The complexity of today’s laundry devices often goes unnoticed, but they consist of a wide array of elements working together to ensure efficiency and reliability. Each element plays a vital role in the overall functionality, allowing the device to perform its essential tasks smoothly. Whether you’re dealing with everyday garments or more delicate fabrics, these systems ensure that the process is both effective and gentle on your clothes.

When it comes to maintenance or repair, recognizing the individual elements of these systems is crucial. From key internal mechanisms that manage water flow to specialized parts responsible for various cycles, understanding how they function can save time and effort. Proper knowledge of these components can also help in identifying potential issues before they escalate into more serious problems.

By exploring the intricate connections between these various elements, you gain valuable insight into their role in maintaining the performance of your household appliance. This knowledge not only helps in troubleshooting but also enhances your appreciation for the technology behind these essential home devices.

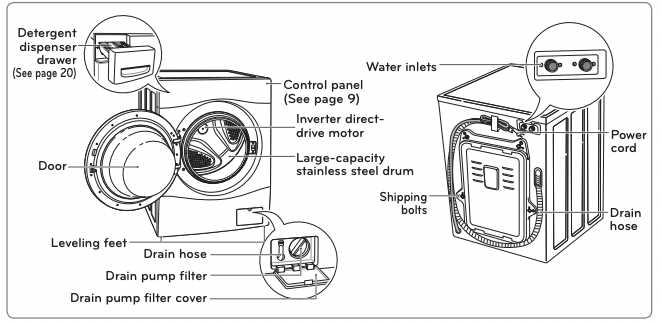

Overview of LG Front Load Washer Components

This section delves into the essential elements of LG’s advanced cleaning appliance, providing insight into their functions and interconnections. Understanding these components is crucial for both users and technicians to ensure optimal performance and maintenance.

Main Elements

The key components contribute to the effective operation of the device. Each element plays a specific role, enhancing the overall efficiency of the appliance. Below is a brief overview of some significant parts:

| Component | Function |

|---|---|

| Drum | Holds the laundry and facilitates the cleaning process through rotation. |

| Motor | Powers the rotation of the drum, enabling various washing cycles. |

| Pump | Removes water from the drum after rinsing, ensuring a proper cycle. |

| Control Panel | Allows users to select settings and monitor the wash cycle progress. |

| Suspension System | Stabilizes the drum during operation, minimizing vibrations. |

Additional Features

In addition to the primary components, various features enhance usability and efficiency. These may include energy-saving options, sensor technology for load detection, and smart connectivity for remote operation.

Main Functions of Key Washing Machine Parts

Understanding the essential components of a laundry appliance reveals their unique roles in ensuring effective performance. Each element contributes significantly to the overall functionality, working in harmony to deliver optimal cleaning results. The interplay of these components is crucial for achieving the desired outcomes in the laundry process.

| Component | Function |

|---|---|

| Drum | Houses garments during the cleaning cycle, allowing for thorough agitation and effective rinsing. |

| Agitator | Moves clothes within the drum to enhance friction and promote deep cleaning. |

| Pump | Removes dirty water after the washing cycle, ensuring proper drainage for the next phase. |

| Motor | Powers the drum’s rotation and agitator’s movements, providing the necessary force for operation. |

| Control Panel | Allows users to select settings, customize cycles, and monitor the status of the appliance. |

| Heating Element | Heats water to the desired temperature, enhancing detergent efficacy and stain removal. |

