When it comes to maintaining or repairing your GE laundry equipment, knowing the layout and function of its internal elements is essential. These machines consist of a variety of components, each playing a crucial role in ensuring smooth operation. From the drum mechanism to the electrical system, understanding how each part fits together can make troubleshooting much easier.

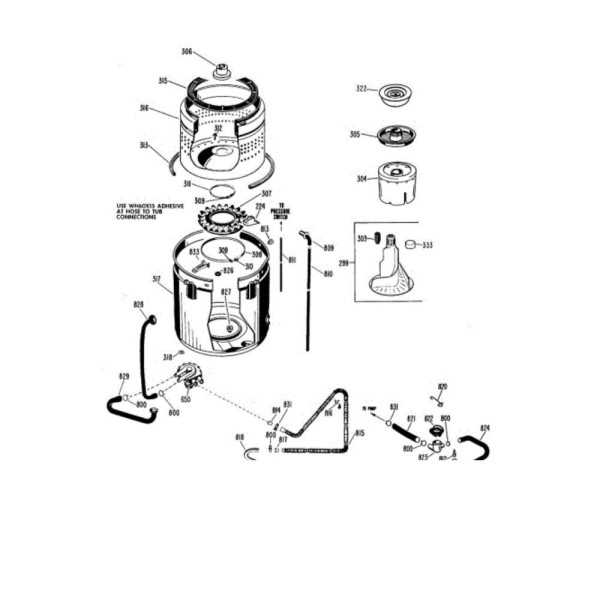

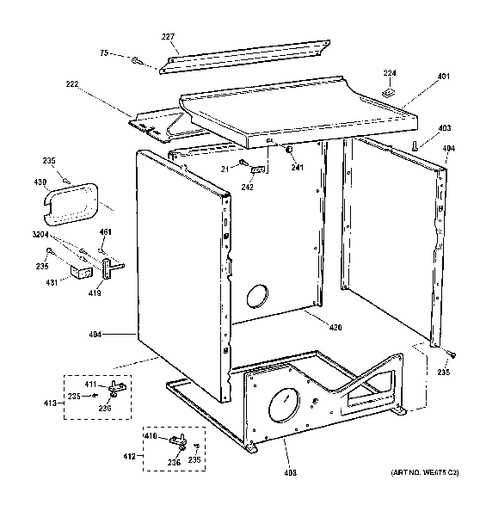

Visual guides can be invaluable when trying to identify specific parts or address any malfunctions. With clear diagrams, you can see where each piece belongs, which aids in disassembly, replacement, or repair. Having a clear reference helps save time and reduces the likelihood of mistakes during maintenance work.

Whether you’re a DIY enthusiast or a professional technician, familiarizing yourself with the internal structure of these machines will empower you to address common issues and enhance their longevity. A well-maintained unit ensures optimal performance, and understanding its key elements is the first step toward that goal.

Understanding GE Top Load Washer Components

Familiarity with the various elements of your GE appliance can enhance both its usage and maintenance. Recognizing how each component functions and interacts with others is essential for optimal performance and longevity. This section explores key features and their significance in the overall operation of the machine.

Key Elements

- Drum: The central chamber where garments are placed for cleaning.

- Agitator: The device responsible for moving clothes within the drum.

- Motor: Powers the agitation and spinning processes.

- Pump: Removes water from the drum post-wash cycle.

- Control Panel: The interface for selecting cycles and settings.

Importance of Each Component

- Drum: Crucial for providing ample space for items while ensuring effective cleaning.

- Agitator: Enhances the movement of fabrics, resulting in a more thorough wash.

- Motor: Its efficiency directly impacts the speed and effectiveness of the entire process.

- Pump: Ensures that excess water is expelled, allowing for a more efficient drying cycle.

- Control Panel: User-friendly interface that simplifies operation and customizes washing preferences.

Essential Parts of a GE Washer Explained

Understanding the key components of your GE appliance can significantly enhance its efficiency and longevity. Each element plays a vital role in the overall functionality, ensuring your laundry is clean and well cared for. Here, we will explore these crucial elements in detail.

Main Components

- Drum: The central chamber where clothes are placed for cleaning.

- Agitator: The mechanism that moves garments through water and detergent.

