When it comes to maintaining a beautiful yard, the right machinery can make all the difference. This guide will explore the intricate design and functionality of a specific type of lawn maintenance vehicle, focusing on how each element contributes to its overall efficiency. With an in-depth look at its structure, users can gain insights into the various components that ensure optimal performance.

Whether you are a seasoned operator or a novice, comprehending the layout of these mechanisms can enhance your maintenance skills. Familiarity with the individual sections not only aids in troubleshooting but also empowers you to make informed decisions during repairs or upgrades. This knowledge ultimately translates to a more effective and enjoyable experience in yard upkeep.

In this article, we will delve into the essential elements that comprise this remarkable machine. By understanding how each part interacts with others, you will appreciate the engineering behind it and be better equipped to handle any challenges that may arise.

Understanding Rear Engine Snapper Mowers

This section aims to explore the unique features and functionalities of specific lawn maintenance machines designed for efficient grass cutting. These machines, with their distinctive layout and design, provide users with maneuverability and ease of use.

Key Features

The layout allows for improved visibility and accessibility, making it easier for users to navigate various terrains. Additionally, the compact design contributes to the overall efficiency of the cutting process, ensuring a clean and precise finish.

Maintenance Considerations

Regular upkeep is essential for optimal performance. Users should focus on routine checks, including blade sharpening and engine servicing, to maintain longevity and reliability. Understanding the components involved can ultimately enhance the overall experience.

Components of the Snapper Mower

This section explores the essential elements that contribute to the functionality and efficiency of the lawn care machine. Understanding these components is vital for proper maintenance and troubleshooting.

Key Mechanisms

The primary mechanisms include the cutting system, which is crucial for achieving a clean and even trim. Additionally, the propulsion system ensures smooth movement across various terrains.

Control Features

Operators benefit from intuitive control features, such as steering and speed adjustment. These controls enhance the user experience and facilitate precise maneuverability, making lawn maintenance more effective.

Common Issues with Rear Engine Models

When it comes to machines designed for efficient lawn maintenance, several typical challenges can arise. Understanding these common problems can help users diagnose issues quickly and keep their equipment running smoothly. Here are some frequent complications encountered with this type of machinery.

Engine Performance Issues

One of the most prevalent concerns is related to the overall performance of the power unit. Users may experience difficulty starting, irregular idling, or a complete failure to operate. Such symptoms often indicate underlying issues such as fuel blockages, air filter contamination, or spark plug malfunctions.

Transmission Troubles

The transmission system can also present various problems. Common signs include slipping gears, unresponsive controls, or unusual noises during operation. These issues may stem from worn-out components, improper lubrication, or misalignment.

| Issue | Potential Cause | Solution |

|---|---|---|

| Starting problems | Fuel blockage or spark plug issues | Check and replace fuel or spark plug |

