When it comes to maintaining your lawn mower, having a clear understanding of its various components is essential. This knowledge not only helps in troubleshooting issues but also ensures that you can efficiently carry out repairs or replacements when necessary. By familiarizing yourself with the internal structure and external elements, you can enhance the longevity and performance of your machine.

Visual representations play a vital role in grasping how different parts interact with one another. These illustrations can serve as valuable references, allowing you to identify components quickly and accurately. Whether you are a seasoned mechanic or a novice user, utilizing these visual aids can simplify the maintenance process.

In this section, we will explore an in-depth look at the essential components of your lawn mower, focusing on their arrangement and functionality. Understanding each element’s role will empower you to make informed decisions when it comes to upkeep and repair.

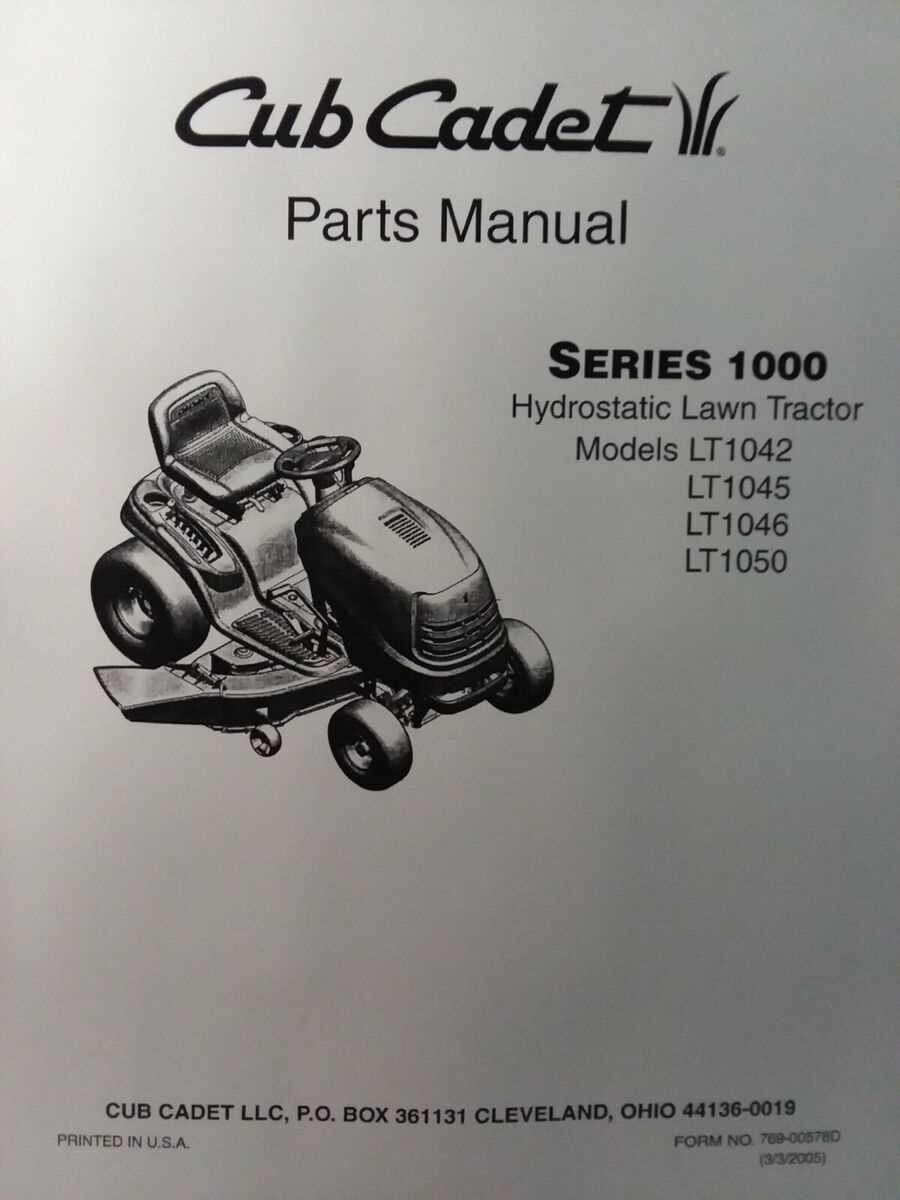

Understanding the essential elements of a lawn tractor is crucial for maintaining optimal performance. Each component plays a significant role in the overall functionality and efficiency of the machine. Here, we break down the primary features that contribute to the seamless operation of your equipment.

