In the realm of home improvement, having a clear grasp of the individual elements that make up your plumbing fixtures is crucial for effective maintenance and repair. Each component plays a significant role in ensuring the overall functionality of the system, and understanding their arrangement can simplify troubleshooting. This section will delve into the essential features that contribute to the seamless operation of these installations.

When faced with challenges related to these fixtures, a comprehensive overview of the configuration can serve as a valuable resource. By familiarizing yourself with the various components, you can enhance your ability to identify issues swiftly and implement effective solutions. This exploration will empower you with the knowledge needed to navigate potential repairs and upgrades confidently.

Whether you are a seasoned professional or a DIY enthusiast, having access to a detailed layout can significantly improve your efficiency. In the following sections, we will provide insights into the distinct features and functionalities of these components, equipping you with the expertise to tackle any plumbing project with assurance.

Understanding Delta 1400 Series Components

Familiarizing oneself with the various elements of a specific faucet model can greatly enhance the user experience and maintenance capabilities. Each component plays a critical role in the overall functionality, contributing to the efficiency and longevity of the fixture. By gaining insights into these individual parts, one can make informed decisions regarding repairs and upgrades.

Key Elements of the Fixture

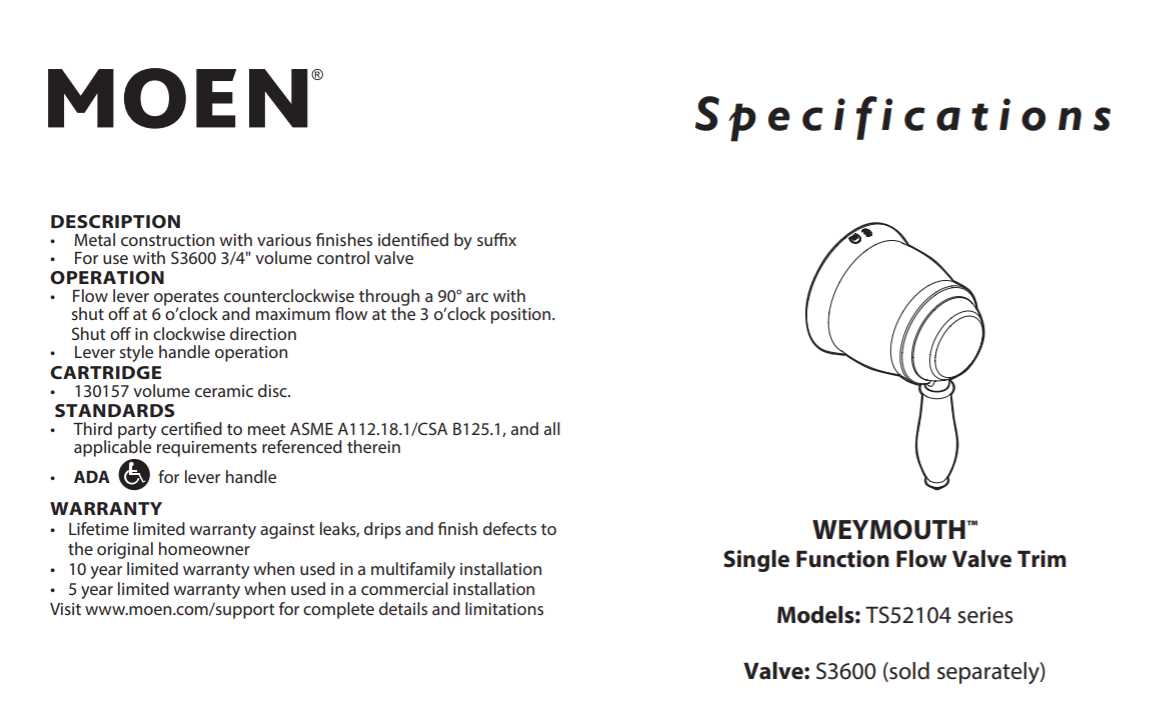

The essential components include the handle, cartridge, spout, and other integral mechanisms that work in harmony to ensure smooth operation. Understanding the function of each part is crucial for troubleshooting and repairs. Below is a breakdown of some vital elements:

| Component | Function |

|---|---|

| Handle | Controls water flow and temperature. |

| Cartridge | Regulates the mixing of hot and cold water. |

| Spout | Directs water to the desired location. |

| O-rings | Prevents leaks and maintains a seal. |

Maintenance and Upgrades

Regular maintenance of these components can prevent common issues such as leaks and reduced water flow. Understanding how each part functions will also assist in selecting suitable replacements or enhancements. Investing time in learning about these essential elements can lead to improved performance and satisfaction with your faucet.

