In the realm of machinery and engineering, a clear understanding of the arrangement and functionality of various elements is crucial. This knowledge not only aids in efficient operation but also enhances the ability to troubleshoot and maintain equipment effectively. The intricate relationship between individual components plays a significant role in ensuring optimal performance.

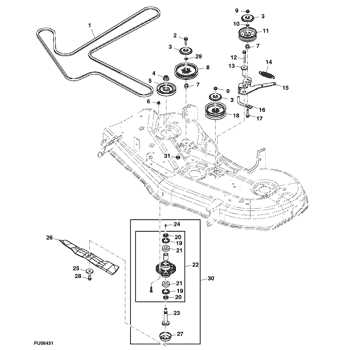

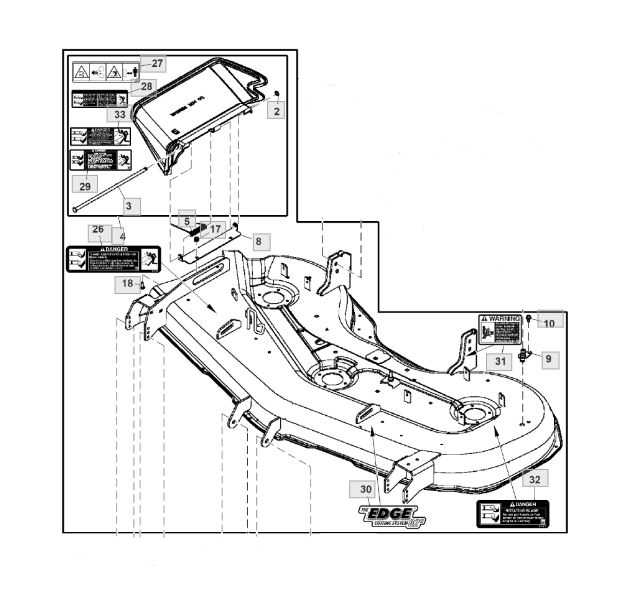

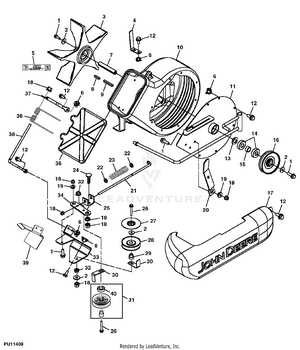

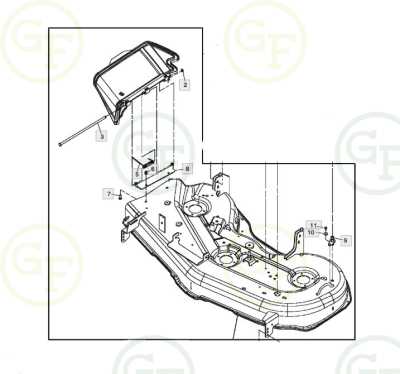

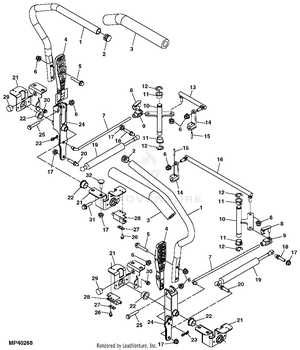

Visual representations serve as invaluable tools for those seeking to grasp the complexities of mechanical structures. By examining how different pieces interact and fit together, one can gain insights into the overall system’s efficiency and potential areas for improvement. Such illustrations offer clarity, allowing users to navigate their machinery with confidence.

Furthermore, comprehending the layout of these elements can facilitate better decision-making during repairs and upgrades. Knowing where each part resides and how it functions within the larger assembly empowers operators to address issues promptly. This not only minimizes downtime but also contributes to the longevity and reliability of the equipment.

Understanding Z445 Parts Diagram

Grasping the layout of components within machinery is essential for effective maintenance and repair. A well-organized visual representation allows users to identify each element’s function and relationship within the overall system. This understanding can significantly enhance troubleshooting efficiency and ensure optimal performance.

Importance of Visual Representations

Visual aids serve as crucial tools for technicians and operators alike. They provide clarity on the arrangement and interconnectivity of various components. By referring to these illustrations, one can quickly ascertain where specific elements are located, facilitating quicker repairs and replacements. This efficiency is vital in minimizing downtime and maintaining productivity.

