The efficient operation of lawn care machinery relies heavily on a well-designed and maintained cutting system. Each element of this system plays a crucial role in ensuring smooth performance, from the blades to the supporting hardware.

Regular upkeep and familiarization with the various elements of the cutting mechanism are essential for both longevity and optimal function. Understanding the specific components and how they interact can help prevent future malfunctions and ensure reliable use over time.

Proper maintenance and timely replacements are key to extending the life of your equipment. By identifying the individual elements and understanding their importance, you can ensure the system operates at its peak efficiency, delivering consistent results with every use.

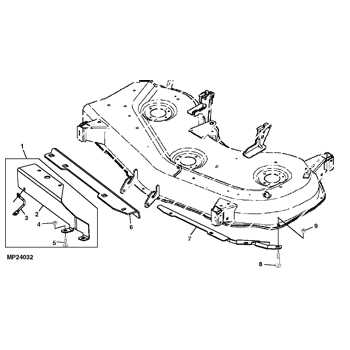

Maintenance of Mower Deck Components

Proper upkeep of cutting equipment ensures its longevity and optimal performance. Regular checks and adjustments prevent issues that could affect the efficiency and durability of essential mechanisms. Key elements, such as blades and belts, should be inspected for wear and replaced as necessary to maintain smooth operation.

Cleaning and Lubrication: Keeping the components free from debris is critical for functionality. After each use, ensure that grass and dirt are cleared away, especially from the cutting mechanism and moving parts. Periodically lubricate joints and bearings to reduce friction and prevent premature wear.

Blade Sharpening and Replacement: Blades need regular sharpening to provide a clean cut. Dull blades can damage the grass and strain the engine, so they should

Understanding Key Mower Deck Parts

When exploring the design of lawn maintenance equipment, it’s essential to understand the different elements involved. Each component plays a critical role in ensuring smooth performance and effective grass cutting. Familiarity with these elements helps in maintaining the system and troubleshooting any issues.

Main Components of the Cutting System

The cutting system is composed of several essential elements that work together to ensure precision and durability. Blades are designed to trim the grass efficiently, while the structure that supports them ensures stability during operation. Proper balance between these components is necessary for optimal functionality.

Additional Functional Elements

Other vital components include mechanisms for height adjustment and support structures that secure the blades. These elements allow users to customize the equipment for different terrains and grass lengths, contributing

Proper Lubrication for Deck Longevity

Maintaining the longevity of your equipment’s cutting platform requires proper care and attention to lubrication. Regular application of the right lubricants ensures smooth operation, reduces wear, and prevents costly breakdowns over time. Focusing on key points of friction and ensuring these areas are well-maintained is crucial for keeping the system functional for longer periods.

Key Areas to Lubricate

Critical points where friction occurs, such as spindles, bearings, and pulleys, need consistent lubrication. Regularly applying the right type of grease will reduce wear and tear, allowing for smooth movement and optimal performance.

Lubrication Frequency

The frequency of lubrication depends on the usage and environmental conditions. For machines frequently exposed to dust and moisture, more frequent application is recommended

Installation Tips for 48-Inch Deck Blades

When preparing to install blades on a 48-inch cutting platform, it’s important to focus on safety and precision. The process involves aligning the blades correctly and ensuring all components are securely fastened to optimize performance and reduce wear over time.

1. Ensure Safety First

Before starting, make sure the equipment is turned off and the spark plug is disconnected. This helps to prevent any accidental starts during the installation. Wearing protective gloves is recommended to avoid injuries while handling sharp edges.

2. Check Blade Orientation

When installing, it’s essential to verify that the sharp edge of the blade faces the correct direction. Installing blades upside down can lead to inefficient cutting and potential damage to the grass and equipment.

3. Tighten Securely

Use a wrench to tighten the bolts holding the blades

Troubleshooting Common Mower Deck Issues

Mechanical systems that handle cutting tasks can sometimes experience difficulties, affecting performance and efficiency. Understanding these challenges and their solutions is essential for ensuring smooth operation and prolonging the lifespan of your equipment. Below are common problems and practical solutions to maintain optimal functionality.

Uneven Cutting

- Check the alignment of the cutting surface to ensure it’s level. Adjust if necessary.

- Inspect the cutting edges for any dullness or damage that could be affecting performance.

- Ensure the wheels or supporting components are in good condition and properly balanced.

Vibration or Noise

- Examine all rotating components to see if any are loose or improperly installed.

- Check for debris or blockages around the cutting area that could cause irregular movements.

- Inspect the bearings and fasteners, tightening or replacing them if needed.

