In any system designed for effective water purification, a variety of essential elements come together to ensure optimal functionality. Understanding the structure and how each component interacts within the whole setup is crucial for maintaining efficiency and longevity. This section will provide an in-depth look at the primary mechanisms involved, focusing on their individual roles and benefits.

Each part within the system contributes to different stages of the process, ensuring that the flow is uninterrupted and the quality remains consistent. Recognizing these elements and their arrangement can greatly assist in troubleshooting and performing maintenance, helping to keep the entire unit in top working condition.

In the following guide, we will explore the various sections of the system in detail, highlighting the essential pieces that make it work seamlessly. From the external frame to the internal mechanisms, this comprehensive breakdown will offer valuable insights into the operational design.

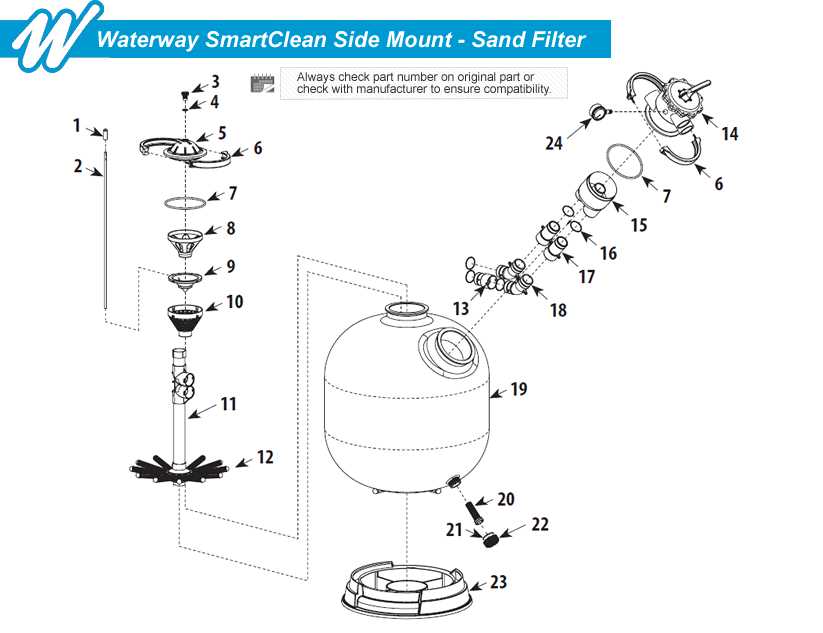

