Maintaining your outdoor machinery is essential for optimal performance and longevity. A comprehensive understanding of the individual elements that make up these machines can significantly enhance their efficiency and reliability. By exploring the intricacies of these components, users can ensure their equipment operates at its peak.

Whether you’re a seasoned gardener or a weekend enthusiast, familiarizing yourself with the structure of your machinery can provide valuable insights. This knowledge not only aids in troubleshooting but also empowers you to carry out effective maintenance and repairs. Engaging with the various mechanisms involved allows for a deeper appreciation of their functionality.

In this section, we will delve into the essential components that constitute these tools, offering a clear overview of their roles and interactions. By the end, you will have a greater understanding of how each piece contributes to the ultimate performance of your lawn care equipment.

Understanding Huskee Riding Mower Components

Familiarizing oneself with the various elements of a lawn maintenance machine is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity of the equipment. By understanding how these parts interact and function, users can troubleshoot issues more efficiently and perform necessary upkeep with confidence.

The structure of the machinery typically includes a powerful engine, which serves as the heart, providing the necessary energy to operate. Coupled with this are the transmission systems that facilitate smooth movement and maneuverability across different terrains. The cutting mechanism is another vital aspect, designed to deliver precise trimming, enhancing the overall aesthetic of the lawn.

Additionally, the steering and control systems are essential for navigation and comfort, allowing the operator to guide the machine effectively. Maintenance of these components, including regular inspections and timely replacements, is key to preventing breakdowns and ensuring a seamless experience. Overall, understanding these vital elements empowers users to maximize the efficiency and reliability of their lawn care equipment.

Key Features of Huskee Mowers

When considering outdoor maintenance equipment, several standout characteristics contribute to their popularity and efficiency. These machines are designed with user-friendly functionalities, robust construction, and advanced technology, ensuring optimal performance in various lawn care tasks.

One notable feature is their powerful engines, which provide reliable power for cutting through thick grass and tackling uneven terrain. Additionally, many models come equipped with ergonomic controls, allowing for effortless maneuverability and comfort during extended use.

Durability is another essential aspect, with high-quality materials and thoughtful engineering that withstand harsh conditions. Many units also offer adjustable cutting heights, enabling users to customize their lawn’s appearance according to personal preferences.

Moreover, ease of maintenance is a key consideration, with accessible components that simplify service tasks. Features such as bagging systems or mulching capabilities enhance versatility, making these machines suitable for various yard sizes and types.

Common Parts in Riding Mowers

When it comes to garden maintenance machines, understanding their essential components is crucial for effective operation and upkeep. Each element plays a vital role in ensuring the equipment runs smoothly and efficiently, contributing to overall performance and longevity.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, converting fuel into mechanical energy. |

| Deck | The structure housing the cutting blades, designed for optimal grass trimming. |

| Transmission | A system that transfers power from the engine to the wheels, allowing for movement and speed control. |

