Understanding the internal structure and configuration of complex equipment is crucial for ensuring smooth operation and longevity. This section offers a detailed look into the essential mechanical elements, providing clarity on their roles and interactions within the system. Whether you’re troubleshooting or performing routine maintenance, having a clear understanding of how each element functions can make all the difference.

Each piece plays a vital role in the overall functionality of the equipment. From the driving mechanism to the smaller connecting elements, every component must work in harmony. In the following overview, you will find explanations of various important mechanisms that contribute to the efficient performance of the machine.

Ensuring the proper fit and alignment of these elements not only boosts performance but also helps prevent wear and tear. By familiarizing yourself with the main components, you’ll be better prepared to maintain and service the equipment effectively, ensuring its long-lasting operation.

Stihl MS460 Parts Diagram Overview

In this section, we’ll explore the key components and how they are interconnected to ensure the efficient operation of a robust chainsaw model. Understanding the layout and arrangement of each element is crucial for both maintenance and repairs.

Here’s a breakdown of some of the main areas to focus on when reviewing the visual guide:

- Engine assembly: The core power source that drives the entire tool, requiring periodic attention to maintain optimal performance.

- Fuel system: Comprising several interconnected parts responsible for delivering fuel efficiently to keep the machine running smoothly.

- Ignition system: Ensures proper starting and consistent operation, often requiring replacement of smaller elements over time.

- Bar and chain: The primary cutting mechanism that demands regular inspection and sharpening for effective use.

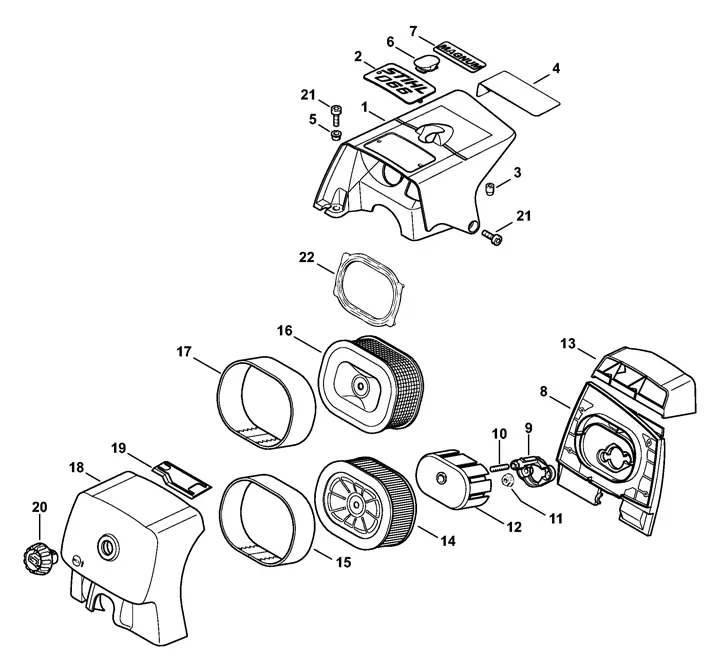

- Air filtration: Designed to prevent debris from entering the motor, prolonging its life and maintaining high efficiency.

Regular examination of these components helps ensure that the machine remains in good working order, preventing larger issues from arising unexpectedly.

Key Components of the Stihl MS460

Understanding the main elements of this high-performance tool is essential for maintaining its efficiency and longevity. Each component works together to ensure smooth operation, whether you’re cutting through dense wood or handling other demanding tasks. Below, we outline the most important sections and their roles in keeping the machine running optimally.

Engine System: The heart of the machine, responsible for generating the power required for heavy-duty tasks. A properly maintained engine ensures reliable performance even under challenging conditions.

Ignition Mechanism: This part triggers the spark needed to start the machine. A reliable ignition ensures smooth startups and consistent operation during use.

Fuel System: Comprising the fuel tank and delivery lines, this system is critical for supplying the engine with a steady flow of fuel. Proper fuel management helps maintain efficiency and prolongs the lifespan of the tool.

Chain and Bar Assembly: These work in unison to perform the actual cutting. The chain’s sharpness and the bar’s alignment are crucial for precise and safe operation.