Key Elements to Identify

When examining such illustrations, it’s important to focus on labels and legends that accompany the visuals. These annotations often denote essential specifications and details necessary for understanding each component’s role. Additionally, recognizing patterns and common groupings can lead to a deeper comprehension of how different sections operate together, ultimately contributing to better operational management.

Key Components of Z445 Explained

Understanding the essential elements of any mechanical system is crucial for effective maintenance and performance. This section delves into the main components that contribute to the functionality and efficiency of the equipment, providing insights into their roles and interactions.

Engine: The heart of the system, this part converts fuel into mechanical energy, powering all operations. Its efficiency directly influences the overall performance, making regular checks vital.

Transmission: This component is responsible for transferring power from the engine to the wheels. It plays a key role in determining speed and torque, allowing for smooth operation across various terrains.

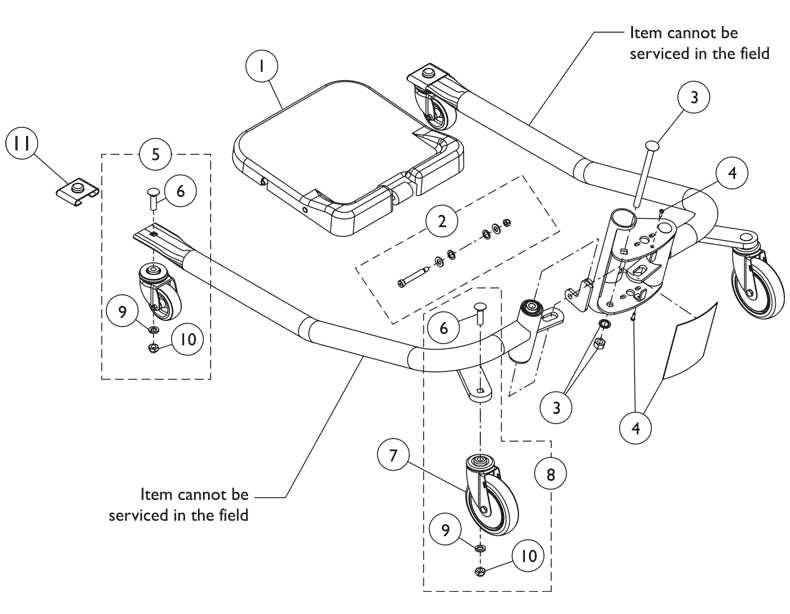

Chassis: Serving as the framework, the chassis supports the entire structure. It must be robust to withstand stresses while maintaining a lightweight profile for agility.

Hydraulic System: This system utilizes fluid power to enable lifting and steering functions. Understanding its mechanics is essential for troubleshooting and ensuring optimal operation.

