Every machine has intricate elements that contribute to its overall functionality. Grasping the layout and interconnection of these components is vital for effective maintenance and operation. A comprehensive visual representation can significantly enhance your understanding of how everything fits together.

Familiarity with these critical elements not only aids in troubleshooting but also empowers you to make informed decisions regarding repairs and upgrades. By delving into the specifics, you can ensure optimal performance and longevity of your device.

Exploring the arrangement of these essential components provides an ultimate roadmap for any enthusiast or professional. It simplifies the complexity involved, transforming potential confusion into clarity and confidence in handling your equipment.

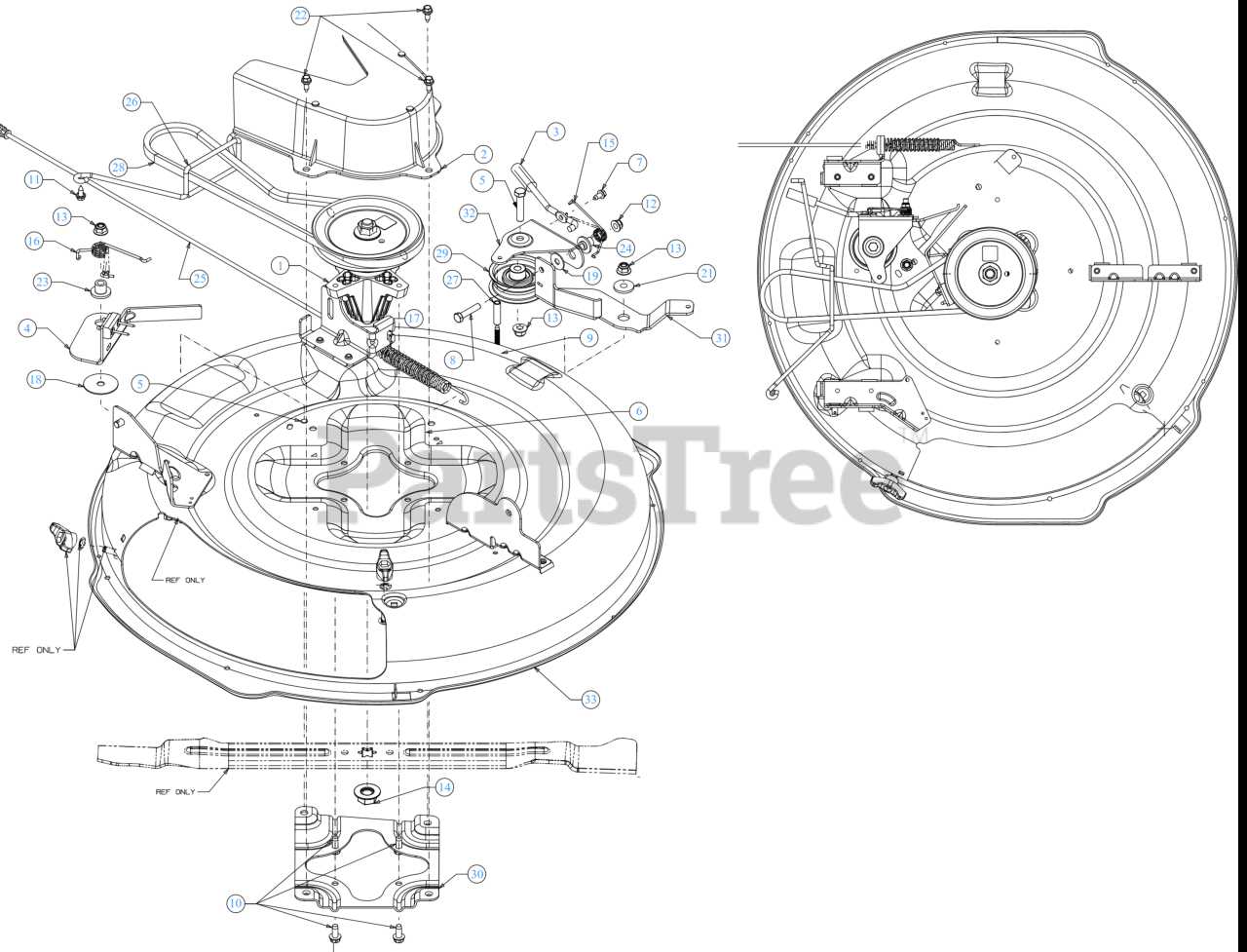

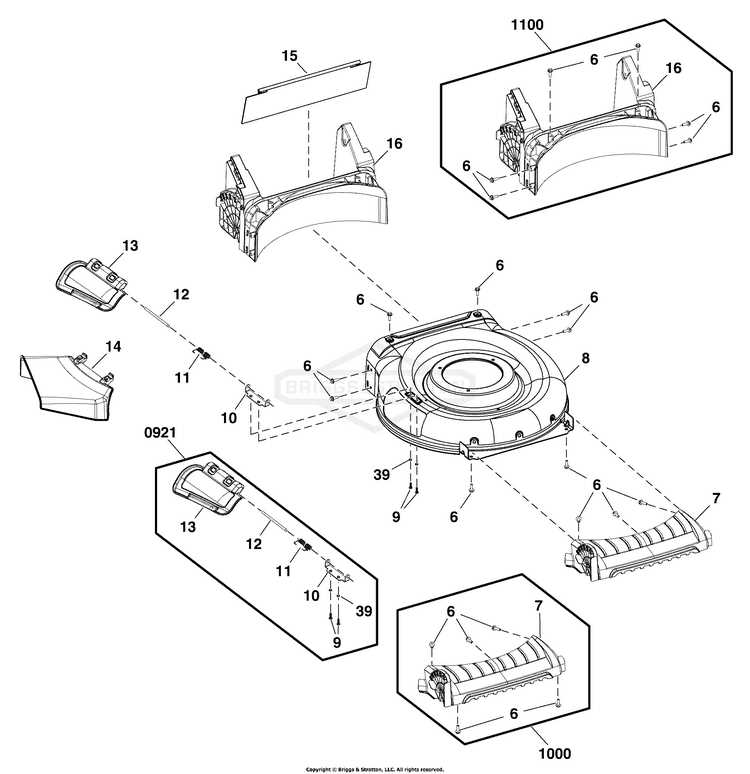

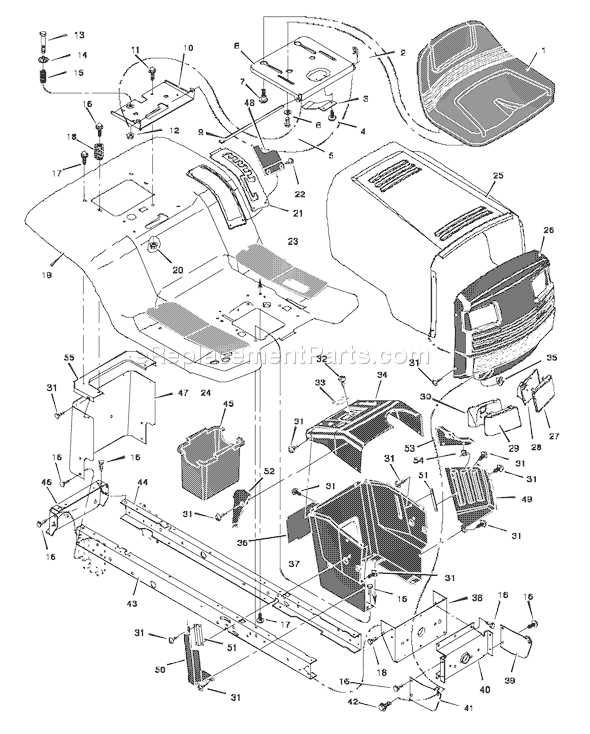

Murray Lawn Mower Deck Overview

This section provides an essential understanding of the components that form the base of a cutting machine. These elements are critical for ensuring effective operation and maintenance. Familiarity with each part will enhance performance and longevity.

Key Components

- Housing: The structure that supports all other elements and protects them from external damage.

- Blades: Sharp instruments responsible for cutting grass at varying heights.

