The functionality of water extraction systems relies on a complex interplay of various elements working in harmony. Each component plays a crucial role in ensuring efficient operation and reliability. By delving into the intricate arrangement of these elements, one can gain insights into how they collectively contribute to the system’s overall performance.

Having a clear visual representation of these essential components enhances comprehension and allows for more effective maintenance and troubleshooting. Understanding the roles of each segment is vital for anyone involved in the management or repair of water extraction mechanisms. Knowledge of these systems empowers users to address potential issues proactively, ensuring a continuous supply of fresh water.

Through this exploration, we aim to break down the structure of these systems, emphasizing the significance of each component and how they interact. This knowledge is invaluable for both professionals and enthusiasts alike, leading to better operational practices and informed decision-making.

This section aims to provide a comprehensive overview of the essential elements involved in a water extraction system. Each component plays a crucial role in ensuring the efficient operation and longevity of the entire setup. By exploring these individual elements, readers can gain a clearer understanding of how they function together to deliver water effectively.

- Overview of the system’s purpose and functionality

- Identification of major components and their roles

- Detailed explanation of operational principles

- Common issues associated with each element

- Maintenance tips to enhance performance

Each of these topics will delve into the specific attributes and functions of the components, providing readers with the knowledge necessary to troubleshoot and maintain their systems. This structured approach will facilitate a better grasp of the intricate relationships among the various elements.

