When maintaining or repairing household devices, knowing the inner workings and individual elements of the equipment becomes crucial. Understanding the intricate relationships between various mechanisms helps ensure optimal performance and longevity of the machine.

Each device is composed of multiple interconnected systems, and familiarity with their arrangement aids in troubleshooting and repairs. Identifying the proper structure of key elements not only streamlines the maintenance process but also empowers the user with knowledge, making them more efficient in handling technical issues.

By examining the functional layout of a machine, users can pinpoint areas that require attention. Proper identification and understanding of core systems allow for better decision-making when dealing with repair or replacement tasks, ensuring the continued reliability of the appliance.

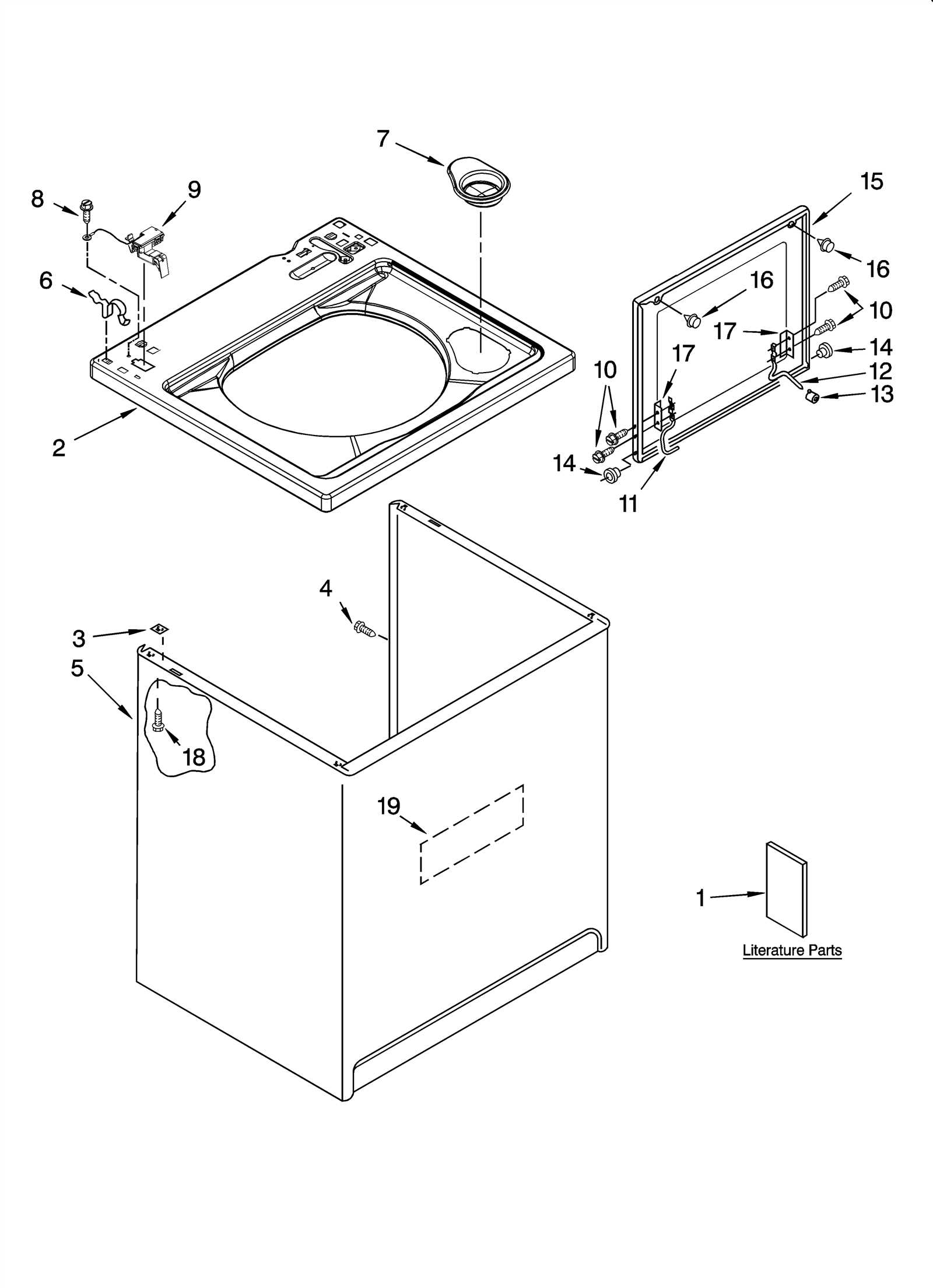

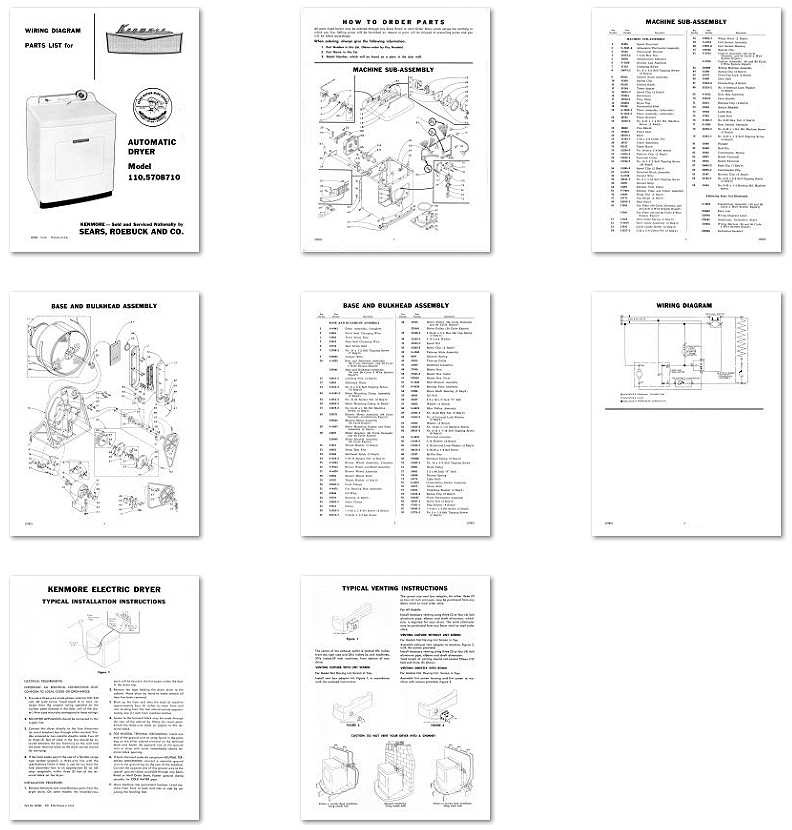

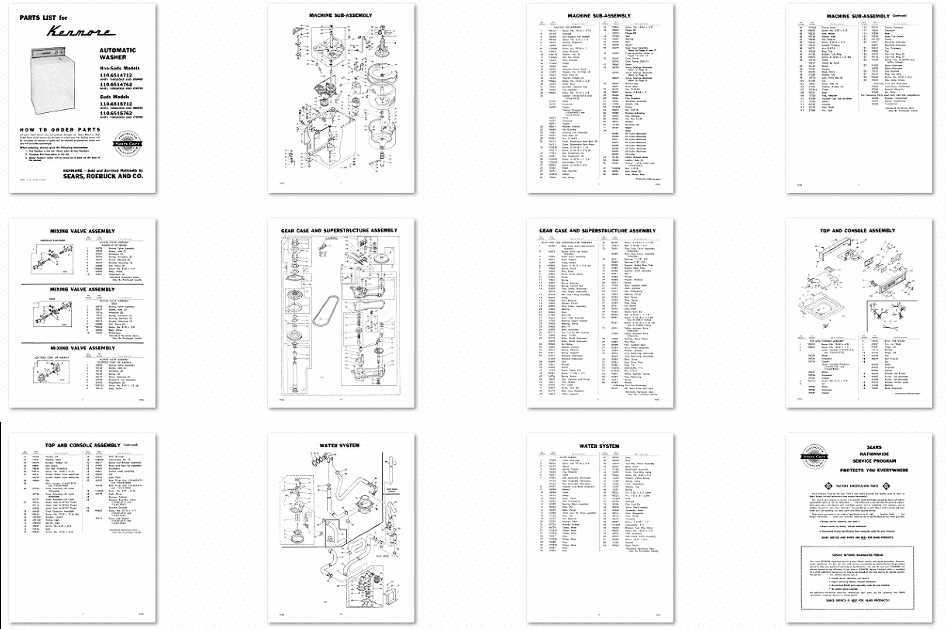

Kenmore 600 Series Washer Components Overview

This home appliance includes a range of interconnected elements that work together to ensure proper operation. Understanding these key mechanisms is essential for both regular maintenance and troubleshooting.

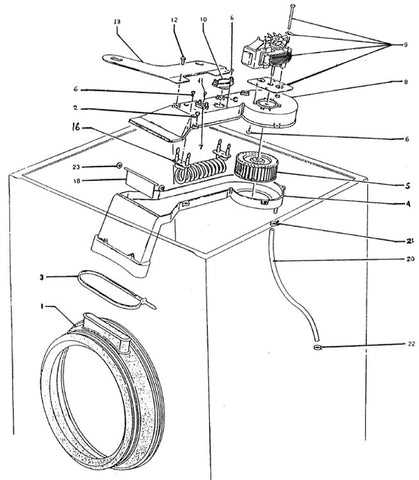

Primary Mechanical Elements

- Drive System: Responsible for moving the rotating drum, this component ensures smooth and efficient cycles.

- Pump: Designed to drain water after each cycle, it plays a crucial role in maintaining the cleaning process.

