In the realm of mechanical engineering, a comprehensive grasp of the various elements that contribute to the functionality of sophisticated systems is crucial. Each segment plays a vital role in ensuring optimal performance, durability, and efficiency. By analyzing these intricate structures, enthusiasts and professionals alike can gain insights into the operational dynamics of their equipment.

Visualization of the intricate layout of these components is essential for anyone seeking to enhance their knowledge. Recognizing how each piece interconnects allows for better troubleshooting, maintenance, and overall appreciation of the technology at hand. The detailed representation not only facilitates understanding but also serves as a valuable reference for modifications and upgrades.

Moreover, delving into the specifics of these mechanical elements can illuminate the innovations that drive modern advancements. From power generation to propulsion, the intricate relationships among various sections highlight the ingenuity involved in design and engineering. This exploration serves as a stepping stone for both beginners and seasoned practitioners aiming to deepen their expertise in this fascinating field.

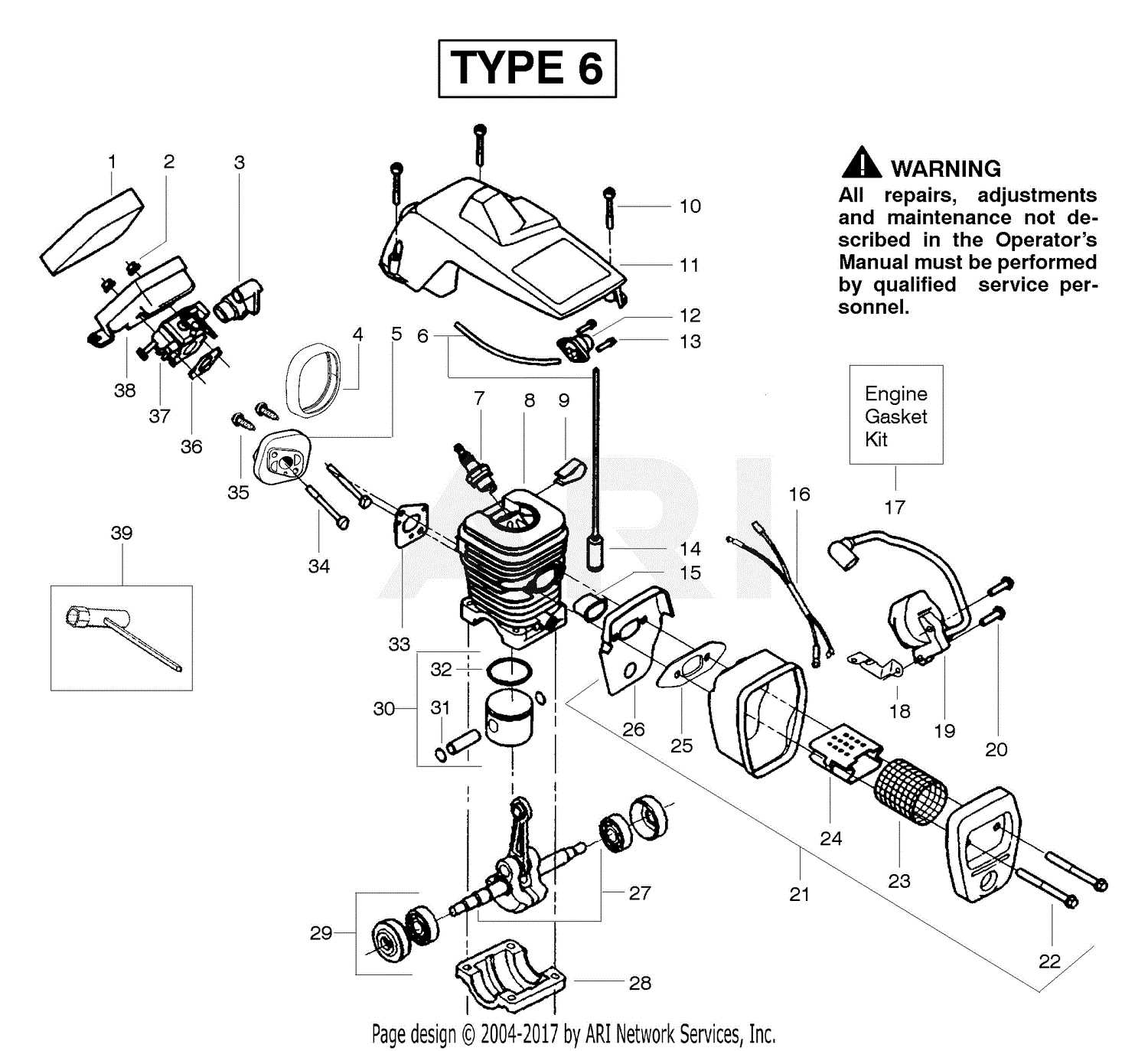

Understanding Predator Engine Basics

This section aims to provide an overview of essential components and their functions in a high-performance machine. By exploring these elements, readers can gain a clearer picture of how they work together to create efficient operation and power delivery.

Key Components Overview

Each element plays a crucial role in ensuring the overall functionality and reliability. Understanding their interactions can significantly enhance maintenance and optimization efforts.