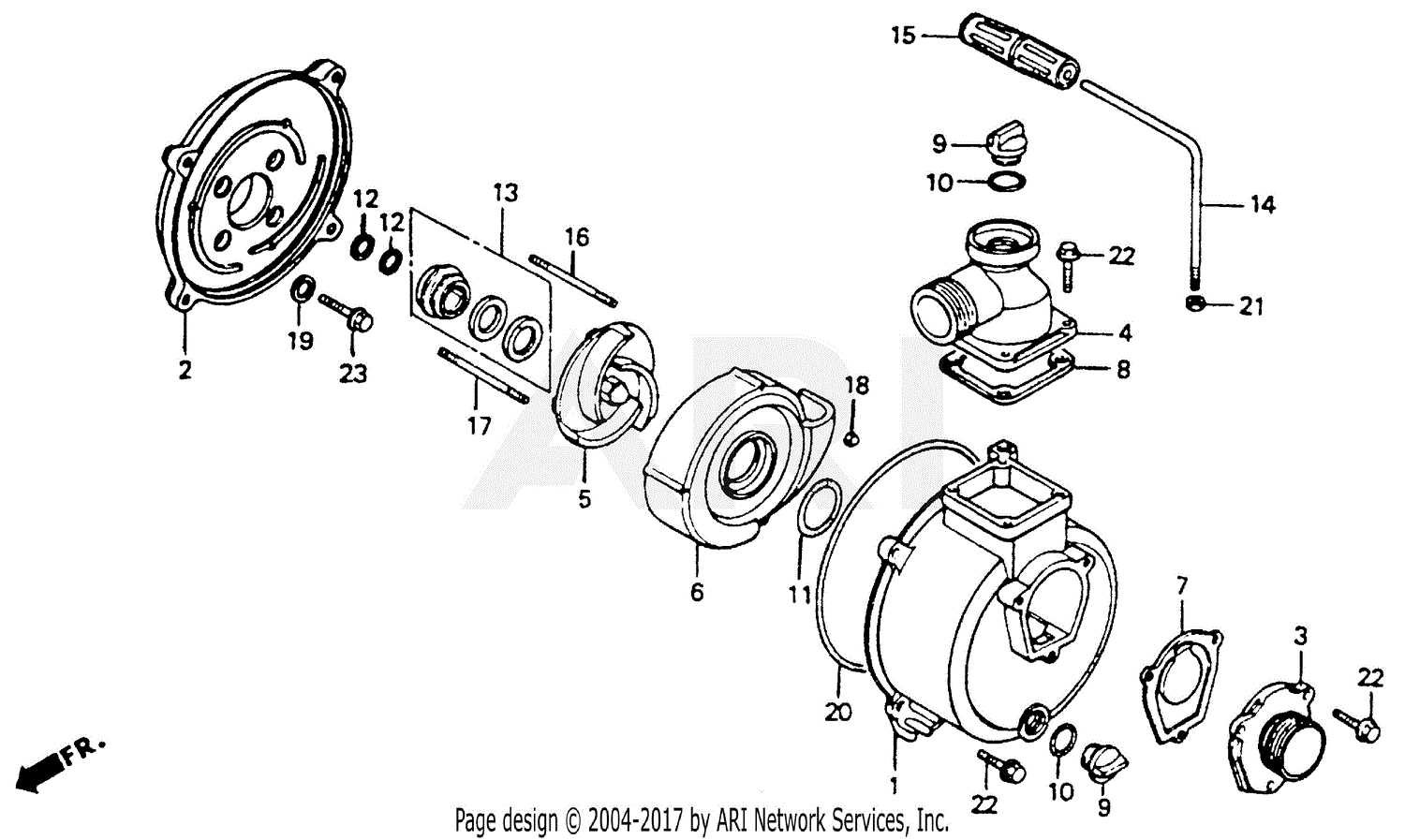

Essential Parts of a Well Pump

Understanding the fundamental components of a groundwater extraction system is crucial for its effective operation and maintenance. Each element plays a significant role in ensuring that water is efficiently drawn from underground sources to meet various needs. Below are the key elements that contribute to the overall functionality of this system.

Key Components

- Motor: This is the driving force that powers the entire system, converting electrical energy into mechanical energy to initiate water movement.

- Impeller: Acting as the heart of the mechanism, it is responsible for moving the water through rotational motion.

- Discharge Head: This top section serves as the outlet for water, directing it to the desired location.

- Check Valve: This component prevents backflow, ensuring that water does not return to the source once it has been lifted.

- Pressure Switch: This device regulates the system’s pressure, activating or deactivating the motor as needed to maintain optimal levels.

Additional Elements

- Pipe System: This infrastructure transports water from the extraction point to its intended destination.

- Strainer: Often installed at the bottom, it filters out debris and prevents larger particles from entering the system.

- Control Box: This unit houses the electrical components and switches necessary for the system’s operation.

- Float Switch: Used to monitor water levels, it triggers the motor based on predefined levels, ensuring efficient operation.

Functionality of Each Component

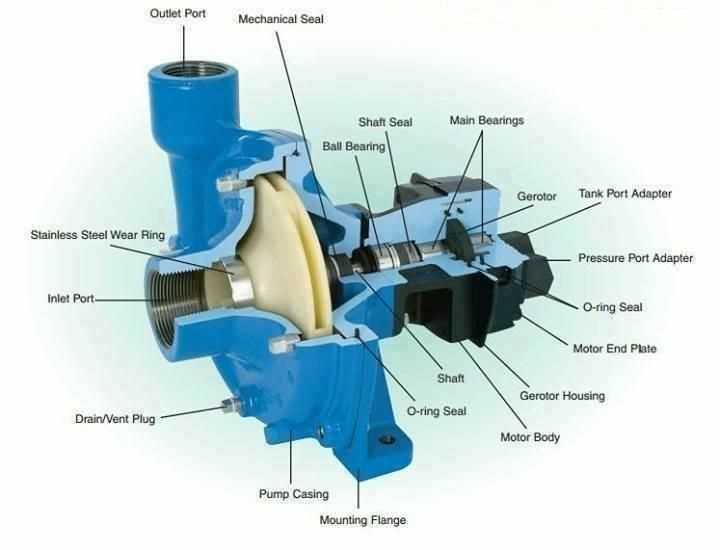

This section delves into the essential roles played by the various elements involved in the extraction system. Understanding how each component contributes to the overall operation can enhance maintenance efforts and optimize performance.