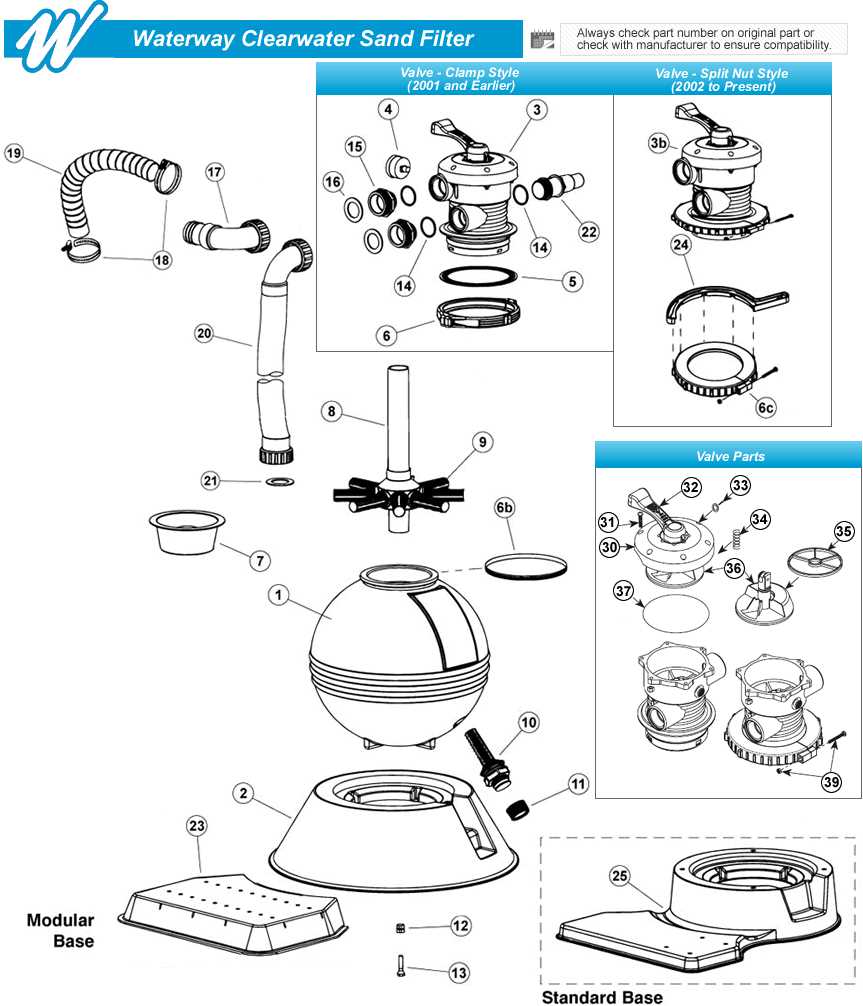

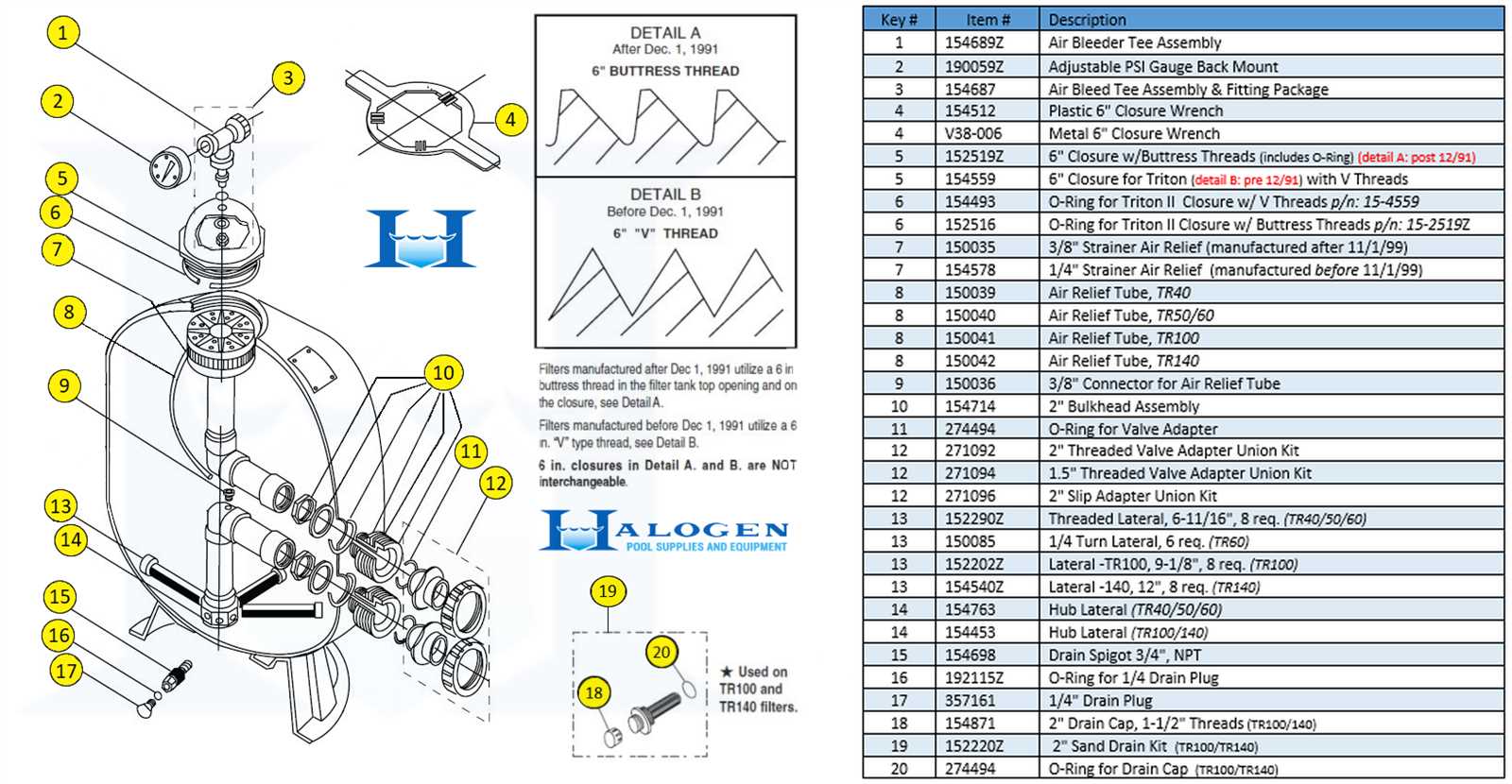

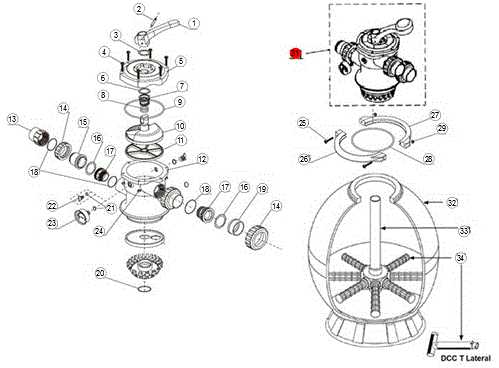

Overview of Waterway Sand Filter Components

This section provides a detailed look at the various elements that make up the structure of an essential pool maintenance system. Each element plays a crucial role in ensuring efficient operation, working together to maintain clean and safe water conditions.

Main Structural Elements

- Tank: The core of the system, designed to hold the medium used for capturing impurities.

- Valve Assembly: A critical component responsible for directing the flow of water through the system in different modes.

- Pressure Gauge: This device monitors the internal pressure, indicating when cleaning or maintenance is required.

Supportive Components

- Laterals: Small elements located at the base, ensuring even distribution and collection of the treated water.

- Drain Plug: Allows for easy removal of water and debris during routine maintenance or winterization.

- O-rings: Seals that prevent leaks, ensuring a tight and efficient operation within the

Understanding the Functionality of Key Parts

The core components of any device that manages water flow are essential for ensuring smooth operation and long-term performance. By grasping the role each element plays, users can better maintain the system and address potential issues that may arise during its operation. This section provides insight into how each key part contributes to the overall efficiency and functionality.

Primary Control Mechanism

The central control mechanism regulates the flow of liquid through the system, ensuring that the direction and pressure are maintained according to the specific operational settings. This component is responsible for the efficient distribution and management of water, making it crucial for seamless performance.

Flow and Pressure Regulator

This part ensures that the right balance of water pressure is maintained within the system. By adjusting the levels as needed, it prevents overloading and protects the entire mechanism from damage, ensuring that everything runs smoothly without interruption.

