In the realm of plumbing and fixtures, comprehending the intricacies of individual elements is crucial for both maintenance and upgrades. A thorough exploration of the various components and their relationships can significantly enhance one’s ability to troubleshoot issues and optimize performance. By dissecting the layout and functionality of these crucial parts, users can gain valuable insights into their systems.

Each element plays a vital role in the overall functionality, and understanding their interactions can lead to more effective repairs and improvements. Whether you are a seasoned professional or a DIY enthusiast, familiarizing yourself with these components fosters a deeper appreciation for the craftsmanship involved. Visual representations of these elements can serve as a valuable reference, guiding users through the complexities of their plumbing setups.

As we delve into the specifics, it becomes apparent that having a clear picture of each component not only aids in identification but also streamlines the process of installation and maintenance. By focusing on the unique characteristics and configurations, individuals can approach their tasks with confidence, ensuring that every aspect of their systems operates harmoniously.

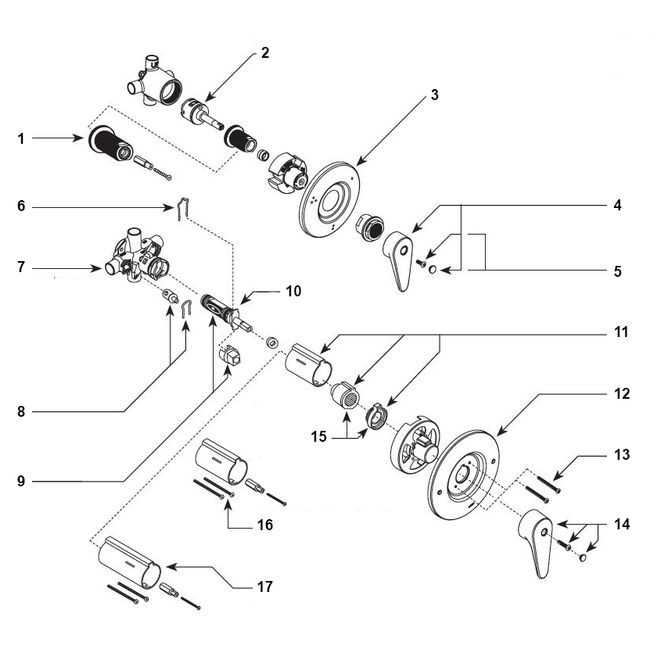

Overview of Delta 600 Series Parts

This section aims to provide a comprehensive understanding of the components associated with a particular product line. Each element plays a crucial role in the overall functionality and performance, ensuring reliability and efficiency in various applications.

Key Components

Among the essential elements, you will find valves, handles, and spouts. These parts contribute significantly to user experience, offering both aesthetic appeal and practical functionality. Each component is designed with precision to facilitate smooth operation.

Maintenance and Replacement

Proper care and timely replacement of these elements are vital for longevity. Understanding the specific roles of each part allows users to identify potential issues and address them effectively. This proactive approach ensures optimal performance and extends the lifespan of the entire assembly.

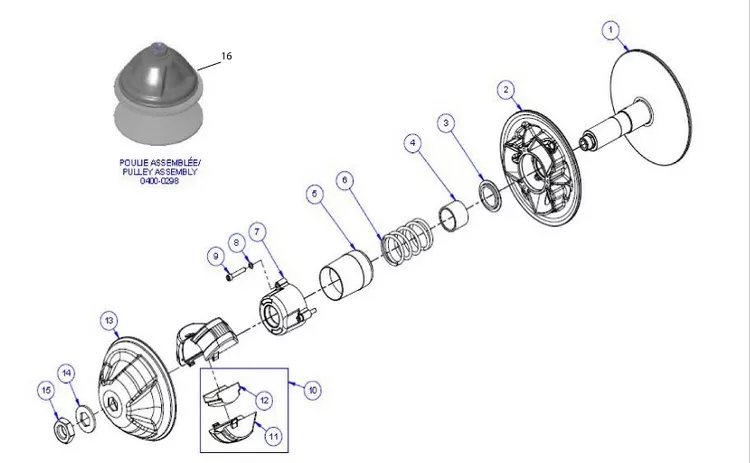

Understanding the Parts Diagram

The visual representation of components serves as a crucial tool for anyone looking to grasp the intricate relationships and functions within a mechanical system. It simplifies complex assemblies into understandable segments, allowing users to identify each element’s role and interconnections.

