Maintaining your lawn care machinery is essential for optimal performance and longevity. Familiarity with the various elements that comprise this equipment can significantly enhance your ability to troubleshoot issues and perform necessary repairs. By understanding these components, you can ensure that your equipment runs smoothly and effectively, enabling you to achieve a well-manicured lawn.

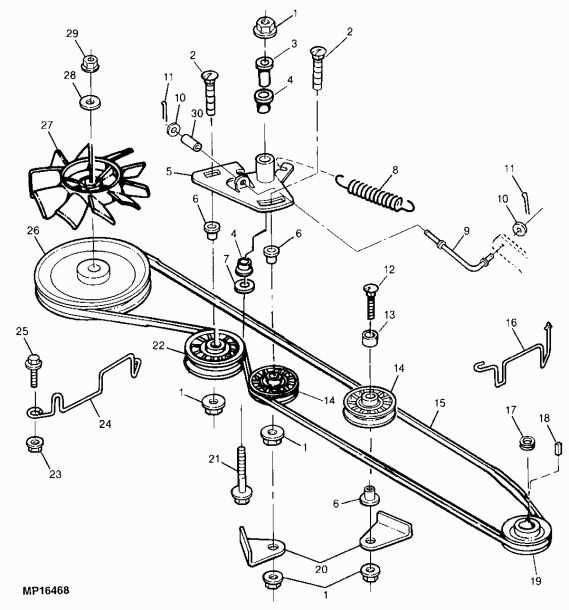

In this section, we will explore an organized visual representation of the essential elements involved in your gardening apparatus. This resource serves as a valuable tool for both novice and experienced users, facilitating a deeper comprehension of the machinery’s functionality. With a clear overview of each element, you can identify specific areas requiring attention and improve your overall maintenance practices.

Equipped with this knowledge, you will be better prepared to tackle any challenges that may arise, ensuring that your equipment remains in peak condition. This understanding not only helps in efficient repairs but also promotes a sense of confidence in managing your gardening tasks effectively.

Overview of Craftsman Riding Mower Model 917 Components

This section provides a comprehensive look at the various elements that make up the specific lawn care equipment, focusing on their functionalities and interrelations. Understanding these components is essential for effective maintenance and troubleshooting, ensuring optimal performance during operation.

The main sections of this equipment include the power source, cutting mechanism, and control systems. Each part plays a critical role in the overall functionality, contributing to a seamless and efficient mowing experience.

The engine serves as the heart of the unit, providing the necessary power for movement and operation of the cutting blades. Proper upkeep of this vital component is crucial for longevity and performance.

Additionally, the cutting assembly is engineered to deliver precise and clean results, ensuring an aesthetically pleasing lawn. Regular checks on the sharpness and condition of the blades are recommended for maintaining efficiency.

Finally, the control system allows the user to maneuver and adjust settings easily, highlighting the importance of familiarization with these features for enhanced usability.

Interpreting Key Symbols in the Parts Schematic

In navigating the graphical representation of components, understanding the symbolic language employed is crucial for effective interpretation. The diagram employs various symbols to denote distinct elements, facilitating identification and comprehension.

Symbol Key

| Symbol | Meaning |

|---|---|

| ○ | Indicates a pivot point or hinge |

| □ | Denotes a mechanical fastening point |

| Δ | Represents an electrical connection or terminal |

| ∅ | Symbolizes a fixed point or stationary component |

These symbols, devoid of textual identifiers, succinctly convey the nature and function of each component depicted within the schematic. By adhering to this symbolic lexicon, users can accurately trace parts, facilitating maintenance and repair tasks effectively.

Locating Specific Parts Using the Diagram

Understanding how to identify individual components within a visual representation can greatly enhance maintenance and repair tasks. By utilizing a detailed illustration, users can efficiently find and select the items they need for their machinery. This process simplifies the navigation through complex assemblies, ensuring accurate identification and sourcing.

Step-by-Step Identification

Begin by familiarizing yourself with the overall layout of the visual guide. Pay close attention to the labels and numbers associated with each part. This organized structure allows for quick reference and helps streamline the search for specific elements.

Using Reference Numbers

Each component typically has a unique identifier. Utilize these reference numbers to cross-check with inventory lists or suppliers. This practice ensures you obtain the correct item, reducing the likelihood of errors during repairs.

Common Maintenance Tips Based on the Diagram

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By understanding the various components and their functions, you can implement a proactive maintenance routine that minimizes issues and enhances performance. Here are some essential tips to keep your machine in optimal condition.

First, routinely check and replace the air filter. A clean filter allows for proper airflow, which is crucial for the engine’s performance. Neglecting this simple task can lead to decreased efficiency and increased fuel consumption.

