When maintaining your outdoor machinery, a comprehensive grasp of its components is essential for ensuring optimal performance and longevity. Every part plays a vital role in the overall functionality, and recognizing how they interact can make maintenance tasks more manageable. This section delves into the intricate details of a specific model, offering valuable insights into the various elements that contribute to its operation.

Whether you are a seasoned user or a newcomer, familiarizing yourself with the layout of essential components can enhance your understanding of how to troubleshoot and repair your equipment effectively. By breaking down the various sections and functions, you can better appreciate the engineering behind these machines and how each piece contributes to their efficiency.

Moreover, having a visual reference of the different elements allows for easier identification during servicing. Knowing where to look for potential issues can save time and prevent unnecessary complications. In the following segments, we will provide a detailed visual guide, making it easier for you to navigate your equipment’s essential components and keep it running smoothly.

Kubota 48 Mower Deck Overview

This section provides a comprehensive understanding of a crucial component designed for lawn maintenance. This equipment is essential for achieving a well-manicured lawn and ensuring optimal performance during operation.

Featuring a robust construction, this implement is engineered to tackle various terrains while delivering precise cutting results. Its design promotes efficiency, allowing users to navigate easily around obstacles and uneven ground.

Key attributes of this tool include:

- Durability: Crafted from high-quality materials for long-lasting use.

- Versatility: Suitable for different types of grasses and conditions.

- Ease of maintenance: Designed for straightforward upkeep and servicing.

- Adjustable height settings: Enables customization for varied grass lengths.

When considering this implement, it is essential to be aware of the various components that contribute to its functionality. Understanding each element will enhance your ability to maintain and optimize performance.

In summary, this equipment is a vital tool for anyone seeking to maintain a pristine landscape. By leveraging its capabilities, users can achieve impressive results while minimizing effort and maximizing efficiency.

Essential Components of the Mower Deck

Understanding the fundamental elements of a cutting apparatus is crucial for maintaining its efficiency and longevity. Each component plays a significant role in ensuring optimal performance, contributing to a seamless mowing experience. Familiarity with these essential elements can help in identifying issues, performing repairs, and ensuring effective operation.

- Blades: The sharp implements responsible for cutting grass to the desired height. Regular sharpening and maintenance are vital for achieving a clean cut.

- Spindles: These rotate the blades and are critical for their proper functioning. They must be well-lubricated and free of debris.

- Belts: They transmit power from the engine to the blades, facilitating smooth operation. Checking for wear and replacing them as needed is essential.

- Mounting Brackets: These secure the entire assembly to the main chassis, ensuring stability during operation. Proper alignment is necessary to prevent undue stress.

- Wheels: They aid in maneuverability and height adjustment. Ensuring they are in good condition affects overall performance.

- Chassis: The framework that houses all components. It must be sturdy and well-maintained to support the entire system.

Regular inspections and maintenance of these vital elements will not only enhance the functionality of the equipment but also prolong its lifespan, ensuring a reliable and effective performance every time.

