The efficiency and functionality of modern heating solutions rely heavily on their individual components. Each element plays a crucial role in ensuring that the system operates smoothly, delivering optimal performance. By grasping the intricacies of these components, one can appreciate how they work in harmony to provide instantaneous heating, enhancing comfort and convenience in everyday life.

In this section, we will explore the essential elements that constitute these innovative systems. Each part is designed to fulfill specific functions, contributing to the overall efficacy of the unit. Familiarizing oneself with these components can lead to better maintenance practices and improved longevity of the system.

Moreover, understanding how these components interact allows for informed decision-making when it comes to repairs or upgrades. With knowledge of the underlying mechanisms, users can troubleshoot common issues effectively, ensuring their systems remain in peak condition.

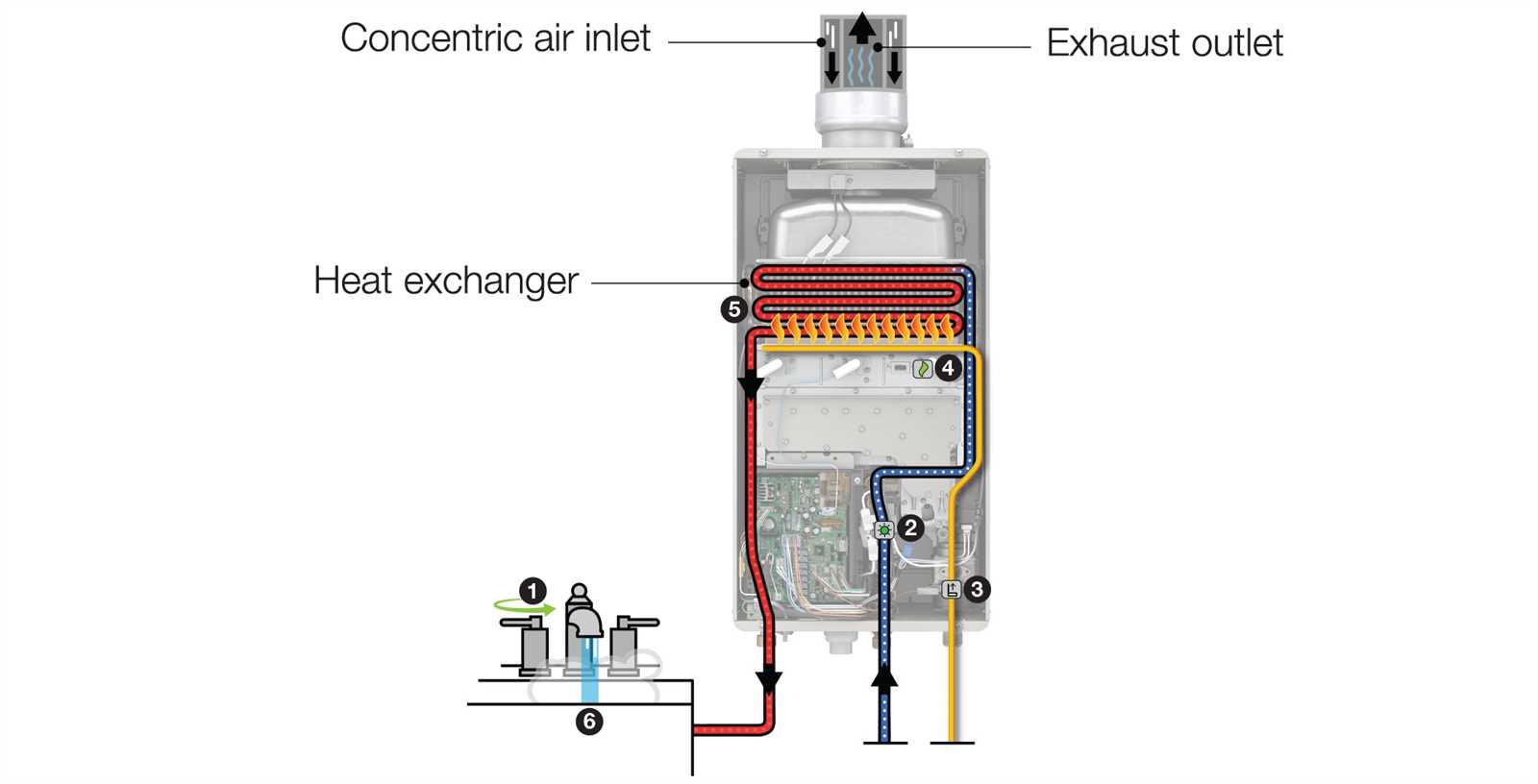

This section aims to delve into the various elements of a continuous heating system, exploring their functions and interrelations. By gaining a clearer understanding of these components, users can effectively troubleshoot issues, perform maintenance, and enhance overall performance.