| Irregular idling | Dirty air filter | Clean or replace air filter |

| Transmission slipping | Worn components | Inspect and replace worn parts |

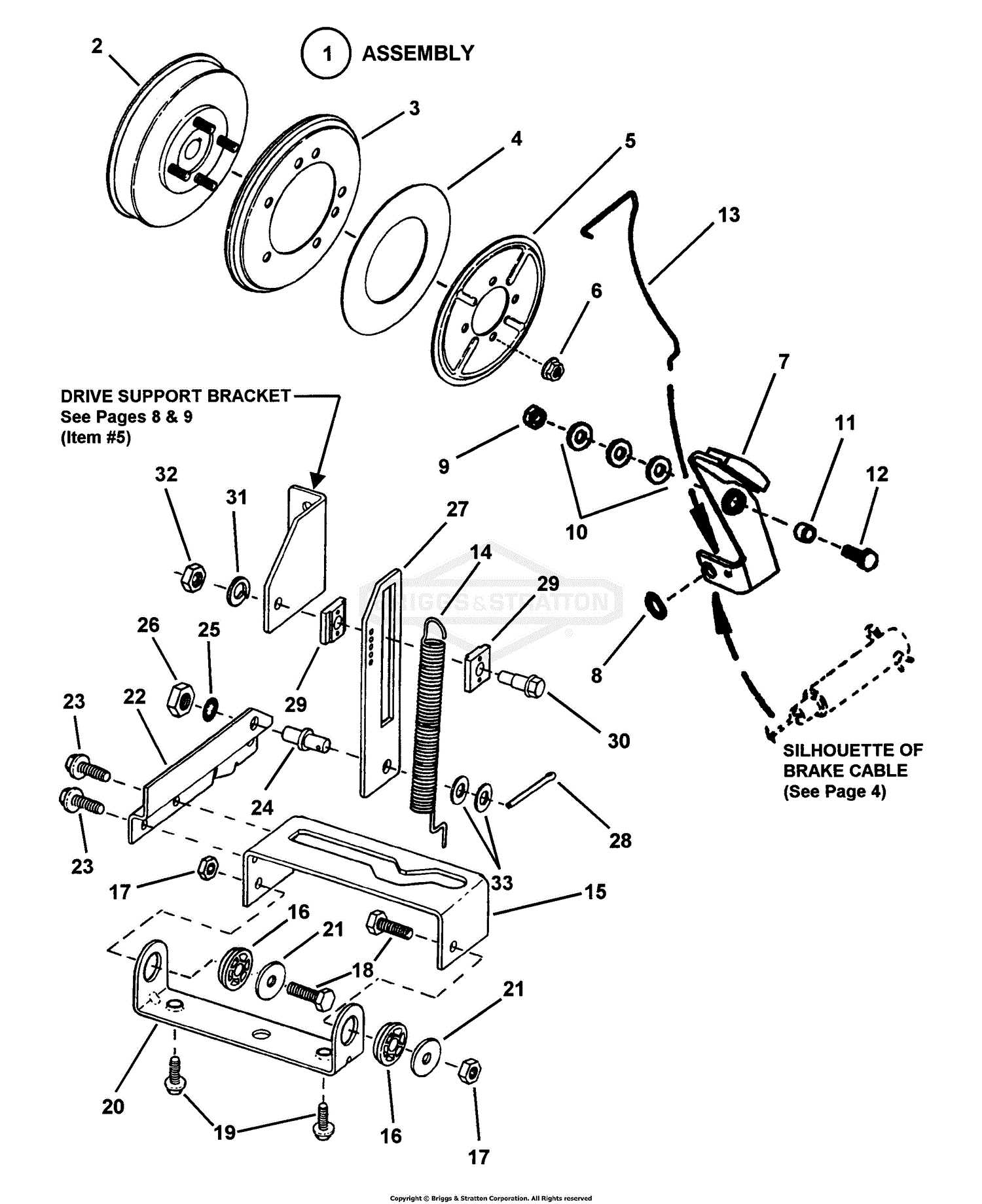

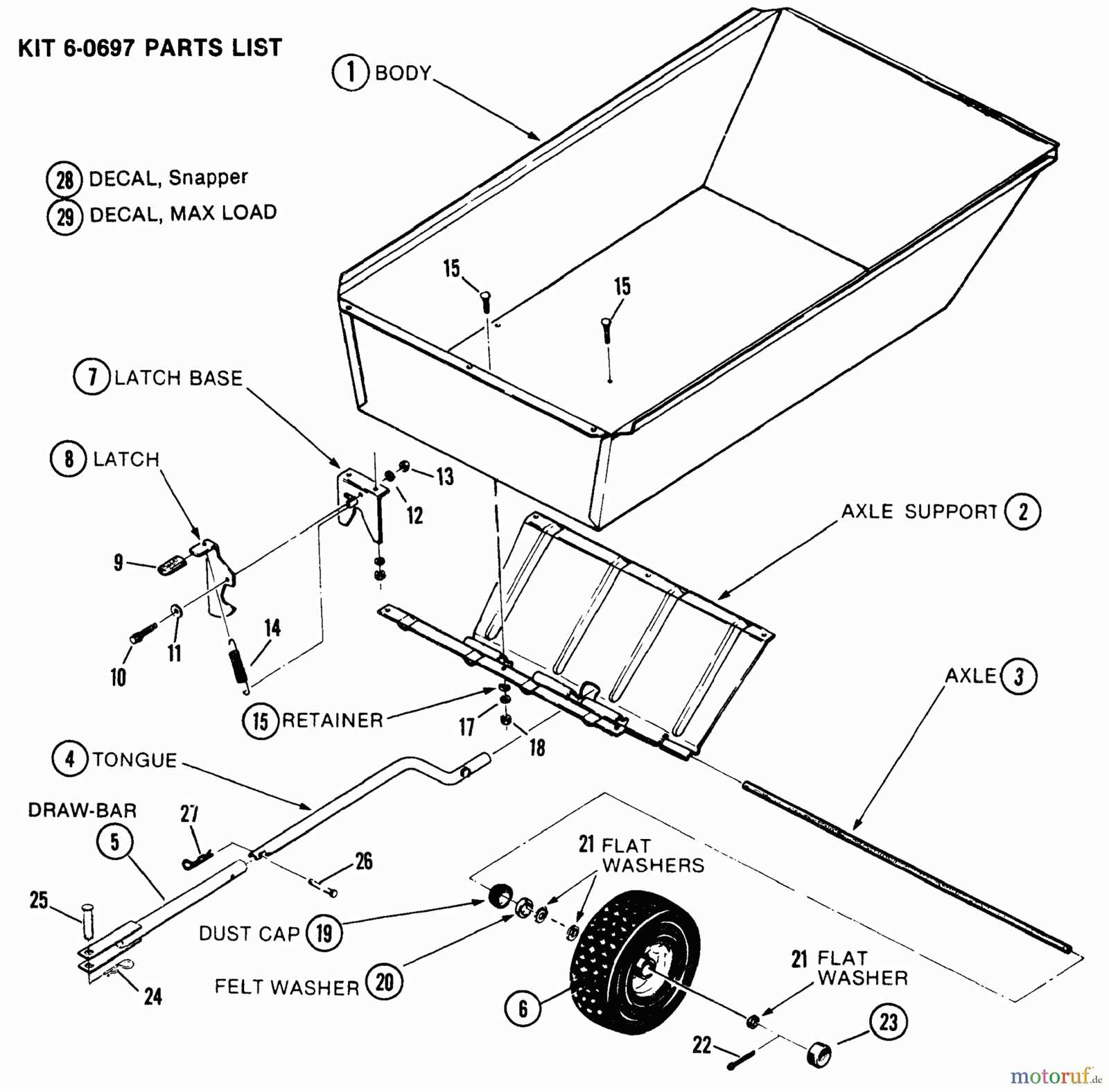

Importance of Parts Diagrams

Understanding the intricacies of mechanical devices is crucial for effective maintenance and repair. Visual representations serve as essential tools, simplifying complex structures and guiding users through various components. These illustrations enhance clarity, ensuring that even novice users can navigate the assembly with confidence.

Moreover, such visual aids facilitate the identification of specific elements, allowing for accurate troubleshooting and replacement. By breaking down the overall system into manageable sections, individuals can better comprehend how each part interacts within the larger framework.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Visual aids help clarify the relationships between different components. |

| Accurate Identification | Facilitates the precise recognition of parts needing attention. |

| Improved Efficiency | Simplifies repair processes, saving time and effort. |

| Informed Decisions | Assists users in making knowledgeable choices regarding repairs. |

In summary, visual representations are invaluable resources that enhance understanding, streamline maintenance, and empower users to effectively manage their equipment.

How to Identify Replacement Parts

Identifying the necessary components for your equipment can seem daunting, but it becomes manageable with the right approach. Understanding the specific attributes and functionality of each element will help streamline the selection process and ensure compatibility with your machine.