Engine and Transmission

The engine serves as the powerhouse of the mower, providing the necessary torque and horsepower to tackle various lawn tasks. It is often coupled with a transmission system that ensures smooth speed transitions and power delivery.

Chassis and Deck

The chassis acts as the framework, supporting all other components and providing stability during operation. Meanwhile, the deck is vital for cutting grass, featuring blades that rotate at high speeds to achieve a clean cut.

- Air Filter: Keeps the engine free from debris.

- Battery: Powers the electrical components and starter.

- Fuel Tank: Holds the gasoline needed for operation.

- Regular maintenance of these key parts can enhance longevity.

- Always consult the manual for specific component information.

- Inspect for wear and tear to prevent operational issues.

Importance of Parts Identification

Understanding the significance of component recognition is crucial for maintaining and optimizing the performance of any machinery. Accurate identification ensures that the correct replacements are sourced, which enhances efficiency and prolongs the lifespan of the equipment.

Recognizing individual elements allows for effective troubleshooting and repairs, minimizing downtime and avoiding unnecessary costs. When users are familiar with their equipment’s structure, they can better assess issues and implement timely solutions, resulting in smoother operations.

Moreover, proper identification aids in ensuring safety during maintenance. Knowing the specific components helps in understanding their functions and interactions, thereby reducing the risk of mishaps. A thorough grasp of the machinery’s build contributes to informed decisions, promoting both operational effectiveness and user confidence.