Key Elements of a Continuous Heating System

The continuous heating system comprises several crucial elements that work in harmony to deliver efficient heating. Each component plays a vital role in ensuring the system operates smoothly.

| Component | Description |

|---|---|

| Heat Exchanger | Transfers heat from the heating source to the fluid, ensuring efficient energy use. |

| Flow Sensor | Detects the flow of the fluid and signals the system to activate heating when needed. |

| Control Unit | Regulates the temperature settings and monitors system performance for optimal efficiency. |

| Burner | Ignites fuel to generate heat, essential for the heating process. |

Importance of Understanding Each Element

Recognizing the importance of each part enables users to identify potential issues and enhance system longevity. Maintenance becomes simpler when individuals are aware of how each component interacts within the overall structure.

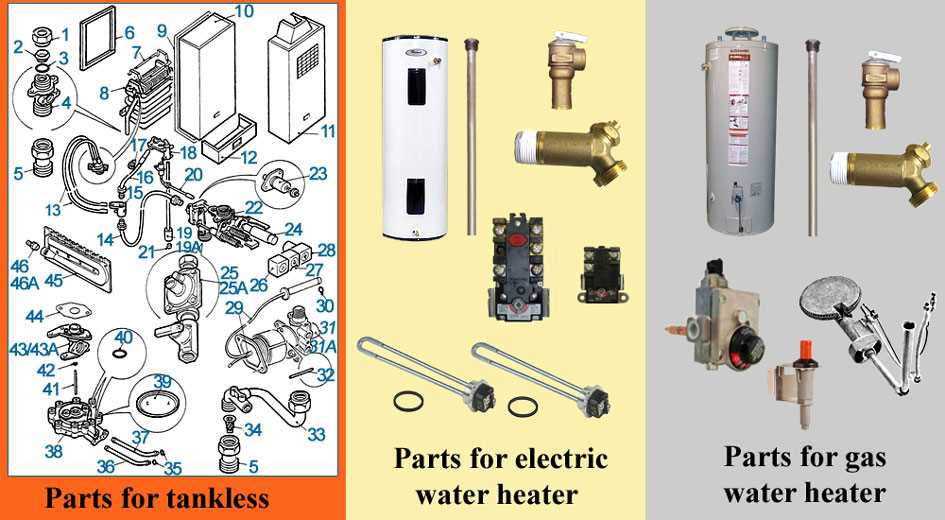

Essential Parts of Tankless Systems

Understanding the core components of instant heating systems is crucial for effective operation and maintenance. Each element plays a significant role in ensuring efficiency and performance, contributing to the overall functionality of the system.

Key Components

- Heat Exchanger: The primary component responsible for transferring heat to the flowing liquid, ensuring rapid warming.

- Control Unit: This electronic panel regulates the system’s operation, including temperature adjustments and flow rate monitoring.