Essential Elements and Their Roles

Each element in the system has a specific purpose that contributes to the efficient retrieval of resources from beneath the surface. From initiating the movement to regulating flow, these components work harmoniously to ensure a reliable operation.

Overview of Key Functions

| Component | Function |

|---|---|

| Motor | Generates the necessary energy to initiate movement within the system. |

| Impeller | Facilitates the transfer of fluid by creating pressure through rotation. |

| Diffuser | Helps in converting kinetic energy into pressure, enhancing flow efficiency. |

| Control Switch | Regulates the operational status, allowing for automatic or manual control. |

| Check Valve | Prevents backflow, ensuring fluid only moves in the desired direction. |

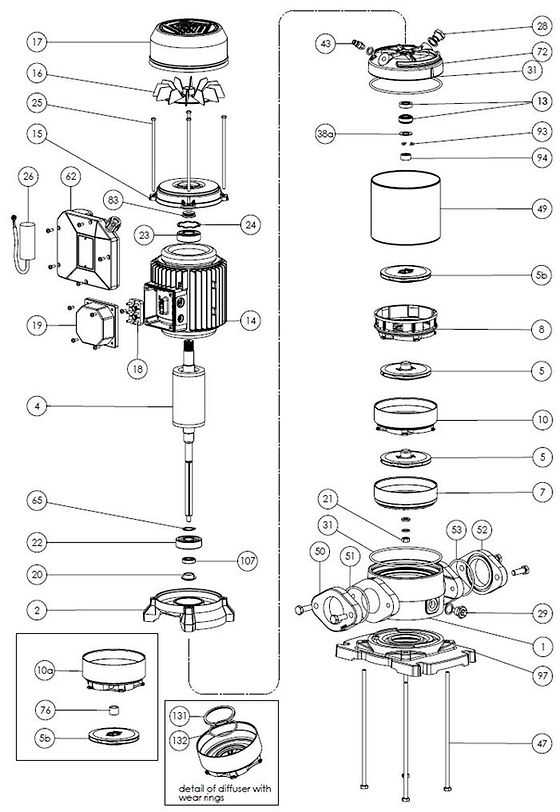

Visual Representation of Pump Parts

Understanding the components of a fluid extraction system is essential for effective operation and maintenance. This section aims to provide an illustrative overview of the various elements involved in such systems, enhancing comprehension of their functionalities and interactions. A clear visual representation aids in recognizing how each element contributes to the overall performance.

| Component | Description |

|---|---|

| Motor | The driving force behind the movement of liquid, converting electrical energy into mechanical motion. |

| Impeller | A rotating element that propels the fluid through the system, creating flow and pressure. |

| Volute | A spiral-shaped casing that directs the flow of liquid exiting the impeller, optimizing efficiency. |

| Discharge Outlet | The point where the extracted fluid exits the system, connecting to the delivery pipeline. |

| Strainer | A protective mesh that filters out debris, preventing damage to internal components. |

Common Types of Well Pumps

When it comes to extracting groundwater, several varieties of devices are designed to serve specific needs and conditions. Understanding these types can help in selecting the most suitable option for various applications, whether for residential use, irrigation, or industrial purposes.

Here are some prevalent types of extraction systems:

- Submersible Systems: These devices are submerged deep within the water source. They operate efficiently at considerable depths, pushing water to the surface through a pipe.

- Jet Systems: Utilizing a jet of water to create suction, these systems are typically installed above the ground. They work well in shallow aquifers and are known for their versatility.

- Hand-operated Units: Often found in remote areas, these manual systems provide an effective solution for drawing water without the need for electricity. They are simple in design and easy to maintain.

- Turbine Systems: Commonly used for deeper water sources, these units feature multiple stages of impellers to lift water efficiently from significant depths.

- Solar-powered Options: Harnessing solar energy, these eco-friendly systems offer a sustainable alternative, particularly in locations with ample sunlight.

Each type serves distinct functions and has its advantages, making it essential to evaluate the specific requirements before making a choice.