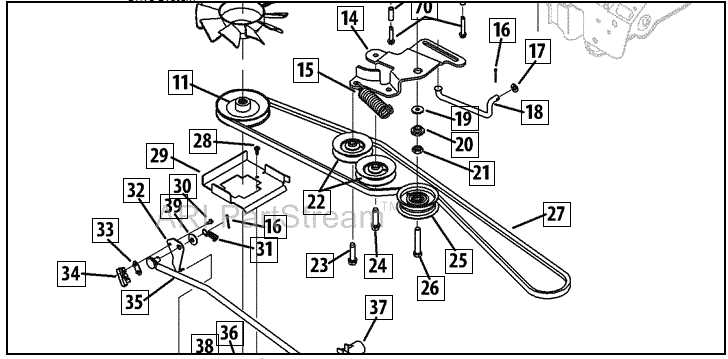

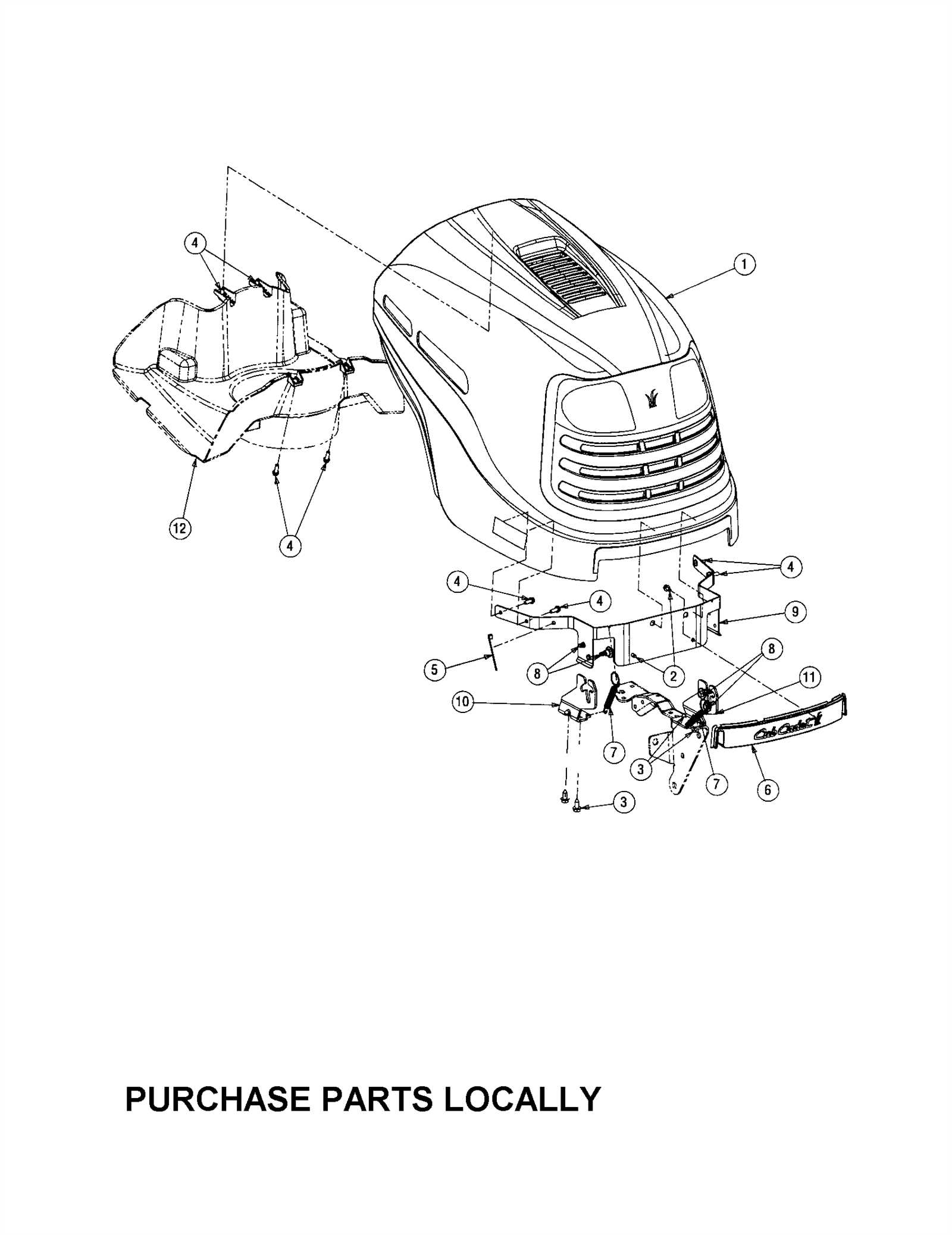

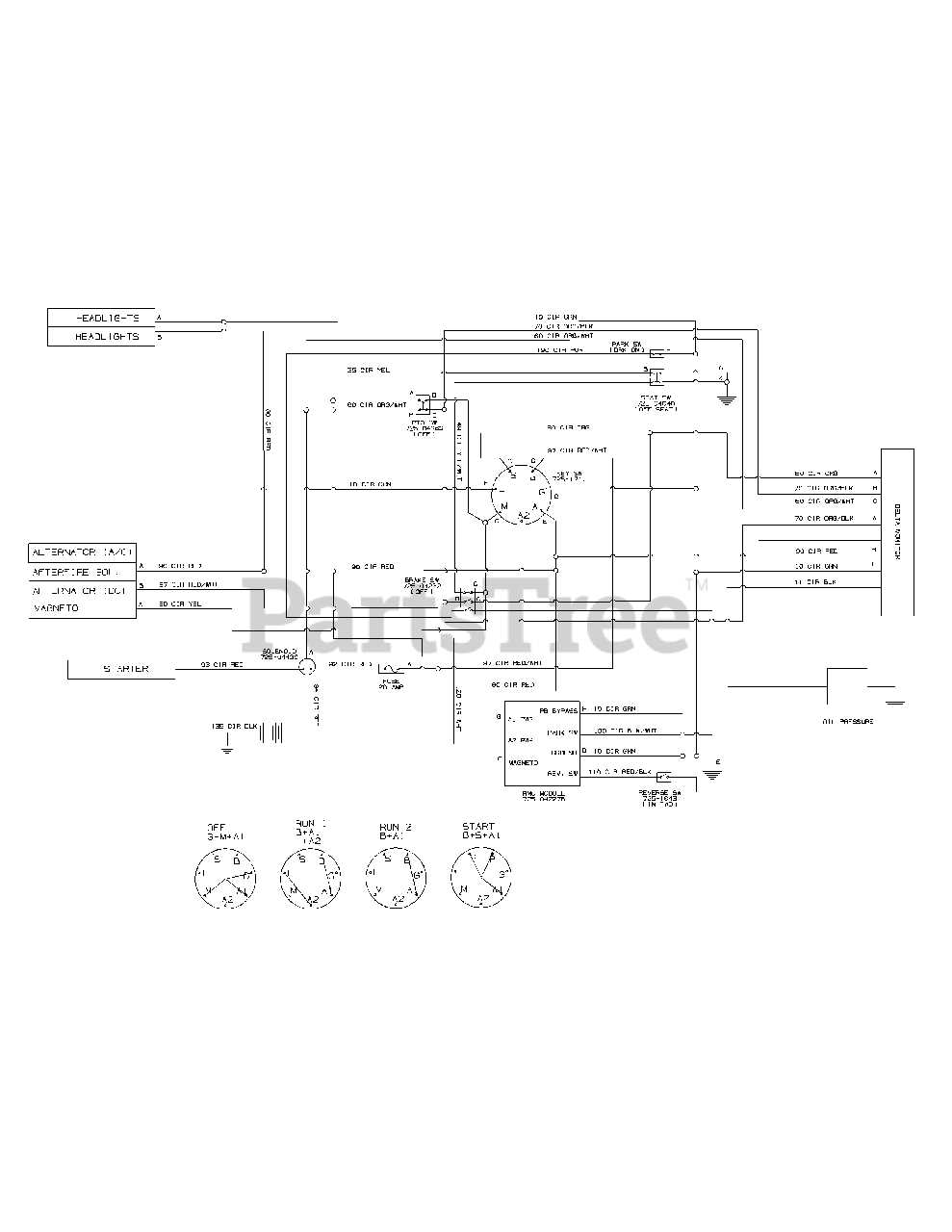

Understanding the Parts Diagram

Analyzing the components layout is essential for efficient maintenance and repair of any machinery. This visual representation allows users to identify each element’s function and its relationship with other parts. By familiarizing oneself with the schematic, operators can better understand how to troubleshoot issues, carry out replacements, and enhance the overall performance of the equipment.

Key Elements of the Schematic

The schematic typically includes labels and numbers corresponding to each component, making it easier to locate specific items. It is crucial to pay attention to the orientation and connections depicted, as these details ensure proper assembly and function. Understanding these elements contributes significantly to effective handling and care of the machine.

Benefits of Familiarity

Being well-acquainted with the layout not only aids in repairs but also enhances safety during operations. Users can avoid common pitfalls and recognize potential issues before they escalate, leading to a more reliable and efficient performance. Regularly consulting the layout can empower users to take proactive measures in their maintenance routines.

Common Replacement Parts

Maintaining optimal performance of your lawn equipment often requires replacing certain components regularly. Understanding the commonly used spare parts can enhance the longevity and efficiency of your machine. Below is a list of essential replacements to consider, ensuring that your equipment remains in peak condition.

| Component | Description | Function |

|---|---|---|

| Blades | Sharp cutting tools attached to the mower deck. | Facilitate effective grass cutting and lawn maintenance. |

| Air Filter | Filters dirt and debris from the air entering the engine. | Ensures clean air for combustion, enhancing engine performance. |

| Belt | Rubber band that transmits power between components. | Drives the mower deck and other moving parts. |

| Battery | Power source for the electric start and accessories. | Provides the necessary energy to start the engine and operate lights. |

| Spark Plug | Device that ignites the air-fuel mixture in the engine. | Ensures proper engine ignition for reliable starting. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular care not only enhances performance but also prevents unexpected breakdowns. Adopting a few simple practices can make a significant difference in the longevity of your machine.