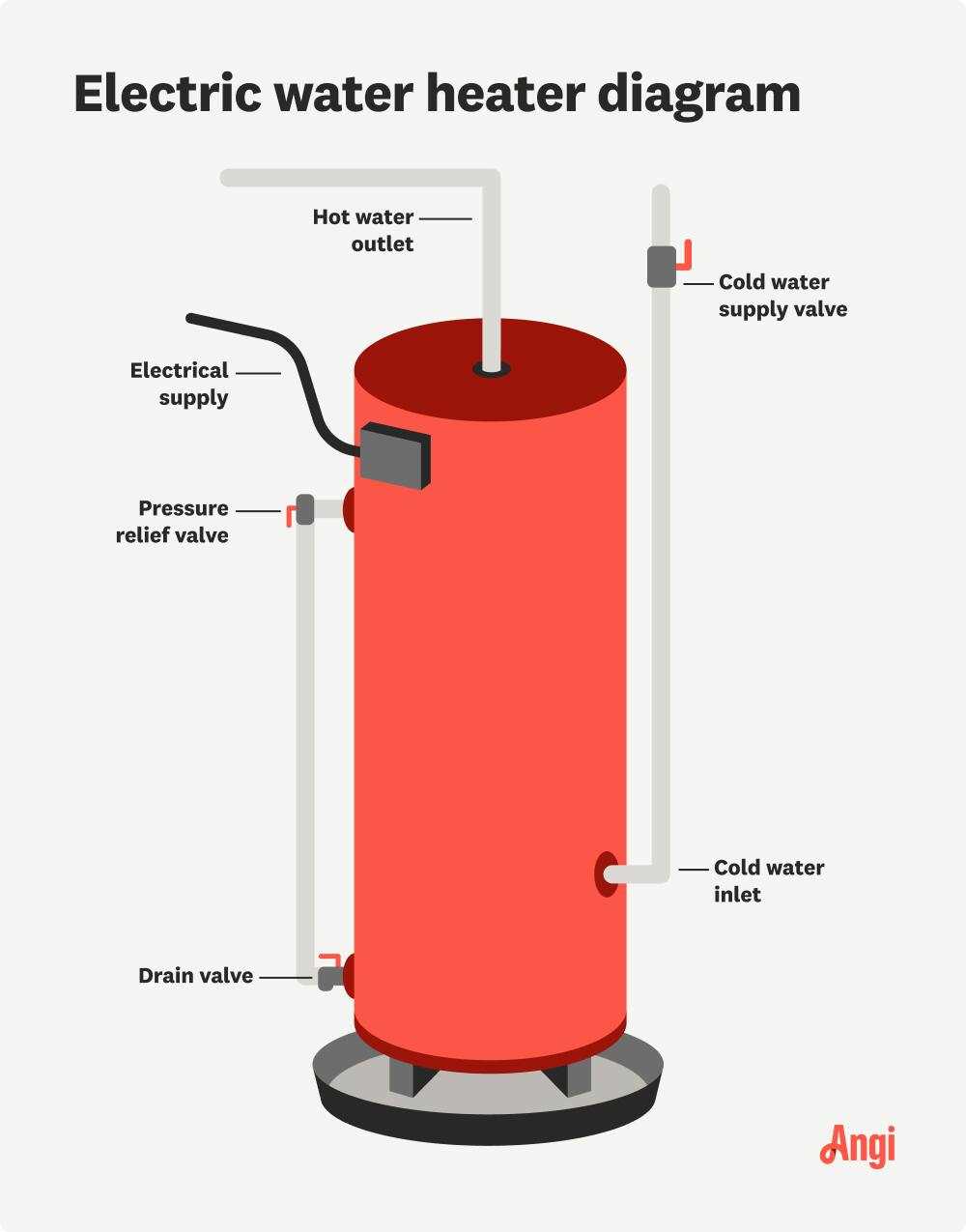

- Inlet and Outlet Fittings: These connections allow the liquid to enter and exit the unit, playing a vital role in maintaining proper flow.

- Flue Venting System: This feature safely expels exhaust gases, ensuring compliance with safety standards.

- Safety Sensors: These devices monitor various parameters, such as temperature and pressure, to prevent malfunctions.

Maintenance Tips

- Regularly check the heat exchanger for scale buildup.

- Ensure the control unit is functioning correctly by performing periodic tests.

- Inspect fittings for leaks or corrosion to maintain efficiency.

- Clean the flue venting system to prevent blockages.

- Test safety sensors to ensure they are responsive.

How Water Heaters Operate Internally

Understanding the internal workings of these heating systems is essential for effective use and maintenance. These devices are designed to deliver hot fluid on demand, utilizing various components that work together seamlessly to ensure efficiency and reliability.

Key Components and Their Functions

The main elements involved in the operation include a heating element, control system, and sensors. The heating element generates warmth, while the control system regulates the temperature based on user settings. Sensors play a crucial role in monitoring the system’s performance and ensuring optimal operation.

Process Overview

When a user initiates a request for hot fluid, the control system activates the heating element. The temperature sensors continually assess the fluid’s heat level, allowing for adjustments to maintain the desired output. This dynamic interaction ensures that the user receives the required temperature without delay, highlighting the efficiency of these modern systems.

Benefits of Each Component Explained

Understanding the various elements of a heating system is crucial for maximizing efficiency and performance. Each component plays a vital role in ensuring the entire setup operates smoothly, providing numerous advantages to users. Here, we delve into the benefits offered by each key element, emphasizing their significance and functionality.

- Heat Exchanger:

This crucial component transfers energy efficiently, allowing for rapid heating of the fluid. Its design promotes optimal thermal conductivity, ensuring quick response times and consistent performance.

- Control Valve:

The control valve regulates the flow and temperature, providing precise management of the heating process. This ensures that the output remains steady, catering to the user’s needs effectively.

- Ignition System:

This system initiates the heating process swiftly and safely. Modern ignitions enhance reliability, minimizing the risk of failure and ensuring immediate activation when required.