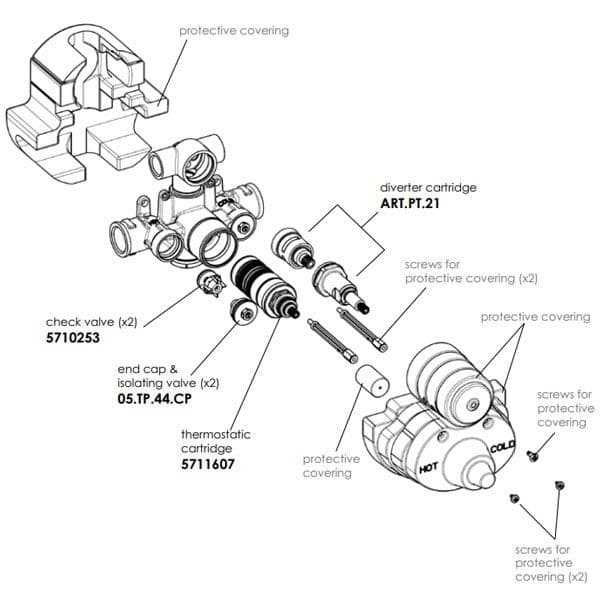

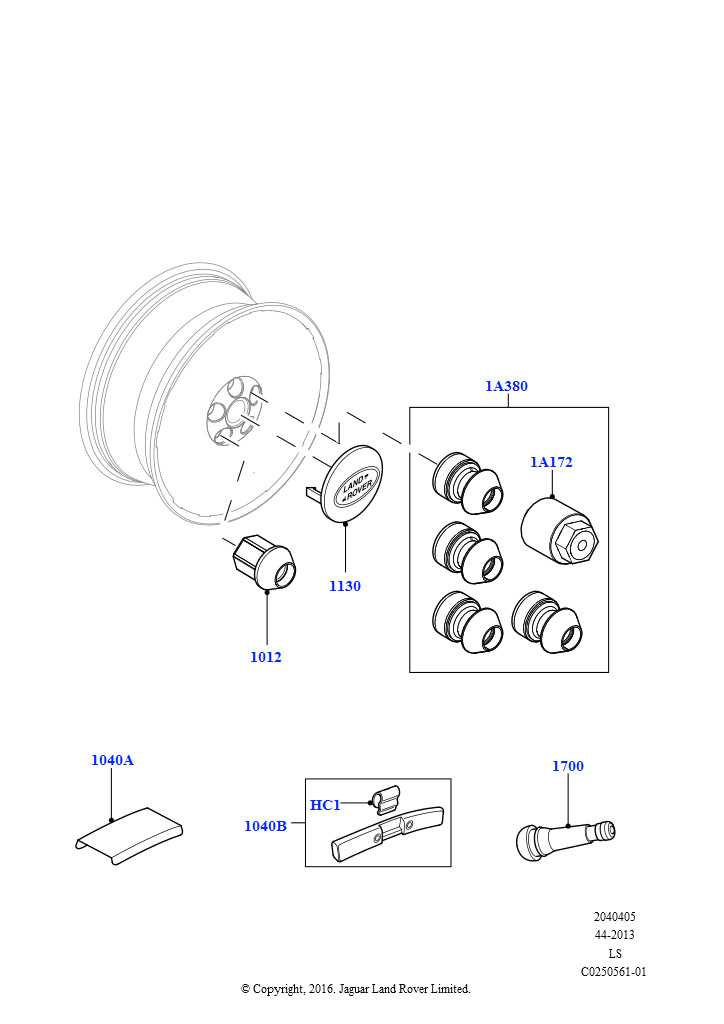

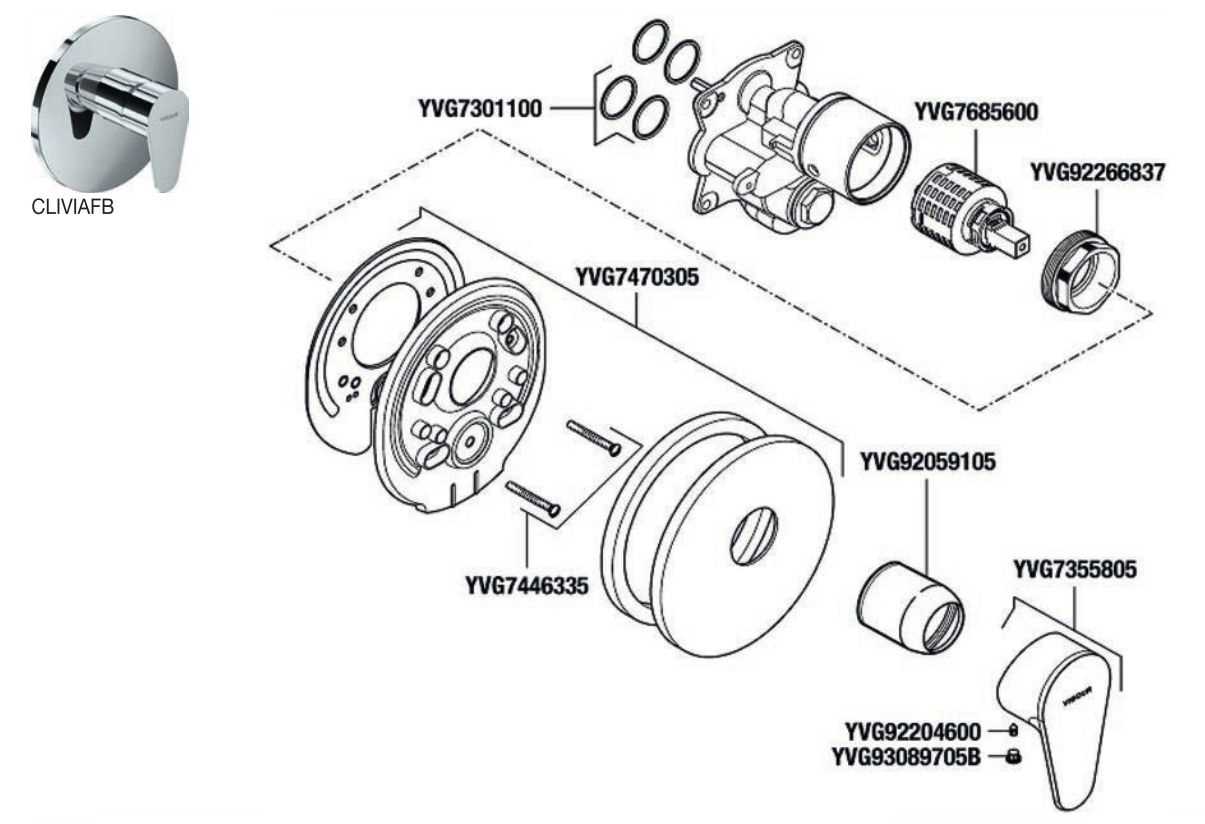

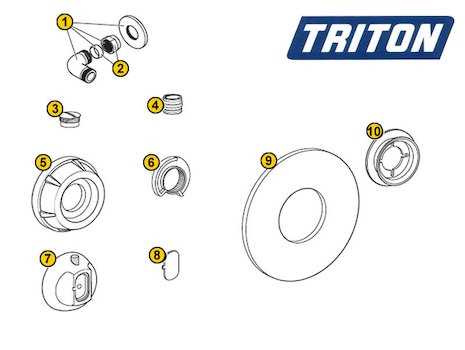

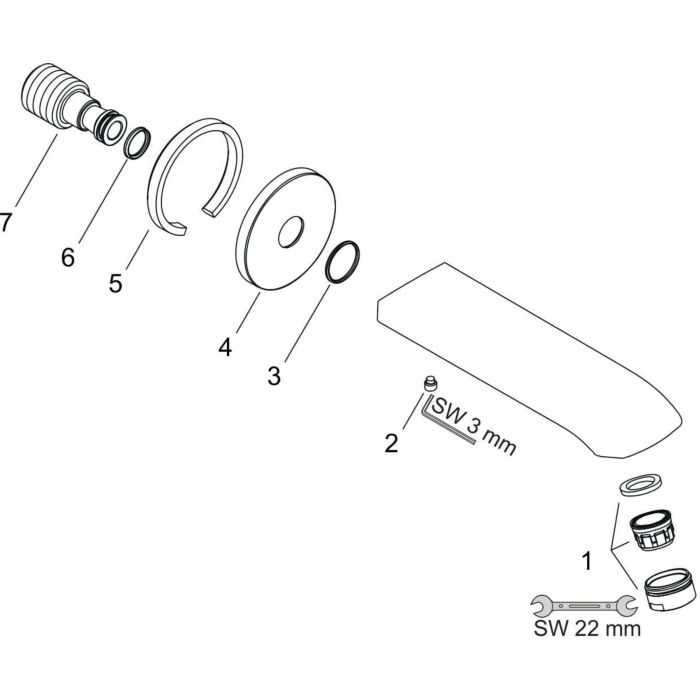

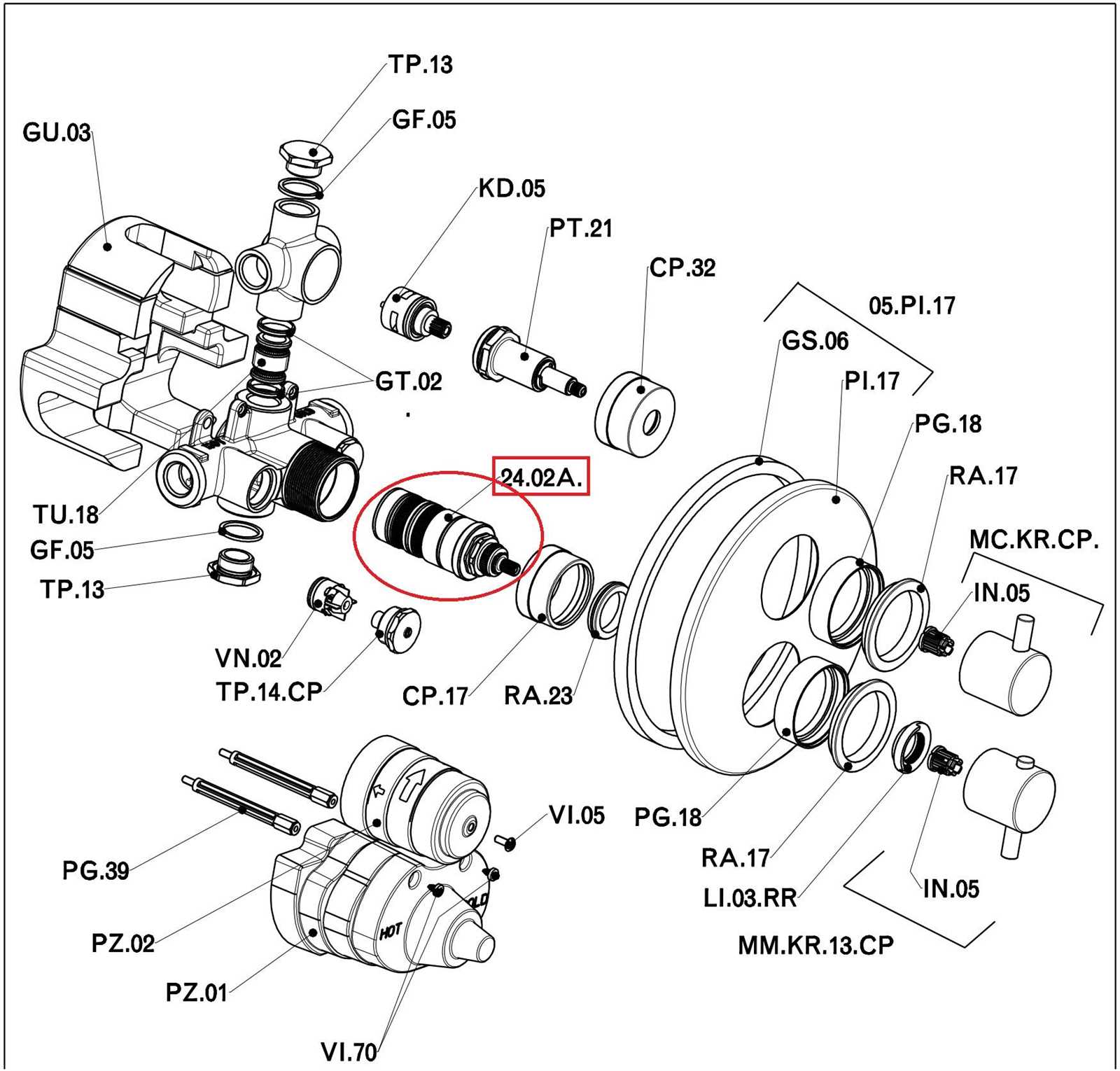

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. These illustrations serve as valuable references for both users and technicians, enhancing the efficiency of maintenance and repair tasks. By providing clear insights into the arrangement and relationship of elements, they simplify complex processes.

Benefits of Visual References

- Facilitate identification of individual elements

- Streamline assembly and disassembly procedures

- Enhance troubleshooting capabilities

- Improve communication between technicians and clients

Enhancing User Experience

Clear visual aids contribute significantly to user satisfaction by enabling a better understanding of equipment operation. When users can easily locate and recognize components, they are more likely to perform maintenance tasks accurately and efficiently. This not only prolongs the lifespan of the machinery but also reduces downtime and repair costs.

- Encourages proactive maintenance practices

- Reduces errors during repairs

- Promotes safety by ensuring proper handling of parts

Common Issues with Delta 1400 Series

Users often encounter a range of difficulties with this popular line of fixtures. Understanding these problems can help in effective troubleshooting and maintenance, ensuring a longer lifespan and optimal performance.

Leakage Problems

One of the most frequent complaints involves unwanted leaks. These issues typically arise from worn-out seals or improper installation. Regular inspection and timely replacement of components can mitigate these concerns.

Performance Fluctuations

Another common challenge is inconsistency in performance, such as fluctuating water pressure. This may be due to debris buildup or malfunctioning valves. Cleaning and servicing these areas can enhance functionality and restore reliable operation.