Regular inspection and timely adjustments are crucial to

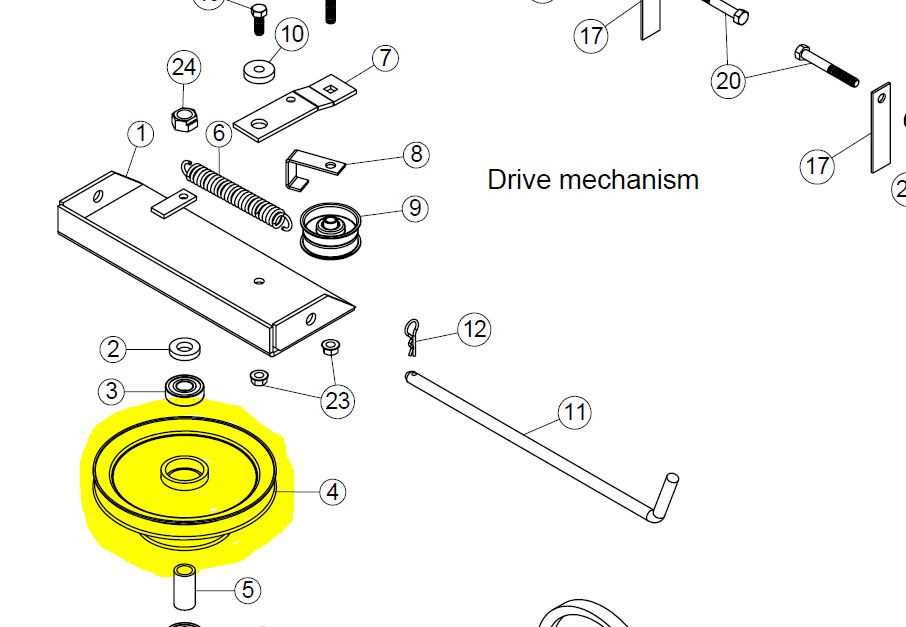

Adjusting Belt Tension for Optimal Performance

Maintaining proper tension in the drive belts is crucial for ensuring efficient operation of lawn care equipment. Correct tension not only enhances the performance but also extends the lifespan of the components involved. This section outlines the steps necessary to achieve optimal belt tension.

Importance of Proper Tension

Having the correct tension in the belts provides several benefits:

- Prevents slippage during operation.

- Reduces wear on the belts and associated parts.

- Enhances the overall efficiency of the machine.

Steps for Adjusting Belt Tension

- Identify the adjustment mechanism specific to your equipment model.

- Loosen the adjustment bolts slightly to allow for movement.

- Check the current tension by pressing down on the belt; it should have some resistance but not be overly tight.

- Adjust the tension to the manufacturer’s specifications by moving the belt idler or adjusting the mounting bracket.

- Tighten the adjustment bolts securely once the desired tension is achieved.

- Test the equipment to ensure proper function and listen for any unusual noises.

Regularly checking and adjusting the belt tension can lead to improved performance and reliability. Make it a routine part of your maintenance schedule to ensure your lawn equipment operates smoothly.

Cleaning and Preventing Deck Clogs

Regular maintenance is essential for optimal performance and longevity of your cutting equipment. A clean and well-maintained system ensures efficient operation and helps avoid blockages that can hinder functionality. By implementing proper cleaning techniques and preventive measures, users can minimize the risk of clogs and enhance the overall effectiveness of their machinery.

Routine Cleaning: It is crucial to clear away grass clippings, debris, and other buildup after each use. This not only prevents blockages but also protects the components from damage caused by excessive residue. Using a suitable tool, gently scrape and remove any accumulated material from the underside and surrounding areas.

Preventive Measures: To further reduce the chances of clogs, consider applying a non-stick coating to the surface. This can help debris slide off more easily and prevent it from sticking. Additionally, ensure that the cutting blades are sharp and properly aligned, as dull blades can contribute to inefficient cutting and increased material buildup.

By prioritizing these practices, users can maintain a clean and efficient cutting system, resulting in better performance and reduced maintenance efforts over time.

Enhancing Cutting Efficiency with Quality Parts

Achieving optimal performance in lawn care requires the utilization of high-quality components that work seamlessly together. The effectiveness of a cutting system relies on the precision and durability of its individual elements. Investing in superior replacements not only improves functionality but also extends the lifespan of the equipment, ensuring a smooth and efficient operation.

Importance of Quality Components

Using premium replacements ensures consistent results and reduces the likelihood of malfunctions. Well-manufactured components enhance the overall performance of the equipment, leading to cleaner cuts and healthier grass. Furthermore, high-quality materials resist wear and tear, allowing for prolonged use without frequent replacements.

Choosing the Right Enhancements

When selecting upgrades, consider compatibility with existing machinery. A proper fit is crucial for maximizing efficiency and minimizing maintenance issues. Opting for recognized brands known for their reliability can significantly impact the cutting effectiveness and operational safety.

Safety Practices for Mower Deck Maintenance

Maintaining cutting equipment requires adherence to essential safety practices to ensure both the longevity of the machine and the well-being of the operator. Proper precautions can prevent accidents and equipment damage while enhancing performance. This section highlights critical safety measures that should be followed during maintenance activities.

Pre-Maintenance Checks

Before starting any maintenance work, it is crucial to inspect the equipment for any visible signs of wear or damage. Ensure that the area is clear of obstacles and that the machine is on a stable surface. Always disconnect the power source to avoid accidental starts. Wearing appropriate personal protective equipment, such as gloves and safety glasses, is essential to safeguard against potential injuries.

Maintenance Procedures

When performing maintenance tasks, such as cleaning or replacing components, follow the manufacturer’s guidelines. Use the recommended tools to avoid damaging parts. Regularly check and tighten bolts and screws, as loose fittings can lead to hazardous situations. After completing maintenance, conduct a thorough inspection to ensure everything is secure and functioning correctly. This diligence helps maintain a safe working environment and enhances the efficiency of the equipment.