- Pump: Responsible for draining the water post-wash cycle.

Support Systems

- Control Panel: The interface that allows you to select wash settings.

- Hoses: Connect the machine to water supply and drainage systems.

- Motor: Powers the drum and agitator, essential for movement.

How to Identify Common Washer Malfunctions

Understanding how to recognize typical issues with your laundry appliance can save you time and prevent costly repairs. Many problems can manifest through unusual sounds, inefficient cleaning, or unexpected leaks. By observing these signs, you can diagnose the underlying cause and determine whether it’s a simple fix or requires professional assistance.

One common symptom is excessive noise during operation. This can indicate loose components or foreign objects lodged in the drum. If you notice the unit shaking more than usual, it may be due to an imbalance or improper loading. Additionally, if your garments come out still dirty or soaked, it may suggest a malfunction in the rinse cycle or drainage system.

Leaking water is another critical sign of trouble. Puddles around the appliance may point to a damaged hose or a faulty door seal. It’s essential to check connections for wear or any signs of damage. Furthermore, if the machine fails to start or frequently stops mid-cycle, this could signify electrical issues or a problem with the control panel.

By paying attention to these indicators, you can effectively troubleshoot and address common issues, ensuring your appliance runs smoothly and efficiently.

Exploring the Control Panel and Settings

The control panel of any appliance is the hub of operation, offering users an interface to manage and customize various functions. It contains buttons, dials, and displays that allow the user to select specific cycles, adjust settings, and monitor the current state of the device. Understanding how each element on this panel works is essential for efficient use and for ensuring that the appliance performs optimally in different scenarios.

To fully grasp the control panel functionality, it is important to break down its components and explore how each option influences the overall process:

- Cycle Selector: The cycle selector allows users to choose the appropriate washing process depending on the type of laundry. Common options include normal, heavy-duty, delicate, and quick wash cycles.

- Temperature Control: This setting adjusts the water temperature, ensuring that clothes are washed at the most suitable heat level, whether cold, warm, or hot, to effectively remove stains while protecting fabrics.

- Spin Speed: The spin speed setting controls the rate at which the drum rotates to remove excess water from the laundry, affecting both drying time and fabric care.

- Delay Start: This feature allows users to schedule a wash cycle to start at a later time, offering flexibility for convenience and energy efficiency.

- Additional Features: Many models also include specialized settings such as extra rinse, fabric softener options, or energy-saving modes that help optimize performance based on user preferences.

In addition to the physical controls, the display panel may provide feedback such as cycle time remaining, error codes, or notifications when a cycle is complete. Familiarizing oneself with these indicators can prevent confusion and help troubleshoot issues more efficiently.

Mastering the control panel ensures users are getting the most out of the appliance, allowing for tailored cycles that meet individual laundry needs while enhancing overall efficiency and fabric care.

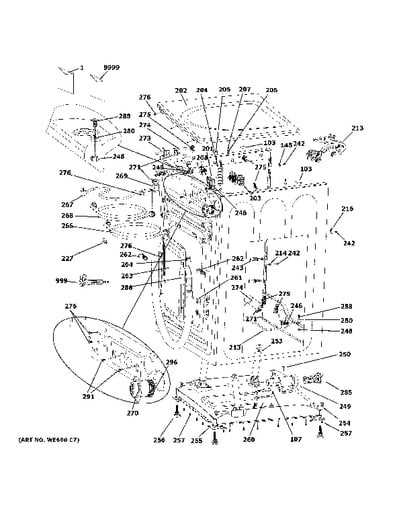

Step-by-Step Guide to Disassembling Your Washer

In this guide, we will walk you through the essential steps to safely dismantle your cleaning machine, ensuring you can access its internal components for maintenance, troubleshooting, or repair. Whether you are looking to fix an issue or clean areas that are not easily visible, this step-by-step approach will help you understand the process and avoid common mistakes. By following the outlined instructions, you’ll be able to confidently take apart your appliance and identify any problematic areas.

1. Disconnect from Power

Before you begin, it’s crucial to disconnect the appliance from the electrical source. Unplug the unit to eliminate any risk of electrical shock or injury. If you’re unsure of how to do this, consult the user manual or contact a professional.