- Spindle Assembly: The mechanism that holds and rotates the cutting blades.

- Lift Mechanism: Allows for adjusting the height of the cutting blades to suit different terrain.

- Mounting Brackets: Secure various components to the main body, ensuring stability and proper alignment.

Maintenance Tips

- Regularly inspect blades for sharpness and replace if worn.

- Clean the housing to prevent grass buildup that can affect performance.

- Check the spindle assembly for any signs of wear and lubrication.

- Ensure all mounting brackets are securely fastened to maintain stability.

- Adjust the lift mechanism to match the specific cutting requirements.

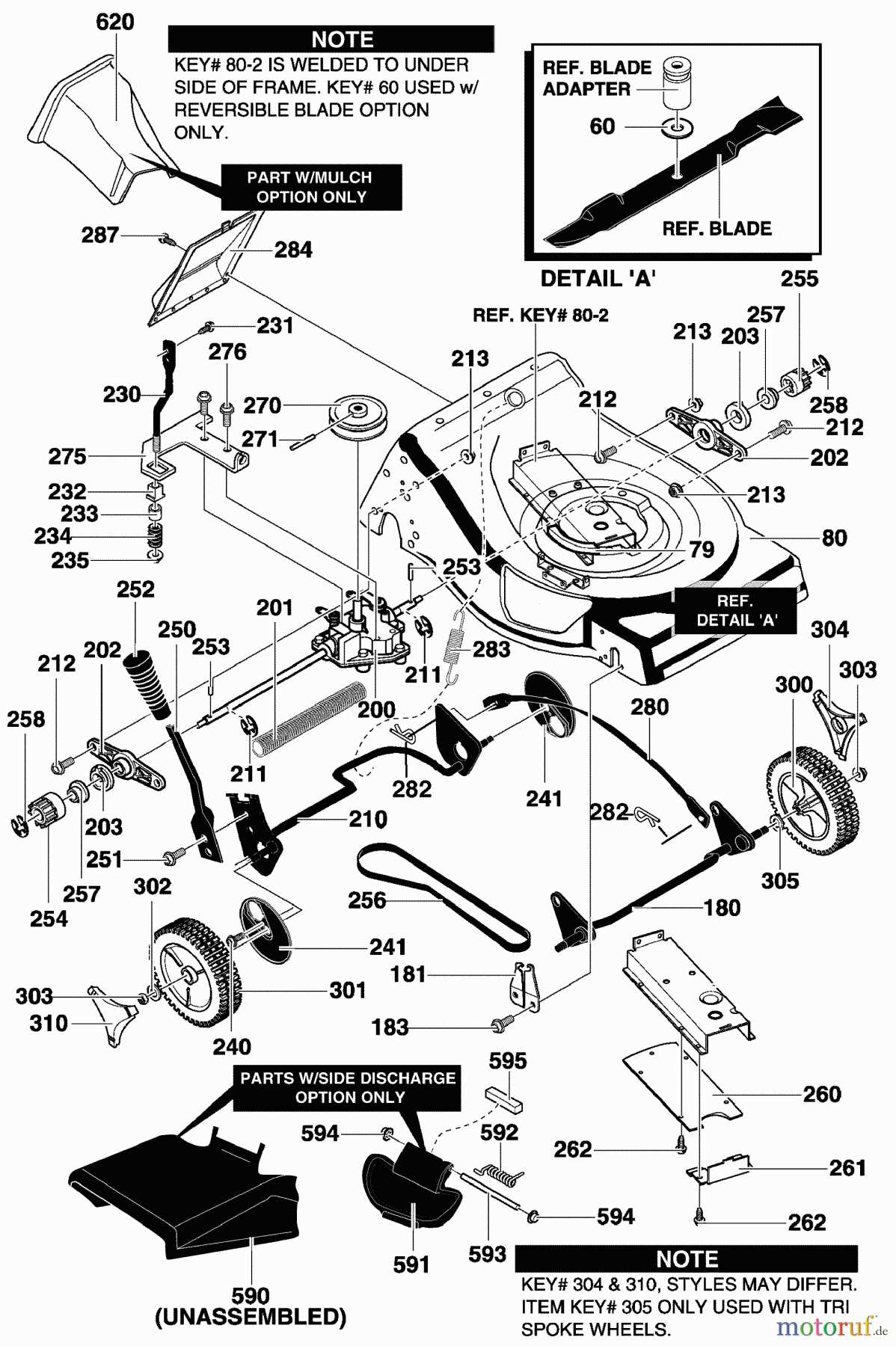

Key Components of the Deck

The efficient operation of any cutting equipment relies heavily on its essential components. Each element plays a critical role in ensuring optimal performance, longevity, and ease of use. Understanding these key parts helps users maintain their equipment effectively and address any issues that may arise during operation.

1. Cutting Blades

The cutting blades are fundamental to the functioning of the equipment. These sharp implements are responsible for achieving a clean and even cut. Regular maintenance, such as sharpening or replacing worn blades, is vital for maintaining efficiency and performance.

2. Housing Structure

The housing structure provides support and protection for the internal components. It ensures stability while minimizing vibrations during operation. A sturdy housing is crucial for durability and can affect the overall performance of the equipment.

In summary, recognizing the significance of these essential components allows users to enhance their understanding and maintenance practices, ultimately leading to a more efficient and reliable performance.

Common Issues with Lawn Mower Decks

Maintaining equipment for yard care is essential for achieving a well-groomed landscape. Various challenges can arise that affect performance and efficiency. Understanding these problems can help users troubleshoot and ensure their machinery operates smoothly.

Frequent Problems

Several typical issues may occur during operation, often stemming from wear and tear or improper maintenance. Identifying these can save time and prevent further damage.

| Issue | Description |

|---|---|

| Uneven Cutting | This can result from dull blades, unlevel frames, or obstructions that interfere with movement. |

| Excessive Vibration | Often caused by loose components or unbalanced blades, leading to discomfort and potential damage. |

| Clumping of Grass | This issue usually arises when grass is too wet or when the cutting mechanism is not functioning effectively. |

| Corrosion | Exposure to moisture and chemicals can lead to rust, which diminishes longevity and performance. |

Preventive Measures

To mitigate these concerns, regular inspection and maintenance are crucial. Ensuring blades are sharp, cleaning after use, and storing properly can enhance functionality and extend the lifespan of the equipment.

