Maintaining and repairing a lawn tractor requires a deep understanding of its individual components and how they interact within the machine. Proper identification of each element plays a crucial role in ensuring efficient performance and longevity. Whether you are a professional technician or a DIY enthusiast, having a clear visual guide of the equipment’s internal structure can simplify the process of identifying and replacing worn or broken parts.

In this guide, we will break down the various sections and essential features of your riding mower, offering a detailed look at the critical elements involved in its operation. Knowing where each part fits and how they work together is key to diagnosing issues and carrying out repairs. We will also cover practical steps for finding compatible replacements, ensuring that your equipment stays in peak condition for years to come.

By familiarizing yourself with the layout and function of the machine’s key components, you gain the ability to troubleshoot more efficiently and carry out maintenance with confidence. From belts to spindles, wheels to steering mechanisms, understanding the full assembly is vital for any repair or upgrade tasks that may arise.

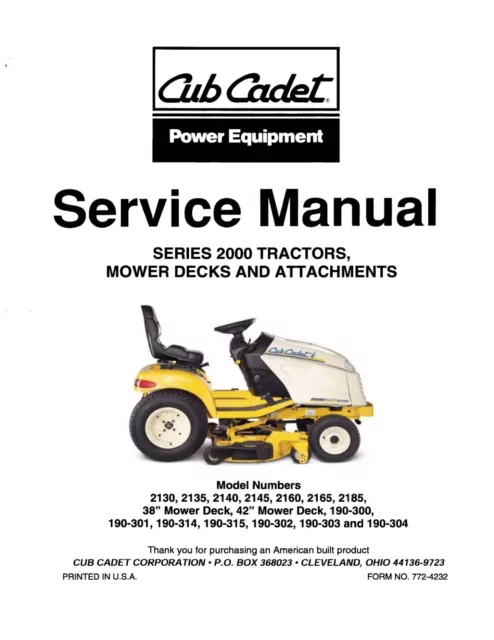

Understanding Cub Cadet HDS 2135

In this section, we will explore the essential components and features of a well-known garden machinery model. The focus will be on comprehending the operational mechanics, key parts, and the overall structure of this equipment, which is designed for effective yard maintenance. By gaining insights into its intricate system, users can ensure proper usage and efficient troubleshooting.

Key Features

The machine in question is equipped with several noteworthy functionalities that make it ideal for both residential and light commercial use. Some of its primary attributes include:

- Durable and robust construction, designed for long-term use in various conditions.

- A reliable engine, offering ample power for lawn care and other outdoor tasks.

- Advanced drive system for ease of operation and smooth movement over rough terrains.

- Multiple cutting height adjustments, allowing users to tailor the equipment for different grass types.

Understanding the System

At its core, this model is an efficient solution for those looking to simplify yard work. By familiarizing oneself with its key elements, users can optimize performance and address any potential issues quickly. The components are designed for seamless operation, but an understanding of their arrangement and functionality is essential to ensure the machinery operates at its best.

- The engine serves as the powerhouse, driving all other components, while the transmission allows for smooth movement across various surfaces.

- The deck and blade system are crucial for cutting precision and ensuring a clean finish on any lawn.

- Transmission mechanisms allow for variable speeds, enabling the user to adapt to different conditions and preferences.

With this basic understanding, it becomes easier to manage the machine’s upkeep and address any operational concerns that might arise during use.

Overview of Parts and Components

This section provides a comprehensive look at the various elements that make up the machinery, highlighting their roles and interconnections.

- Engine: The heart of the equipment, responsible for power generation.

- Transmission: Facilitates the transfer of power to the wheels, ensuring smooth operation.

- Chassis: The framework that supports all components, providing stability and durability.

- Control Systems: Allow the operator to manage the machine’s functions effectively.

- Attachments: Versatile tools that enhance functionality for specific tasks.

Understanding each component is essential for maintenance and optimal performance.

