The efficient operation of any grass-cutting system relies heavily on the harmonious interaction of various components. Each element plays a crucial role in ensuring the machine runs smoothly, providing precision and consistency. By exploring the detailed layout of these systems, you can gain a deeper understanding of their structure and functionality.

From the primary cutting blades to the support mechanisms, every element has a specific purpose. Proper maintenance and timely replacement of worn elements are essential for optimal performance. This section aims to provide a clear understanding of the critical components involved in the functioning of such a cutting system.

In the following guide, we will highlight key areas that require regular inspection, as

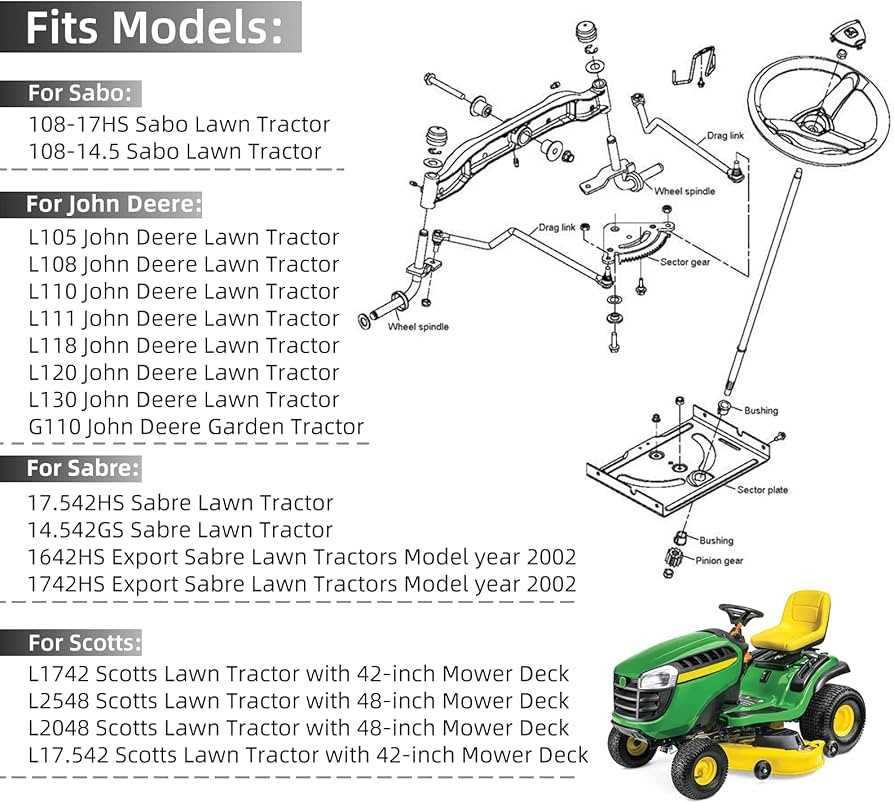

L110 John Deere 42 Inch Mower Deck Parts Overview

This section provides a comprehensive look at the components that make up the cutting system used in a popular outdoor machine. Each element is crucial for maintaining smooth operation and achieving high-quality results during lawn maintenance. Understanding how these individual pieces work together will help ensure optimal performance and longevity of your equipment.

- Blades: The sharp edges that handle the actual grass cutting. Regular sharpening or replacement ensures precise and clean cuts.

- Spindle Assembly: Supports the blades, allowing them to spin freely and efficiently while reducing wear and tear on the system.

- Belt System: Transfers power from the engine to the cutting mechanism. Keeping the belt in good condition is vital for consistent functionality.

- Pulleys:

Main Components of the L110 Mower Deck

Understanding the key elements of this cutting platform helps maintain its functionality and prolong its lifespan. Each piece is carefully designed to work in unison, ensuring smooth operation and efficient cutting performance. Below is a closer look at the primary components that make up this essential system.

