When it comes to maintaining outdoor spaces, having the right tools is essential for efficiency and effectiveness. This section will explore the intricate details of a particular model that has gained popularity among users for its robust performance. By understanding the essential components, users can enhance their experience and ensure the longevity of their equipment.

In this exploration, we will delve into the various elements that contribute to the functionality of this cleaning device. From the core mechanisms to the auxiliary features, each part plays a vital role in achieving optimal results. Knowledge of these components can help users troubleshoot issues and perform necessary maintenance.

Ultimately, having a comprehensive understanding of the inner workings allows for better handling and utilization of the machine. This information serves as a valuable resource for both new and experienced users looking to maximize their investment in cleaning technology.

Understanding Simpson 3000 Pressure Washer Components

When it comes to high-efficiency cleaning equipment, grasping the essential elements is crucial for optimal performance. This knowledge not only aids in maintenance but also enhances your ability to troubleshoot issues effectively. Each component plays a significant role in ensuring that the device operates smoothly and meets your cleaning needs.

Engine serves as the powerhouse, converting fuel into mechanical energy. This energy drives the entire system, highlighting the importance of regular checks to maintain its functionality.

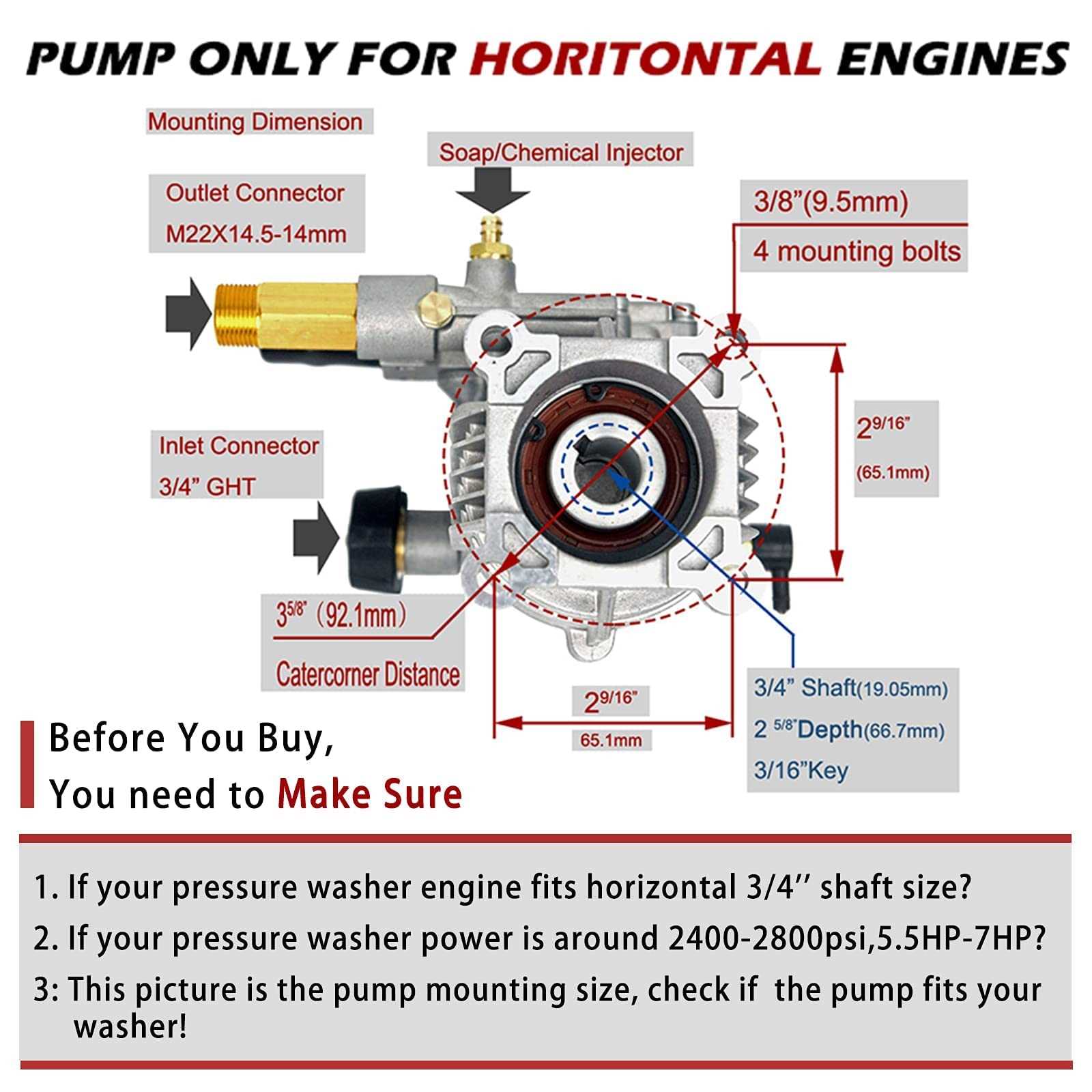

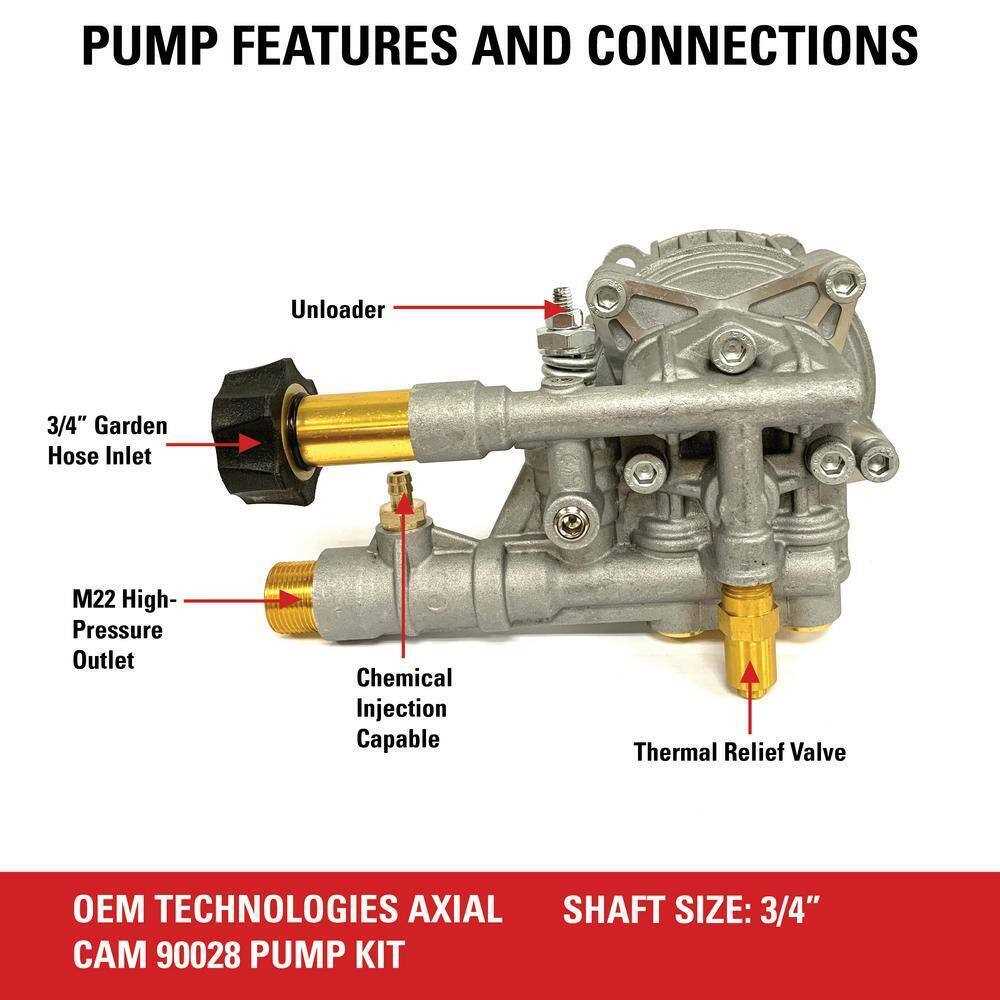

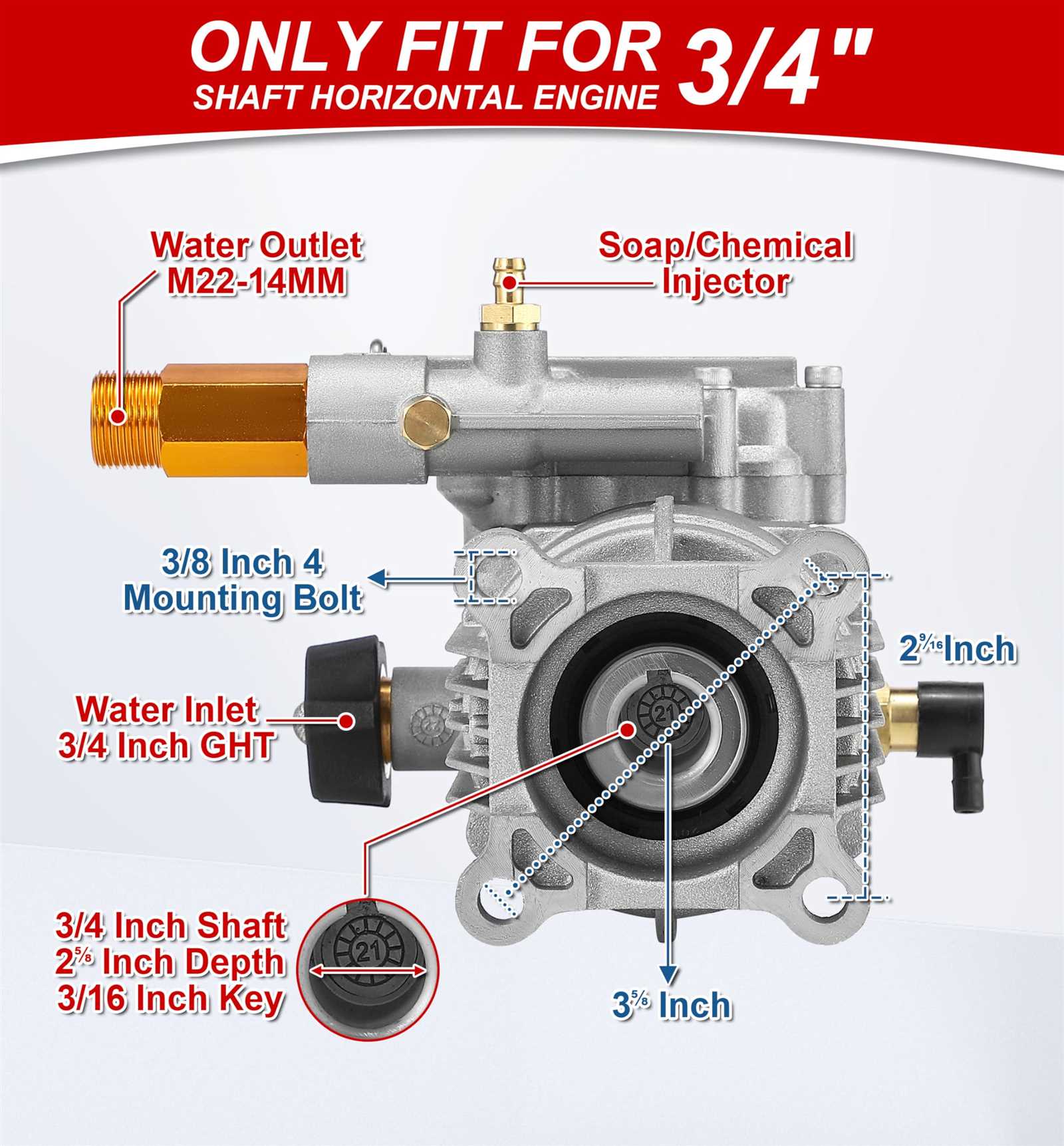

Pump is responsible for generating the necessary pressure, transforming standard water flow into a forceful stream. Understanding its operation and potential wear is vital for ensuring the longevity of your equipment.

Hoses act as the conduits for water, transporting it from the source to the cleaning nozzle. Regular inspection for wear and tear can prevent leaks and enhance overall efficiency.

Nozzle directs the flow of water, allowing for various spray patterns suited to different surfaces. Familiarity with the types of nozzles available can greatly improve cleaning results.

Each of these components, along with others like the frame and wheels, contributes to the overall functionality and effectiveness of your cleaning apparatus. Understanding their roles will empower you to maintain and utilize your equipment to its fullest potential.

Common Issues with Pressure Washer Parts

Understanding the frequent challenges associated with cleaning equipment components can greatly enhance maintenance and performance. Many users encounter problems that, if addressed promptly, can prolong the lifespan of the machine and improve efficiency.

Clogging and Blockages

Clogs are one of the most prevalent issues, often resulting from debris accumulation in the intake or nozzle. Regular cleaning and inspection can help mitigate this problem, ensuring smooth operation and consistent output.