- Control Panel: The central hub where users can adjust settings and select different cycles for specific laundry needs.

Additional Functional Units

- Suspension System: Reduces vibration and ensures the stability of the appliance during operation.

- Water Inlet Valve: Manages the flow of water into the drum, allowing the proper amount for each cycle.

- Heating Element: Regulates the water temperature for efficient cleaning and ensures optimal performance.

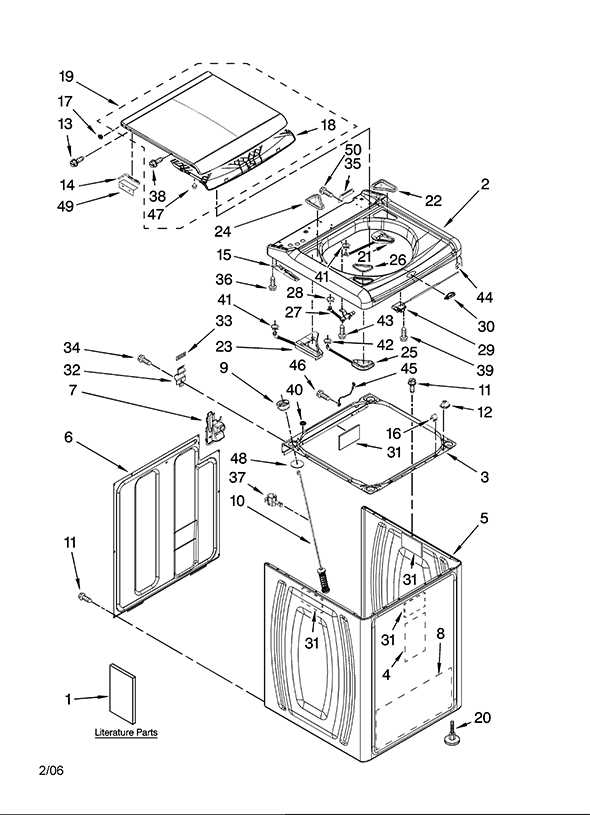

Identifying Key Parts of the Washer

Understanding the essential elements of a cleaning appliance is crucial for efficient maintenance and repairs. Each component plays a specific role, contributing to the overall functionality of the device. By knowing these elements, you can more easily diagnose issues and ensure optimal performance.