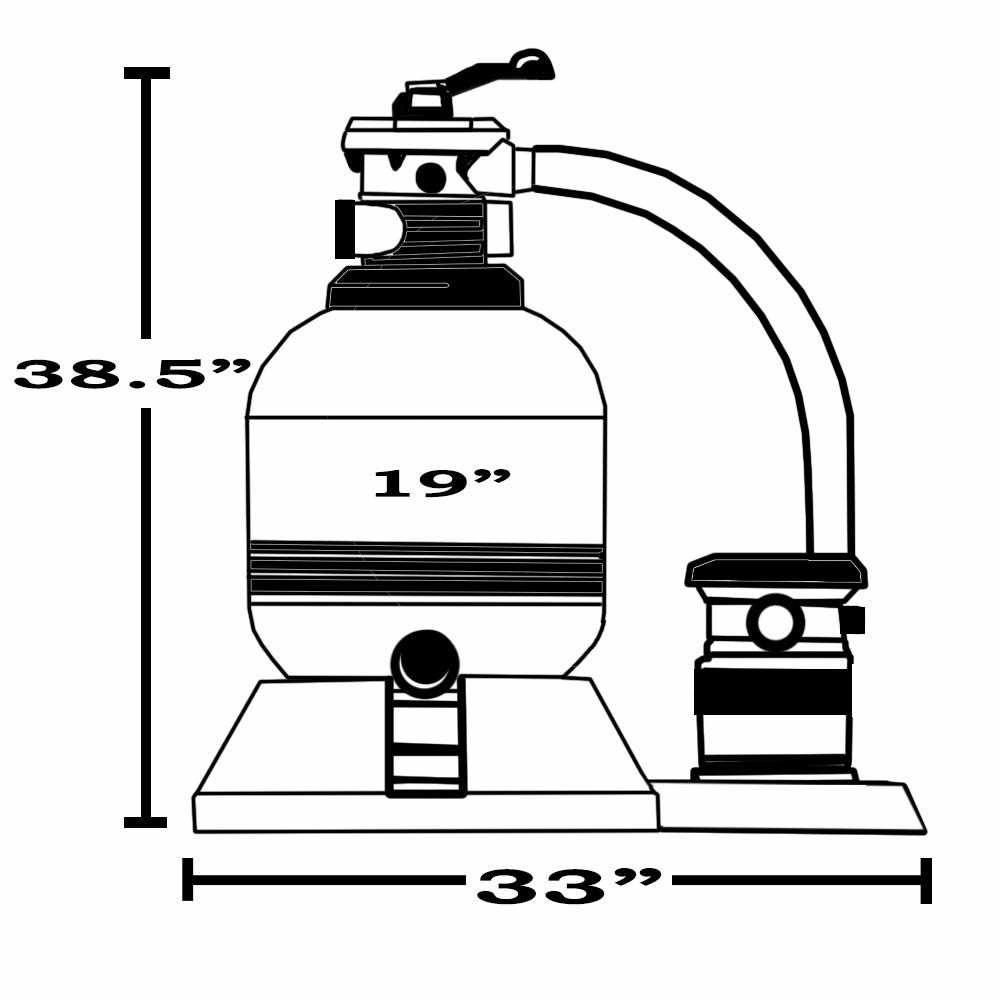

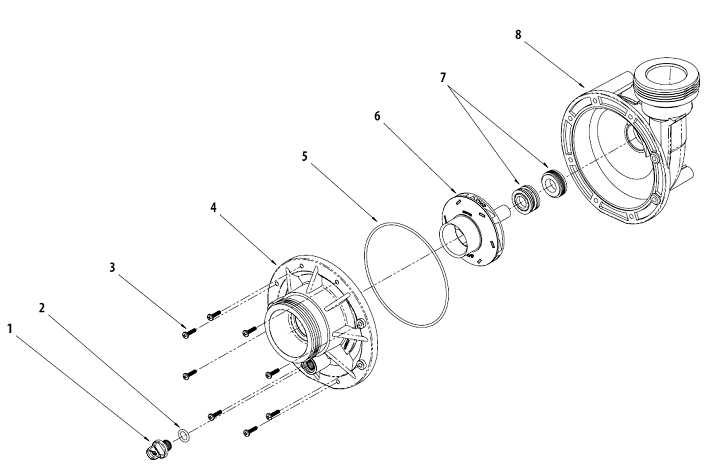

Assembly and Structure of a Sand Filter

The design of this type of equipment relies on several key components working together to provide efficient performance. Understanding the basic construction is crucial for ensuring proper operation and maintenance. In this section, we will explore how the various elements are assembled and function as a whole.

Component Function Outer Shell Encases and supports the entire structure, protecting internal mechanisms. Top Valve Controls the flow of liquid into and out of the system, regulating different modes of operation. Central Column Distributes incoming liquid evenly through the media, optimizing performance. Internal Support Prevents the media from moving and ensures proper filtration efficiency. Drain Outlet Allows for easy removal of water during cleaning or maintenance cycles. How to Identify Common Sand Filter Issues

Regular maintenance and timely problem detection are crucial for ensuring the smooth operation of your pool’s filtration system. Over time, a variety of malfunctions can arise, affecting water clarity and system efficiency. Understanding these issues early can prevent more serious damage and costly repairs.

Signs of Malfunctioning

A key indicator of a problem is poor water circulation or reduced flow. This might be noticed when the pump struggles to maintain a consistent pressure, or when water returns to the pool at a slower rate. Additionally, cloudy or murky water can signal that the system is not working as it should, allowing impurities to pass through without proper filtering.

Pressure Gauge Fluctuations

Another common problem is irregular readings on the pressure gauge. A sudden drop or spike in pressure can indicate blockages, such as debris clogging the system. It may also suggest internal damage that needs to be addressed immediately. Monitoring the pressure regularly helps in catching such issues before they escalate.

Regular inspections of the system’s components and performance can go a long way in identifying potential issues. By staying proactive, you can extend the lifespan of your filtration system and maintain optimal pool conditions.

Replacement Tips for Sand Filter Components

Regular maintenance and timely replacement of essential components can ensure your system operates efficiently for many years. Understanding when and how to replace key parts is crucial for maintaining the longevity of your equipment.