- Temperature Sensor:

Equipped to monitor the temperature accurately, this component helps maintain optimal conditions. It provides real-time feedback, allowing for adjustments that enhance safety and efficiency.

- Ventilation System:

Proper ventilation is essential for safety and efficiency. It ensures that exhaust gases are expelled effectively, reducing the risk of hazards and maintaining indoor air quality.

Each of these components contributes significantly to the overall efficiency, safety, and functionality of the heating system, making it essential to understand their individual roles for optimal use.

Common Issues and Solutions

Many individuals encounter challenges with their instant heating devices, which can lead to discomfort and inconvenience. Understanding these frequent problems and their resolutions can help maintain optimal performance and enhance user satisfaction.

Temperature Fluctuations

Temperature fluctuations are a common complaint, where the output does not remain consistent. This issue can arise due to various factors, including insufficient flow rate or incorrect temperature settings. To resolve this, ensure the flow rate meets the unit’s specifications and adjust the settings as necessary.

Low Flow Rate

Low flow rate can significantly affect the efficiency of heating units. If users notice reduced output, it may be due to sediment buildup or a malfunctioning inlet valve. Regular maintenance, including flushing the system and inspecting valves, is essential to prevent this issue. Cleaning or replacing filters can also help restore proper flow.

Maintenance Tips for Long-lasting Performance

Ensuring the longevity and optimal functionality of your system requires regular care and attention. By implementing a few simple maintenance practices, you can significantly enhance the efficiency and lifespan of your equipment.

Routine Inspections: Regularly check your device for any signs of wear or damage. Inspecting connections, seals, and fittings can prevent minor issues from escalating into major problems.

Descaling Procedures: Mineral buildup can impair performance over time. It’s advisable to conduct descaling at least once a year to maintain smooth operation. Use a suitable descaling solution to remove deposits efficiently.

Filter Replacement: If your model includes filters, ensure they are changed as per the manufacturer’s recommendations. Clean filters promote better circulation and efficiency, preventing strain on the unit.

Temperature Settings: Keep the temperature settings at an optimal level. Excessively high temperatures can lead to unnecessary stress on components, while too low settings might not meet your demands adequately.

Professional Servicing: Consider scheduling professional inspections annually. A trained technician can identify potential issues that may not be visible to the untrained eye and perform necessary repairs or adjustments.

By following these guidelines, you can ensure your system operates efficiently, providing you with reliable service for years to come.

Comparing Different Tankless Models

When considering modern solutions for home heating systems, it’s essential to explore various options available on the market. Different models provide unique features that cater to diverse needs, ensuring both efficiency and cost-effectiveness. By understanding the key distinctions, you can select the right choice that aligns with your household’s specific requirements.

Energy Efficiency and Performance

One of the primary factors to compare across models is how they handle energy consumption. Some designs focus on minimizing energy use, while others offer more power for larger homes or high-demand situations. Look for units with efficient performance ratings and features like smart regulation to make a well-informed decision.

Installation and Maintenance

Another aspect to keep in mind is the complexity of installation and ongoing upkeep. Certain models are simpler to set up, requiring fewer adjustments to existing infrastructure. Maintenance varies as well, with some units offering advanced self-cleaning functions to reduce the need for frequent servicing.

Installation Guidelines and Best Practices

Proper installation is essential to ensure optimal performance and longevity of your system. Following a clear set of guidelines can help prevent common issues and maximize efficiency. Here are some key points to consider during setup.

Key Steps for a Successful Setup

- Ensure adequate space around the unit for ventilation and maintenance access.

- Verify that the electrical and plumbing connections meet the required specifications.

- Check local building codes to comply with any specific requirements.

- Consider installing safety shutoff valves to facilitate easier repairs or replacements.

Common Mistakes to Avoid

- Improper placement, which can limit airflow or cause overheating.

- Using incompatible materials for connections, which could lead to leaks or malfunctions.

- Skipping routine inspections during installation, potentially missing critical adjustments.

By adhering to these best practices, you can ensure a more reliable and efficient setup, reducing the likelihood of future complications.

Upgrades and Accessories for Efficiency

Improving the performance of your system is often about making the right enhancements. By choosing the right add-ons, you can significantly boost efficiency and extend the lifespan of the unit, making it more cost-effective in the long run.

Top Efficiency-Boosting Additions

- Smart controllers: These allow for better regulation of energy use, optimizing performance while reducing waste.

- Recirculation pumps: Designed to minimize delay, these pumps keep the flow at a ready state, cutting down on waiting times.

- Filtration systems: Regular use of filters pre