| Component | Function |

|---|---|

| Control Panel | Allows users to select cycles and manage settings for efficient operation. |

| Agitator | Moves clothes through the water and detergent, ensuring thorough cleaning. |

| Drum | Holds the clothing during the washing process and rotates during cycles. |

| Water Inlet Valve | Controls the flow of water into the machine at the beginning of a cycle. |

| Pump | Removes water from the appliance after the cleaning and rinsing phases. |

Common Issues with Washer Components

Understanding the challenges that can arise with various elements of a household appliance is crucial for maintaining its optimal performance. Regular use can lead to wear and tear, causing components to malfunction or operate inefficiently.

Below is a table highlighting common problems associated with different parts of this essential cleaning device:

| Component | Issue | Potential Cause |

|---|---|---|

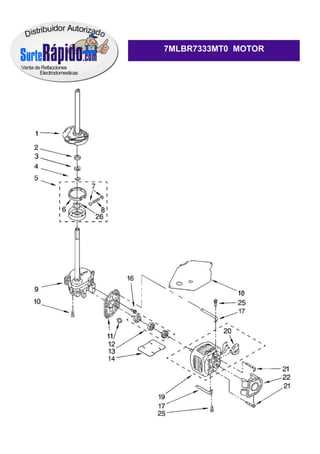

| Motor | Failure to spin | Overheating or worn-out parts |

| Drum | Unusual noise | Imbalance or foreign objects |

| Pump | Water drainage problems | Clogged filter or damaged impeller |

| Control panel | Non-responsive buttons | Electrical issues or damaged wiring |

How to Replace the Drain Pump

Replacing the device responsible for water removal from your appliance is an essential task when faced with drainage issues. This process involves careful removal of the old unit and installing a new one, ensuring that the equipment functions properly and efficiently. It’s important to handle all steps with precision to avoid any potential water leakage or improper connections.

Step 1: Disconnect the power

Before starting, ensure the power supply is completely disconnected to prevent accidents. Safety should always be a priority when working with electrical components.

Step 2: Access the drain area

Remove the back panel or base cover of the appliance to gain access to the area where the water drainage component is located. You may need a screwdriver to carefully loosen any screws.

Step 3: Remove the faulty pump

Disconnect the hoses attached to the faulty unit, ensuring no residual water spills. Unscrew the mounting screws, and gently remove the damaged component.

Step 4: Install the new pump

Position the new pump in place, secure it with screws, and reattach the hoses. Double-check that all connections are tight to avoid leaks during future use.

Step 5: Test the installation

After reassembling the appliance, reconnect the power supply and run a short cycle to confirm the proper functioning of the newly installed part. Check for any leaks or unusual noises.

Understanding the Control Panel Functions

The interface of any modern appliance provides users with the ability to manage various settings and operations. By navigating through different buttons and dials, one can fine-tune the machine’s performance to suit specific needs, ensuring efficient use and optimal results.

Below is a table highlighting common features found on control interfaces and their respective functionalities:

| Function | Description |

|---|---|

| Cycle Selection | Allows the user to choose between various cleaning cycles depending on the fabric type and load size. |

| Temperature Control | Enables adjustment of water temperature to ensure proper care for different fabrics. |

| Spin Speed | Regulates the speed at which the drum spins, affecting how dry the load will be after the cycle. |

| Start/Pause Button | Used to begin or temporarily stop the current cycle. |

Guide to Washer Tub Maintenance

Proper care and upkeep of the appliance’s inner basin are essential for optimal performance and longevity. Regular maintenance can prevent common issues such as buildup, unpleasant odors, and inefficient operation. Understanding how to maintain this critical component ensures the machine runs smoothly and effectively, providing clean laundry every time.

One of the most effective ways to maintain the inner basin is through routine cleaning. Over time, residues from detergent, fabric softeners, and dirt can accumulate, leading to potential blockages and odors. To clean the basin, consider running a hot water cycle with a specialized cleaning agent designed for this purpose. This helps dissolve any buildup and keeps the area fresh.