Air Filtration: This component prevents dust and debris from entering the engine. Regular cleaning or replacement of the filter is necessary to avoid performance issues.

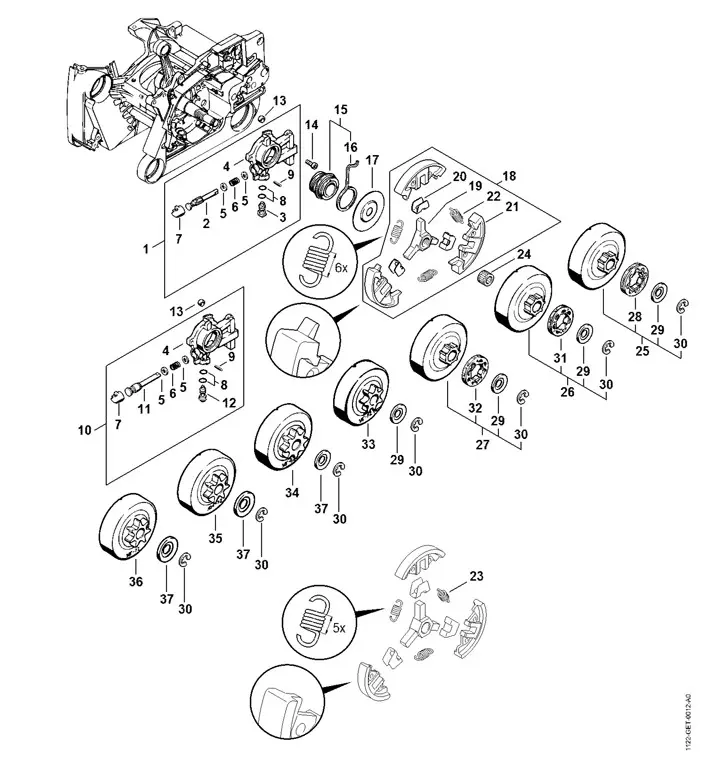

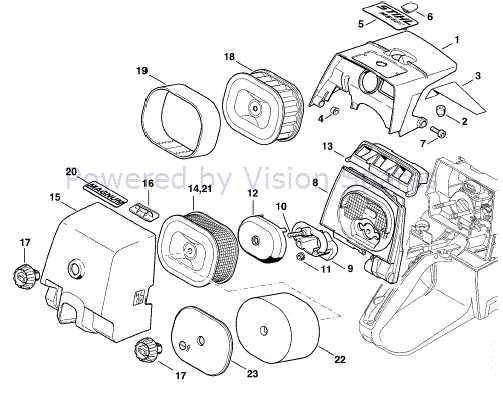

Engine Assembly Breakdown

The internal structure of a chainsaw’s power unit is a complex yet efficient system, designed for optimal performance. Understanding how each component connects and interacts within this system is essential for proper maintenance and repair. From the core combustion chamber to peripheral elements like seals and gaskets, the engine assembly contains several critical elements that contribute to the tool’s smooth operation.

Key Components

The engine assembly includes fundamental elements like the crankshaft, piston, and cylinder, which work together to generate the necessary motion. Additionally, parts such as the flywheel and carburetor play significant roles in ensuring fuel is properly mixed and delivered, and the engine runs at optimal speed. All these parts are strategically placed within the engine housing, allowing for effective heat dissipation and energy transfer.

