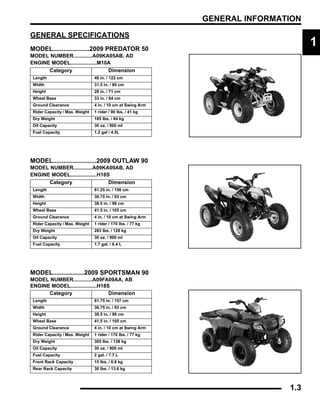

Exploring the layout and configuration of various components within a mechanical vehicle can provide a deeper understanding of its operation. Knowing the arrangement of each element is crucial for maintaining functionality and ensuring smooth performance over time.

In this context, recognizing how different elements are interconnected allows for better troubleshooting and maintenance. By gaining insights into the positioning and relationship of each element, users can address potential issues effectively, extending the lifespan of their equipment.

This guide offers a detailed view of the assembly, helping enthusiasts and professionals alike navigate the intricacies of their machines with ease. A thorough understanding of this layout is essential for both routine upkeep and more complex repairs.

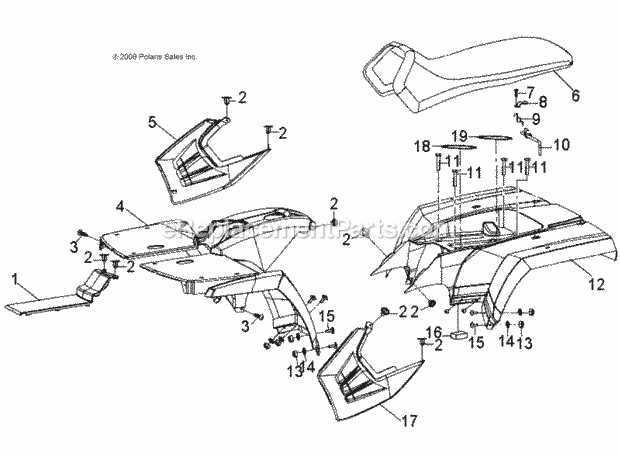

Polaris Sportsman 90 Parts Diagram

Understanding the layout and structure of various components is essential for keeping the vehicle in peak condition. This overview provides a clear picture of how the different elements connect and function together, ensuring smooth operation and longevity. Whether for maintenance or upgrades, knowing how each section fits into the whole can make all the difference.

Key Elements Overview

Within the structure, several critical pieces come together to form a cohesive system. Mechanical connections are designed to ensure efficient power transfer, while other segments focus on stability and control. By familiarizing yourself with these, you’ll be better equipped to address any issues that may arise over time.

Maintenance Tips for Optimal Performance

Regular inspection of the vehicle’s components is crucial for avoiding unexpected problems. Pay attention to the interlocking mechanisms and ensure they remain free of wear and tear. Proper lubrication and cleaning can extend the lifespan of these crucial elements, providing a smoother ride and more reliable performance.

Key Components Overview

This section provides a general insight into the essential elements that make up the structure and functionality of the vehicle. Understanding the primary components helps in maintaining and optimizing performance over time.

- Engine Unit: The powerhouse that drives the vehicle, offering the necessary force and control for various terrains and speeds.

- Suspension System: A crucial element that ensures stability and smooth movement, absorbing shocks and adjusting to uneven surfaces.

- Transmission Mechanism: Facilitates the transfer of power from the engine to the wheels, allowing efficient control and speed regulation.

- Brake Assembly: An essential feature for safety, providing the ability to slow down or halt the vehicle when necessary.

- Fuel Delivery System: Supplies the engine with the required fuel mixture, ensuring consistent operation and efficiency.

These components work together seamlessly to deliver a balanced and reliable driving experience, each playing a vital role in the overall operation.

Understanding the Engine Layout

Comprehending the arrangement of a motor’s components is crucial for maintenance and troubleshooting. The engine setup involves various interconnected elements, each playing a role in ensuring smooth operation and power delivery. Familiarity with this layout can greatly enhance the ability to diagnose issues and maintain optimal performance.

Main Sections of the Motor

The motor is generally divided into several key sections, each containing specific mechanisms that contribute to its overall function. Understanding these sections helps identify the role of each component and how they work together.

- Cylinder Block: The core of the motor, housing the chambers where fuel combustion takes place.

- Crankcase: Encloses the crankshaft and provides a reservoir for lubricating oil, ensuring smooth operation of moving parts.

- Cooling System: Includes channels and a radiator to manage heat levels, preventing overheating during prolonged use.

Connections and Auxiliary Components

Several auxiliary components and connections ensure the motor’s efficient operation. These parts interact closely with the main sections to regulate fuel intake, exhaust, and temperature.

- Fuel Intake System: Manages the flow of fuel into the combustion chambers, adjusting the mixture for efficient burning.

- Exhaust Pathways: Directs gases out of the motor, reducing pressure build-up and ensuring a continuous cycle of combustion.

- Electrical Wiring: Powers the ignition and various sensors, playing a vital role in monitoring and adjusting performance.

A clear understanding of these aspects provides a solid foundation for anyone looking to maintain or repair their motor, making it easier to identify

Guide to Suspension System Parts

The suspension setup is essential for ensuring a smooth and controlled ride over uneven terrains. It absorbs shocks from the ground and maintains stability during movement, providing comfort and handling control. A well-maintained system contributes to the overall safety and efficiency of the vehicle, allowing it to navigate diverse landscapes.