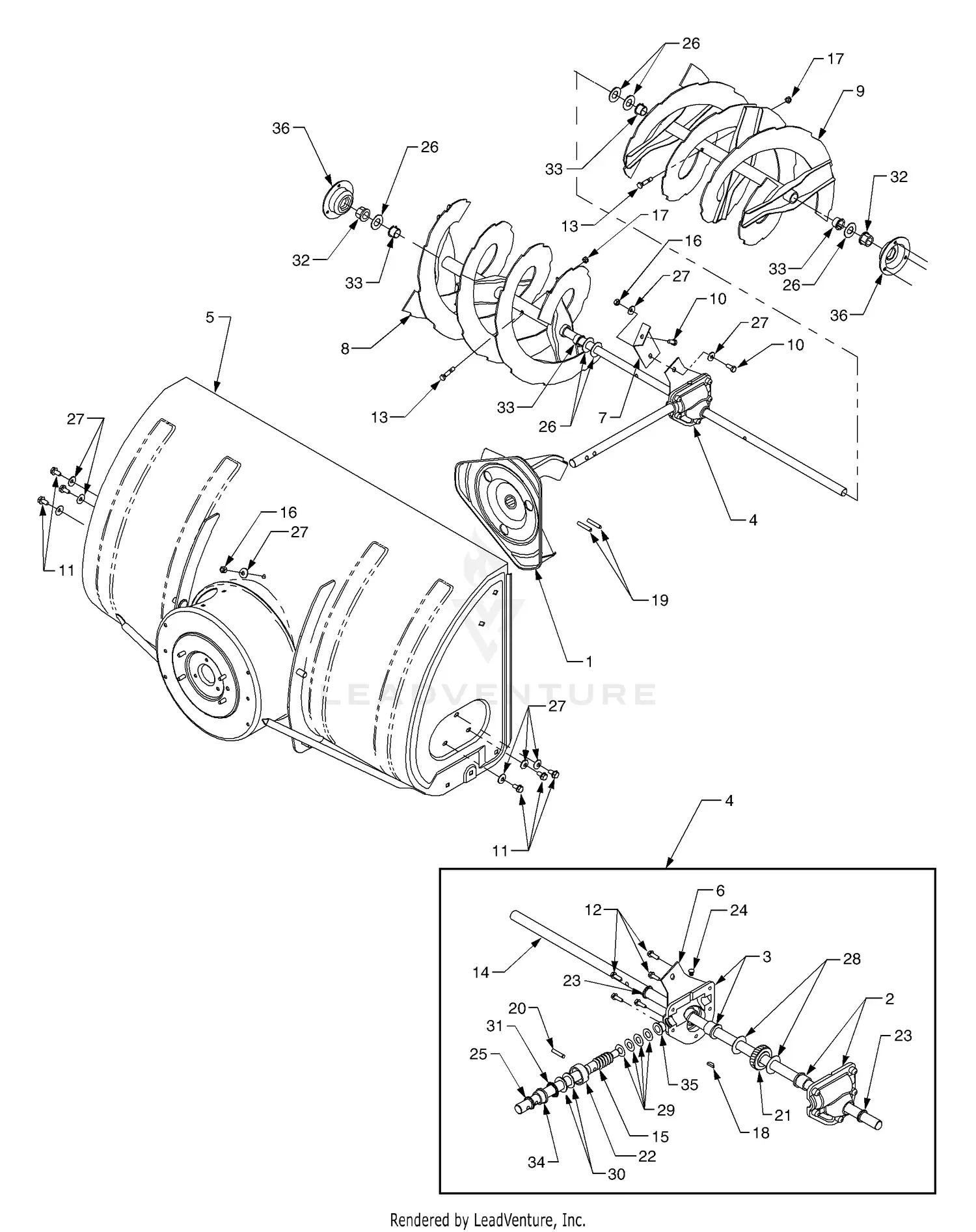

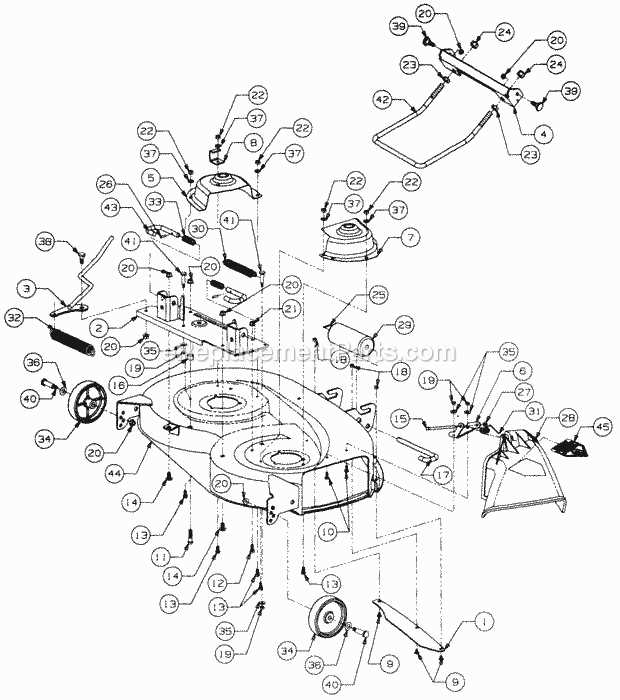

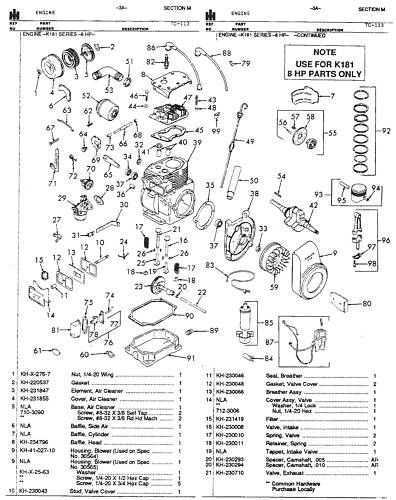

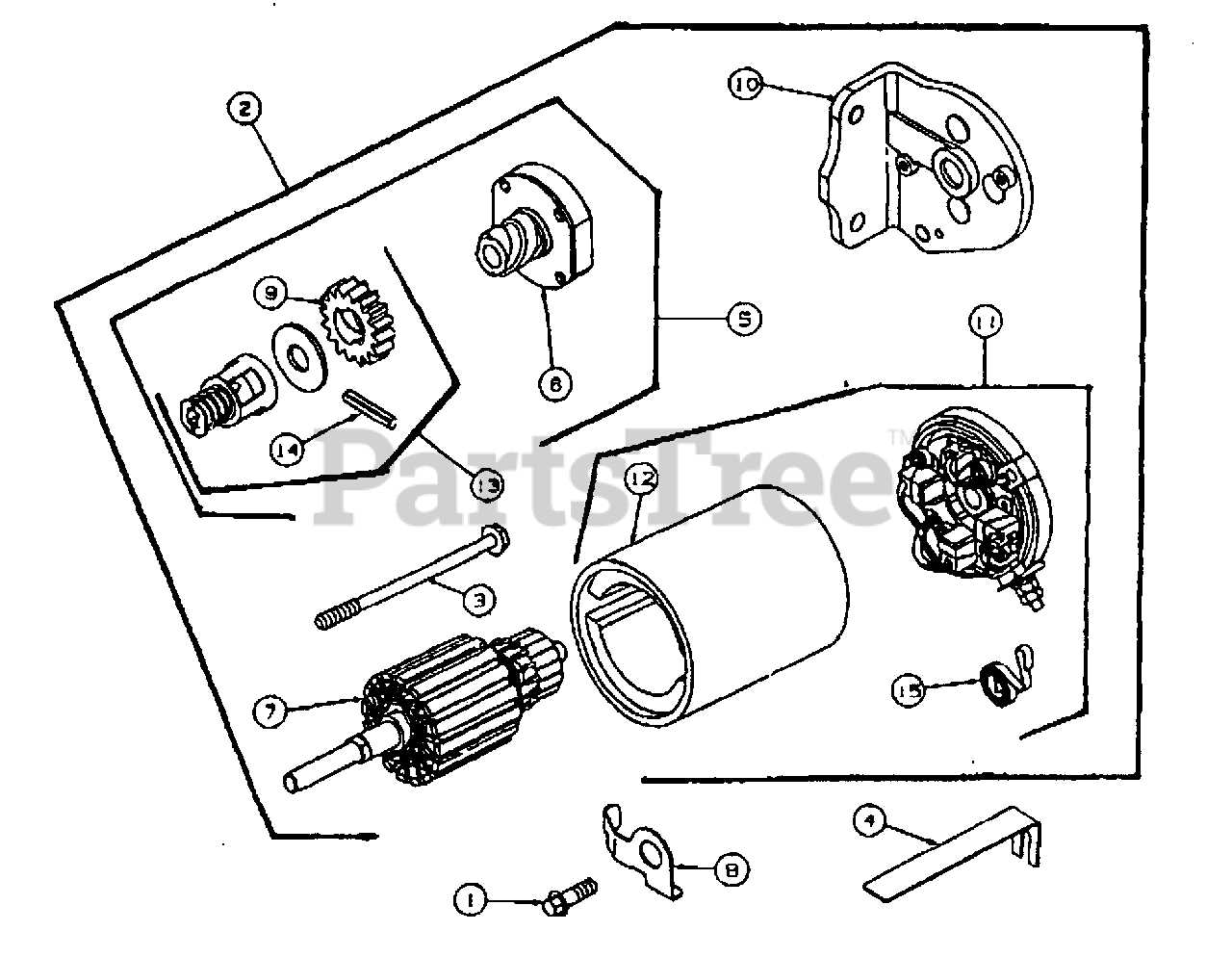

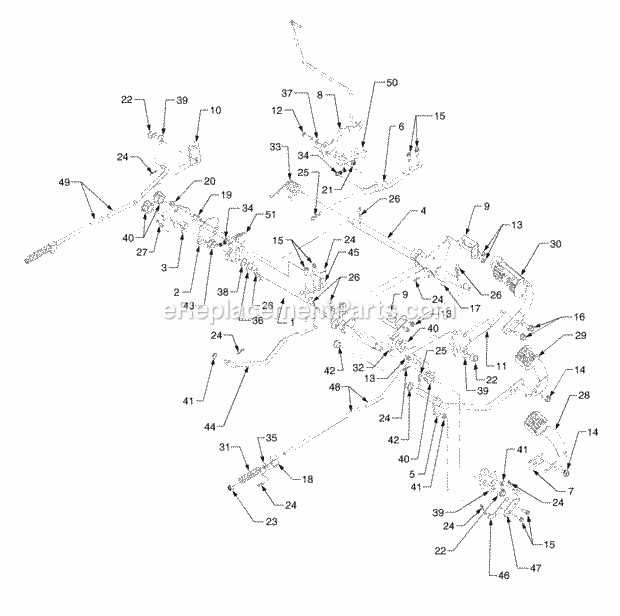

Importance of a Parts Diagram

When maintaining or repairing machinery, having a visual reference that clearly shows the components and their arrangement is essential. This tool aids in understanding how each piece fits together, ensuring proper assembly and function. Without such a reference, identifying and sourcing specific elements can become time-consuming and challenging, potentially leading to errors in repairs or maintenance.

Facilitating Efficient Repairs

Having access to a detailed schematic allows technicians or users to locate the exact part needed without confusion. It provides a clear, organized view of the entire system, which significantly reduces the risk of overlooking crucial components during disassembly or reassembly. Moreover, it aids in identifying potential wear and tear, helping to avoid future breakdowns.

Minimizing Downtime and Costs

With a precise reference, the process of locating and replacing broken or worn elements is quicker and more accurate. This results in reduced downtime and less disruption to daily tasks. Additionally, it can prevent unnecessary purchases of incorrect or incompatible components, helping to control maintenance costs effectively.

In conclusion, a well-designed visual reference plays a critical role in ensuring both efficiency and accuracy in the upkeep of machinery. Its value lies in saving time, reducing costs, and extending the lifespan of the equipment.

Common Issues with Lawn Tractor Models

Lawn tractors are powerful machines designed to handle various yard maintenance tasks, from mowing to hauling. However, even the most reliable equipment can experience malfunctions or wear over time. It is essential for owners to be aware of the common problems that may arise, enabling them to troubleshoot and address issues effectively before they lead to major breakdowns.