2. Remove the Exterior Panels

Next, remove the exterior casing, typically secured with screws. These screws are often located at the back or beneath the appliance. Use a screwdriver to carefully loosen them and set them aside in a safe location for reassembly later. Once the panels are free, gently lift them off and place them aside.

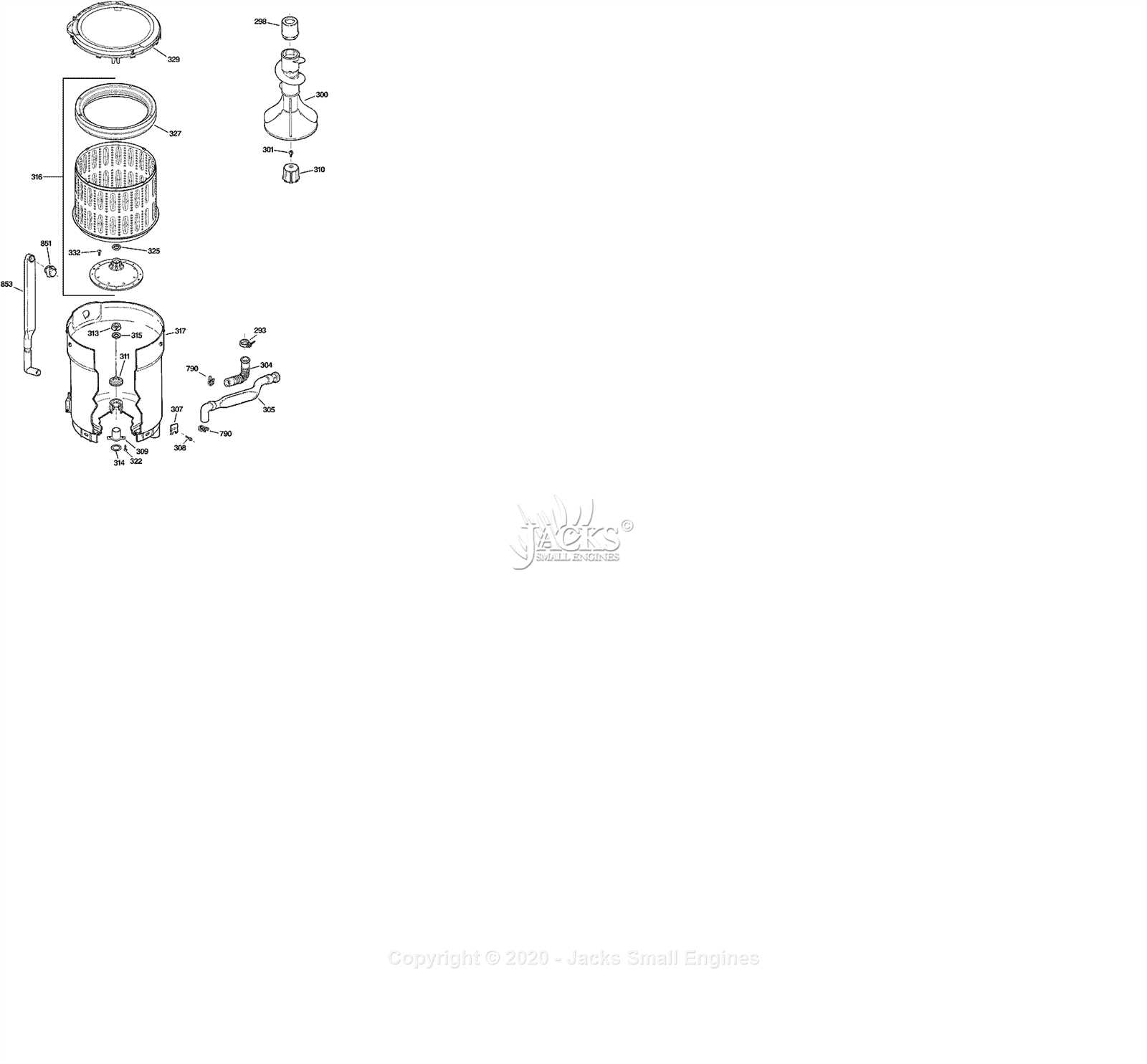

3. Detach the Drum

Once the outer casing is removed, the next step is to detach the drum. This part of the appliance is usually held in place by a few bolts or brackets. You may need to use a wrench or socket set to carefully loosen these fasteners. Pay close attention to how the drum is secured, as reassembling it incorrectly can cause issues later on.