Wear and Tear

Wear on seals, hoses, and connectors can lead to leaks and decreased functionality. It is essential to replace worn components regularly to maintain optimal performance and prevent further damage.

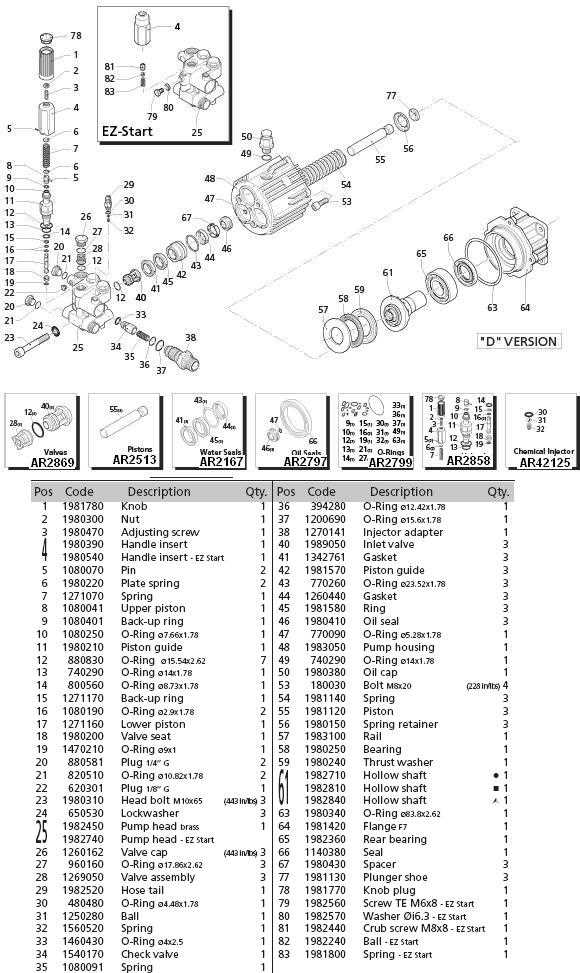

How to Read a Parts Diagram

Understanding an illustration that outlines components can significantly enhance your ability to identify and replace various elements in machinery. This guide will help you navigate the essential features and symbols commonly found in these illustrations.

Here are key steps to effectively interpret an illustration:

- Familiarize Yourself with the Legend:

The legend provides crucial information about symbols and color codes. Make sure to refer to it as you analyze the visual.

- Identify the Components:

Look for labeled parts, which often correspond to specific items within the machinery. Each component is typically numbered for easy reference.

- Understand Connections:

Pay attention to lines or arrows that indicate how parts are connected or interact. This will help you grasp the assembly’s function.

- Check for Annotations:

Annotations may provide additional insights, such as dimensions or material specifications. These details can be vital for accurate replacements.

By following these steps, you can efficiently analyze and utilize the illustration to support your maintenance or repair tasks.

Essential Tools for Maintenance Tasks

Proper upkeep of equipment and tools is crucial for ensuring their longevity and efficiency. Having the right implements on hand not only simplifies the process but also enhances the quality of the work performed. Below are some key instruments that can facilitate various maintenance activities.

Basic Hand Tools

- Screwdrivers: Essential for fastening and loosening screws of different sizes.

- Wrenches: Ideal for gripping and turning nuts and bolts.

- Pliers: Useful for holding objects firmly and cutting wires.

- Hammers: Necessary for driving nails and assembling parts.

Specialized Maintenance Instruments

- Grease Gun: Important for lubricating moving parts to reduce friction.

- Multimeter: Essential for measuring electrical values and diagnosing issues.

- Torque Wrench: Crucial for applying precise force to bolts and nuts.

- Safety Goggles: Necessary for protecting eyes during various tasks.

Equipping yourself with these essential tools will enhance your maintenance capabilities, making each task more efficient and effective.

Identifying Wear and Tear on Parts

Understanding the signs of degradation in equipment components is essential for maintaining optimal functionality and extending lifespan. By recognizing these indicators early, users can prevent minor issues from evolving into significant malfunctions. This section will explore common signs of wear, helping you to assess your machinery effectively.

Common Indicators of Damage

Look for visible signs such as cracks, discoloration, or excessive corrosion on metal surfaces. Gaskets and seals often show wear through leaks or deformation, indicating they may need replacement. Furthermore, inspect moving components for unusual noises or resistance during operation, which could suggest internal damage.