Engine Problems

One of the most frequent issues with lawn tractors involves engine performance. These problems can manifest as poor starting, reduced power, or the engine stalling mid-operation. In some cases, a clogged air filter, fuel system malfunction, or issues with spark plugs can be the culprit. Regular maintenance, such as changing filters and ensuring proper fuel quality, can significantly reduce the likelihood of engine trouble.

Transmission and Drive System Issues

Another area that tends to cause concern is the transmission and drive system. If a tractor is having difficulty moving forward or backward, it could be a sign of a problem with the drive belt, pulley, or transmission linkage. Over time, these components can wear out or become misaligned, leading to decreased performance. Inspecting these parts regularly and making necessary adjustments can prevent costly repairs.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Clogged air filter or fuel system issues | Replace air filter, inspect and clean fuel system |

| Loss of power | Worn spark plugs or fuel delivery issues | Replace spark plugs, check fuel quality |

| Transmission slippage | Worn belts or misaligned pulleys | Inspect and replace belts, align pulleys |

Staying proactive with regular inspections and timely repairs can help owners keep their lawn tractors in good working order for years to come.

How to Interpret the Diagram

Understanding technical illustrations related to machinery can be a critical skill when performing repairs or maintenance. These visual aids are designed to help you identify and organize components, ensuring correct assembly and replacement of worn-out parts. The key to using these guides effectively is knowing how to read the symbols, numbers, and layout provided in the chart.

To begin, it’s important to recognize the structure of the visual representation. It typically consists of multiple sections, each corresponding to a specific area or group of components. Follow these steps to make the most of the chart:

- Examine the overall layout to identify the sections. These are often divided by the type of part or by the machine’s different systems.

- Locate the numbers and labels next to each item. These indicate specific parts or tools and usually correspond with an inventory or parts list.

- Pay attention to the lines or arrows connecting the items. These suggest how parts are linked or where they fit within the assembly process.

- Understand any additional symbols or annotations. These may represent specific instructions, like torque specifications or maintenance tips.

- Cross-reference with the manual or reference materials to verify part names, ensuring that the right components are being identified for replacement or service.

Once you become familiar with the format, interpreting these guides becomes much more intuitive, making maintenance tasks more efficient and accurate.

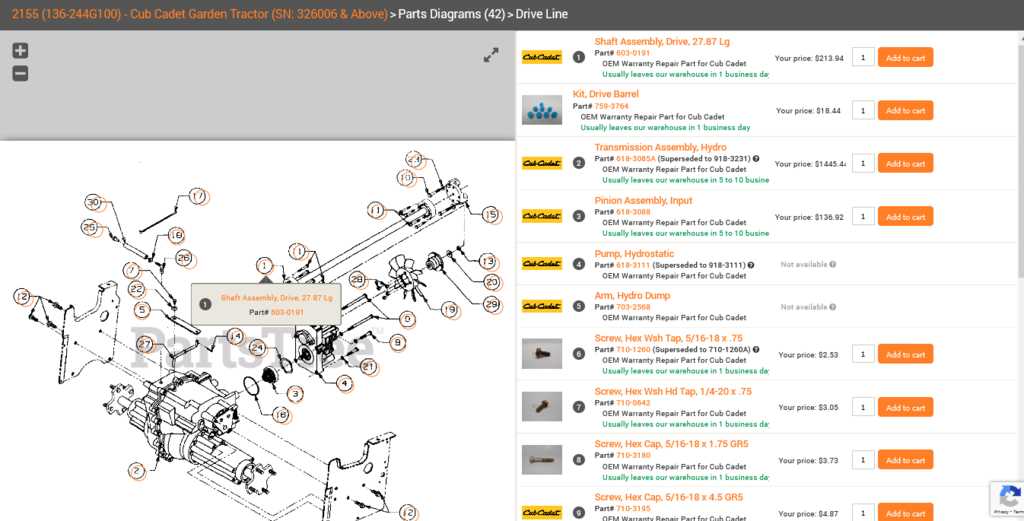

Finding Replacement Parts Easily

When maintaining or repairing your outdoor equipment, locating the right components is essential for a smooth and efficient process. Having access to clear information and resources can significantly simplify the search for the necessary items, ensuring compatibility and reducing downtime. Whether you’re replacing a worn-out belt, a broken blade, or any other essential piece, knowing where to find the correct parts is key to keeping your machine in top shape.