Component Function Blades Responsible for trimming grass with precision, providing an even cut. Spindle Assemblies Connect the blades to the mechanism, enabling them to rotate effectively. Belt Transfers power from the en Blade Assembly and Its Role in Cutting

The blade assembly is a key component responsible for efficient grass cutting. Its sharp edges and balanced structure allow for clean and precise slicing, ensuring the optimal health of the lawn. The design and arrangement of the blades play a significant role in determining how effectively the grass is trimmed, as well as how evenly the cut is distributed across the surface.

Importance of Blade Sharpness

Maintaining sharp blades is essential for achieving a smooth cut. Dull blades can tear the grass instead of slicing it, which can cause damage and lead to an uneven appearance. Regular sharpening and proper care of the blades are crucial to maintain the performance and extend the life of the cutting system.

Blade Balance and Performance

A well-balanced blade assembly ensures stability during operation. Imbalanced blades can cau

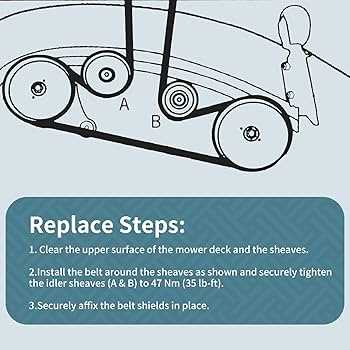

Belt System: Ensuring Smooth Mower Operation

The belt system plays a critical role in the performance of your equipment, ensuring the seamless transfer of power to essential components. A well-maintained and correctly tensioned belt ensures that the machine operates efficiently, reducing wear and tear on other mechanical parts. Proper care of this system helps maintain overall performance and longevity.

Regular Inspections are vital to avoid potential disruptions. Checking for signs of wear, such as fraying, cracks, or stretching, can help detect issues before they lead to more significant problems. A damaged or improperly adjusted belt can result in inefficient operation and strain other parts of the system.

Additionally, keeping the belt clean and free of debris prevents unnecessary friction and heat buildup. This step ensures that the belt remains flexible and operates at its full potential, contributing to the smooth functioning of the entire setup.

Understanding the Spindle Mechanism

The spindle mechanism plays a critical role in the operation of many cutting devices. It is responsible for transferring power from the engine to the cutting blades, enabling smooth and efficient operation. Understanding how this system functions is essential for maintaining performance and prolonging the life of the equipment.

How the Spindle Transfers Power

At the core of the spindle system is a shaft that connects the rotating blades to the power source. As the motor engages, the spindle transfers rotational energy through the shaft, causing the blades to spin. This direct connection ensures that the blades reach optimal speed for cutting through various materials.

Importance of Proper Maintenance

Regular upkeep of the spindle assembly is essential to prevent wear and tear. Lubrication of the bearings, checking for alignment, and replacing worn-o

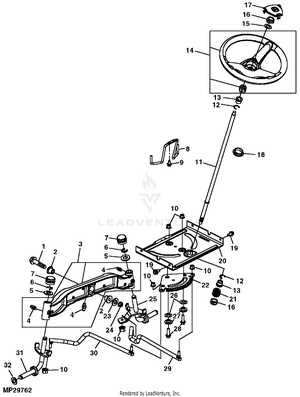

Pulley System Functions and Maintenance

The pulley system plays a vital role in the operation of various machinery, enabling the efficient transfer of power through rotational motion. By utilizing a series of wheels and belts, this system facilitates the movement of components, ensuring smooth functionality. Proper understanding and maintenance of this system are essential to prolong its lifespan and enhance overall performance.

Functions of the Pulley System

This system primarily serves to reduce the amount of effort required to lift or move loads. By changing the direction of force and distributing weight evenly, it allows for greater control and efficiency in operation. Additionally, the use of multiple pulleys can significantly increase mechanical advantage, making tasks easier to accomplish.