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, generating power. |

| Piston | Moves within the cylinder, converting combustion energy into mechanical work. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Valves | Regulate the intake of air and fuel and the exhaust of gases. |

Maintenance and Efficiency

Regular inspection and understanding of these components can lead to improved efficiency and longevity. Being proactive in care ensures optimal performance, ultimately enhancing user experience.

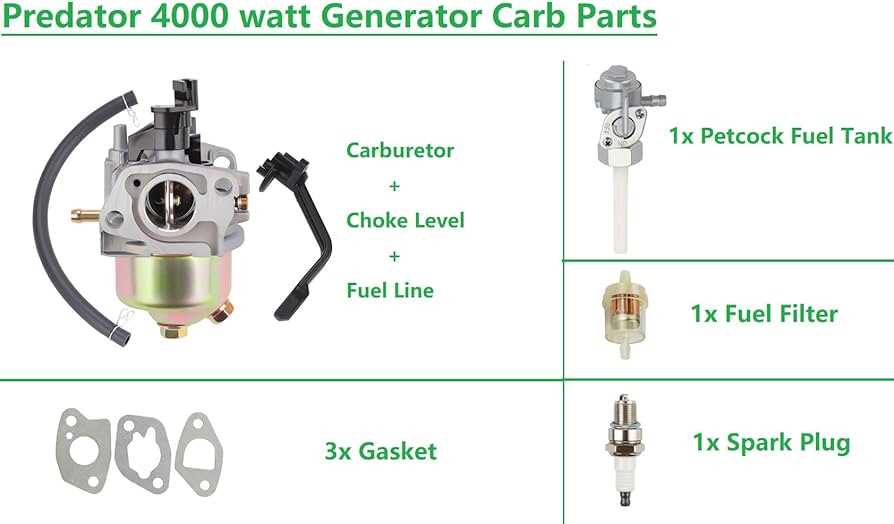

Key Components of Predator Engines

Understanding the essential elements that contribute to the functionality of small power units is crucial for anyone interested in mechanical design or repair. These critical components work in harmony to deliver efficient performance and reliability, making it important to familiarize oneself with their specific roles and characteristics.

Core Elements

The main constituents of these machines encompass various mechanisms that drive their overall operation. Each component serves a unique purpose, ensuring that the unit operates smoothly and effectively. Recognizing these parts not only aids in maintenance but also enhances the knowledge required for troubleshooting and upgrades.

Functionality Overview

Below is a table summarizing the fundamental components and their respective functions:

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process and creates pressure for power generation. |

| Piston | Moves within the cylinder to compress the air-fuel mixture and transfer energy. |

| Crankshaft | Converts the linear motion of the piston into rotational motion to drive the output. |

| Camshaft | Controls the timing of valve openings and closings, regulating airflow into the combustion chamber. |