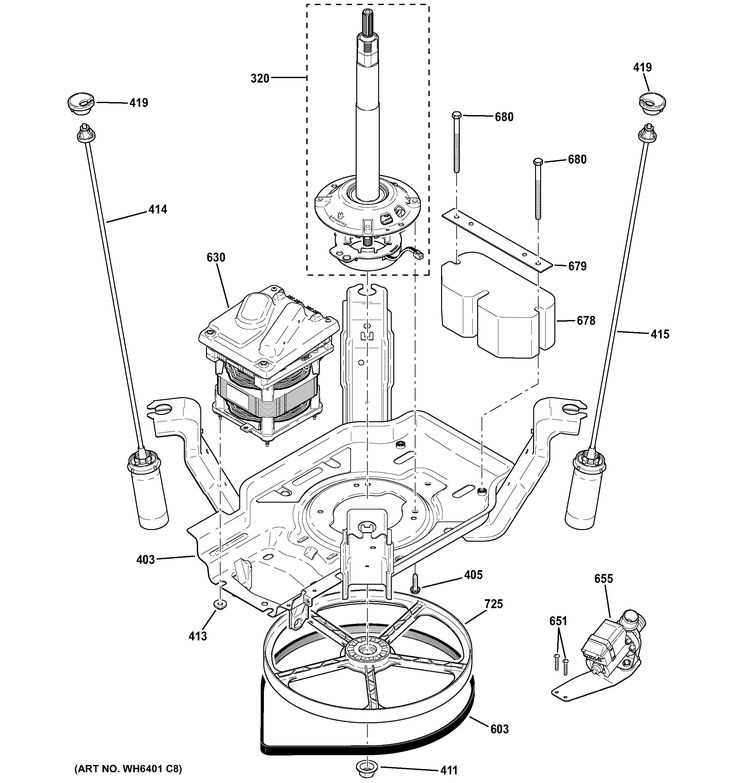

4. Inspect the Internal Components

With the drum detached, take the opportunity to inspect the internal mechanisms such as the motor, belt, and pulley system. Look for signs of wear, damage, or build-up of debris. Cleaning or replacing worn-out parts at this stage can help prevent future issues.

5. Reassemble the Machine

After completing your inspection or repairs, carefully reassemble the unit by reversing the steps. Ensure all screws and fasteners are tightened securely to avoid any instability when the appliance is in use. Double-check that the drum, motor, and other critical components are properly aligned and connected before reattaching the outer casing.

By following these steps, you will have successfully disassembled your cleaning unit, allowing you to address issues effectively or prepare it for regular maintenance.

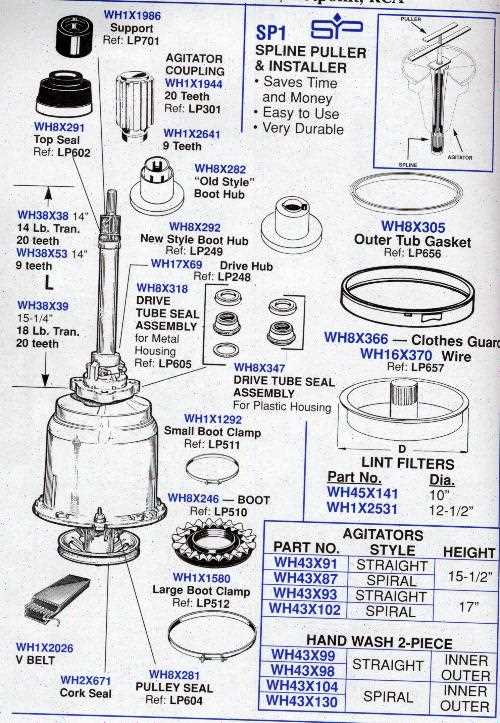

Replacing the Agitator and Drum Assembly

Replacing the agitator and drum assembly is a crucial maintenance task that can restore optimal performance to your appliance. These components work together to ensure effective movement of your clothing during the cleaning cycle. Over time, wear and tear can cause them to malfunction, leading to inefficient washing. Understanding the steps to replace these parts can help you save time and money while keeping your machine in top condition.