Recognizing Wear and Tear

Over time, various elements in the system may show signs of aging, such as cracks, reduced efficiency, or leaks. Regular inspections are important to identify these issues early. If you notice a decrease in performance, it’s likely time to replace certain pieces.

Steps for Replacing Key Components

- Shut off the system and release any pressure to avoid injury or damage.

- Carefully remove the worn-out parts, making sure not to disturb surrounding components unnecessarily.

- Check compatibility when purchasing new parts, ensuring they match the system’s specifications.

- Install the new component securely, following the manufacturer’s guidelines for proper placement and tightening.

- Restart the system and monitor for any leaks or unusual behavior to confirm the successful replacement.

By following these steps and conducting regular checks, you can keep your system in peak condition and avoid unexpected breakdowns.

Maintenance Guide for Sand Filter Efficiency

Ensuring optimal performance of your water purification system requires regular upkeep and attention to detail. Proper maintenance not only prolongs the lifespan of the equipment but also enhances its effectiveness in providing clean and clear water. By following a few essential practices, you can maintain high functionality and efficiency.

Regular Inspection: Conduct frequent evaluations of the system to identify any wear or damage. Look for signs of leaks, corrosion, or unusual noises that may indicate a problem. Early detection can prevent costly repairs and ensure smooth operation.

Cleaning Procedures: Routine cleansing is vital for maintaining the performance of the system. Remove any accumulated debris or buildup, as these can impede flow and reduce efficiency. Implement a schedule for thorough cleaning to keep the components in top condition.

Media Replacement: The effectiveness of the filtration media diminishes over time. It is crucial to monitor the condition of the medium and replace it when necessary to maintain optimal purification levels. Consult the manufacturer’s guidelines for recommended intervals for replacement.

Pressure Monitoring: Keep an eye on the pressure gauge to ensure it remains within the recommended range. Significant deviations may indicate blockages or other issues that require immediate attention. Regular monitoring can help maintain consistent performance.

System Calibration: Periodic adjustments and calibrations are necessary to ensure the system operates at peak efficiency. Follow the manufacturer’s instructions for making any necessary tweaks to settings or configurations.

By adhering to these guidelines, you can ensure that your purification system operates efficiently, providing high-quality water while minimizing maintenance costs.