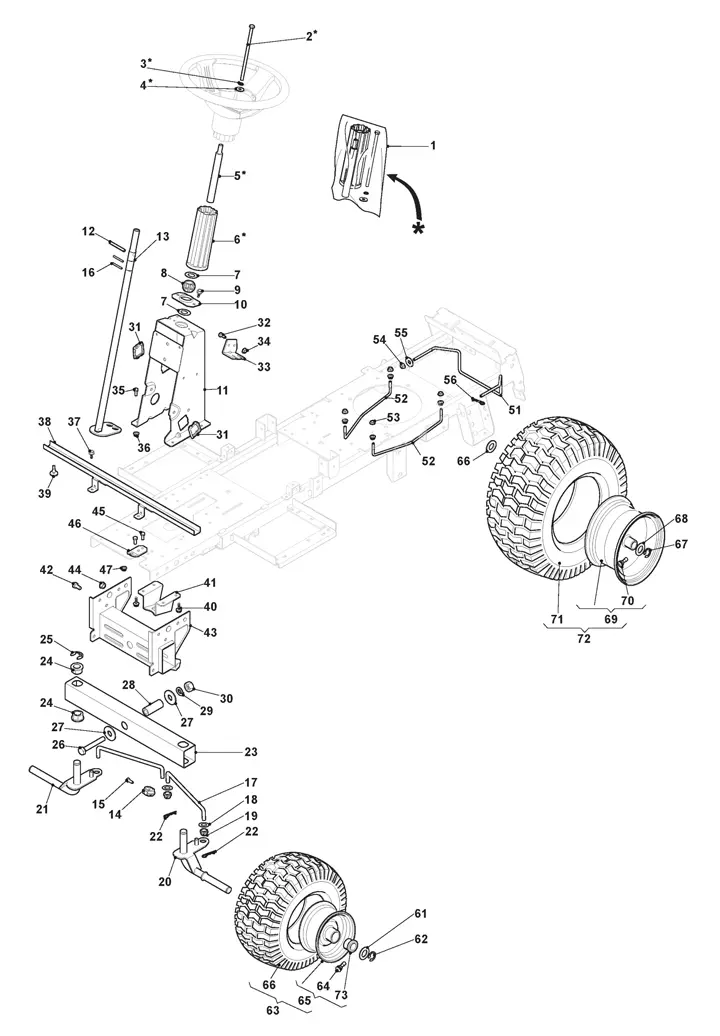

| Wheels | Critical for mobility, these elements enable navigation across various terrains. |

| Seat | The operator’s area, designed for comfort and ease of control during operation. |

| Blades | Sharp tools responsible for cutting grass, often adjustable for different heights. |

| Fuel Tank | The reservoir that holds the necessary liquid to power the engine. |

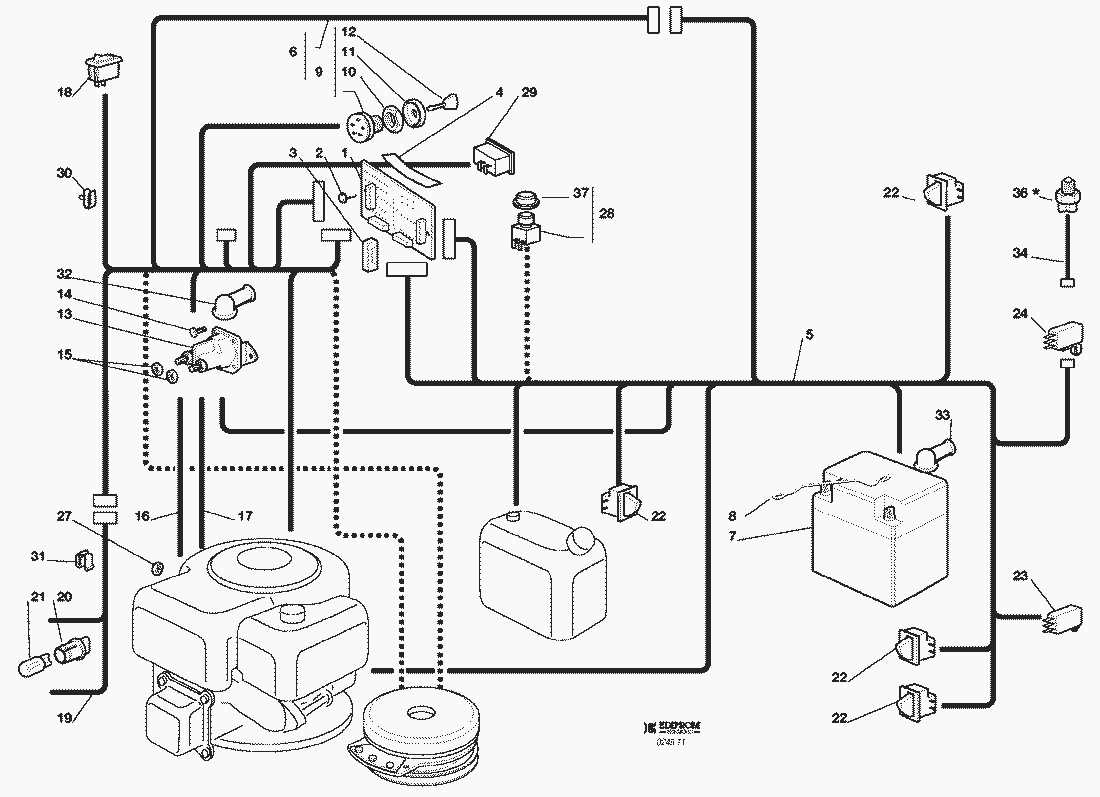

| Battery | Supplies electrical power for starting the engine and operating lights and other electrical components. |

Familiarity with these critical components not only aids in maintenance but also enhances the overall user experience, ensuring tasks are completed efficiently and effectively.

