In the realm of automotive mechanics, a comprehensive grasp of the intricate systems that enable smooth vehicle maneuverability is essential. This segment delves into the various elements that play a pivotal role in guiding a truck’s trajectory, ensuring both safety and responsiveness on the road.

From the essential linkages to the advanced technology that enhances handling capabilities, understanding these components is crucial for any enthusiast or professional in the field. Each piece contributes to a harmonious balance that allows for precise navigation, regardless of the driving conditions.

By exploring detailed illustrations and schematics, one can gain insight into the functionality and interaction of these vital elements. This knowledge not only aids in maintenance and repair but also enhances appreciation for the engineering that underpins modern automotive design.

Dodge Ram 1500 Steering Overview

This section provides a comprehensive look at the essential components that ensure precise handling and control of your vehicle. Understanding these elements is crucial for maintaining optimal performance and enhancing safety on the road.

Key Components

At the heart of the system lies the mechanism that allows for smooth navigation. This includes crucial items such as the linkage, column, and actuator, all of which work in unison to provide responsiveness and stability. Regular inspection of these components is vital to prevent wear and ensure longevity.

Maintenance Tips

To maximize efficiency, routine checks and timely replacements are recommended. Pay close attention to any unusual sounds or resistance while maneuvering, as these may indicate underlying issues. Proactive care can lead to a more reliable driving experience.

Importance of Steering Components

Essential mechanisms play a crucial role in ensuring a vehicle’s maneuverability and control. These elements facilitate the interaction between the driver and the road, enabling precise navigation and stability during travel.

Key Functions

- Enhancing driver feedback

- Ensuring vehicle stability

- Facilitating smooth turns

Maintenance Considerations

- Regular inspections to identify wear and tear

- Timely replacements to avoid complications

- Proper lubrication to ensure optimal function

Common Steering Issues in Dodge Ram

Vehicles often experience a variety of challenges related to directional control, impacting safety and performance. Recognizing and addressing these concerns early can enhance driving experience and prolong the lifespan of the vehicle.

Typical Symptoms

Drivers may notice several signs indicating potential issues with the directional control system. These can range from unusual sounds to difficulty in maneuvering. Here are some common symptoms:

| Symptom | Possible Cause |

|---|---|

| Vibration or shaking | Worn components or misalignment |

| Unresponsive handling | Low fluid levels or leaks |

| Grinding noises | Worn bearings or gears |

| Pulling to one side | Uneven tire pressure or alignment issues |

Preventive Measures

To mitigate these issues, regular maintenance is crucial. This includes checking fluid levels, inspecting components for wear, and ensuring proper alignment. Addressing minor concerns promptly can prevent more significant problems down the line.