Familiarity with such illustrations enhances comprehension, making it easier to locate specific elements when troubleshooting or performing maintenance. By examining the layout, individuals can quickly navigate the structure, facilitating efficient repairs and modifications.

Ultimately, mastering this visual guide is essential for optimizing performance and ensuring longevity in any mechanical system.

Key Components of the Delta 600

Understanding the essential elements of this system is crucial for efficient maintenance and operation. Each component plays a significant role in ensuring optimal performance and longevity. Below are the primary constituents that define its functionality:

- Control Mechanism: This component regulates the flow and pressure, allowing for precise operation.

- Sealing Elements: These are vital for preventing leaks and maintaining system integrity.

- Flow Channels: Designed to guide the liquid through the system, ensuring smooth and uninterrupted movement.

- Support Structure: Provides the necessary stability and durability, crucial for handling operational stresses.

- Fasteners: These small yet essential items ensure that all parts are securely attached and aligned.

In conclusion, a comprehensive understanding of these core elements allows users to troubleshoot effectively and enhance the overall performance of the system.

Common Issues and Solutions

In the realm of plumbing fixtures, users often encounter various challenges that can disrupt the functionality of their equipment. Addressing these common problems effectively is crucial for maintaining optimal performance and longevity. This section outlines frequent complications along with practical solutions to enhance the user experience.

Frequent Leaks

One of the most prevalent issues is leakage, which can stem from worn-out seals or improper installation. To resolve this, it is advisable to inspect all connections and replace any deteriorated components. Ensuring a tight fit and using appropriate sealing materials can also help mitigate future leaks.

Reduced Water Pressure

Another common concern is diminished water pressure, often caused by blockages or mineral buildup. Regular cleaning of aerators and filters can significantly improve flow rates. In cases of persistent low pressure, checking for obstructions in the supply lines or consulting a professional may be necessary to identify underlying issues.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and efficiency of your equipment. Implementing a routine care schedule can significantly extend its lifespan and enhance performance.

Routine Inspection

- Check for signs of wear and tear regularly.

- Ensure all moving parts are functioning smoothly.

- Look for leaks or any unusual noises during operation.

Cleaning Practices

- Dust and debris can impact functionality, so clean the surfaces frequently.

- Use appropriate cleaning agents to avoid damage to sensitive components.

- Ensure that ventilation areas are unobstructed to promote optimal airflow.

Where to Find Replacement Parts

Locating components for your equipment can often seem daunting, but various resources are available to assist you in this process. Understanding where to search will save time and ensure you obtain the necessary items quickly and efficiently.

Online Retailers

One of the most convenient ways to acquire necessary components is through online retailers. Websites specializing in hardware and equipment often have a wide selection and detailed descriptions. Make sure to check for reputable sellers to guarantee quality.

Local Supply Stores

Visiting nearby supply shops can also be beneficial. These stores typically stock essential items and provide the added advantage of expert advice from staff. Don’t hesitate to inquire about specific components you need; they might offer alternative solutions.

Importance of Accurate Diagrams

Clear and precise visual representations are essential for understanding complex machinery and components. They serve as valuable tools for both professionals and enthusiasts, facilitating effective communication and accurate assembly.

Benefits of accurate representations include:

- Enhanced comprehension of intricate systems.

- Reduced errors during maintenance and repairs.

- Streamlined training processes for new technicians.

- Improved safety through correct identification of parts.

Inaccurate illustrations can lead to significant challenges, such as:

- Misinterpretation of component functions.

- Increased downtime due to assembly mistakes.

- Heightened risk of accidents.

Ultimately, investing in precise visual aids contributes to the longevity and reliability of equipment.

Upgrading Your Delta 600 Series

Enhancing your equipment can significantly improve performance and longevity. By focusing on key components, you can ensure a smoother operation and a more efficient experience. Upgrades not only refresh functionality but also contribute to overall satisfaction with your tools.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Motor | High-Torque Motor | Increased power and efficiency |

| Blades | Premium Blades | Sharper cuts and improved durability |

| Handles | Ergonomic Handles | Enhanced comfort during use |

Each enhancement can be tailored to meet specific needs, allowing for a personalized approach to improving your setup. Investing in quality replacements or upgrades will ultimately lead to a superior operational experience.