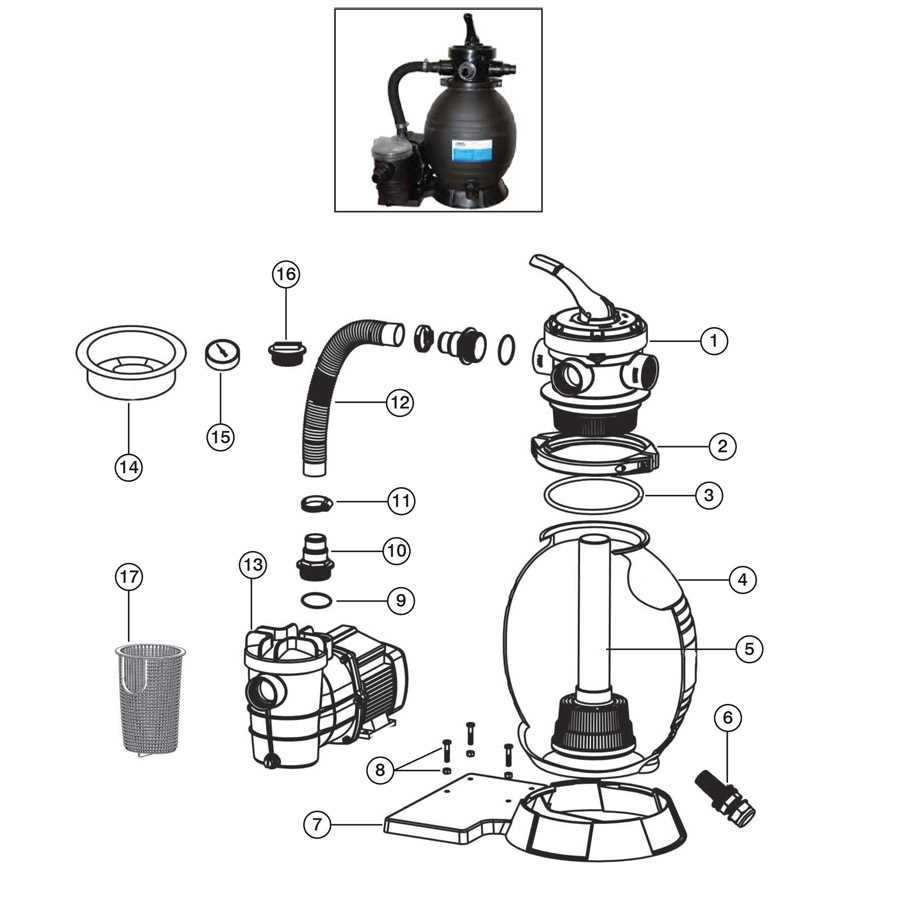

Water Flow Path in a Sand Filter System

The process of fluid movement through a purification apparatus is crucial for ensuring optimal performance and effective cleaning. Understanding the trajectory of the liquid as it traverses various components is essential for maintaining efficiency and longevity. Each segment of the system plays a pivotal role in directing the flow, enhancing the overall quality of the treated substance.

Entry Phase

Initially, the liquid enters through an inlet, where it is directed into the main chamber. This area is designed to accommodate the incoming flow, allowing for even distribution across the entire cross-section. Proper entrance design mitigates turbulence and promotes a smooth transition into the subsequent stages.

Filtration Stage

As the liquid progresses, it encounters various materials that facilitate the removal of impurities. The flow path encourages the substance to interact with these filtering mediums, which capture particles and contaminants. This phase is vital for achieving clarity and purity, ensuring that the output meets the desired standards.

Choosing the Right Filter Media

Selecting the appropriate medium for your purification system is crucial for achieving optimal performance and efficiency. The right choice enhances the clarity and quality of the water while minimizing maintenance requirements.

When evaluating various materials, consider factors such as particle size, density, and composition. Granular substances with larger granules tend to allow for better flow rates, while finer options are more effective at capturing smaller particles. Additionally, the chemical properties of the medium can influence its ability to remove specific contaminants.

It is also essential to assess the longevity of the medium, as some options may require frequent replacement while others can last for years. Always ensure that the selected material is compatible with your existing system to avoid any operational issues.