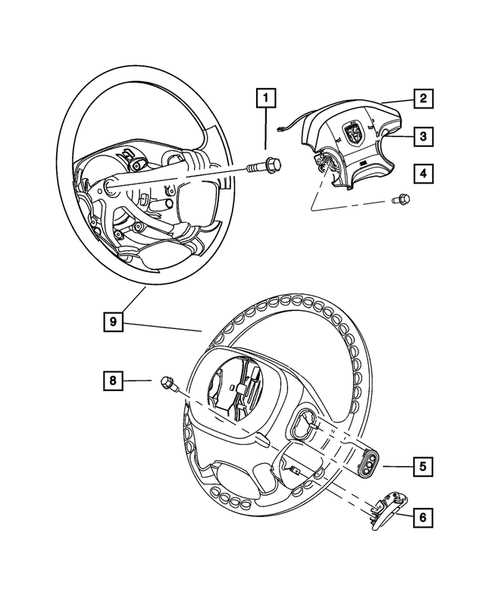

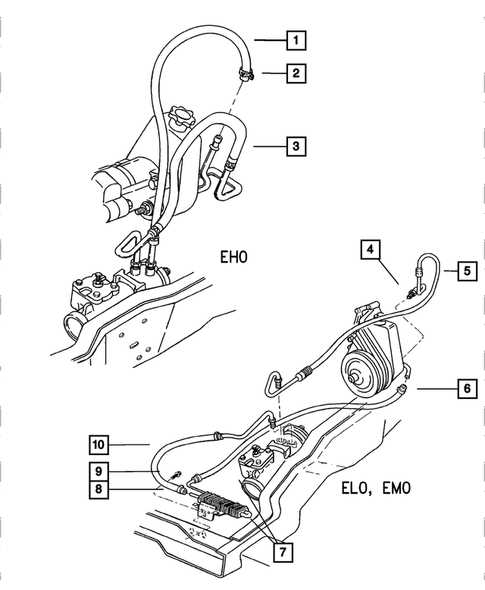

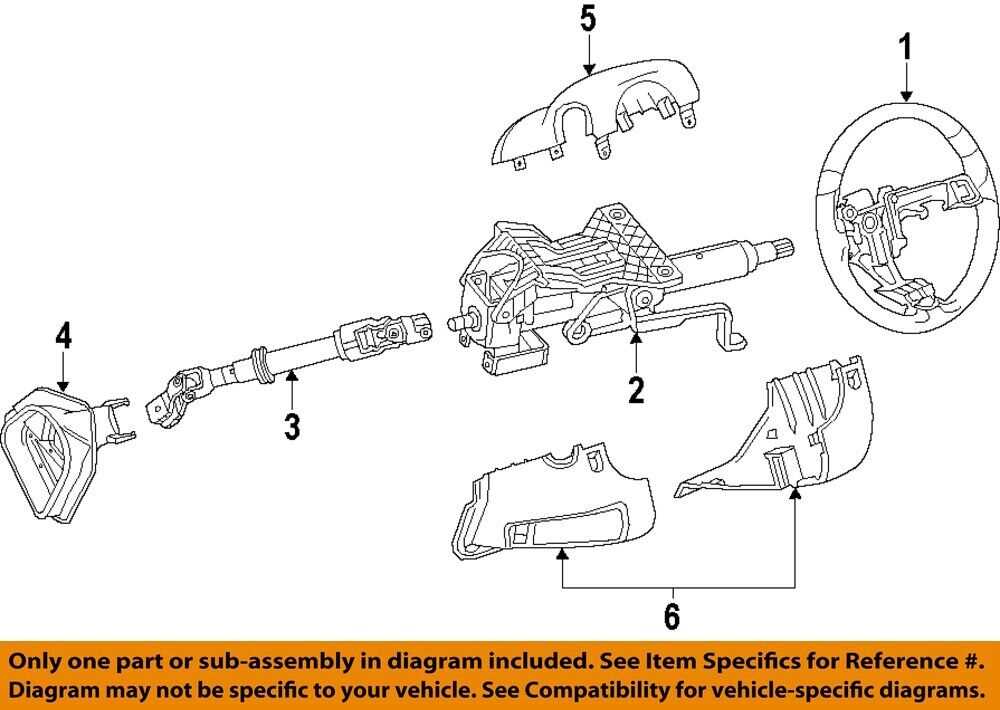

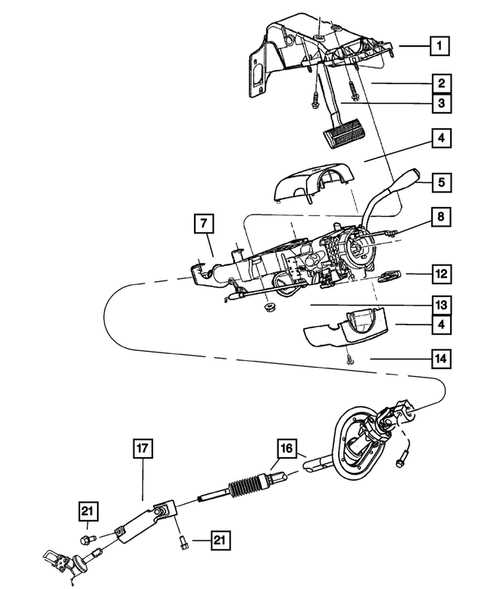

Identifying Parts in Diagrams

Understanding visual representations of mechanical assemblies is essential for effective maintenance and repair. By familiarizing oneself with these illustrations, one can easily locate and identify individual components, facilitating a more efficient workflow. Each symbol and line serves a purpose, conveying critical information about the relationships and functions of various elements within the system.

When examining such visuals, it is important to pay attention to labels and annotations that clarify the role of each section. These notations often include numerical references and descriptive names, which help streamline the process of sourcing replacements or undertaking repairs. A clear comprehension of the layout not only enhances practical skills but also fosters a deeper appreciation of the overall design and mechanics at play.