In addition to regular cleaning, it’s important to inspect the basin for any signs of wear or damage. Cracks, chips, or other defects can affect the appliance’s efficiency and lead to leaks. If any issues are detected, timely repairs or part replacements can help avoid more significant problems down the line.

Finally, ensure that the seals and gaskets surrounding the basin are in good condition. These components play a vital role in preventing leaks and maintaining proper pressure within the system. Periodic checks and replacements as necessary can enhance the overall functionality of the machine and extend its lifespan.

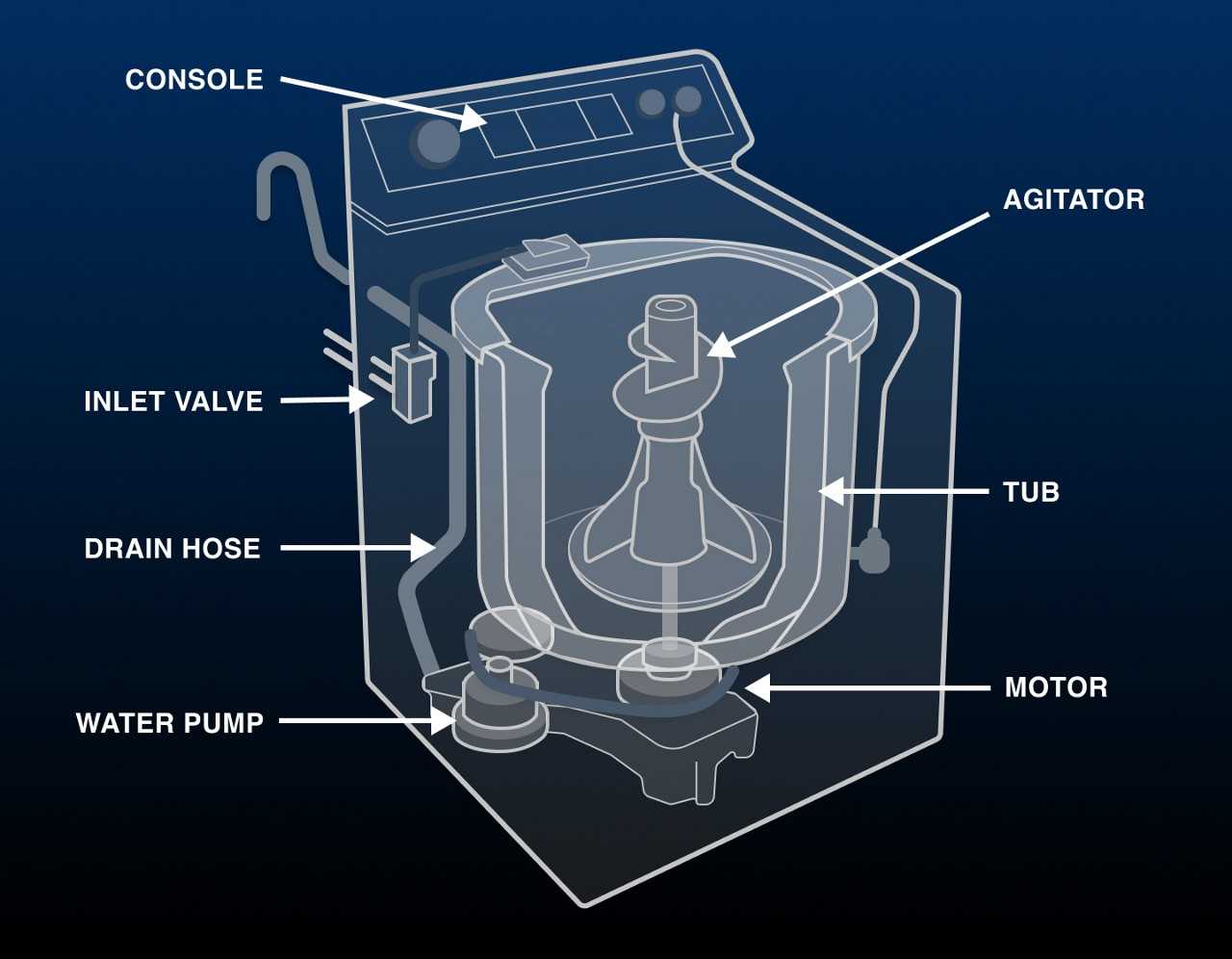

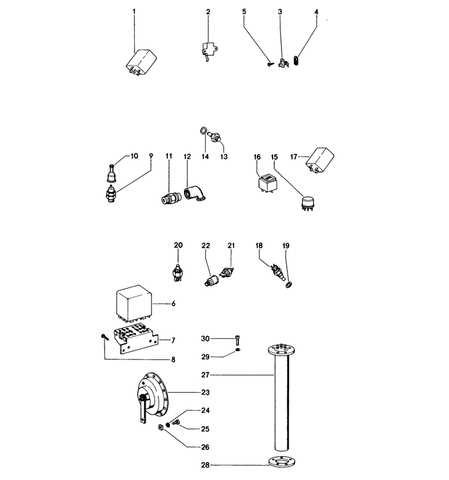

Exploring the Water Inlet Valve System

The water inlet valve system plays a crucial role in regulating the flow of water into the appliance. This mechanism ensures that the correct amount of liquid is available for optimal functioning during various cycles. Understanding its components and how they interact can help in maintaining efficiency and preventing issues related to water supply.

Components of the Inlet Valve System

The water inlet valve system comprises several essential elements that work together to manage water flow. Key components include:

- Water Inlet Valve: The primary control mechanism that opens and closes to allow water to enter.

- Solenoid: An electromagnetic device that actuates the inlet valve based on electronic signals.

- Hoses: Flexible tubes that transport water from the source to the inlet valve.

- Filters: Screens that prevent debris and impurities from entering the system.

Understanding Valve Operation

The operation of the inlet valve system is vital for the effective use of the appliance. The process typically involves:

- Receiving electronic signals from the control board.

- Activating the solenoid, which opens the valve.

- Allowing water to flow through the hoses and into the appliance.

- Shutting off the valve once the desired water level is reached.

Tips for Replacing the Washer Belt