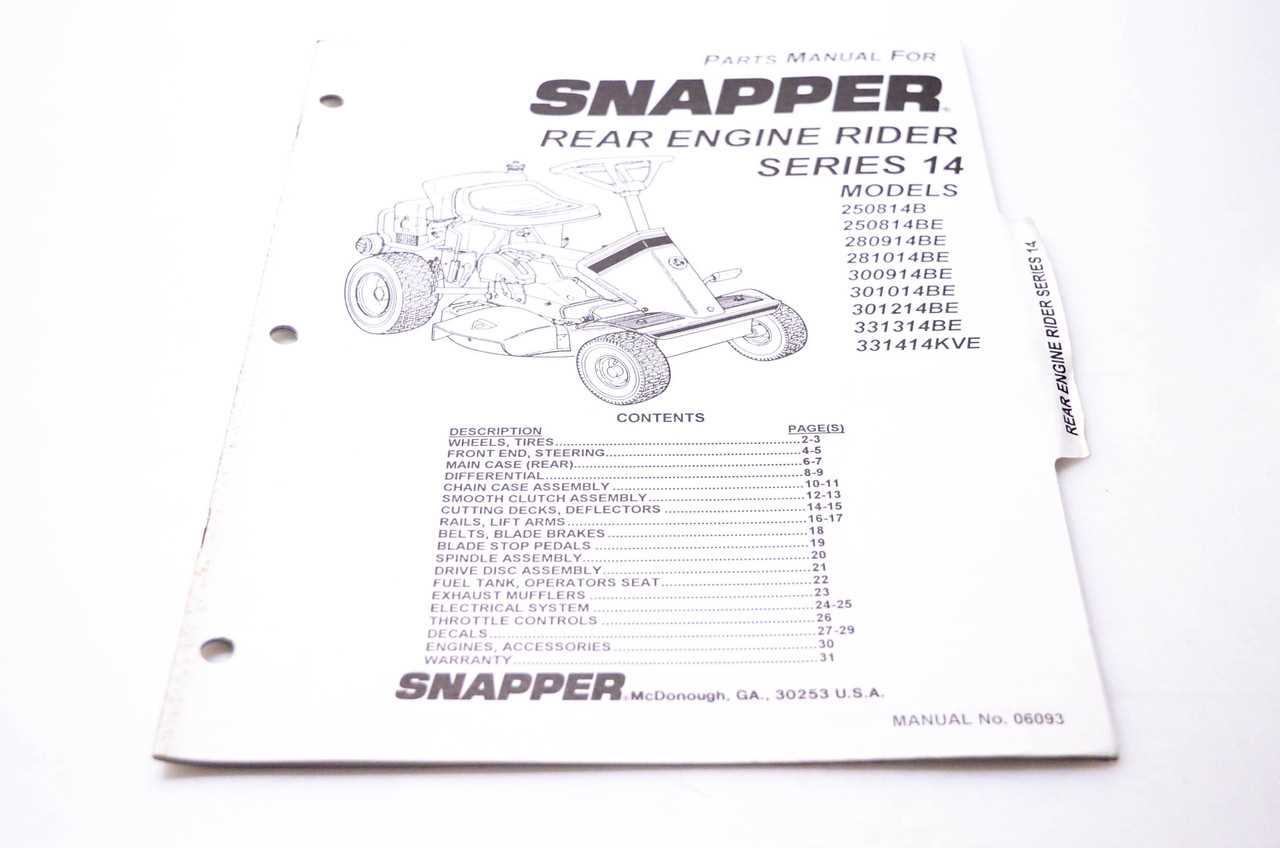

Begin by consulting the manufacturer’s manual. This document typically contains detailed information about each component, including part numbers and descriptions. If the manual is unavailable, online resources or forums dedicated to equipment enthusiasts can provide valuable insights.