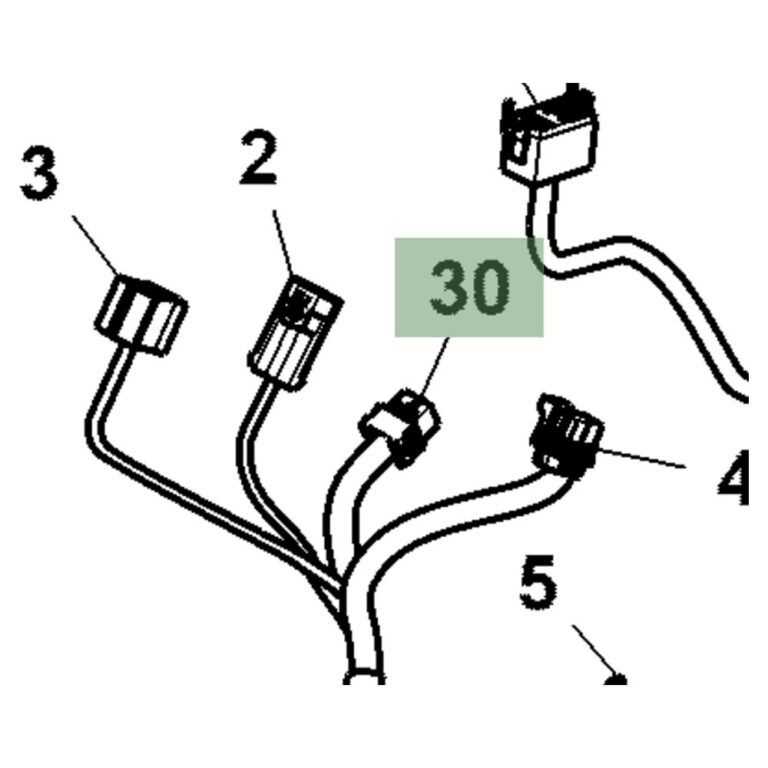

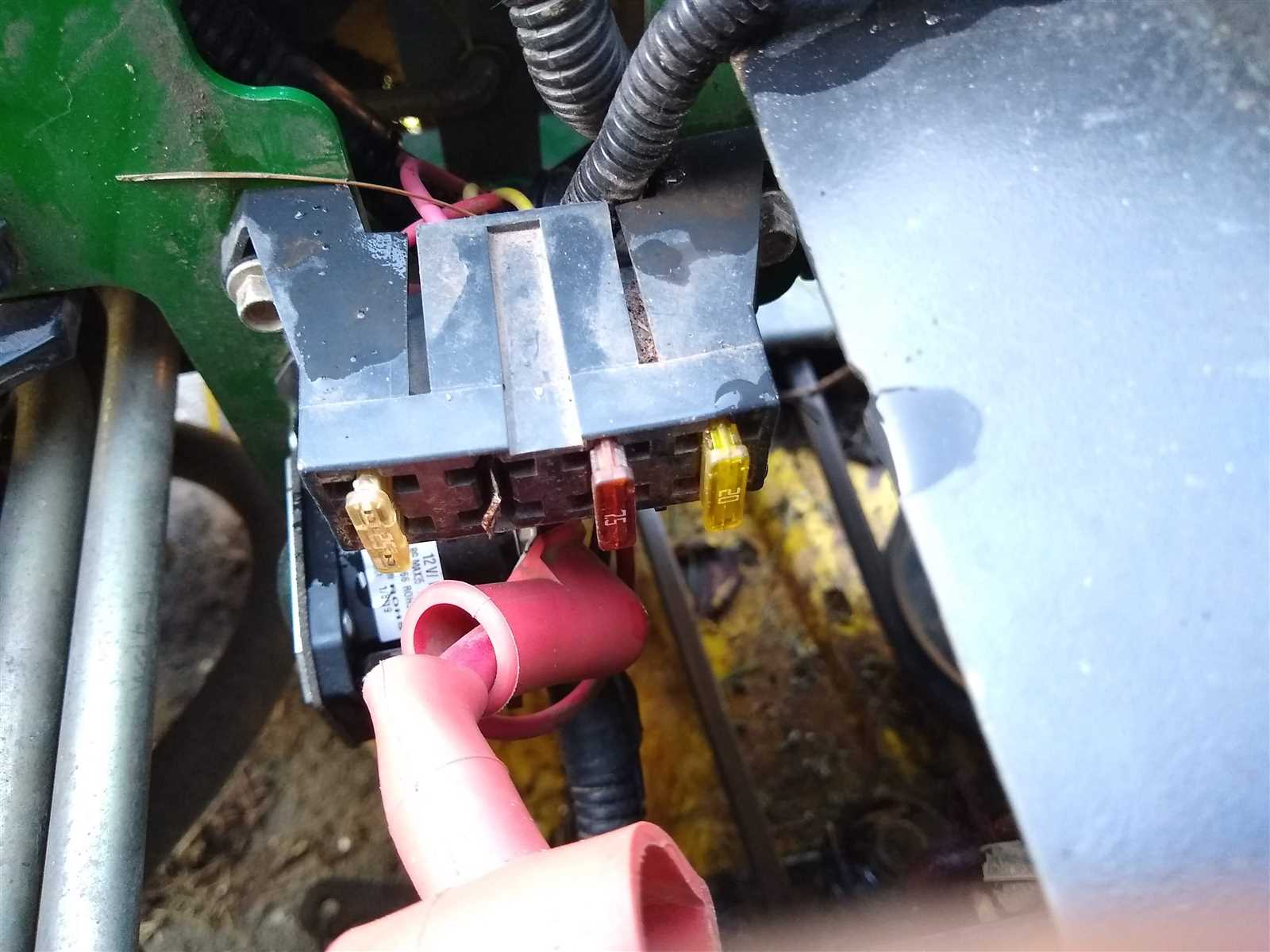

Electrical System: Comprising various wiring, switches, and batteries, this system provides the necessary power for lights, ignition, and other electronic components, contributing to the overall efficiency and safety of the machinery.