Installation Guidelines for Well Pumps

Properly setting up a water extraction system is crucial for optimal performance and longevity. This section outlines essential recommendations to ensure effective installation, enhancing efficiency while minimizing future maintenance challenges.

Preparation and Site Assessment

Before commencing the installation, conduct a thorough evaluation of the site. Consider factors such as soil composition, water table depth, and proximity to electrical sources. Ensuring compliance with local regulations and acquiring necessary permits is vital. Engage with professionals to assess any potential obstacles, such as nearby structures or environmental concerns.

Connection and Integration

During the assembly process, follow the manufacturer’s specifications meticulously. Utilize suitable connectors and fittings to secure all components. Ensure that the electrical system is safely integrated, using appropriate grounding techniques. Regularly inspect connections to prevent leaks and maintain system integrity.

Note: Always consult with qualified technicians if uncertainties arise during the setup process.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your water retrieval system is crucial for consistent performance. Regular care and attention can significantly extend the lifespan of your equipment, preventing costly repairs and replacements. Implementing a few simple practices can help maintain optimal functionality while promoting a reliable source of hydration.

Regular Inspections

Conducting frequent assessments of your setup can identify potential issues before they escalate. Look for signs of wear or corrosion, and ensure that all components are functioning correctly. Pay close attention to electrical connections and seals, as these are critical for effective operation.

Routine Cleaning

Keeping your equipment clean is essential for preventing build-up that can hinder performance. Regularly remove debris and sediment from intake areas and other components. Additionally, use appropriate cleaning solutions to avoid damaging any surfaces. Maintaining cleanliness not only promotes efficiency but also enhances the longevity of your system.

Troubleshooting Common Issues

When dealing with water extraction systems, various challenges may arise that hinder their efficient operation. Identifying and resolving these issues is essential for maintaining optimal functionality. This section will address frequent problems and offer solutions to help ensure a smooth experience.

Understanding the typical complications that can occur is the first step toward effective resolution. Below is a table summarizing some of the most common difficulties and their potential remedies.

| Issue | Possible Causes | Solutions |

|---|---|---|

| No water flow | Clogged intake, faulty motor, or damaged components | Inspect the intake for blockages, check the motor for functionality, and replace any damaged parts. |

| Low water pressure | Leaking pipes, air leaks, or worn seals | Examine pipes for leaks, ensure all connections are secure, and replace worn seals as necessary. |

| Excessive noise | Improper installation, loose fittings, or worn bearings | Ensure proper alignment during installation, tighten loose connections, and lubricate or replace bearings. |

| Frequent cycling | Malfunctioning pressure switch or waterlogged tank | Test the pressure switch for accuracy and consider replacing it if faulty; check for tank waterlogging. |

By addressing these issues promptly, users can significantly improve the longevity and performance of their water extraction systems.

Safety Considerations for Users

Ensuring safety is paramount when dealing with components that provide essential services to homes and businesses. Understanding how to properly manage these devices can prevent accidents and promote a secure working environment.

Before engaging with any equipment, users should keep the following precautions in mind:

- Always disconnect the power source before performing any maintenance or inspections to avoid electric shock.

- Utilize protective gear such as gloves and goggles to shield against potential hazards during handling.

- Follow the manufacturer’s instructions carefully to ensure proper assembly and disassembly.

- Be aware of the weight and size of the components; use proper lifting techniques or equipment to prevent injury.

- Inspect all connections and seals regularly to prevent leaks that could cause harm or damage.

Additionally, consider the following guidelines to enhance safety:

- Regularly check for signs of wear and tear to identify potential risks before they escalate.

- Maintain a clean work area to minimize the chance of accidents caused by clutter or obstructions.

- Ensure that any necessary permits are obtained if modifications or installations require them, complying with local regulations.

- Educate all users on emergency procedures to ensure quick and effective responses to any incidents.

By prioritizing these safety measures, individuals can significantly reduce the risk associated with the operation and maintenance of essential equipment.