Regular Inspections

Conducting frequent checks helps identify wear and tear early. Look for any signs of damage or corrosion, particularly in the critical components. Addressing minor issues promptly can prevent them from developing into major problems.

Fluid Changes and Cleanliness

Maintaining clean fluids is vital for optimal function. Change the oil and other necessary liquids at recommended intervals. Additionally, keep the exterior and interior free of debris and dirt. A clean machine operates more efficiently and reduces the risk of malfunctions.

Where to Find Genuine Parts

When it comes to maintaining your equipment, it’s crucial to ensure that you’re using the correct components for optimal performance. Finding reliable and authentic replacements can significantly extend the life of your machine and ensure smooth operation.

Authorized Dealers

The best place to start your search is with certified retailers. These stores are often licensed to sell original components that are specifically designed to match the exact specifications of your model. By choosing authorized outlets, you guarantee that you’re purchasing high-quality, compatible items.

Online Retailers

Many trusted websites also offer a wide range of replacement items. Make sure to choose online sellers with verified credentials to ensure you’re getting genuine components. Look for reviews and ratings from other customers to confirm the quality of the product before making a purchase.

DIY Repairs and Safety Precautions

Performing maintenance on your equipment at home can save time and money, but it requires attention to detail and a focus on safety. Understanding the machine’s structure and identifying potential risks are essential before any repairs begin. Clear planning and proper use of tools are necessary to ensure efficient and safe work.

Before starting, always disconnect the power source to prevent accidental starts. Wear appropriate safety gear such as gloves and eye protection, and ensure that your work area is well-lit and free from obstacles. Using the correct tools for each task is crucial, as improper equipment can lead to damage or personal injury.

Keep in mind that routine inspections can help prevent larger issues from arising. Regularly checking for loose bolts, worn-out components, and oil levels will extend the life of the machine. If you encounter complex mechanical problems, consult a professional to avoid costly mistakes.