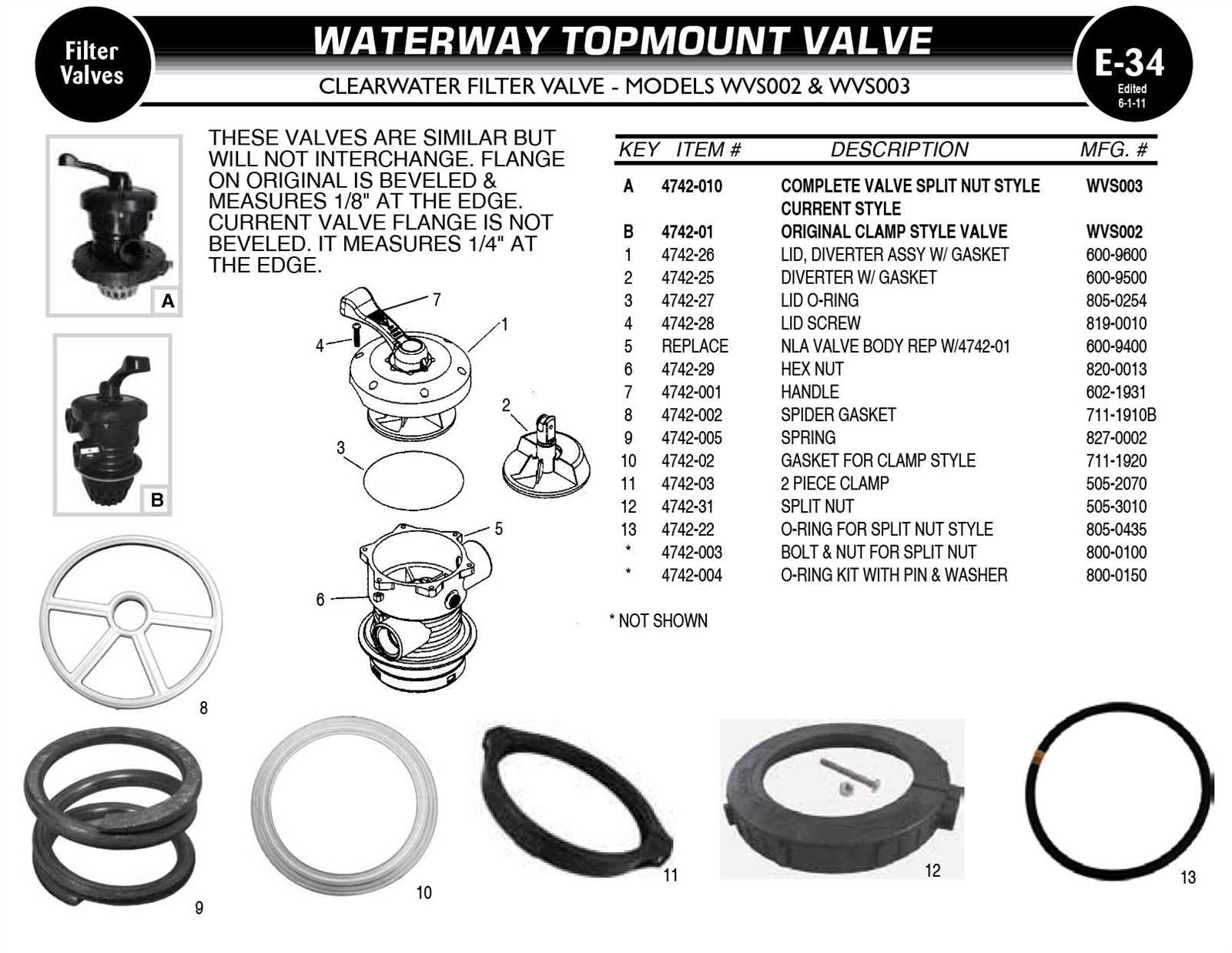

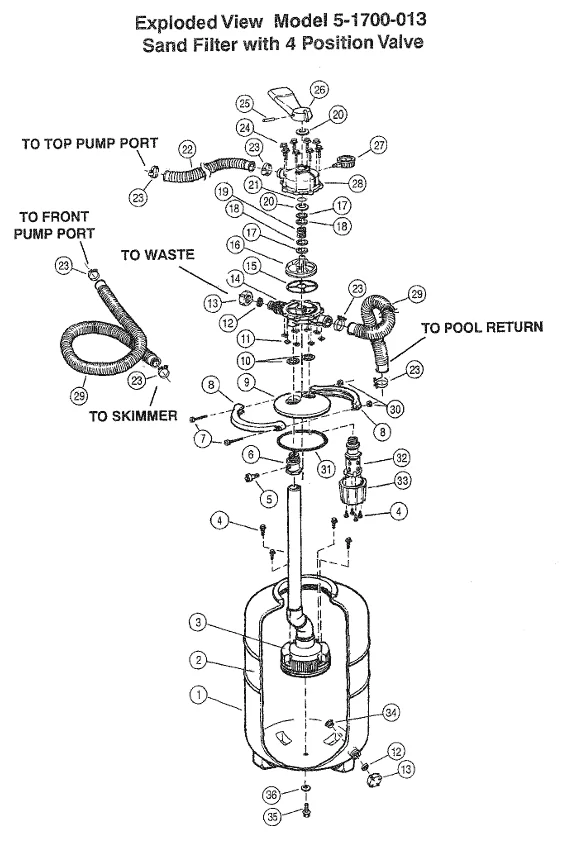

Inspecting and Troubleshooting Filter Valves

Ensuring the optimal performance of valve mechanisms is crucial for maintaining a well-functioning system. Regular checks can help identify issues before they escalate, thereby prolonging the lifespan of the equipment and enhancing overall efficiency. This section provides a comprehensive guide on how to examine and address common problems associated with these essential components.

Common Issues to Look For

- Leaks: Inspect for any signs of fluid escaping around the valve seals.

- Blockages: Check for debris or sediment that may obstruct the flow.

- Wear and Tear: Look for any visible damage, such as cracks or corrosion.

- Inconsistent Operation: Notice if the valve is not opening or closing properly.

Steps for Troubleshooting

- Visual Inspection: Start with a thorough examination of the valve and surrounding areas.

- Check Connections: Ensure that all fittings are secure and not leaking.

- Test Operation: Manually operate the valve to assess its functionality.

- Replace Faulty Components: If any parts are damaged, consider replacing them to restore proper function.

- Consult Documentation: Refer to manuals or guidelines for specific troubleshooting techniques related to your system.

By following these steps, one can effectively address common challenges associated with valve mechanisms, ensuring smooth operation and longevity of the system.