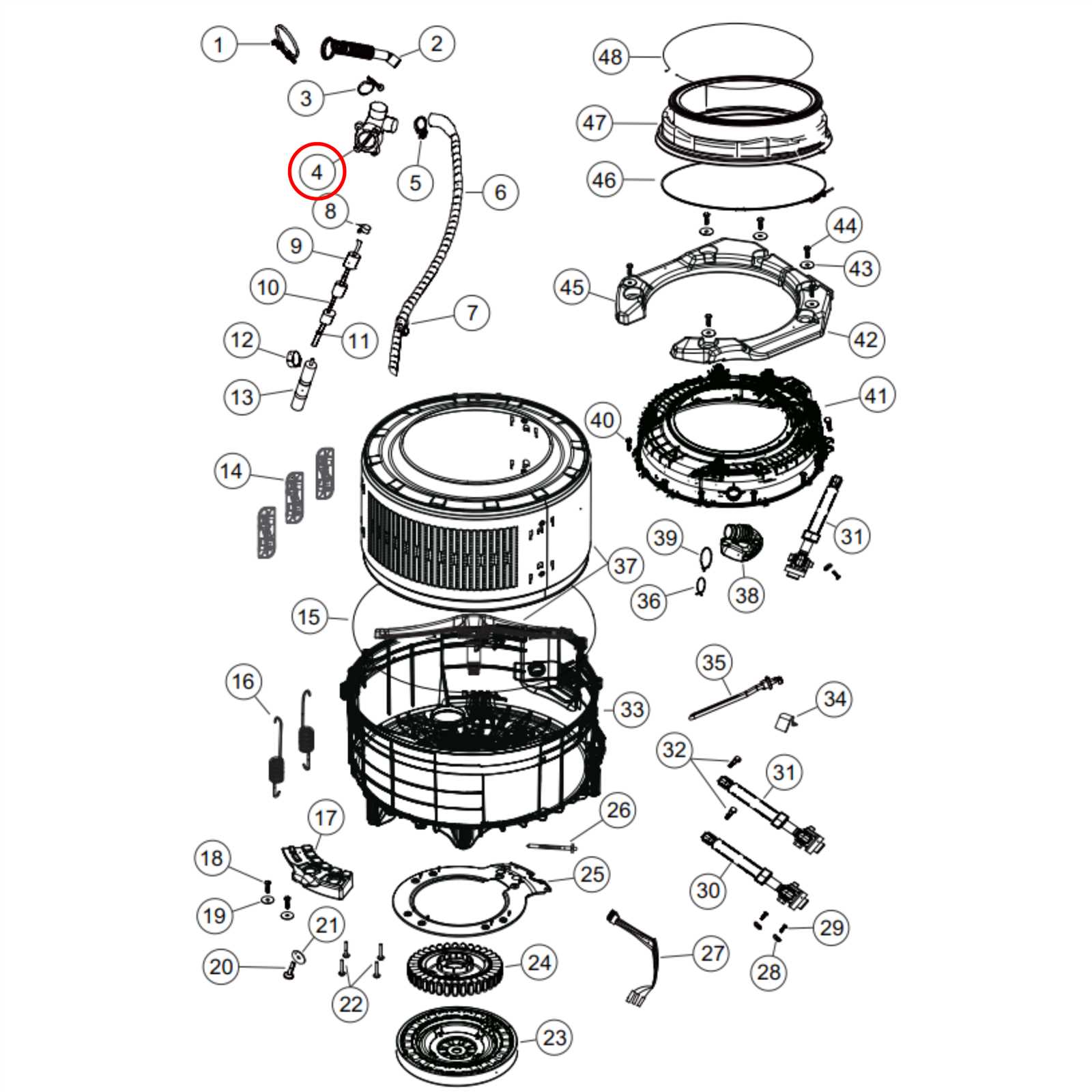

Understanding the Drum and Tub Assembly

The assembly of the drum and tub plays a crucial role in the functionality of any laundry appliance. This combination is designed to facilitate efficient cleaning and rinsing cycles while ensuring durability and reliability. Understanding its structure and operation can help users optimize performance and maintain the longevity of the appliance.

The drum, typically located within the outer tub, is where garments are placed for cleaning. It is engineered to rotate during operation, creating the necessary agitation to remove dirt and stains. The outer tub, on the other hand, serves as a container that holds water and supports the drum’s movement.

| Component | Description |

|---|---|

| Drum | The inner cylinder that rotates to agitate clothes. |

| Outer Tub | The stationary container that holds water during cycles. |

| Mounting Springs | Supports the drum and absorbs vibrations during operation. |

| Seals | Prevent water leakage between the drum and outer tub. |

Understanding these components and their functions helps users recognize the importance of maintenance and the impact of wear and tear on the efficiency of the unit.

The Role of the Water Inlet Valve

The water inlet valve is a crucial component in the functionality of a laundry appliance, playing a significant part in controlling water flow during the operation cycle. This element is responsible for managing the entry of water, ensuring that the right amount reaches the internal system for efficient performance.

Typically, the water inlet valve operates as follows:

- It opens and closes to regulate water flow based on the appliance’s settings.

- When activated, it allows water to enter the drum, facilitating the cleaning process.

- It ensures the appropriate temperature is maintained by mixing hot and cold water when necessary.

Maintaining the water inlet valve is essential for optimal performance. Regular checks can prevent issues such as:

- Inadequate water supply, leading to poor cleaning results.

- Water leaks, which can cause damage to surrounding areas.

- Inconsistent water temperature, affecting the overall washing experience.

Understanding the function of this component helps in troubleshooting and ensuring the longevity of the appliance. Prompt attention to any signs of malfunction can enhance efficiency and reliability.