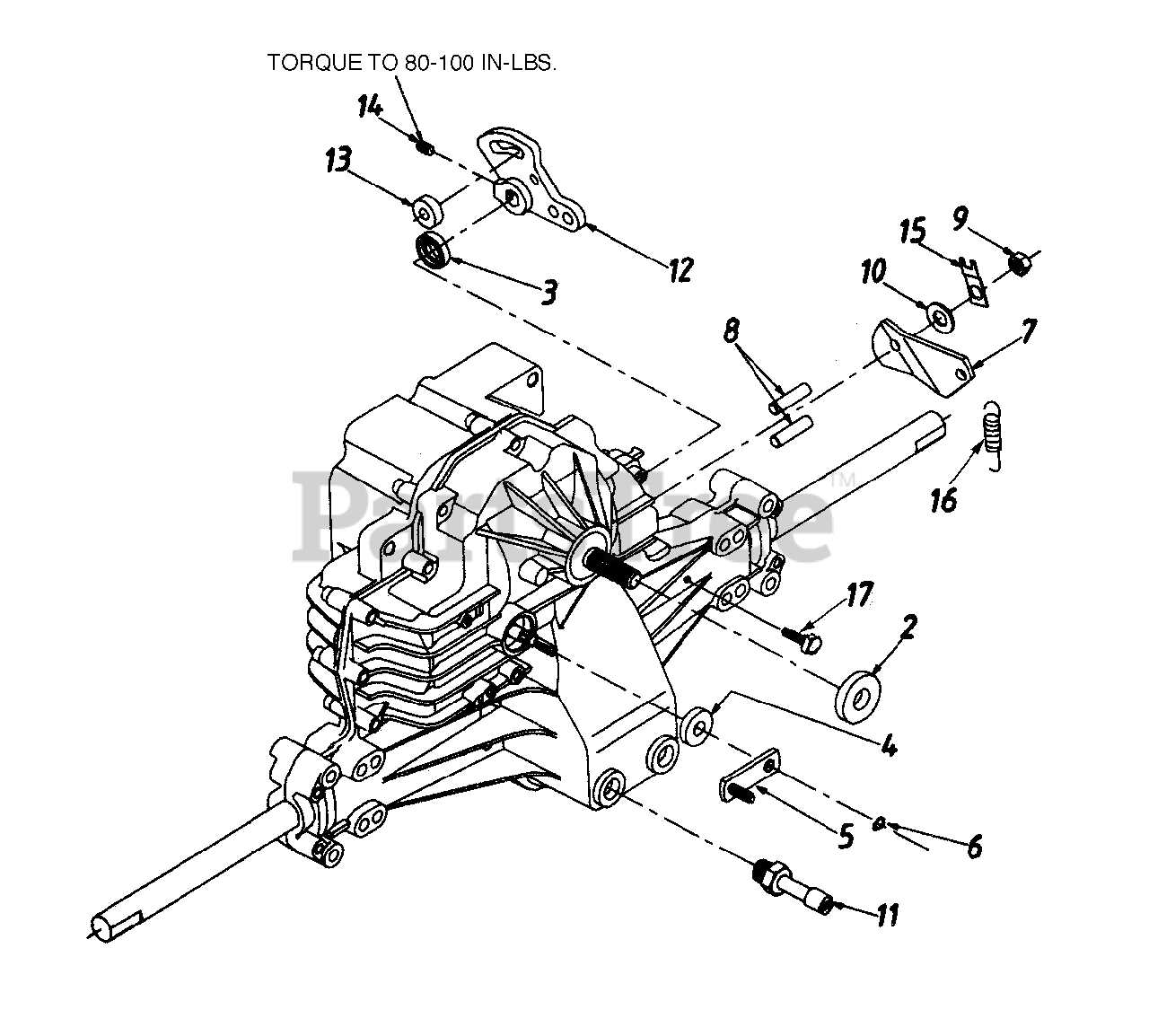

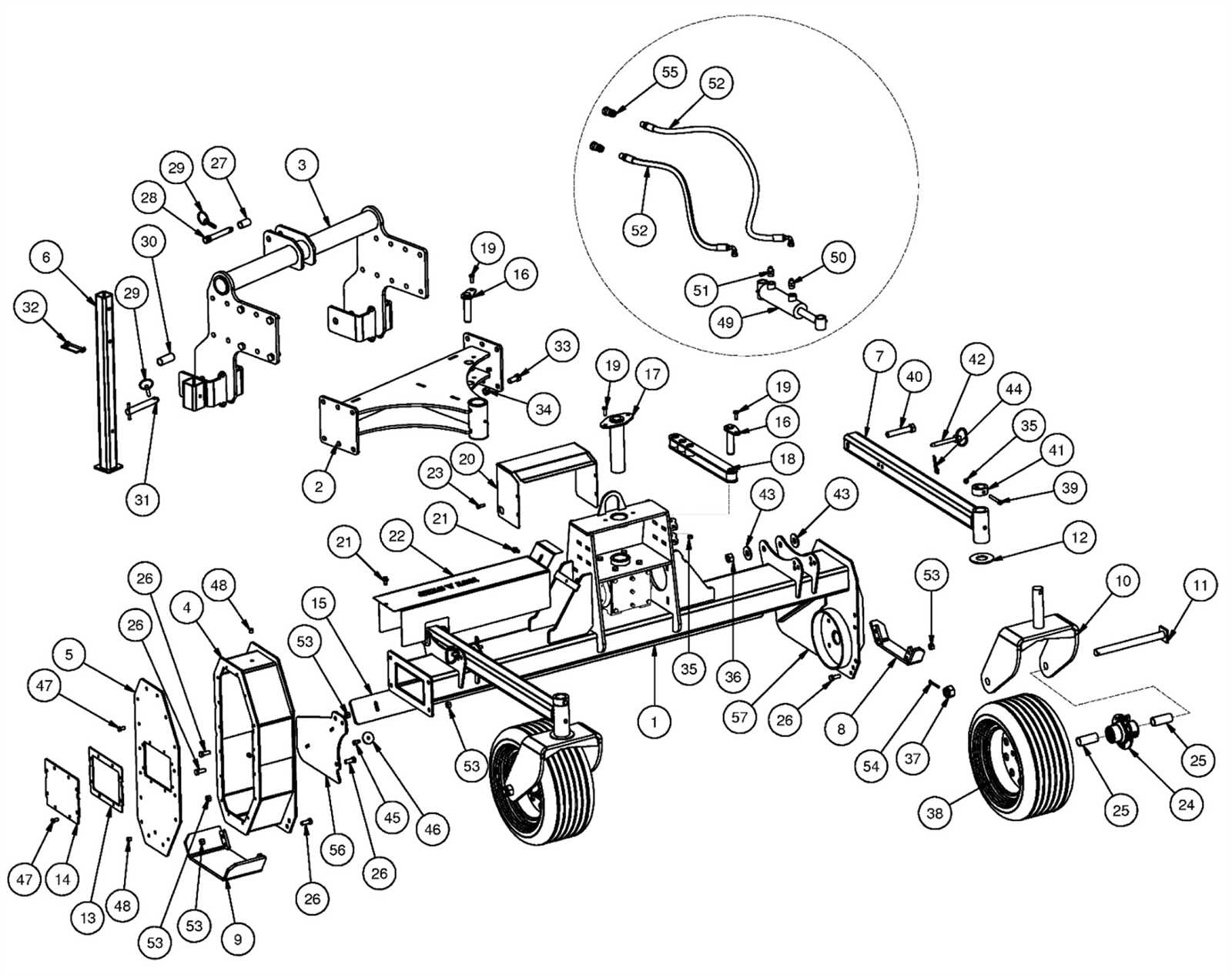

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a detailed overview, allowing users to identify individual elements and their relationships within a system.

To effectively interpret these visual guides, consider the following steps:

- Familiarize Yourself with Symbols: Each symbol represents a specific item or function. Learn what each signifies to avoid confusion.

- Identify Key Sections: Diagrams are often divided into sections. Recognizing these areas can help streamline your search for specific components.

- Trace Connections: Follow lines that indicate how parts interact. This understanding can assist in troubleshooting issues.

- Refer to Part Numbers: Many illustrations include unique identifiers for items. Keep a list of these to simplify ordering replacements.

By mastering these techniques, you’ll enhance your ability to navigate complex visual guides and ensure efficient repairs.

Maintaining Your Huskee Equipment

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues from escalating into costly repairs.

Start by routinely checking and cleaning components to ensure everything operates smoothly. Pay attention to belts, blades, and filters, as these elements often require replacement or adjustment over time. Keeping the equipment clean helps avoid rust and debris buildup, which can hinder functionality.

Additionally, monitor fluid levels and change them as necessary. Oil and coolant play critical roles in maintaining engine health and preventing overheating. Establish a maintenance schedule to keep track of these tasks, ensuring that your machinery remains in top condition throughout its lifespan.