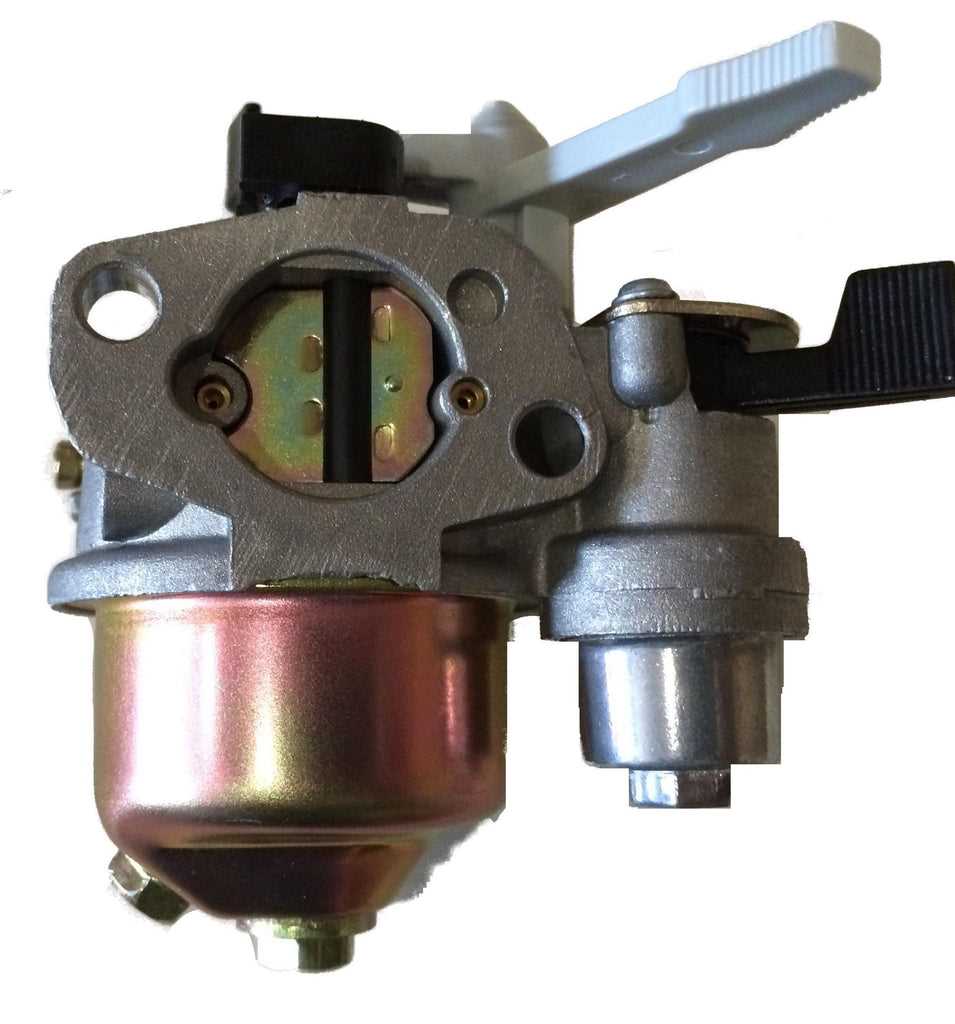

| Fuel System | Delivers fuel to the combustion chamber, ensuring optimal mixing with air for efficient burning. |

By gaining insight into these crucial components, one can better appreciate how each part contributes to the overall performance and efficiency of the system.