Moreover, engaging with these representations allows for a better grasp of assembly and disassembly procedures. Recognizing how components fit together can reduce the risk of errors during maintenance. As one becomes more adept at interpreting these visuals, troubleshooting becomes a more manageable task, ultimately contributing to improved performance and longevity of the equipment.

Maintenance Tips for Steering System

Ensuring the longevity and efficiency of your vehicle’s directional control mechanism is crucial for safe driving. Regular upkeep not only enhances performance but also helps in identifying potential issues early on, preventing costly repairs.

Regular Inspections

- Check for leaks in the hydraulic fluid.

- Inspect the condition of the links and joints.

- Look for signs of wear on the boots and seals.

Fluid Maintenance

- Change the fluid as recommended by the manufacturer.

- Top off the fluid to the appropriate level.

- Flush the system if contaminants are present.

Replacement Parts for Ram 1500

Maintaining the integrity of your vehicle is essential for optimal performance and safety. When components wear out, replacing them with high-quality alternatives ensures reliability and enhances driving experience. This section explores essential components that can be upgraded or substituted for a smoother operation.

Key Components to Consider

Control Units: These elements play a crucial role in vehicle maneuverability. Choosing durable replacements can significantly improve responsiveness.

Benefits of Upgrading

Opting for enhanced alternatives can lead to greater durability and improved handling. Investing in quality replacements not only boosts performance but also extends the lifespan of your vehicle.

Aftermarket vs. OEM Components

When considering replacement options for vehicle components, two primary categories often emerge. Each choice has distinct advantages and potential drawbacks, influencing the decision-making process for many owners.

- OEM Components:

- Manufactured by the original maker.

- Ensures perfect fit and compatibility.

- Often comes with a warranty for peace of mind.

- Aftermarket Components:

- Produced by third-party manufacturers.

- May offer enhanced performance or different features.

- Generally more affordable than OEM options.

Ultimately, the choice between these options depends on factors like budget, desired quality, and specific performance needs. Exploring these alternatives can help owners make informed decisions.

Tools Needed for Steering Repairs

When tackling repairs related to the directional system of a vehicle, having the right tools is essential for ensuring efficiency and safety. A well-equipped toolkit can simplify the process and help prevent damage to components.

Essential Tools

| Tool | Purpose |

|---|---|

| Socket Set | For removing and tightening bolts. |

| Wrench Set | To adjust nuts and screws in tight spaces. |

| Torque Wrench | Ensures bolts are tightened to specifications. |

| Pry Bar | Assists in separating components. |

Safety Equipment

In addition to standard tools, safety gear is vital. Gloves, goggles, and protective footwear can prevent injuries while performing repairs. Ensuring proper safety measures will ultimately lead to a smoother repair experience.

Step-by-Step Repair Process

This section outlines a comprehensive procedure for restoring the directional control system of a pickup vehicle. Following a systematic approach ensures each component is addressed, promoting optimal performance and safety.

1. Gather Necessary Tools and Materials: Begin by collecting all required tools, including wrenches, sockets, and a torque wrench. Ensure you have replacement components on hand to facilitate a smooth repair process.

2. Lift the Vehicle: Utilize a hydraulic jack and jack stands to elevate the vehicle securely. This will provide sufficient space to access the components underneath.

3. Remove the Old Components: Carefully detach the worn or damaged elements. Pay attention to the orientation and placement of each part to aid in reassembly. It’s advisable to take notes or photographs during this stage.

4. Inspect Surrounding Areas: Examine related components for wear or damage. Addressing any additional issues now can prevent future complications.

5. Install New Components: Position the replacement elements according to the notes taken earlier. Ensure everything is aligned correctly before tightening bolts and fasteners.

6. Reassemble and Secure: Reattach any removed parts, making sure to follow the manufacturer’s specifications for torque settings. This step is crucial for maintaining integrity and safety.

7. Lower the Vehicle: Carefully remove the jack stands and lower the vehicle back to the ground. Check that everything is secure before proceeding.

8. Test the System: Once reassembled, perform a test drive to evaluate the functionality. Listen for unusual noises and observe the responsiveness to ensure all components are operating as intended.

9. Final Inspection: After the test drive, conduct a thorough check of all connections and fasteners. Make any necessary adjustments to guarantee optimal performance.