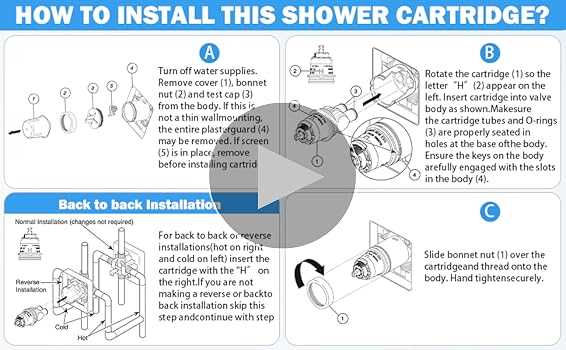

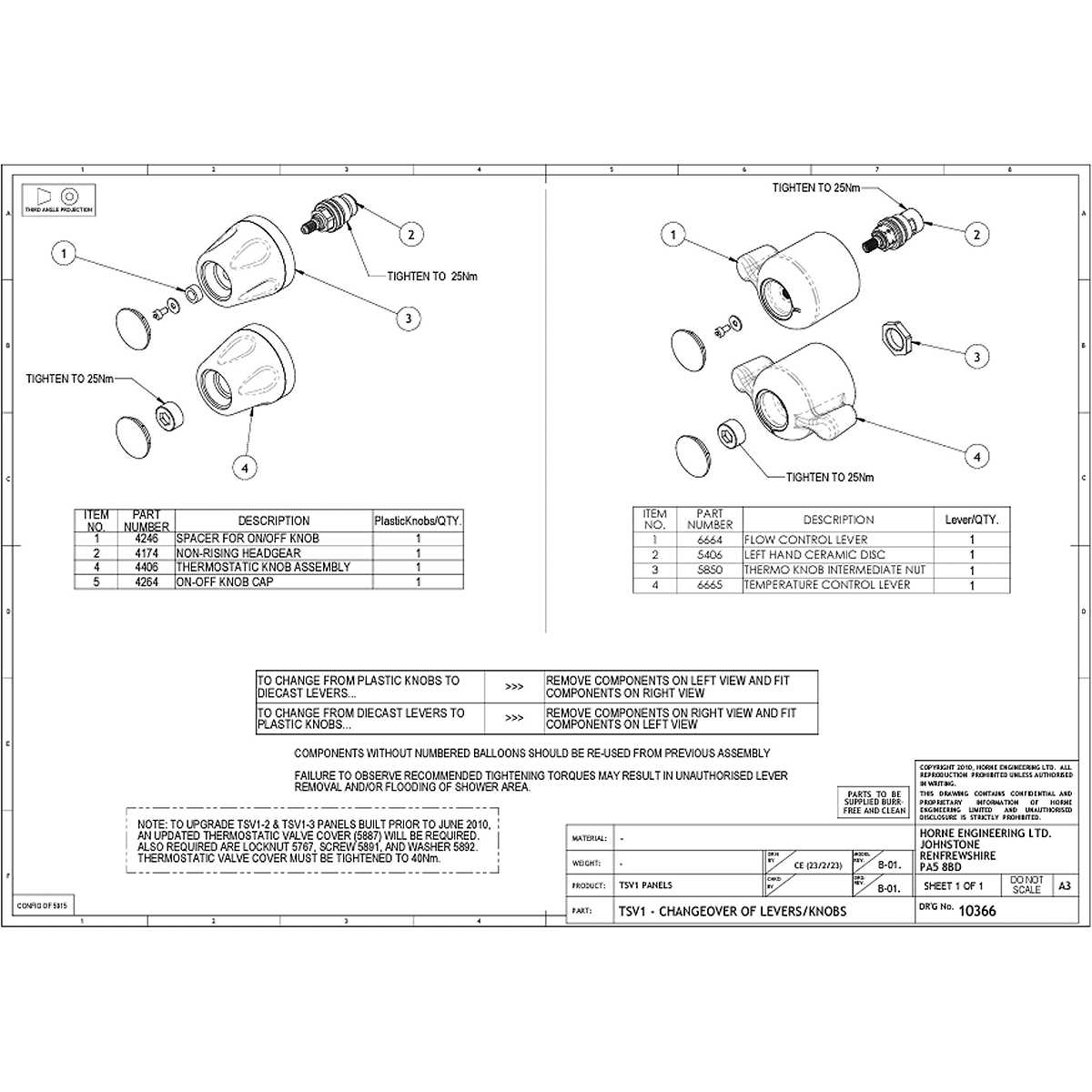

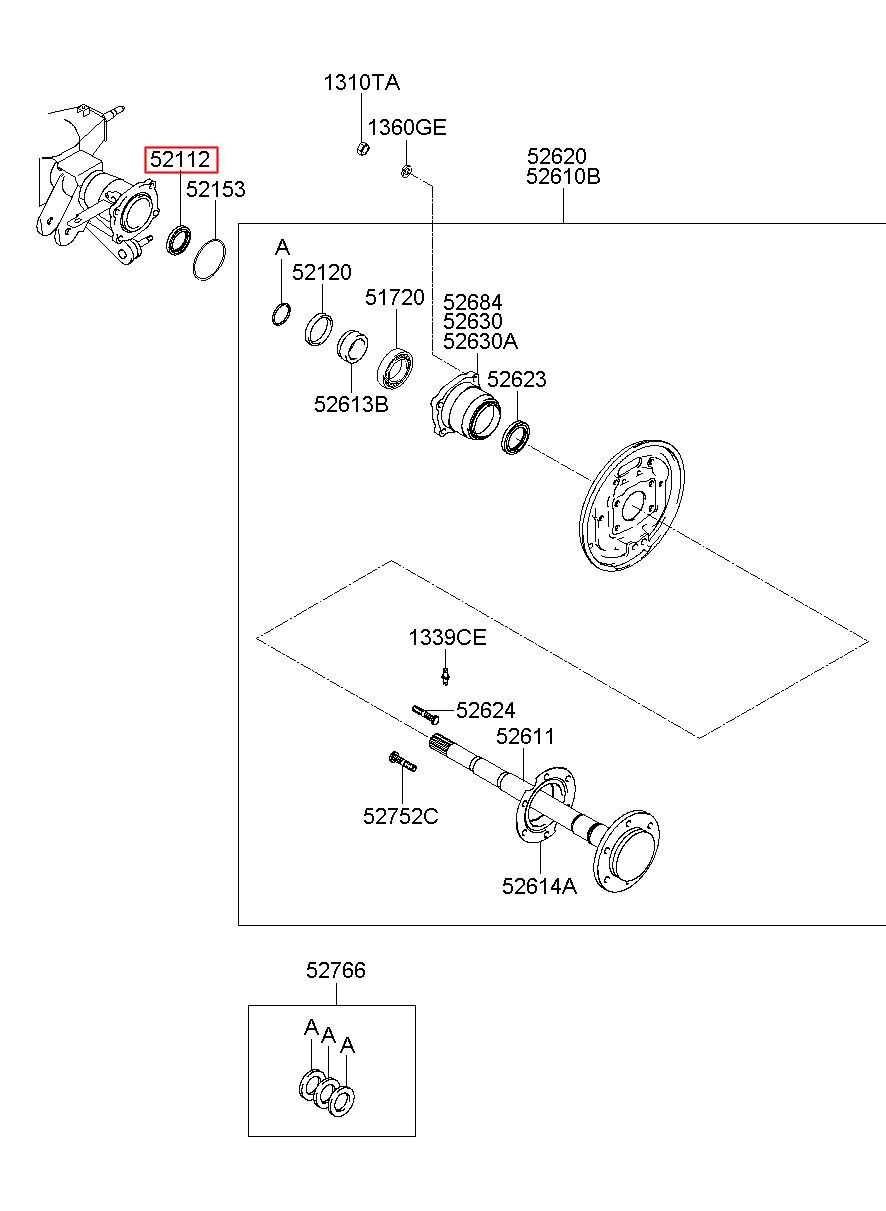

How to Read the Diagram

Understanding the layout of components is essential for effective maintenance and repair tasks. A visual representation provides clarity on how various elements interact and fit together. Familiarizing yourself with this illustration can enhance your troubleshooting skills and streamline your workflow.

Key Elements to Identify

Begin by recognizing the different symbols and lines used in the illustration. Each symbol typically represents a specific component, while the connecting lines indicate relationships or pathways between them. Knowing these can help you locate parts quickly and understand their functions.

| Symbol | Description |

|---|---|

| Circle | Represents a junction or connection point. |

| Square | Indicates a standard component, such as a valve or fitting. |

| Arrow | Shows the direction of flow or movement. |

Interpreting Connections

Once you’ve identified the symbols, focus on the connections between them. Arrows often guide you on how parts relate to one another, providing insight into the operational sequence. Pay attention to any annotations or numbers, as they can offer additional details regarding specifications or assembly order.

Replacing Parts in Delta 1400

Maintaining your equipment’s performance is crucial for ensuring longevity and efficiency. When components wear out or malfunction, timely replacement can restore functionality and prevent further damage. Understanding the process of swapping out these elements can empower you to tackle repairs with confidence and ease.