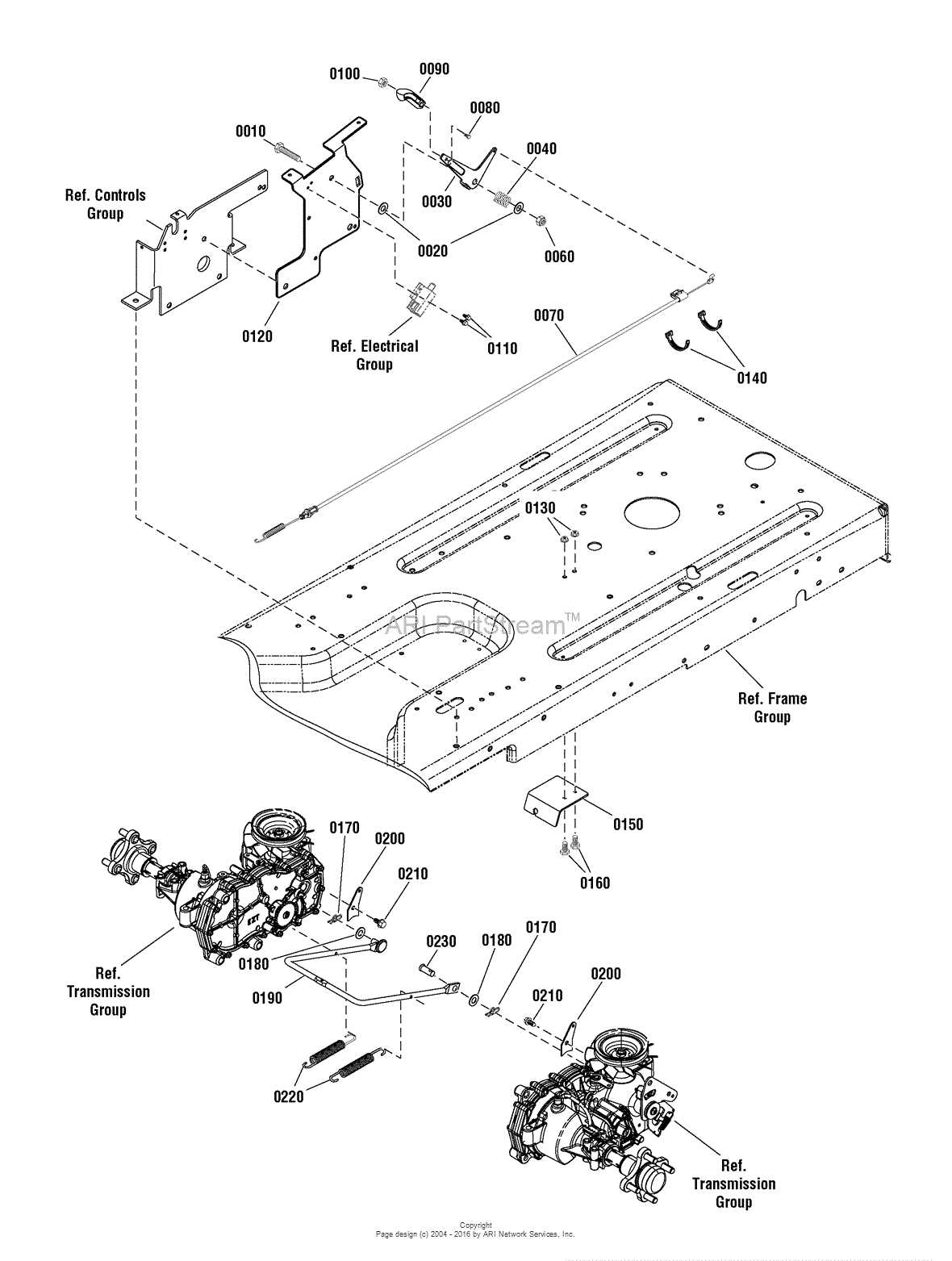

How to Read the Parts Diagram

Understanding a component illustration is essential for effective maintenance and repairs. These visual aids provide a detailed representation of various elements, making it easier to identify and locate specific items within the assembly. By familiarizing yourself with the layout and symbols used, you can streamline your repair processes and ensure your equipment operates smoothly.

Identifying Key Elements

Begin by examining the legend or key, which typically explains the symbols and color codes used in the illustration. This section is crucial for recognizing different components and their respective functions. Pay close attention to any labels that indicate part numbers or descriptions, as this information is vital when ordering replacements or seeking further assistance.

Following the Flow

Next, analyze how the elements are interconnected. Tracing lines and arrows can indicate relationships between various components, such as how one piece fits into another or the sequence of assembly. Understanding these connections helps in diagnosing issues and determining which parts may need attention or replacement.

By mastering the interpretation of these visual references, you empower yourself to maintain your equipment more effectively, ensuring longevity and optimal performance.

Common Issues with Kubota Deck Parts

When it comes to maintaining outdoor equipment, users often encounter a variety of challenges that can hinder performance and efficiency. These issues can arise from wear and tear, improper usage, or even environmental factors. Understanding these common difficulties can help in identifying symptoms early and addressing them effectively.

One prevalent concern is the buildup of debris, which can affect functionality and lead to overheating. Regular cleaning is essential to prevent clogs and ensure smooth operation. Additionally, improper alignment of components can result in uneven cutting and increased strain on the machine, causing premature wear. This emphasizes the importance of regular checks and adjustments to maintain optimal performance.

Another frequent problem involves the degradation of materials over time. Components can become brittle or corroded, compromising their integrity. Users should be vigilant in inspecting for signs of fatigue, such as cracks or rust, to avoid sudden failures. Moreover, wear on blades can lead to ineffective cutting, making it necessary to replace them periodically to maintain a clean and precise finish.

Lastly, inadequate lubrication can lead to friction and overheating, causing mechanical failures. Regular maintenance, including checking oil levels and applying the appropriate lubricants, is crucial for longevity. By being aware of these issues and addressing them promptly, users can enhance the reliability and lifespan of their equipment.

Maintenance Tips for Mower Deck

Proper upkeep of your cutting apparatus is crucial for achieving optimal performance and longevity. Regular attention to its components not only enhances efficiency but also ensures a safe operation. This section outlines essential care practices that can help maintain the functionality of your equipment.