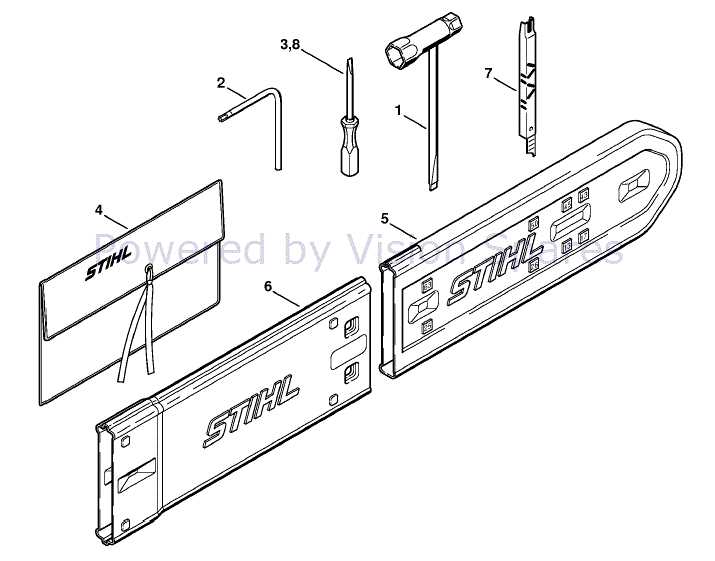

Chainsaw Bar and Chain Structure

The structure of a chainsaw’s cutting system is crucial for efficient operation. It consists of several key components that work together to ensure precise cutting and durability during use. Understanding these elements will help maintain the chainsaw’s performance over time.

- Guide Bar: The long, flat component that holds the chain in place and provides a stable surface for the chain to rotate around. It comes in various lengths depending on the type of cutting tasks.

- Chain: A loop of interconnected teeth designed to cut through wood. The sharpness and quality of the chain impact the cutting efficiency and safety of the tool.

- Drive Links: Located on the inner side of the chain, these links fit into the guide bar’s groove, helping the chain rotate smoothly along the bar.

- Bar Nose: The tip of the

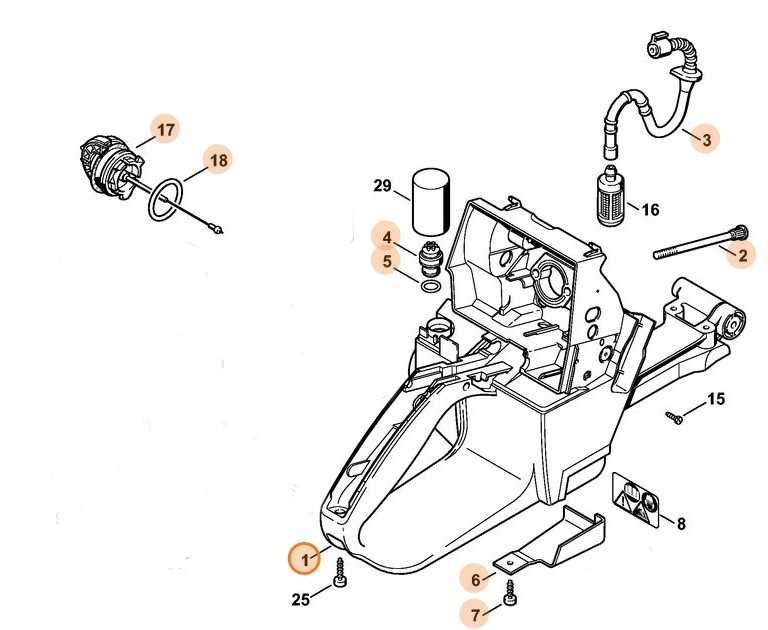

Carburetor and Fuel System Parts

The proper functioning of the engine depends heavily on the quality and condition of the fuel delivery components. A well-maintained carburetor ensures that the right mixture of air and fuel is delivered for efficient operation. Understanding the key elements involved in this system can help with maintenance and troubleshooting, allowing the engine to run smoothly under various conditions.

Carburetor: This essential component is responsible for blending fuel and air in the correct ratio before it enters the engine. Keeping it clean and properly adjusted is crucial for optimal performance.

Fuel Lines: These tubes transport fuel from the tank to the carburetor. Regular inspection for cracks or blockages is important to prevent any disruptions in fuel flow.

Fuel Filter: Positioned along the fuel line, the filter ensures that impurities do not reach the carburetor, which could lead to clogs or poor performance. Replacing it periodically helps maintain system integrity.