Cooling System: Essential for maintaining optimal operating temperatures, this system prevents overheating and ensures longevity. Regular maintenance helps avoid performance issues and costly repairs.

By familiarizing oneself with these key elements, operators can enhance their understanding of the machinery, leading to better maintenance practices and improved operational efficiency.

Importance of Accurate Diagrams

Precise illustrations are essential for understanding complex systems. They provide clarity, ensuring users can navigate intricacies with ease. When details are represented accurately, it fosters efficiency and minimizes errors during assembly or maintenance.

Moreover, these visual aids serve as a universal language, bridging communication gaps among diverse teams. With well-defined representations, all stakeholders can collaborate effectively, leading to enhanced productivity and streamlined processes.

| Benefits | Description |

|---|---|

| Clarity | Helps in understanding complex structures easily. |

| Efficiency | Reduces the likelihood of mistakes during tasks. |

| Collaboration | Facilitates better teamwork among diverse groups. |

| Training | Serves as a valuable resource for new personnel. |

How to Read the Z445 Diagram

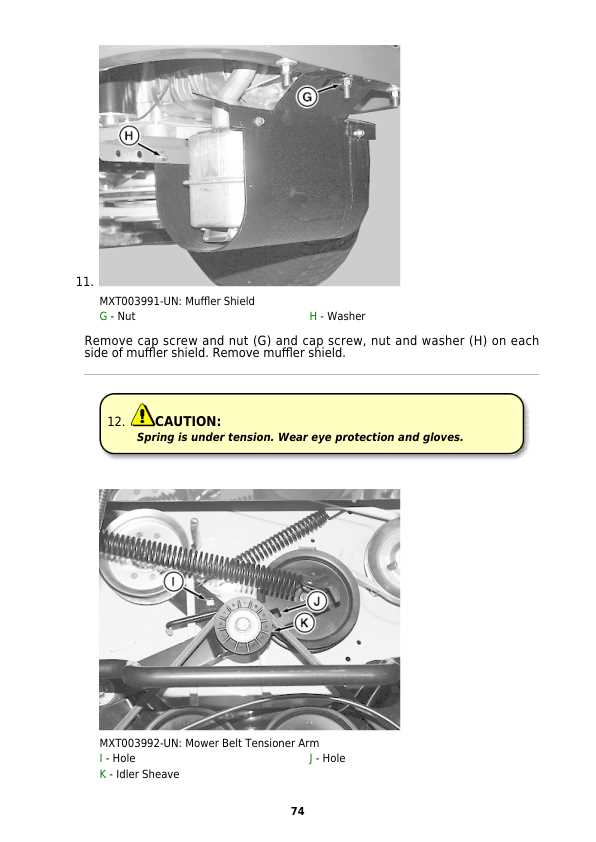

Understanding technical illustrations can greatly enhance your ability to perform maintenance and repairs. These visuals serve as essential guides, providing insights into the components and their relationships within a system. By familiarizing yourself with the conventions used in these graphics, you can efficiently identify parts and comprehend their functions.

To effectively interpret these visuals, pay attention to the following elements:

| Element | Description |

|---|---|

| Labels | Each component is typically marked with a unique identifier, making it easier to locate and reference. |

| Connections | Lines and arrows indicate how various elements interact, highlighting the flow of processes and energy. |

| Legend | A key may be provided to explain symbols or color codes used throughout the illustration. |

| Orientation | Ensure you understand the viewpoint presented; some diagrams are viewed from above, while others are side views. |

By taking the time to study these components, you can enhance your troubleshooting skills and make informed decisions during repairs. Familiarity with these illustrations is crucial for efficient maintenance and ensuring optimal performance.