Maintenance Tips

Regular inspections are key to identifying potential problems. Clean all surfaces to remove debris and grime that can hide issues. Additionally, keep a log of any irregularities observed during use to track the performance over time. By adopting a proactive approach, you can ensure that your equipment remains in peak condition.

Where to Buy Replacement Components

Finding the right components for your cleaning machine can be essential for maintaining its efficiency. Numerous sources are available, ranging from online retailers to local shops, offering various options to suit your needs.

Online Marketplaces: Websites such as Amazon, eBay, and specialized retailers provide a wide selection of components, often at competitive prices. You can easily compare different brands and read customer reviews to make informed decisions.

Local Hardware Stores: Your neighborhood hardware store may stock essential components, allowing you to inspect items before purchasing. This can be especially beneficial if you need assistance from staff who are knowledgeable about the products.

Manufacturer Websites: Directly visiting the official site of the manufacturer can be advantageous. They typically offer authentic components and detailed information on compatibility, ensuring you find exactly what you need.

Repair Shops: Local repair services often have access to high-quality components and can provide expert advice. Consulting them may save you time and ensure proper installation.

Ultimately, choosing the right source for replacement components can enhance the longevity and performance of your equipment.

Step-by-Step Repair Guide

This guide provides a clear and concise approach to fixing common issues associated with your cleaning device. By following these steps, you can efficiently identify problems and apply effective solutions, ensuring your equipment operates at peak performance.

Before you start, gather all necessary tools and replacement components. Familiarize yourself with the layout of your equipment to make the repair process smoother.

| Step | Action | Notes |

|---|---|---|

| 1 | Disconnect from power source | Safety first–always ensure the unit is off. |

| 2 | Inspect hoses for damage | Look for cracks or leaks that may affect functionality. |

| 3 | Check the motor for issues | Listen for unusual sounds or vibrations during operation. |

| 4 | Replace worn or damaged components | Use only manufacturer-approved parts for replacements. |

| 5 | Reassemble the unit carefully | Ensure all connections are secure before reconnecting to power. |

| 6 | Test the equipment | Run a short cycle to verify that everything functions correctly. |

By adhering to these steps, you can effectively troubleshoot and resolve issues, prolonging the life of your cleaning apparatus.

Upgrading Your Pressure Washer’s Efficiency

Enhancing the performance of your cleaning machine can lead to significant improvements in its functionality and longevity. By implementing a few strategic upgrades, you can boost its effectiveness, reduce operational costs, and achieve superior results in your cleaning tasks.

Optimal Maintenance Practices

Regular upkeep is essential for ensuring that your equipment runs smoothly. Cleaning filters and checking hoses for wear and tear can prevent inefficiencies. Additionally, using high-quality fluids and lubricants designed for your specific model can enhance performance and extend the lifespan of components.

Upgrading Components for Better Performance

Consider investing in enhanced nozzles or attachments that improve the versatility of your device. Upgraded accessories can provide various spray patterns, allowing for tailored cleaning solutions. Furthermore, a more powerful motor or pump can drastically increase output and reduce cleaning time, making your chores quicker and more efficient.

Preventive Maintenance Tips for Longevity

Ensuring the extended life of your cleaning equipment requires consistent care and attention. By implementing a few simple yet effective maintenance practices, you can enhance performance and avoid unnecessary repairs. Regular upkeep not only improves efficiency but also contributes to a more satisfying user experience.

1. Regular Inspections: Periodically check all components for signs of wear and tear. Look for cracks, leaks, or corrosion that may indicate the need for replacement or repair.

2. Clean Filters and Hoses: Keeping filters and hoses free from debris is essential for optimal functionality. Rinse them regularly to prevent clogs that can hinder performance.

3. Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This helps reduce friction and prolongs the lifespan of components.

4. Use Quality Supplies: Invest in high-quality cleaning solutions and accessories. Substandard products can damage equipment and decrease efficiency.

5. Store Properly: When not in use, store your machine in a clean, dry place. Protect it from extreme temperatures and moisture to avoid potential damage.

6. Follow Usage Guidelines: Adhere to the operational guidelines outlined in the user manual. Proper usage minimizes stress on the equipment and ensures optimal performance.

By following these preventive measures, you can significantly extend the life of your cleaning device, ensuring it remains a reliable tool for all your tasks.