Significance of the Control Panel in Operation

The control interface serves as the central hub for managing various functions and settings within the appliance. It plays a crucial role in user interaction, allowing individuals to select specific cycles, adjust timings, and customize operations according to their preferences.

Moreover, this panel provides essential feedback through indicators and displays, enhancing the overall user experience. It ensures that individuals remain informed about the current state of the appliance, promoting efficient usage and maintenance.

By facilitating seamless communication between the user and the appliance, the control interface contributes significantly to operational efficiency. Its design and functionality are vital for ensuring that all cycles run smoothly and effectively, ultimately leading to optimal performance.

How the Drain Pump System Works

The drainage mechanism in modern appliances plays a crucial role in ensuring efficient operation. This system is designed to remove excess water after a cycle, preventing overflow and maintaining optimal performance. Understanding how this component functions is essential for troubleshooting and maintenance.

Components of the Drainage System

The main elements of the drainage setup include the pump, hoses, and filters. The pump actively expels water, while the hoses facilitate its movement towards the designated outlet. Filters prevent debris from clogging the system, ensuring a smooth flow.

Operational Process

When a cycle concludes, the control unit activates the pump, initiating water removal. As the pump operates, it creates suction, drawing water through the hoses and pushing it out. This process not only eliminates excess liquid but also helps to maintain the appliance’s overall efficiency.

Exploring the Motor and Belt Mechanism

The intricate system that drives a laundry appliance is essential for its operation. At the heart of this system are two crucial components: the motor and the belt. Together, they form the backbone of the machine’s functionality, facilitating the smooth rotation and movement necessary for effective cleaning.

Understanding the Motor’s Role

The motor serves as the powerhouse of the device, converting electrical energy into mechanical motion. This process is vital for the following reasons:

- It enables the rotation of the drum.

- It controls the speed and efficiency of the operation.

- It can adapt to different cycles and settings.

In modern designs, motors are often equipped with advanced features that enhance their performance, ensuring reliable and quiet operation.

The Function of the Belt

The belt is a key link between the motor and the drum. It plays a significant role in transmitting power from the motor to the drum, allowing for movement. Important aspects include:

- Durability and resistance to wear over time.

- Flexibility to accommodate various drum sizes.

- Efficient energy transfer to minimize power consumption.

Understanding these components and their interactions is crucial for anyone looking to troubleshoot or maintain their appliance effectively.

Identifying Common Washer Door Parts

Understanding the various components of the entrance mechanism can enhance maintenance and troubleshooting efforts. Each element plays a crucial role in ensuring effective functionality and user safety. Recognizing these parts can help you diagnose issues more efficiently and facilitate timely repairs.

Key Components of the Entrance Assembly

The entrance assembly typically includes several essential elements. Among these, the latch mechanism secures the door during operation, preventing accidental openings. The hinge allows smooth movement when opening and closing, ensuring a tight seal to maintain proper operation. Additionally, a rubber gasket creates a watertight barrier, minimizing leaks and preventing water from escaping during cycles.

Understanding the Control Mechanisms

Control systems integrated into the entrance assembly are vital for functionality. The door lock switch prevents operation unless the door is securely closed, safeguarding users from potential hazards. Furthermore, the sensor detects the door’s position, providing feedback to the overall system. Recognizing these control features can aid in identifying malfunctions and ensuring the safety of the appliance.

Maintaining the Detergent Dispenser Effectively

To ensure optimal performance of your cleaning appliance, regular care of the dispensing unit is essential. This component plays a crucial role in the overall cleaning process, delivering the right amount of detergent at the appropriate time. By following a few simple maintenance steps, you can enhance its efficiency and prolong its lifespan.

Regular Cleaning: It is vital to periodically remove and clean the dispenser. Residue from detergents can accumulate over time, leading to clogs and ineffective operation. Detach the unit and rinse it under warm water, using a soft brush to eliminate any stubborn buildup.

Check for Blockages: Inspect the dispensing area for any obstructions that might hinder the flow of liquid. Ensure that the inlet holes are clear and free from debris. A blockage can prevent the proper distribution of detergent, affecting the cleaning results.

Proper Usage: Use the recommended type and amount of cleaning agents to avoid excess suds and residue. Following the manufacturer’s guidelines ensures that the dispenser operates efficiently, minimizing wear and tear.

Seasonal Maintenance: Consider performing a thorough inspection of the unit at the beginning of each season. This practice allows you to address any potential issues before they escalate, ensuring consistent performance throughout the year.

By implementing these straightforward maintenance practices, you can keep your dispensing unit in excellent condition, facilitating effective cleaning while avoiding common problems associated with neglect.