Primer

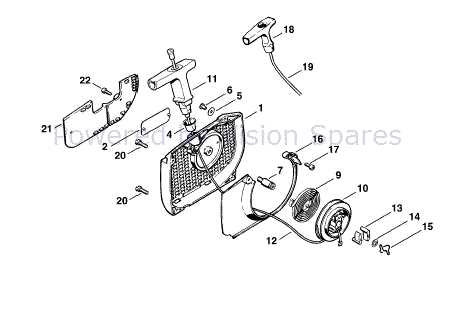

Ignition System Components

The ignition system is a crucial part of any engine, responsible for initiating combustion within the combustion chamber. This system typically consists of several components that work together to create and deliver a spark, ensuring the engine runs efficiently and reliably. Understanding each element’s function is essential for maintaining optimal performance and troubleshooting potential issues.

Key elements of the ignition system include the spark plug, which ignites the fuel-air mixture, and the ignition coil, responsible for transforming battery voltage into a high-voltage spark. Additionally, the ignition module plays a vital role in controlling the timing of the spark, ensuring it occurs at the right moment for effective combustion. Other important parts may include wires and connectors that facilitate the flow of electrical current between these components.

Regular inspection and maintenance of the ignition system components can help prevent engine misfires and starting problems, contributing to the overall longevity and efficiency of the equipment.

Handle and Control Mechanism Layout

The arrangement of the grip and control systems in a chainsaw is vital for ensuring optimal operation and user comfort. This layout not only facilitates ease of use but also enhances safety during operation. A well-designed handle and control configuration allows the operator to maintain a firm grip while accessing all necessary functions without unnecessary strain.

Ergonomics of the Handle

Ergonomic design is crucial in the construction of the handle. It should be shaped to fit comfortably in the user’s hand, providing a secure grip that minimizes fatigue during extended use. The materials used should offer a non-slip surface, enhancing control even in wet conditions. Proper positioning of the handle enables the user to maneuver the tool effectively, reducing the risk of accidents.

Control Layout and Accessibility

The layout of control mechanisms is another critical aspect of the design. All controls, including throttle and stop functions, should be intuitively placed within easy reach of the operator’s fingers. This arrangement ensures quick response times and allows for seamless operation, which is essential in high-pressure situations. Clearly labeled controls further improve usability, enabling operators to make adjustments with confidence.

Maintenance Tips for Chainsaw Parts

Proper upkeep of a chainsaw is crucial for its longevity and performance. Regular maintenance not only ensures optimal functionality but also enhances safety during operation. By following a systematic approach to caring for essential components, users can prevent common issues and extend the lifespan of their equipment.

Regular Inspection

Conducting routine checks is vital to identify any wear or damage. Here are some key areas to inspect:

- Chain tension: Ensure it is neither too loose nor too tight.

- Guide bar: Look for signs of wear or bending.

- Filters: Check air and fuel filters for clogs or dirt accumulation.

- Sprocket: Inspect for signs of wear and ensure it rotates smoothly.

Cleaning and Lubrication

Keeping the chainsaw clean and well-lubricated is essential for its efficiency. Follow these steps:

- Clean the exterior regularly to remove dust and debris.

- Lubricate the chain and guide bar to reduce friction.

- Replace or clean the air filter periodically to ensure optimal airflow.

- Use appropriate oils designed for your equipment to maintain peak performance.

By adhering to these maintenance practices, users can enjoy a more reliable and efficient cutting tool for years to come.

Where to Find Genuine Stihl Parts

When it comes to maintaining outdoor power equipment, sourcing authentic components is crucial for optimal performance and longevity. Utilizing genuine items ensures that your tools function as intended and are safe to operate. Many users often wonder where they can locate these original components for their machines.

Authorized Dealers: One of the most reliable sources for authentic replacements is through certified retailers. These establishments not only offer a wide range of components but also provide expert advice and support tailored to your specific model.

Online Marketplaces: Numerous websites specialize in outdoor equipment, featuring a comprehensive selection of genuine items. Be sure to verify the seller’s credibility and check for customer reviews to ensure you’re purchasing from a trustworthy source.

Manufacturer’s Website: Visiting the official site of the equipment manufacturer can also be beneficial. Here, you can find direct links to authorized dealers and possibly even purchase components directly from the manufacturer.

Local Repair Shops: Many local repair services are equipped to sell original components and can offer personalized assistance. Consulting with professionals can also help you identify any specific needs for your equipment.

By considering these options, you can ensure that your machinery remains in top condition and continues to perform effectively for years to come.