Replacing the drive belt in a laundry machine can significantly enhance its performance and efficiency. Understanding the correct procedure and having the right tools on hand can simplify the process and reduce potential frustrations. This guide offers valuable insights to ensure a smooth replacement experience.

Gather Necessary Tools and Materials

Before beginning the replacement process, ensure you have all the essential tools and materials. Commonly required items include a socket wrench set, screwdrivers, and a replacement belt. Having these items ready will streamline the procedure and help avoid unnecessary delays.

Follow Safety Precautions

Safety should always be a priority when working with electrical appliances. Unplug the machine from the power source before starting any repairs. Additionally, it is advisable to wear gloves to protect your hands from sharp edges and potential injuries while handling components.

Maintaining the Agitator for Optimal Performance

Ensuring the efficiency of your laundry machine involves regular upkeep of essential components. One critical element in this process is the central rotating mechanism, which plays a significant role in the cleaning effectiveness. Proper care and timely maintenance of this part can lead to enhanced performance and longevity.

Regular Inspection and Cleaning

Frequent evaluations can help identify any signs of wear or debris accumulation. Follow these steps for effective inspection:

- Disconnect the appliance from the power source before starting.

- Remove any visible lint or foreign materials from the agitator area.

- Check for signs of damage or wear on the rotating component.

Lubrication and Replacement

Keeping the central mechanism well-lubricated is essential for smooth operation. Here are some tips:

- Use a suitable lubricant recommended for mechanical parts.

- Apply lubricant sparingly to avoid excess buildup.

- Consider replacing worn parts to maintain optimal functionality.

By following these maintenance practices, you can ensure that the central rotating mechanism continues to function effectively, providing reliable service for your laundry needs.