small malfunction can lead to significant operational failures. A clear representation of the system’s structure allows for more efficient troubleshooting and enhances the overall longevity of the equipment.

Understanding Fisher Plow Mechanics

In the world of snow removal, the ability to efficiently clear roads and driveways relies heavily on the mechanical systems of the equipment used. These systems consist of various interconnected components that work together to ensure optimal performance. From lifting and angling mechanisms to hydraulic systems, each element plays a critical role in the functionality of the entire assembly. Gaining insight into how these systems operate can help in diagnosing issues, performing maintenance, and improving overall efficiency.

Key Functional Elements

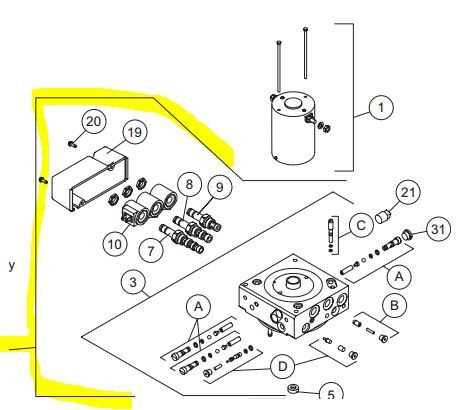

At the core of any snow-clearing setup are the lifting and angling mechanisms. These systems allow the user to position the blade in a way that maximizes efficiency while minimizing the strain on the vehicle. The lifting system usually operates through hydraulic cylinders that raise and lower the blade, while the angling mechanism adjusts the angle of attack based on the operator’s needs. Each of these functions is essential for controlling the direction and depth of the snow being cleared.

Hydraulic Systems and Control

One of the most important aspects of these setups is the hydraulic system. This network of pumps, hoses, and cylinders provides the force needed to move and position the blade. The hydraulic system is controlled by valves and levers, which allow the operator to make fine adjustments quickly and easily. Without a well-functioning hydraulic system, it would be nearly impossible to achieve the precision necessary for effective snow clearing.

Maintaining the various components and ensuring they are working harmoniously is key to a well-functioning system. Regular checks on fluid levels, seals, and mechanical linkages can prevent downtime and ensure that the equipment remains operational during critical snow events.

Essential Components of Fisher Plows

Understanding the key elements that contribute to the efficiency and functionality of snow removal equipment is crucial for optimal performance. Each component plays a significant role in ensuring reliability, durability, and effectiveness during harsh winter conditions.

Structural Elements

The framework consists of robust materials designed to withstand extreme forces. These foundational pieces provide the necessary support for the entire system, ensuring stability during operation.

Control Mechanisms

Advanced control systems allow for precise maneuvering and adaptability to various conditions. These components enable operators to adjust settings seamlessly, enhancing overall efficiency and safety.

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through the intricate layout of each element involved in the system. By mastering how to interpret these visuals, one can easily identify, locate, and order the necessary components for any project.

When examining these visuals, pay attention to the following key elements:

| Element | Description |

|---|---|

| Labels | Each component is often marked with a unique identifier, helping to quickly reference it in accompanying lists or manuals. |

| Connections | Lines or arrows indicate how different elements are linked, providing insight into the assembly or disassembly process. |

| Legend | A legend explains the symbols and notations used, which is crucial for accurate interpretation of the visual. |

| Scale | Understanding the scale is vital for grasping the relative size of components and their arrangement within the whole. |

By familiarizing yourself with these features, you can navigate the complexities of any system with confidence and efficiency, ensuring that you have the right elements for your needs.

Common Issues with Plow Parts

When operating essential equipment for winter maintenance, users often encounter a variety of challenges that can affect performance and efficiency. These issues may arise from wear and tear, environmental factors, or improper maintenance practices, ultimately impacting the effectiveness of the equipment.

Wear and Tear: Over time, components may experience significant deterioration due to frequent use. This can lead to reduced functionality and the need for timely replacements.

Corrosion: Exposure to moisture and salt can result in rust formation, compromising the integrity of critical components. Regular inspection and maintenance are crucial to mitigate this issue.

Improper Installation: Incorrectly installed elements can cause misalignment and operational inefficiencies. Ensuring that all components are fitted correctly can prevent further complications.

Mechanical Failures: Internal malfunctions can occur unexpectedly, often requiring professional assessment to determine the root cause and necessary repairs.

Incompatibility: Using mismatched components may lead to performance issues, highlighting the importance of compatibility in ensuring smooth operation.

By understanding these common challenges, operators can take proactive measures to enhance longevity and reliability, ensuring optimal performance throughout the winter season.