Finally, consult the user manual for specific guidelines tailored to your equipment. Understanding the recommended practices can help you delve deeper into the nuances of maintenance, ultimately leading to a more reliable and efficient machine.

Identifying Wear and Tear Issues

Understanding the signs of degradation is essential for maintaining optimal functionality of your equipment. Regular inspection can help identify potential problems before they escalate, ensuring longevity and performance. Recognizing early indicators of damage allows for timely interventions, minimizing downtime and repair costs.

Common Indicators of Degradation

Several key signs can reveal the state of your machinery. These include unusual noises, vibrations, or changes in operation. Observing these factors can guide you in assessing the condition and determining necessary maintenance actions.

Visual Inspection Checklist

| Indicator | Possible Issue | Action Needed |

|---|---|---|

| Cracks or chips | Structural weakness | Replace or repair affected components |

| Unusual noises | Loose or worn parts | Tighten or replace as necessary |

| Excessive vibration | Imbalance or misalignment | Rebalance or realign components |

| Fluid leaks | Seal failure | Inspect and replace seals or gaskets |

| Decreased performance | Wear in critical systems | Evaluate and service worn parts |

By staying vigilant and adhering to a regular inspection routine, you can effectively manage the health of your machinery and prevent unexpected failures.

Finding Replacement Parts Online

In today’s digital age, sourcing components for outdoor machinery has become more accessible than ever. The internet offers a plethora of platforms where enthusiasts can locate the necessary items to restore their equipment to optimal performance.

Start by exploring specialized websites that cater to machinery supplies, as they often have comprehensive catalogs. Search filters can help narrow down options based on model and specifications, ensuring you find exactly what you need.

Additionally, consider joining online forums or communities dedicated to outdoor equipment. Members frequently share their experiences, recommending trusted sellers and providing valuable insights on maintenance and repairs.

Price comparison is crucial when searching online. Various retailers may offer different prices for similar items, so taking the time to evaluate options can lead to significant savings. Don’t forget to check customer reviews for quality assurance before making a purchase.

DIY Repairs for Mower Parts

Engaging in self-repairs for outdoor equipment can be a rewarding experience. Not only does it save money, but it also fosters a deeper understanding of the machine’s mechanics. Many issues can be resolved with a bit of knowledge, some basic tools, and a willingness to learn. This section will explore practical approaches to fixing common components, empowering enthusiasts to tackle repairs with confidence.

Before beginning any maintenance task, it’s essential to gather the necessary tools and reference materials. Having a clear view of the components involved and understanding their functions will simplify the process. Additionally, ensuring that the machine is powered off and safely positioned is critical for avoiding accidents.

One common issue involves the cutting mechanism. If it isn’t performing effectively, checking the blade sharpness is a great starting point. Dull blades can cause uneven cuts and increased strain on the engine. With the right tools, blades can be sharpened or replaced, restoring optimal performance.

Another frequent challenge is related to the drive system. If the equipment is struggling to move or responding sluggishly, examining the belts and pulleys can reveal wear or damage. Replacing frayed belts can be straightforward, often requiring only basic tools and following a step-by-step guide.

Lastly, addressing electrical components should not be overlooked. A faulty battery or corroded connections can lead to starting issues. Cleaning terminals and ensuring a good battery charge can often resolve these problems. For more complex electrical issues, consulting a repair manual or online resources can provide valuable insights.

By undertaking these repairs, users can extend the life of their machines while gaining valuable skills. Each successful fix enhances confidence and paves the way for tackling more advanced repairs in the future.

Best Practices for Mower Storage

Properly storing your lawn equipment is essential for maintaining its functionality and extending its lifespan. By following a few key practices, you can ensure that your machinery remains in excellent condition during the off-season or when not in use.

- Clean Thoroughly: Before storing, remove any grass clippings, dirt, or debris. Use a brush or a cloth to clean the exterior, and consider washing with water if needed.

- Drain Fluids: If the equipment will be stored for an extended period, drain the fuel and oil to prevent any degradation or contamination. This step helps avoid potential engine issues when you’re ready to use it again.

- Sharpen Blades: Ensure that the cutting blades are sharp before storage. This will enhance performance when you resume using the equipment.

- Check for Repairs: Inspect all components for wear or damage. Address any repairs needed before putting the equipment away to avoid future problems.

- Store in a Dry Location: Keep your equipment in a sheltered area, such as a garage or shed, away from moisture. This will prevent rust and other weather-related damage.

By implementing these best practices, you can keep your equipment running smoothly and ready for use whenever you need it.