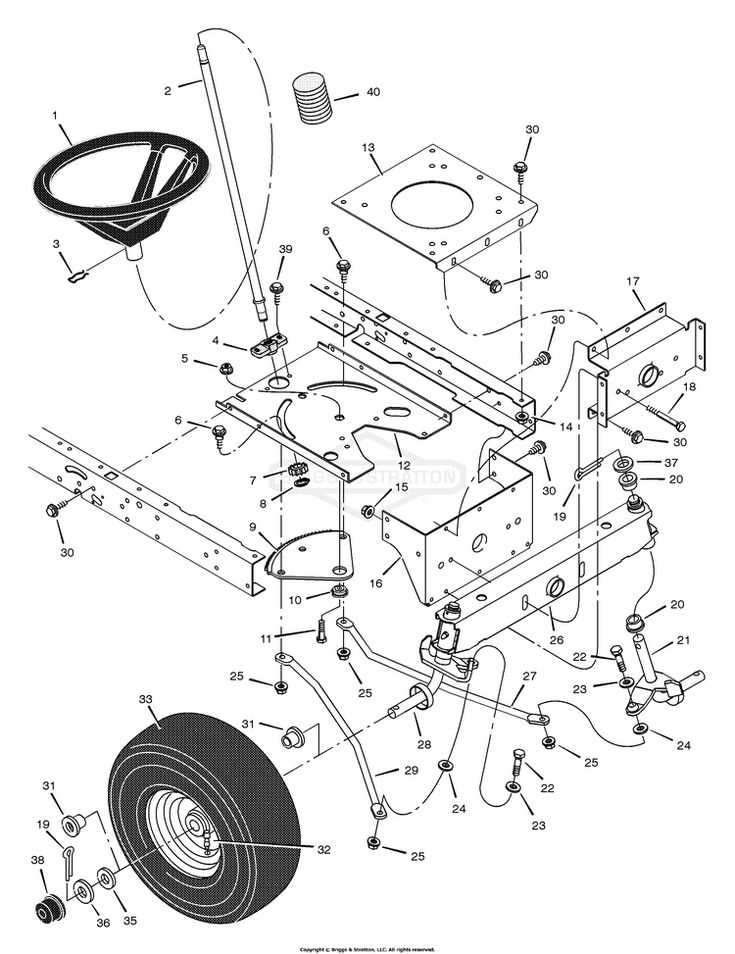

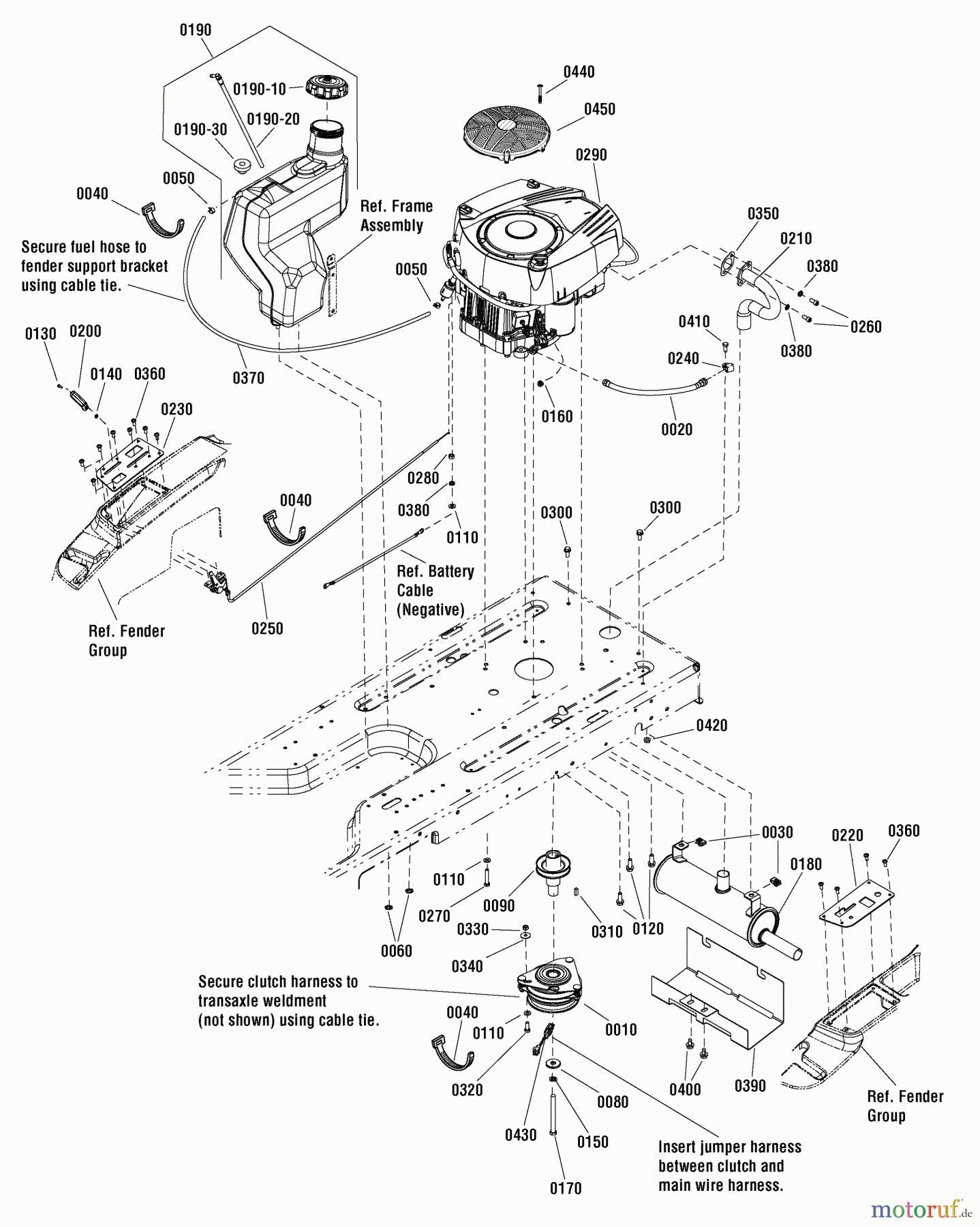

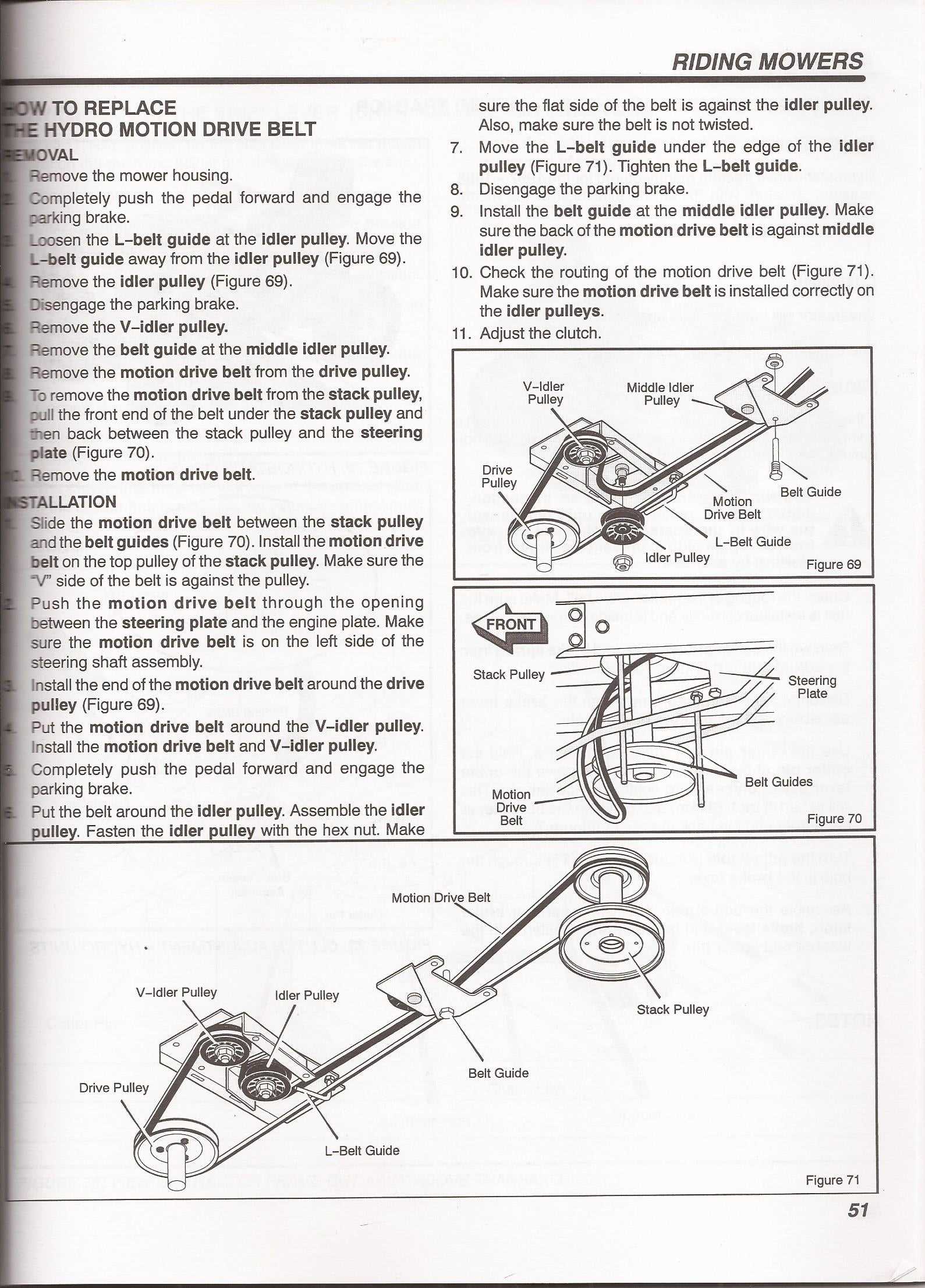

Understanding Deck Assembly and Disassembly

Proper comprehension of the assembly and disassembly process is crucial for maintaining optimal performance. This section aims to provide clarity on the essential steps involved in managing the various components effectively.