Main Components of the Suspension Setup

The structure includes several key elements, each playing a vital role in handling and stability. Springs serve to absorb vertical forces, cushioning the ride from sudden bumps. Shock absorbers help in controlling the motion of springs, preventing excessive bouncing and maintaining wheel contact with the ground. Together, these elements create a balance between comfort and control.

Linkages and Stability Enhancers

Various connecting elements ensure that the movement between the wheels and frame remains smooth. Linkages act as connectors, guiding the wheel movement in coordination with the frame. Stabilizers minimize body roll during turns, improving the vehicle’s balance and steering response. Proper functioning of these components ensures a reliable and secure driving experience, making the system adaptable to various conditions.

Electrical System and Wiring Map

The electrical framework plays a crucial role in ensuring the efficient operation of various components. It connects key elements through a network of cables, allowing power to flow and control functions to be managed. A clear understanding of this structure aids in troubleshooting and maintaining optimal performance.

Main Connections Overview

The setup includes primary circuits that handle power distribution to essential elements, such as lights, ignition, and safety mechanisms. These circuits are connected through fuses and relays, offering protection against overloads and ensuring consistent functionality.

Wiring Pathways and Junctions

The wiring layout is designed to streamline connections between the power source and various components. Organized into pathways, these cables converge at junction points, simplifying the routing of power and signals across the system. Proper maintenance of these connections is essential for uninterrupted operation.

Brake System Components Explained

The braking system is a crucial aspect of any vehicle, ensuring safety and control during operation. Understanding its components can help in maintenance and troubleshooting. This section provides an overview of the essential elements that make up a typical braking system.

Key Components

- Brake Pads: These are the friction materials that press against the brake rotors to create the necessary stopping force.

- Brake Rotors: Circular discs that rotate with the wheels; they work with the brake pads to slow down or stop the vehicle.

- Calipers: The devices that house the brake pads and apply pressure to them against the rotors when the brake pedal is pressed.

- Brake Lines: Tubes that carry brake fluid from the master cylinder to the calipers, allowing for the transmission of force.

- Master Cylinder: The component that converts the force applied to the brake pedal into hydraulic pressure.

Understanding Functionality

The interaction between these elements is vital for effective braking. When the brake pedal is engaged, the master cylinder generates hydraulic pressure, which travels through the brake lines to the calipers. This pressure forces the brake pads against the rotors, creating friction that slows the vehicle down. Regular maintenance of these components ensures optimal performance and safety on the road.

Transmission and Drive Chain Diagram

This section provides an overview of the components responsible for transferring power from the engine to the wheels. Understanding the functionality of these elements is crucial for effective maintenance and performance optimization.

Key Components

The transmission and drive chain system includes several essential parts that work together to ensure smooth operation. Here are the main elements:

- Gearbox: Converts engine power into usable torque.

- Drive Chain: Transfers power from the gearbox to the wheels.

- Chain Sprockets: Guide and engage the chain for efficient movement.

- Clutch Mechanism: Allows for the engagement and disengagement of power transmission.

Maintenance Tips

Regular maintenance of the transmission and drive chain components is vital for longevity and optimal performance. Consider the following tips:

- Check for wear and tear on the drive chain regularly.

- Ensure proper lubrication to reduce friction.

- Inspect gear engagement and clutch operation frequently.

- Replace any worn parts promptly to avoid further damage.

Steering Mechanism Parts Breakdown

The steering system of an all-terrain vehicle plays a crucial role in ensuring precise handling and control. Understanding the components involved in this mechanism is essential for proper maintenance and troubleshooting. This section will explore the various elements that contribute to the effective operation of the steering system.

Key Components of the Steering System

- Steering Wheel: The primary interface for the operator, allowing for direction control.

- Steering Column: Connects the steering wheel to the mechanism, transmitting the operator’s input.

- Gearbox: Converts the rotational movement from the steering wheel into lateral movement.

- Linkages: These rods and joints connect various parts, facilitating movement throughout the system.

- Steering Knuckles: Pivot points that allow the wheels to turn based on the operator’s input.

Maintenance Considerations

Regular checks on the steering components can prevent malfunctions. Look for signs of wear or damage in the linkages and joints. Lubrication of moving parts is also vital for smooth operation. Keeping the steering system in optimal condition enhances both safety and performance.

Maintenance Tips for Polaris Sportsman 90

Proper upkeep of your all-terrain vehicle is essential for optimal performance and longevity. Regular maintenance not only enhances safety but also ensures that the machine operates smoothly across various terrains. Following a structured maintenance routine can prevent unexpected breakdowns and extend the lifespan of critical components.

Routine Inspections

Conducting regular inspections can help identify potential issues before they escalate. Pay attention to the following areas:

- Engine oil level and quality

- Brake system functionality

- Tire pressure and tread condition

- Battery charge and connections

Cleaning and Lubrication

Keeping your vehicle clean is vital for preventing rust and ensuring all parts function efficiently. Additionally, regular lubrication of moving parts minimizes friction and wear. Consider these steps:

- Wash the exterior to remove dirt and debris

- Lubricate the chain and other moving components

- Inspect and clean air filters to maintain airflow

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Tire Inspection | Every ride |

| Battery Check | Monthly |

| Brake Inspection | Every 100 hours |