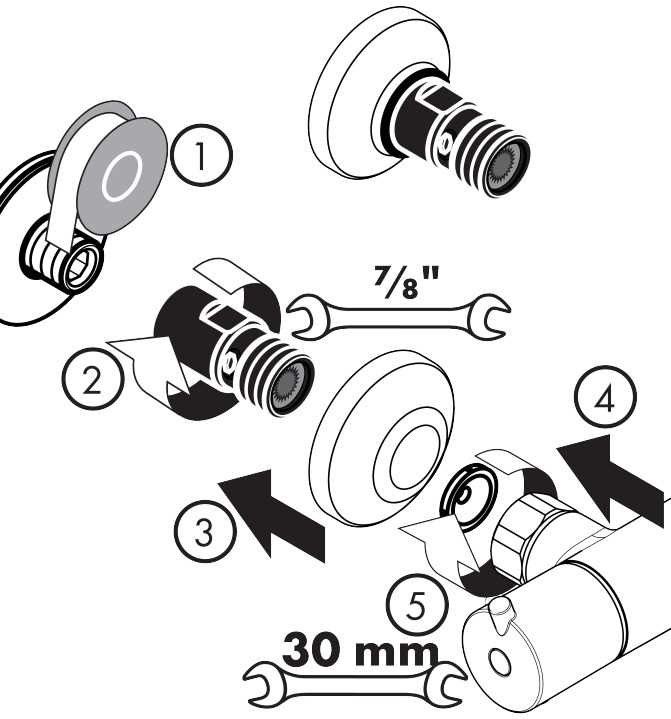

Identifying Components for Replacement

The first step in the replacement process involves recognizing which elements require attention. Common indicators include unusual noises, leaks, or decreased performance. Familiarize yourself with the various components, as this knowledge will streamline the troubleshooting process.

Step-by-Step Replacement Guide

Once you have pinpointed the components needing replacement, follow these guidelines to ensure a smooth procedure:

| Step | Action |

|---|---|

| 1 | Turn off the power supply to the unit. |

| 2 | Remove any necessary coverings or casings. |

| 3 | Carefully disconnect the faulty component. |

| 4 | Install the new component, ensuring proper alignment. |

| 5 | Reattach any coverings or casings. |

| 6 | Restore power and test the unit to confirm functionality. |

Following these steps will help maintain the efficiency of your equipment, ensuring it operates smoothly for years to come.

Finding Authentic Replacement Parts

Ensuring the longevity and functionality of your equipment requires sourcing genuine components. When repairs are necessary, the challenge lies in distinguishing between original items and imitations. This section will guide you through the process of identifying and acquiring authentic replacements that meet your specific needs.

Identifying Genuine Components

To secure original items, start by researching reputable suppliers. Look for vendors who provide clear information regarding the origin and specifications of their offerings. Checking for certifications and customer reviews can further enhance your confidence in the authenticity of the components.

Where to Purchase

Consider official retailers or authorized distributors to obtain the required items. These sources often have a comprehensive inventory and are more likely to guarantee the quality of their products. Additionally, exploring online marketplaces can yield valuable options, but always verify the seller’s credibility to avoid counterfeit goods.

Ultimately, investing time in finding authentic replacements will ensure the reliability and efficiency of your tools, leading to better performance in the long run. Prioritize quality and trustworthiness in your search to maintain the integrity of your equipment.

Maintenance Tips for Delta 1400

Regular upkeep of your fixture is essential to ensure optimal performance and longevity. Following a few simple strategies can help prevent issues and maintain efficiency over time.

Routine Checks

Conduct frequent inspections to identify wear and tear. Look for signs of leaks or irregular noises that may indicate potential problems.

Cleaning and Lubrication

Keep components clean and well-lubricated to enhance functionality. Use appropriate cleaning agents and avoid abrasive materials that could cause damage.

| Task | Frequency |

|---|---|

| Inspect for leaks | Monthly |

| Clean surfaces | Weekly |

| Lubricate moving parts | Every 3 months |

Upgrades for Improved Performance

Enhancing the efficiency and functionality of your equipment can significantly impact its overall performance. By integrating advanced components and technologies, users can experience smoother operation, increased durability, and heightened effectiveness in various tasks. This section explores several modifications that can lead to superior performance.

Essential Modifications

- Power Supply Enhancement: Upgrading to a more robust power source can lead to improved performance and reliability.

- Advanced Blades: Installing high-quality blades designed for specific materials can optimize cutting precision and speed.

- Motor Upgrades: A more powerful motor can enhance operational efficiency and reduce strain during extensive use.

Additional Accessories

- Dust Collection Systems: Implementing an efficient dust collection system helps maintain a clean workspace and improves visibility.

- Guide Rails: Precision guide rails can enhance stability and accuracy, ensuring cleaner cuts.

- Lubrication Systems: Automated lubrication solutions can reduce wear and tear, extending the lifespan of critical components.

By considering these upgrades, users can significantly enhance the capabilities and longevity of their tools, leading to more efficient and enjoyable work experiences.