First, it is vital to gather all necessary tools and materials. Ensuring you have everything on hand can streamline the entire process. Next, familiarizing yourself with the configuration of elements will enhance your understanding of how each piece interacts.

During disassembly, taking a systematic approach is key. Documenting the order of removal can prevent confusion when reassembling. Similarly, cleaning components as they are taken apart will ensure longevity and efficiency once reattached.

Finally, when reassembling, double-check each component for wear or damage. Proper alignment and secure fastening are essential to restore functionality. Emphasizing these aspects will lead to successful management of your equipment.

Replacement Parts for Murray Mowers

When it comes to maintaining outdoor equipment, ensuring all components are in optimal condition is essential for performance and longevity. Understanding the necessary elements can help keep your machinery running smoothly, allowing you to tackle any task effectively.

Key Components

- Blades

- Belts

- Engines

- Wheels

- Fuel filters

Benefits of Quality Replacements

- Improved efficiency

- Extended lifespan

- Enhanced safety

- Cost-effectiveness over time

Importance of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to diminished efficiency, increased repair costs, and even safety hazards. By dedicating time to routine inspections and care, users can prevent many common issues and enhance the overall functionality of their equipment.

Enhancing Performance

Regular attention to your equipment can significantly boost its operational effectiveness. By cleaning, lubricating, and adjusting components as needed, one can maintain peak performance levels. This not only makes tasks easier but also ensures that the machine operates smoothly, reducing the risk of breakdowns during critical moments.

Extending Lifespan

Just as with any complex tool, proper care contributes to a longer service life. When components are routinely checked and maintained, the wear and tear is minimized. This proactive approach can save users considerable time and money in the long run, avoiding premature replacements and extensive repairs.

Identifying Your Mower Model

Understanding the specific model of your cutting machine is essential for effective maintenance and repairs. Each version comes with distinct features and specifications that determine compatibility with various components. Recognizing these characteristics can streamline your search for the right accessories and ensure optimal performance.

Start by locating the identification label, typically found on the chassis or engine. This label usually includes the model number, serial number, and manufacturer details. Cross-referencing this information with official resources will help you pinpoint the exact model and its requirements.

Additionally, consider the design elements and functionalities of your equipment. Features such as blade size, wheel configuration, and engine type can provide further insights into the specific model. By carefully examining these aspects, you can delve deeper into the unique attributes that set your machine apart.

Tools Needed for Repairs

Proper maintenance and restoration require specific implements to ensure efficient functionality and longevity. Having the right tools at your disposal can simplify the process, allowing for precise adjustments and replacements when necessary.

Essential Implements

Start with a basic toolkit that includes wrenches, screwdrivers, and pliers. These are fundamental for loosening and tightening various components. Additionally, consider a socket set for tackling stubborn bolts and a torque wrench to achieve the correct tightness.

Specialized Tools

For more intricate tasks, you may need specialized devices such as blade sharpeners and alignment gauges. These tools facilitate accurate modifications, ensuring optimal performance and safety during operation.

Where to Buy Replacement Parts

Finding quality components for your equipment can significantly enhance its performance and longevity. There are various avenues to explore when searching for reliable sources, each offering unique advantages and considerations.

| Source Type | Description |

|---|---|

| Online Retailers | Many websites specialize in selling replacement components, providing a wide selection and competitive pricing. |

| Local Dealers | Authorized sellers often carry original components and can offer expert advice on compatibility and installation. |

| Second-Hand Markets | Platforms like classifieds and auctions may yield affordable options, though quality assurance is crucial. |

| Manufacturer’s Website | Purchasing directly from the original maker ensures authenticity and access to specific items not found elsewhere. |