Next, pay attention to the blades. Dull blades not only struggle to cut grass effectively but can also stress the engine. Sharpening or replacing blades as needed will result in a cleaner cut and promote healthy grass growth.

Additionally, regularly inspect the belts for signs of wear or fraying. Properly functioning belts ensure that the machine operates smoothly and can prevent more significant mechanical failures down the line.

Don’t forget to check the oil level and quality. Keeping the engine well-lubricated is vital for its health. Change the oil according to the manufacturer’s recommendations to avoid sludge buildup that can lead to engine damage.

Lastly, keep an eye on the tires. Proper inflation and tread condition are essential for stability and maneuverability. Regularly inspecting and maintaining the tires will enhance the overall handling of the equipment.

Replacing Parts: Step-by-Step Guide

Maintaining the efficiency of your outdoor equipment often requires the replacement of certain components. This guide provides a structured approach to help you navigate the process, ensuring that you can restore your machine to optimal performance with ease and confidence.

Step 1: Gather Necessary Tools and Materials

Before starting the replacement process, make sure you have all the required tools at hand. Common items include wrenches, screwdrivers, and safety gloves. Additionally, have the new components ready for installation.

Step 2: Disconnect Power Source

Safety is paramount. Always disconnect the power source to prevent any accidental starts while you’re working. This step is crucial to ensure your protection during the replacement process.

Step 3: Remove the Old Component

Carefully examine how the existing part is secured. Use the appropriate tools to detach it, making sure to keep track of any screws or fasteners that may be needed for the new piece.

Step 4: Install the New Component

Position the new part in place, aligning it with the existing mounts. Secure it firmly using the screws or fasteners you saved from the previous component. Ensure everything is tightened adequately to avoid any loose connections.

Step 5: Reconnect Power and Test

Once the installation is complete, reconnect the power source. Conduct a test run to confirm that the new component functions properly. Pay attention to any unusual sounds or vibrations that may indicate improper installation.

Step 6: Regular Maintenance

To prolong the lifespan of your equipment, incorporate regular checks and maintenance into your routine. This practice helps identify potential issues early and ensures that your machine remains in excellent working condition.

Understanding Part Numbers and References

In the realm of machinery maintenance and repair, having a solid grasp of identification codes is essential. These unique alphanumeric sequences serve as keys to unlocking the specifics of components, ensuring compatibility and efficiency in replacements. Recognizing how these codes function can streamline the repair process and enhance overall performance.

The Structure of Identification Codes

Typically, identification codes consist of a series of numbers and letters, each segment conveying crucial information. For instance, the initial characters often indicate the manufacturer, while subsequent numbers may relate to the specific component type or its intended use. Understanding this structure allows for quicker identification and reduces the likelihood of errors in ordering or installation.

Decoding References for Effective Repairs

Reference numbers can also differ based on the context, such as whether the part is original or an aftermarket alternative. Familiarity with these variations is vital for sourcing reliable replacements. Always consult the appropriate manuals or online resources to cross-reference and verify the details before proceeding with any repair or upgrade.

Using the Diagram for Troubleshooting

When faced with issues in your machine, having a detailed visual representation can be invaluable. This tool allows users to identify components and their interconnections, making it easier to locate potential problems. By referring to this illustration, you can methodically diagnose faults and streamline the repair process.

Begin by examining the visual closely to familiarize yourself with each part’s function. Understanding the layout helps pinpoint where malfunctions may arise. If a specific area shows signs of wear or damage, you can compare it against the corresponding section in the visual guide to determine if replacement is necessary.

Additionally, pay attention to any inconsistencies between the diagram and the physical state of your equipment. Often, parts can shift or become misaligned, leading to performance issues. The illustration serves as a reference to check that everything is in its designated place, ensuring optimal operation.

In summary, utilizing this visual aid not only simplifies the troubleshooting process but also enhances your understanding of how each element works together. This knowledge is crucial for effective maintenance and ensuring longevity of your machinery.

Additional Resources for Craftsman Mower Owners

For individuals seeking to enhance their experience with outdoor equipment, various resources can provide valuable insights and support. Whether you are looking for maintenance tips, troubleshooting guidance, or community discussions, there are numerous avenues to explore that can assist in keeping your machinery running smoothly.

Online Forums and Communities

Engaging with online forums can be an excellent way to connect with other enthusiasts. These platforms often feature discussions on common issues, shared experiences, and advice from seasoned users. Participating in these communities can help you gain new perspectives and solutions to challenges you may encounter.

Manufacturer’s Website and Support

Visiting the official website of the manufacturer offers access to a wealth of information, including user manuals, FAQs, and product support. Many sites also provide video tutorials and maintenance schedules that can help you perform essential tasks effectively. Utilizing these resources can significantly enhance your understanding and management of your equipment.