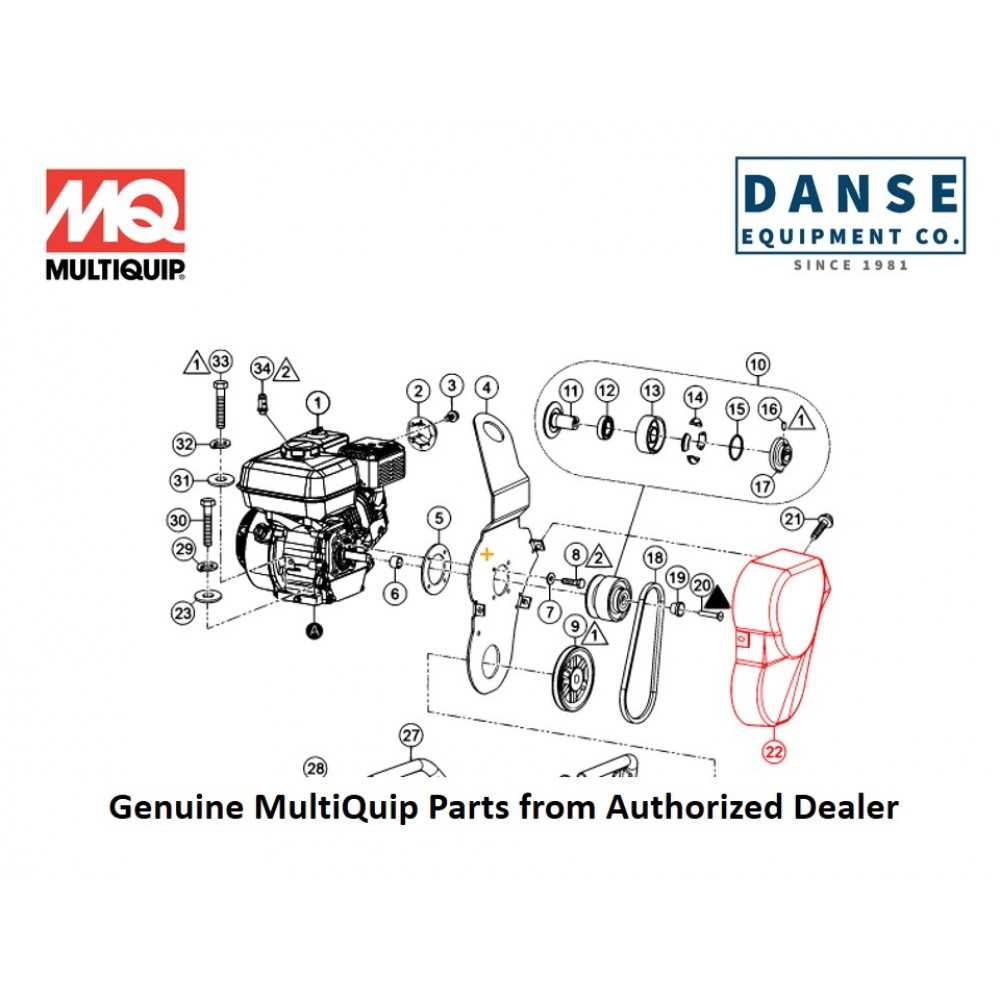

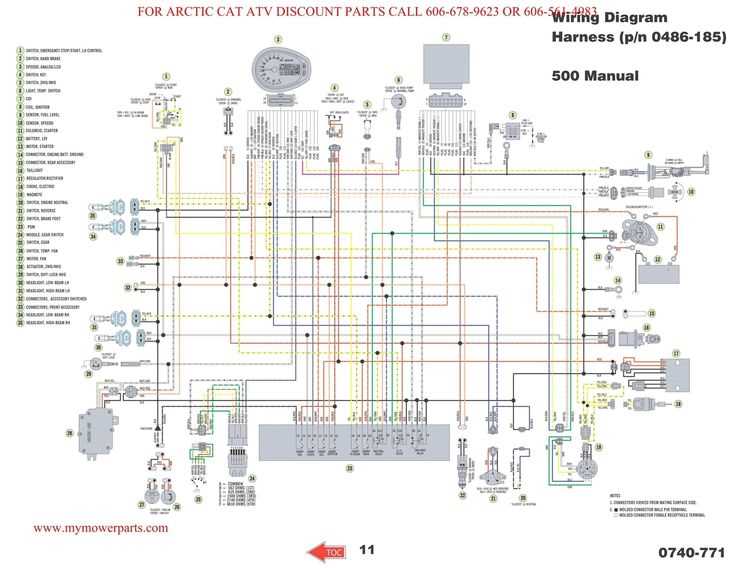

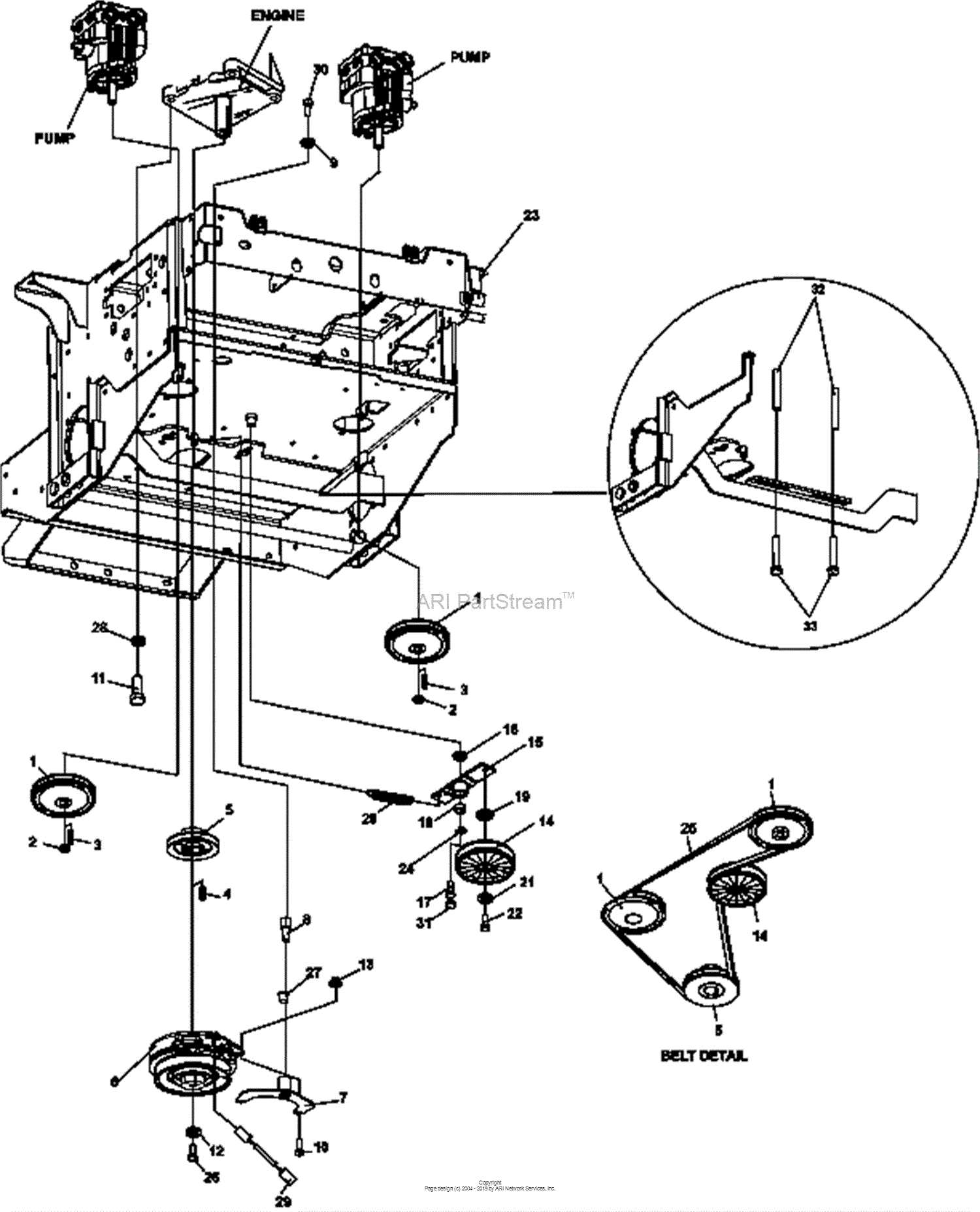

How to Read Engine Diagrams

Understanding technical illustrations is essential for grasping complex machinery functions. These visuals provide a detailed representation of components and their interrelationships, allowing for effective maintenance and troubleshooting.

Identifying Symbols and Labels

Begin by familiarizing yourself with common symbols and terminology. Each element typically has a unique representation, which can vary between manuals. Pay attention to labels as they guide you through the layout.

Interpreting Connections and Flow

Focus on how components are interconnected. Arrows often indicate movement or flow, highlighting the operational sequence. Delving into these details will enhance your comprehension of the overall system’s functionality.