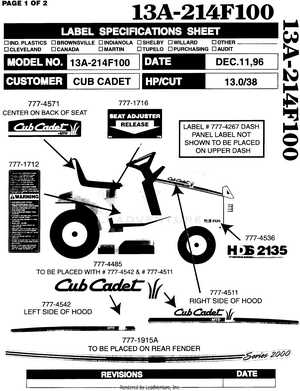

Utilize Manufacturer Resources

One of the best approaches to finding the right components is to refer to the manufacturer’s official resources. Most manufacturers provide detailed manuals and reference guides, often available online, that allow you to cross-reference the exact item needed based on your equipment’s model. This ensures that you are getting the precise replacement, designed specifically for your model.

Explore Authorized Dealers and Online Retailers

In addition to the manufacturer’s own materials, authorized dealers and online retailers can be invaluable when searching for replacements. Many platforms offer user-friendly search features, where you can enter your equipment’s details to find compatible options. Some sites also provide customer support and forums, where you can ask questions and get advice from experienced users or professionals.

Finally, taking advantage of reviews and ratings can further guide your decision. Customer feedback often highlights the quality and longevity of parts, which can be particularly useful when selecting between different brands or sellers.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for extending the lifespan of any outdoor equipment. By adhering to basic maintenance guidelines, you can ensure that your machine remains in optimal working condition for years to come. Regular attention to key components and timely servicing will not only enhance performance but also help prevent costly repairs down the line.

Here are some helpful tips to keep in mind for optimal durability:

- Regular Oil Changes: Ensure that the engine oil is changed as per the manufacturer’s recommendations. Clean oil promotes efficient operation and protects the engine from wear.

- Inspect Air Filters: A clean air filter is crucial for engine performance. Check it regularly and replace it when it becomes dirty or clogged to maintain optimal air flow.

- Sharpen the Blades: Keep the cutting blades sharp. Dull blades will strain the engine and result in uneven cutting, which can negatively affect both the machine and the grass.

- Check Belts and Cables: Inspect the belts and cables periodically for wear or damage. Replace any frayed or worn components to avoid breakdowns during use.

- Clean the Undercarriage: After every use, clear the undercarriage of debris, grass clippings, and dirt. This prevents the buildup of material that could impede the machine’s operation and airflow.

- Maintain Tire Pressure: Properly inflated tires ensure optimal traction and even ground contact. Regularly check and maintain the recommended tire pressure.

Following these straightforward maintenance practices will help prolong the life of your equipment, ensuring smooth and reliable performance over time. Regular upkeep also reduces the likelihood of major repairs and helps maintain the value of your investment.

Where to Purchase Authentic Parts

When it comes to maintaining your outdoor equipment, sourcing genuine components is crucial for optimal performance and longevity. Authentic replacements ensure that your machine operates smoothly and efficiently, reducing the risk of breakdowns and costly repairs.

Several options are available for acquiring these essential items. Authorized dealers are often the best choice, as they provide a wide range of original items and have the expertise to assist you in selecting the correct components. Additionally, many manufacturers offer online stores where you can browse their inventory and make purchases directly, ensuring that you receive high-quality products.

Another viable option is specialty retailers that focus on outdoor machinery. These establishments often stock a variety of genuine items and can provide valuable advice on installation and maintenance. Online marketplaces can also be a resource, but it’s important to verify the authenticity of the items and the reputation of the seller to avoid counterfeit goods.

In conclusion, investing time in finding reliable sources for original components will pay off in the long run, helping you maintain the efficiency and durability of your equipment.

Customer Reviews and Experiences

This section aims to highlight the feedback and stories shared by users regarding their experiences with a particular brand of outdoor equipment. Insights from actual users can provide valuable perspectives on performance, reliability, and overall satisfaction.

| Customer Name | Experience | Rating |

|---|---|---|

| John D. | Highly efficient for mowing; saves me time. | 5/5 |

| Sarah L. | Great durability, but could use a bit more power. | 4/5 |

| Mike T. | Easy to operate; customer service was excellent. | 5/5 |

| Emily R. | Had some issues initially, but they were resolved quickly. | 3/5 |