Common Issues with Z445 Parts

When working with mechanical components, certain challenges often arise that can affect performance and reliability. Understanding these common complications can help in maintaining efficiency and ensuring longevity. Regular maintenance and awareness of typical failures are essential for smooth operation.

Wear and Tear

Over time, frequent use can lead to significant wear on critical components. This deterioration can manifest as friction between moving elements, resulting in reduced efficiency. Regular inspections can help identify signs of wear early, allowing for timely replacements before they cause more extensive damage.

Compatibility Issues

Incompatibility between different elements can lead to operational failures. Components that are not designed to work together may cause malfunctions or even physical damage. Ensuring that all elements are correctly matched is vital for optimal functionality and safety.

Maintenance Tips for Z445 Components

Regular upkeep of machinery components is crucial for optimal performance and longevity. By implementing a few simple practices, you can ensure that all elements function efficiently and reduce the risk of unexpected breakdowns.

- Inspect regularly for wear and tear to catch potential issues early.

- Keep all surfaces clean to prevent debris buildup, which can hinder performance.

- Lubricate moving parts as per the manufacturer’s recommendations to reduce friction.

- Check for loose fittings and tighten them to maintain stability.

Furthermore, consider the following practices:

- Schedule periodic professional assessments to identify hidden problems.

- Replace worn components promptly to prevent further damage.

- Document maintenance activities for future reference and improved planning.

By adhering to these guidelines, you will ultimately enhance the reliability and efficiency of your equipment.

Comparing Z445 to Similar Models

This section explores how the model in question stands against its counterparts, focusing on key features, performance metrics, and design elements. Understanding these differences and similarities can help consumers make informed decisions based on their specific needs.

Performance Overview

When evaluating performance, various aspects such as engine capacity, horsepower, and fuel efficiency play crucial roles. Comparing these specifications provides insights into how well each model meets operational demands.

| Model | Engine Capacity (cc) | Horsepower | Fuel Efficiency (mpg) |

|---|---|---|---|

| Model A | 600 | 20 | 25 |

| Model B | 650 | 22 | 24 |

| Model C | 700 | 21 | 26 |

Design Features

In addition to performance, the aesthetic and functional design aspects are essential for user experience. Factors such as weight, maneuverability, and user-friendly controls differentiate these machines significantly.

Finding Replacement Parts for Z445

When it comes to maintaining machinery, ensuring you have the right components is crucial for optimal performance. Locating suitable replacements can sometimes feel overwhelming, but with the right approach, the process can be streamlined. Identifying reliable sources and understanding the specifics of what you need can save time and enhance efficiency.

Identifying Necessary Components

Before searching for replacements, it’s essential to recognize which elements require attention. Conducting a thorough inspection can help determine the condition of each part. Creating a checklist of needed items can also facilitate a more organized search, making it easier to track down what you need.

Where to Search

There are various avenues to explore when looking for suitable replacements. Online retailers often have extensive catalogs, while local suppliers may provide immediate access to what you require. Additionally, forums and communities dedicated to machinery can offer valuable insights and recommendations, connecting you with experienced individuals who have faced similar challenges.

Utilizing Diagrams for Troubleshooting

Effective resolution of mechanical issues often relies on visual representations that illustrate the components and their interconnections. These schematics serve as invaluable tools for identifying and diagnosing problems, enabling technicians to streamline their approach and enhance their understanding of complex systems.

Benefits of Visual Aids in Problem Solving

- Clarity: Visual guides simplify complex structures, making it easier to pinpoint specific elements that may be malfunctioning.

- Efficiency: By quickly identifying the relevant parts, technicians can minimize time spent on repairs and reduce the risk of errors.

- Communication: These illustrations facilitate clearer communication among team members, ensuring everyone is on the same page during troubleshooting.

Steps to Effectively Use Visual Representations

- Familiarize Yourself: Spend time understanding the layout and symbols used in the visual aids to enhance your diagnostic skills.

- Identify Symptoms: Start by noting the symptoms of the issue before consulting the visual guide.

- Trace Connections: Use the illustration to follow connections between components and locate potential points of failure.

- Document Findings: Keep a record of identified issues and resolutions for future reference, contributing to a more comprehensive troubleshooting process.