Common Issues and Troubleshooting Tips

When working with small mechanical systems, users often encounter various challenges that can hinder performance. Understanding these common problems and how to address them is essential for maintaining optimal functionality. This section aims to provide insights into frequent malfunctions and practical solutions that can help restore efficiency.

Frequent Challenges

One of the most prevalent issues involves irregular operation, often caused by fuel-related complications. Poor-quality fuel or improper mixing can lead to inefficient combustion, resulting in reduced power output. Additionally, wear and tear on components can create friction, leading to overheating and other mechanical failures. Regular inspection and timely replacement of worn parts are crucial to avoid these situations.

Troubleshooting Strategies

To effectively diagnose problems, start by checking fuel supply and ensuring that it meets the necessary specifications. Inspect all connections and seals for any signs of leaks or blockages. Furthermore, cleaning air filters and ensuring adequate airflow can significantly enhance performance. For persistent issues, consider consulting the manufacturer’s manual for specific troubleshooting steps tailored to your model.

Maintenance Tips for Predator Engines

Regular upkeep is essential for optimal performance and longevity of your machine. By following these guidelines, you can ensure that your equipment operates efficiently and remains in excellent condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 20 hours | Replace old oil to prevent wear and tear. |

| Air Filter Inspection | Every 10 hours | Check for dirt buildup; clean or replace as needed. |

| Spark Plug Check | Every 50 hours | Inspect and replace to ensure proper ignition. |

| Fuel System Cleaning | Every season | Remove impurities to maintain fuel flow and efficiency. |

| General Inspection | Before each use | Check for leaks, loose components, and overall condition. |

By adhering to these maintenance tips, you can enhance the reliability and performance of your equipment, ultimately extending its lifespan.

Upgrading Parts for Enhanced Performance

Improving the functionality and efficiency of your machinery can significantly elevate its overall capabilities. By carefully selecting and replacing specific components, you can achieve higher power output, better responsiveness, and increased durability. This approach not only enhances performance but also optimizes fuel efficiency and reduces wear over time.

One effective method to enhance performance is through the installation of high-flow air intake systems. These systems facilitate improved airflow, allowing for better combustion and increased power. Additionally, upgrading the exhaust system can reduce back pressure, promoting a more efficient exit of gases and enhancing overall performance.

Another critical area for enhancement is the ignition system. Opting for advanced ignition coils and high-performance spark plugs can result in a more efficient burn of the fuel-air mixture, leading to improved acceleration and smoother operation. Furthermore, incorporating a performance tuning chip can optimize fuel delivery and ignition timing, providing a noticeable boost in power.

Finally, consider upgrading suspension components for improved handling and stability. Enhanced shocks and struts not only provide better control but also contribute to a smoother ride, allowing the vehicle to handle increased power with ease. Each of these upgrades plays a vital role in transforming your machine into a more powerful and efficient version of itself.

Where to Find Replacement Parts

When it comes to maintaining machinery or equipment, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Various avenues are available for individuals seeking reliable replacements, from specialized retailers to online marketplaces. This guide aims to assist in navigating these options effectively.

Online Marketplaces

One of the most convenient ways to locate necessary components is through online platforms. Websites like Amazon, eBay, and specialized automotive or equipment supply sites offer a wide array of products, often with detailed specifications and customer reviews. Utilizing filters can help narrow down searches based on compatibility and brand, ensuring that users find the right fit for their specific needs.

Local Retail Stores

For those who prefer a hands-on approach, visiting local retail shops can be beneficial. Many home improvement centers and automotive supply stores stock a variety of components. Engaging with knowledgeable staff can also provide valuable insights and recommendations, making the process of finding suitable replacements more efficient.

Benefits of Using Genuine Components

Utilizing authentic components for maintenance and repairs can significantly enhance the performance and longevity of your machinery. Genuine items are designed to meet specific standards, ensuring optimal compatibility and functionality.

Quality Assurance

- Manufactured to strict specifications

- Durable materials that withstand wear and tear

- Consistent performance over time

Cost-Effectiveness

- Reduces the risk of failures and breakdowns

- Minimizes maintenance costs in the long run

- Improves resale value of the machinery