In the world of mechanical engineering, comprehending the intricate assemblies that enable efficient operation is crucial. This section aims to unravel the complexities associated with specific systems, shedding light on their functional components and how they interact.

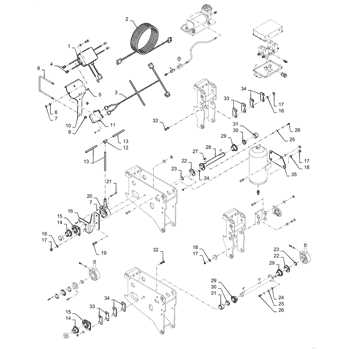

Visual representations play a pivotal role in grasping these mechanisms. By examining detailed illustrations, one can gain insights into the arrangement and relationship of each element, fostering a deeper understanding of their ultimate purpose.

Moreover, mastering these schematics not only enhances technical knowledge but also aids in troubleshooting and maintenance, ensuring optimal performance in various applications. Let us delve into the specifics and explore the intricacies that define these assemblies.

Understanding Tru Count Air Clutch Mechanism

This section explores the intricacies of a specific engagement mechanism used in agricultural equipment. By examining its functionality, we can appreciate how it enhances performance and efficiency in various applications.

- Principle of Operation: The system operates by utilizing pressure to engage or disengage components smoothly.

- Components Involved: Key elements include valves, cylinders, and actuators, each playing a critical role.

- Benefits: This design minimizes wear, reduces downtime, and allows for precise control.

Understanding this mechanism is essential for maintenance and optimization, ensuring seamless operation in the field.

Components of the Air Clutch System

This section explores the essential elements that contribute to the efficient functioning of a pneumatic engagement mechanism. Understanding these components is crucial for optimal operation and maintenance, ensuring reliability in various applications.

Key Elements

Among the primary components are the compressor, which generates the necessary pressure; the actuator, responsible for engaging and disengaging the mechanism; and the reservoir, which stores the compressed air for consistent performance. Each of these parts plays a vital role in the overall system.

Functionality and Maintenance

Regular inspection and maintenance of these elements are imperative. Proper upkeep not only extends the lifespan of the system but also enhances its efficiency. Understanding the interaction between components can lead to improved performance and reduced downtime.

Importance of Accurate Diagrams

Precise visual representations are crucial for effective understanding and communication within any technical field. They serve as essential tools that enhance clarity and facilitate knowledge transfer, allowing users to grasp complex systems quickly.

Benefits of Precision

- Improved comprehension of intricate components.

- Reduction of errors during assembly and maintenance.

- Enhanced training for new personnel.

Impact on Efficiency

- Streamlined workflows due to clear instructions.

- Faster problem-solving capabilities when issues arise.

- Increased safety through better understanding of operations.

Common Issues in Air Clutch Parts

Understanding the frequent challenges encountered in this mechanism is crucial for effective maintenance and operation. Various components can face wear and malfunction, leading to performance issues.

- Leaks: Often result from deteriorated seals or damaged fittings, leading to pressure loss.

- Contamination: Dirt or moisture can compromise functionality, affecting responsiveness.

- Misalignment: Improper installation can cause uneven wear and stress on the system.

- Corrosion: Exposure to harsh environments can lead to rust and deterioration of metal components.

Addressing these issues promptly ensures optimal performance and extends the lifespan of the mechanism.

Maintenance Tips for Air Clutch Systems

Proper upkeep of pneumatic engagement mechanisms is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances reliability but also prevents costly repairs in the future. This section outlines essential practices to maintain these systems effectively.

Routine Inspections

- Check for leaks: Regularly inspect hoses and connections for any signs of air leakage.

- Inspect seals: Ensure that all seals are intact and functioning properly to prevent air loss.

- Monitor performance: Observe the system’s engagement and disengagement to identify any irregularities.

Lubrication and Cleaning

- Use appropriate lubricants: Apply the recommended lubricant to moving parts to reduce friction.

- Keep components clean: Remove dirt and debris from the mechanism to prevent wear and tear.

- Schedule periodic cleaning: Implement a routine cleaning schedule to maintain optimal functionality.

Adhering to these maintenance practices will help ensure that your pneumatic systems operate efficiently and reliably throughout their lifespan.

Comparing Tru Count with Other Brands

This section explores the differences between a leading manufacturer and its competitors in the agricultural equipment sector. Understanding these distinctions can help users make informed decisions based on functionality, reliability, and performance.

Key Features

- Durability and longevity

- Ease of installation and maintenance

- Performance in various conditions

Customer Feedback

- Brand loyalty among users

- Reviews highlighting strengths and weaknesses

- Comparative analysis of service support

Step-by-Step Assembly Instructions

This section provides a comprehensive guide to assembling components efficiently and accurately. Following these instructions will ensure optimal performance and longevity of the assembled unit.

Preparation

Before starting, gather all necessary tools and components. Ensure that your workspace is clean and well-lit to facilitate the process. Familiarize yourself with each piece to enhance your understanding of how they fit together.

Assembly Process

Begin by connecting the base component securely. Next, attach the intermediary pieces in a sequential manner, following the specified order. Tighten all connections firmly to prevent any movement during operation. Finally, perform a thorough inspection to confirm everything is properly aligned and secure.

Tools Needed for Installation

Successfully completing the installation process requires a selection of essential instruments and equipment. Having the right tools on hand will ensure efficiency and accuracy, ultimately leading to a smoother operation.

- Wrenches

- Screwdrivers

- Pliers

- Torque wrench

- Socket set

- Drill

- Measuring tape

Gathering these items in advance will help streamline the procedure and minimize potential setbacks.

Real-Life Applications of Air Clutches

In various industrial sectors, mechanisms utilizing pneumatic engagement systems are vital for enhancing efficiency and performance. These systems allow for smooth transitions and precise control in applications ranging from manufacturing to transportation.

Manufacturing Industry: In factories, pneumatic mechanisms facilitate the operation of conveyor belts and assembly lines, enabling seamless movement of products and reducing wear on mechanical components.

Aerospace: In aviation, these systems are essential for controlling landing gear and other critical functions, ensuring reliability and safety during flight operations.

Automotive: Vehicles equipped with pneumatic systems benefit from improved drivability, allowing for better torque distribution and smoother gear shifts, enhancing overall driving experience.

Robotics: In robotics, pneumatic engagement is employed for precise movement and manipulation, providing the flexibility required for intricate tasks in automation.

Overall, these systems play a crucial role in improving operational capabilities across diverse fields, demonstrating their ultimate importance in modern engineering solutions.