Maintenance Guidelines

Regular upkeep of the pulley system is crucial for optimal performance. Here are some essential maintenance practices:

Maintenance Task Frequency Description Visual Inspection Weekly Check for any signs of wear, damage, or misalignment in the pulleys and belts. Lubrication Monthly Apply lubricant to bearings and moving parts to reduce friction and wear. Adjustment As Needed Ensure proper tension on belts and alignment of pulleys to prevent slippage. Replacement Annually Replace worn or damaged belts and pulleys to maintain efficiency. By following these guidelines, operators can ensure that the pulley system remains in good condition, thereby enhancing the overall functionality of the equipment.

How to Properly Adjust the Mower Deck

Ensuring optimal cutting performance is crucial for achieving a well-manicured lawn. Correctly positioning the cutting apparatus helps maintain an even height and improves overall efficiency. This section will guide you through the necessary steps to effectively adjust the equipment for the best results.

Follow these steps to achieve the proper alignment:

- Begin by parking the machine on a flat, level surface to ensure accurate adjustments.

- Check the height settings of the cutting apparatus, which should match your desired grass length.

- Inspect the condition of the blades; sharp and well-maintained blades are essential for a clean cut.

- Make sure the mounting brackets are secure and free from wear, as loose components can lead to uneven cutting.

After completing the initial checks, proceed with the adjustments:

- Utilize a ruler or tape measure to determine the height from the ground to the blade tips at several points.

- Adjust the height levers or bolts according to the manufacturer’s specifications to achieve a uniform height across the cutting apparatus.

- Perform a trial run in a small section of grass to evaluate the effectiveness of your adjustments.

- If needed, make further tweaks until you reach the desired cutting height.

Finally, regularly check and maintain the apparatus to ensure consistent performance throughout the mowing season.

Troubleshooting Common Mower Deck Issues

When maintaining your cutting equipment, encountering operational problems is a common occurrence. Addressing these concerns promptly is essential to ensure optimal performance and longevity. This section will guide you through identifying and resolving frequent complications, allowing for a more efficient and effective experience.

Identifying Performance Issues

One of the primary concerns is inadequate cutting performance, which can result from various factors. The following table outlines potential causes and their corresponding solutions:

Issue Possible Cause Recommended Solution Uneven Cutting Worn or damaged blades Inspect and replace blades if necessary Clumping of Grass Clogged discharge chute Clear any debris and ensure proper airflow Excessive Vibration Loose or misaligned components Tighten screws and align parts accordingly Maintenance and Care Tips

Regular maintenance is vital to prevent issues from arising. Ensure to conduct routine checks and perform the necessary upkeep to extend the lifespan of your equipment. Always refer to the manufacturer’s guidelines for best practices regarding care and operation.

Best Practices for Replacing Worn-Out Parts

Maintaining optimal performance in machinery requires regular attention to its components. When these elements begin to show signs of wear, timely replacement is crucial to ensure efficiency and longevity. Adhering to best practices during this process can prevent future issues and enhance the overall functionality of the equipment.

1. Regular Inspection: Routine checks allow for early identification of damaged or degraded components. Look for signs such as unusual noises, decreased efficiency, or visible wear. Proactive assessments can lead to timely interventions.

2. Use Quality Replacements: Always choose high-quality replacements that meet or exceed manufacturer specifications. This ensures compatibility and enhances durability, reducing the likelihood of future breakdowns.

3. Follow Manufacturer Guidelines: Each model comes with specific recommendations for replacement procedures. Adhering to these guidelines ensures proper installation and functionality, minimizing the risk of errors that could lead to further damage.

4. Keep Tools Handy: Having the right tools readily available simplifies the replacement process. Invest in a quality toolset designed for the specific tasks required, as this can save time and effort during maintenance.

5. Document Maintenance Activities: Keeping a detailed record of replacements and inspections helps track the history of the machinery. This documentation can be valuable for future reference, allowing for informed decisions regarding maintenance schedules.

6. Seek Professional Help if Needed: If unsure about the replacement process, do not hesitate to consult a professional. Expert advice can provide clarity and ensure that the work is done correctly, preventing potential complications.