Maintenance Tips for Longevity

Proper upkeep of your snow removal equipment is essential to ensure its durability and optimal performance throughout the years. Regular maintenance not only minimizes the risk of unexpected failures but also improves efficiency and extends the lifespan of the machinery. By addressing minor issues before they escalate, you can avoid costly repairs and downtime. Below are some key practices to help maintain your equipment effectively.

Routine Inspections

Performing regular checks is crucial for early detection of wear and tear. Focus on areas that are most likely to experience strain, such as hydraulic systems, fasteners, and structural components. Make sure to inspect the following:

- Hydraulic hoses and connections for leaks or cracks

- Fasteners and bolts for tightness

- Control cables for smooth movement

- Wear on components that come in contact with surfaces, such as cutting edges

Lubrication and Cleaning

Keeping moving parts lubricated and clean is key to preventing friction and corrosion. Use high-quality lubricants recommended by the manufacturer, and apply them at regular intervals. Additionally, remove debris that can accumulate in hard-to-reach areas.

- Grease joints and pivot points as needed

- Clean dirt, ice, and debris from critical components after each use

- Check fluid levels and replace them according to the manufacturer’s guidelines

By staying proactive and implementing these essential maintenance practices, you will maximize the efficiency and longevity of your equipment, allowing it to perform reliably throughout the season.

Choosing Quality Replacement Parts

When maintaining or repairing heavy-duty equipment, selecting the right components is crucial for ensuring optimal performance and longevity. Low-quality replacements can lead to frequent breakdowns, increased maintenance costs, and, in some cases, safety risks. Therefore, it’s essential to carefully evaluate each option available on the market before making a purchase decision.

Here are some factors to consider when choosing high-quality alternatives:

- Material Quality: Look for components made from durable, high-strength materials. This ensures that they can withstand harsh conditions and extended use without degrading quickly.

- Compatibility: Ensure the replacement is designed specifically for your equipment model. Using parts that are not compatible can lead to operational inefficiencies or damage to the system.

- Manufacturer Reputation: Opt for brands that are known for producing reliable and durable components. Research customer reviews and ratings to assess the quality of the products.

- Warranty: A robust warranty can provide peace of mind, offering protection in case the part fails prematurely.

- Cost vs. Value: While it may be tempting to go for the cheapest option, consider the long-term value. Sometimes paying slightly more upfront for a high-quality component can save you more in repairs and replacements down the road.

By taking these factors into account, you can make an informed decision and ensure that your equipment remains efficient and reliable for years to come.

Installation Guide for New Parts

This section provides essential steps for successfully integrating new components into your machinery. Proper installation ensures optimal performance and longevity.

- Gather Necessary Tools

- Screwdrivers

- Wrenches

- Pliers

- Safety gear

Familiarize yourself with the specific instructions and diagrams included in the manual.

Ensure that the workspace is clean and well-lit to avoid any mishaps during the installation process.

Carefully detach any outdated elements while keeping track of hardware for reinstallation.

Follow the manual’s guidance to place each part accurately and securely.

After installation, run a thorough check to confirm that everything operates correctly.

Safety Considerations While Plowing

When engaging in snow removal operations, ensuring the safety of both the operator and the surrounding environment is paramount. Adopting proactive measures can prevent accidents and facilitate a more efficient workflow. Awareness of potential hazards and proper preparation are essential components of a successful endeavor.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This gear can shield you from harsh weather conditions and minimize the risk of injuries. Additionally, it is crucial to conduct a thorough inspection of the machinery before use. Checking for any mechanical issues or worn components can significantly reduce the chances of malfunctions while working.

Maintaining clear communication with others in the vicinity is vital. Use hand signals or radios to inform your team of your movements and intentions. Furthermore, be mindful of your surroundings, especially in areas with pedestrians or other vehicles. Slow and deliberate actions can help avoid collisions and ensure everyone’s safety.

Lastly, familiarize yourself with the equipment’s operational manual and adhere to all safety guidelines provided by the manufacturer. Understanding the machine’s capabilities and limitations will empower you to make informed decisions during operation, contributing to a safer and more effective snow clearing process.

Where to Find Diagrams Online

Finding detailed schematics for various equipment is essential for maintenance and repairs. The internet offers a plethora of resources to access these visuals, which can greatly assist in understanding assembly and functionality.

Reliable Resources

- Manufacturer Websites

- Online Retailers

- Specialized Forums

- Technical Support Pages

Search Strategies

- Use specific keywords related to the equipment.

- Check online communities for shared resources.

- Explore video tutorials that often include visual aids.

- Visit social media groups focused on repairs and maintenance.