1. Regular Cleaning: After each use, it’s important to remove any grass clippings, dirt, and debris that accumulate on the underside of the cutting assembly. Use a scraper or a brush to keep the surfaces clear. This prevents corrosion and maintains sharpness.

2. Inspecting Blades: Check the sharpness of the blades regularly. Dull edges can lead to uneven cuts and increased strain on the engine. Sharpen them as needed, and replace them if they become damaged or excessively worn.

3. Lubrication: Ensure all moving parts are properly lubricated to reduce friction and wear. Use appropriate lubricants and follow the manufacturer’s recommendations for intervals.

4. Tightening Fasteners: Periodically check all bolts and screws to ensure they are tight. Vibration during operation can cause them to loosen, potentially leading to component failure.

5. Seasonal Maintenance: At the beginning and end of the cutting season, conduct a thorough inspection. Replace any worn or damaged parts, and consider servicing the engine to keep everything in peak condition.

By implementing these care practices, you can prolong the lifespan of your cutting equipment and maintain its effectiveness throughout the season.

Replacement Parts Availability and Options

Ensuring the proper functioning of your equipment often requires finding compatible components. Whether it’s routine maintenance or addressing unexpected issues, having access to the necessary items can significantly extend the lifespan of your machine. It’s important to explore various avenues for sourcing replacement elements, both through authorized suppliers and third-party providers.

OEM vs Aftermarket Solutions

Original manufacturer options offer the advantage of precise compatibility, often backed by warranty and quality assurances. On the other hand, aftermarket alternatives may provide a more affordable solution, often with comparable performance. Understanding the benefits and limitations of each can help you make an informed decision that suits your specific needs.

Online and Local Resources

Many owners turn to digital platforms to find the components they need, as online retailers can offer a wider selection and convenience. Local dealers, however, may provide immediate availability and the opportunity to consult with experts directly. Combining both methods can ensure you find the right part quickly and efficiently.

Step-by-Step Assembly Instructions

In this section, you will find clear instructions on how to carefully piece together all necessary components to ensure smooth operation. Following these steps in the correct order will help you avoid mistakes and ensure a reliable and efficient outcome.

Step 1: Prepare the Area

Before you begin, make sure you have a clean, organized workspace. Lay out all the tools and materials you will need for easy access. This will help streamline the process and prevent unnecessary interruptions.

Step 2: Align the Frame

Start by positioning the main structure on a flat surface. Ensure that the base is stable, as this is crucial for proper alignment during the assembly. Double-check that everything is level before proceeding to the next step.

Step 3: Secure the Main Components

Attach the key sections together by fastening them securely. Use the appropriate fasteners and follow the tightening instructions carefully to avoid damaging any of the materials. Ensure all

Safety Precautions During Repairs

Before undertaking any maintenance or adjustments, it is essential to prioritize personal safety. Following the proper safety guidelines can prevent accidents and injuries, ensuring a smoother and more secure repair process.

Turn Off Power: Always disconnect the power source before beginning any repairs. This step is critical to avoid unexpected starts or electrical hazards.

Wear Protective Gear: Ensure you are wearing appropriate safety equipment, such as gloves, safety glasses, and durable footwear. This helps protect against sharp tools, flying debris, and other potential hazards.

Secure the Equipment: Make sure the machinery is stable and properly supported. Use blocks or jacks if necessary to prevent it from moving while you’re working.

Avoid Distractions: Stay focused during repairs. Distractions can lead to mistakes, which might result in injury or damage to the equipment.

Follow Manufacturer Guidelines: Adhere to the recommended procedures outlined in the service manual. This ensures that repairs are done correctly and reduces the risk of accidents.

By maintaining focus on these safety practices, the repair process becomes not only more efficient but also significantly safer for everyone involved.

Upgrades for Improved Mowing Performance

Enhancing the efficiency of your grass-cutting equipment can make a significant difference in the quality and speed of your work. By focusing on a few key modifications, you can boost the overall effectiveness and lifespan of your machine, ensuring smoother operations and a cleaner result.

Blade Modifications

One of the primary factors in achieving optimal results is upgrading your cutting edges. Different blade designs serve unique purposes, whether for fine trimming or heavy-duty tasks. Consider switching to high-lift or mulching options depending on the terrain and your needs.

- High-lift: Provides better airflow, making it ideal for clearing large areas and ensuring even cuts.

- Mulching blades: Designed to chop grass into finer pieces, reducing the need for bagging and promoting healthy lawns.

Improved Airflow and Suction

A well-ventilated cutting system can greatly affect how smoothly and efficiently grass is processed. Ensuring that airflow is optimized allows for quicker cuts, cleaner discharge, and less buildup of debris.