Next, examine the components visually. Look for identifying marks, numbers, or labels on the items you wish to replace. Many manufacturers imprint essential information directly onto the parts, which can assist in finding exact matches.

Finally, consider the age and model of your machine. Older models may require more effort to locate compatible components. In such cases, reaching out to specialized retailers or second-hand parts suppliers can be beneficial.

Maintenance Tips for Longevity

Ensuring the extended life of your outdoor equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents costly repairs, allowing you to enjoy your investment for years to come.

Regular Cleaning

Cleaning your machinery after each use is essential. Remove debris, grass clippings, and dirt to prevent buildup that can lead to rust or malfunctions. Use a soft brush and mild detergent to maintain its appearance and functionality.

Periodic Inspections

Conduct frequent checks on all components, including belts, blades, and tires. Look for signs of wear or damage and replace parts as needed. Staying proactive can significantly reduce the risk of unexpected breakdowns.

Where to Find Quality Parts

Finding reliable components for outdoor machinery is essential for maintaining performance and longevity. Quality replacement pieces not only enhance efficiency but also ensure safety during operation. Various sources can provide the necessary items, catering to different needs and preferences.

Online Retailers: A multitude of e-commerce platforms specializes in selling machinery components. Websites dedicated to outdoor equipment often feature a vast selection, complete with customer reviews and competitive pricing. This allows for easy comparison and informed purchasing decisions.

Local Supply Stores: Visiting nearby hardware or specialty shops can be beneficial. These stores often carry a range of components and provide the advantage of immediate availability. Additionally, knowledgeable staff can offer valuable insights and recommendations.

Manufacturer Websites: Official manufacturer sites are an excellent resource for sourcing authentic components. They frequently offer detailed catalogs and diagrams, ensuring compatibility and reliability. Moreover, purchasing directly from the manufacturer may come with warranties or guarantees.

Online Marketplaces: Platforms such as auction sites and classified ads can yield unique finds at lower prices. However, it is crucial to verify the seller’s reputation and the quality of the items being offered to avoid potential issues.

Community Forums: Engaging with online communities or forums dedicated to outdoor equipment can provide helpful recommendations for reputable sources. Members often share their experiences and can guide you towards reliable vendors or alternative options.

By exploring these avenues, you can ensure that you acquire high-quality components, ultimately enhancing the performance and durability of your equipment.

DIY Repairs for Mower Owners

Maintaining your outdoor machinery can save you time and money. By learning how to perform simple repairs, you can keep your equipment in top condition and extend its lifespan. This guide will provide you with essential tips and tricks to tackle common issues, ensuring your device remains efficient and reliable.

Common Issues and Fixes

- Blades Dullness: Regularly check and sharpen blades to ensure a clean cut.

- Battery Problems: Inspect connections and charge regularly to avoid starting issues.

- Fuel System Maintenance: Keep fuel clean and change filters as needed to prevent clogs.

- Transmission Troubles: Check for leaks and ensure proper lubrication to maintain smooth operation.

Tools You Might Need

- Socket set for loosening and tightening bolts.

- Screwdriver set for various screws.

- Sharpening tool for blades.

- Wrench for adjusting components.

- Cleaning supplies for routine maintenance.

By addressing these common challenges, you can enhance the performance of your outdoor machinery and enjoy a smoother experience during use. Regular attention to these areas will lead to a longer, more efficient operational life.

Upgrading Your Mower’s Performance

Enhancing the efficiency of your machine can significantly improve its capabilities and longevity. Whether you aim for a smoother operation or increased power, there are various modifications available that can help achieve your goals.

| Upgrade Type | Benefits |

|---|---|

| Blade Replacement | Improved cutting efficiency and cleaner results. |

| Air Filter Upgrade | Enhanced airflow leading to better performance. |

| Fuel System Enhancements | Greater fuel efficiency and reduced emissions. |

| Battery Upgrade | Longer run time and faster starts. |

By considering these modifications, you can delve into various options that ultimately maximize your equipment’s potential.