Steps for Removing the Agitator

To begin the replacement, you’ll need to carefully remove the agitator. Start by disconnecting the power supply and ensuring there is no water remaining in the drum. Next, open the lid and remove any screws securing the agitator. It may also be necessary to detach the central column by unscrewing any bolts that hold it in place. Once loose, gently lift out the agitator, being mindful of any attached components or wiring that may need to be disconnected.

Installing the New Drum Assembly

With the old agitator removed, you can now focus on installing the new drum assembly. Align the new assembly with the base and ensure that it fits securely into place. Reattach any screws or bolts that were previously removed, making sure the entire unit is firmly seated. Once installed, run a short cycle with water to check for proper function and ensure no leaks or unusual noises occur. This will confirm that the new parts are working as expected.

Key Electrical Parts and Troubleshooting Tips

Understanding the essential electrical components of your appliance is crucial for effective maintenance and troubleshooting. Familiarity with these elements can help identify common issues, leading to faster resolutions and a smoother operation.

Essential Electrical Components

- Control Board: The brain of the machine, responsible for managing cycles and functions.

- Power Cord: Supplies electricity to the unit; check for damage or loose connections.

- Motor: Drives the agitation and spinning; listen for unusual noises that may indicate a problem.

- Water Level Sensor: Detects the amount of water needed; malfunction may lead to overfilling or insufficient filling.

- Door Lock Assembly: Ensures safe operation; if malfunctioning, the appliance may not start.

Troubleshooting Tips

- Check Connections: Ensure all electrical connections are secure and free of corrosion.

- Inspect for Faulty Components: Look for burnt or damaged parts, especially in the control board and motor.

- Test the Power Supply: Verify that the outlet is functioning and providing adequate voltage.

- Reset the Appliance: Sometimes, a simple reset can resolve minor electronic glitches.

- Consult the Manual: Reference the user manual for specific error codes and troubleshooting advice.

Maintenance Tips for Long-Lasting Performance

Proper upkeep is essential to ensure your appliance operates efficiently for years. Regular care and attention can prevent unnecessary wear and extend the life of your equipment. Below are some simple maintenance guidelines to help you keep everything running smoothly, minimizing the need for costly repairs or replacements.

Routine cleaning, careful inspection, and timely adjustments are key to maintaining optimal performance. Taking a few minutes each month to address potential issues will greatly reduce the risk of major breakdowns. The following table outlines practical tips and tasks that should be performed regularly.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean lint filter | After every use | Prevents blockages and promotes efficient operation |

| Inspect hoses for leaks or cracks | Monthly | Reduces the risk of water damage and ensures proper water flow |

| Check and level the unit | Every 6 months | Prevents vibrations and potential damage to internal components |

| Clean detergent drawer | Every 2-3 months | Prevents buildup of detergent residue and promotes efficient rinsing |

| Run a maintenance cycle with cleaning solution | Every 3-6 months | Removes buildup of grime and ensures the interior stays fresh |

By incorporating these small but effective tasks into your maintenance routine, you can ensure your appliance remains in optimal condition, providing consistent performance over time.

Where to Find Genuine GE Replacement Parts

Finding authentic components for your appliances can be a crucial step in ensuring their longevity and efficiency. Quality replacements not only maintain functionality but also contribute to the overall performance of your machine. Here are some reliable sources to consider when searching for genuine GE components.

Authorized Retailers

One of the best options for locating authentic GE items is through authorized retailers. These stores are certified to sell genuine components and often have knowledgeable staff to assist you. Consider the following:

- Visit local appliance stores that carry GE products.

- Check large home improvement retailers, as they often have dedicated sections for genuine components.

- Look for online marketplaces that feature verified sellers of GE items.

Official GE Website

The official GE website is another reliable source for authentic components. The site provides comprehensive information about the available items and can guide you through the purchasing process. Key benefits include:

- A wide selection of components for various appliance models.

- Access to detailed specifications and compatibility information.

- Customer support for inquiries regarding your specific needs.

By sourcing from these reputable avenues, you can ensure that your appliances continue to operate smoothly and efficiently for years to come.