In the realm of agricultural machinery, the efficiency of equipment greatly depends on the quality and functionality of its connectors. These essential mechanisms enable seamless interaction between various implements and the tractor, ensuring that tasks are performed with precision and ease. A thorough comprehension of these components is crucial for both operators and enthusiasts, as it facilitates better maintenance and troubleshooting.

Each connector consists of several key elements that work in harmony to provide stability and control. Familiarity with these components not only enhances the user experience but also prolongs the lifespan of the machinery. By delving into the intricacies of this system, one can unlock a deeper appreciation for the engineering marvels that support agricultural practices.

In this exploration, we will outline the various sections that comprise these connectors, highlighting their functions and interrelations. Understanding these segments is vital for anyone involved in the agricultural field, whether for practical application or academic inquiry. With a clear visualization of these components, operators can make informed decisions, ultimately leading to improved productivity in their agricultural endeavors.

Understanding the Three Point Hitch

The mechanism in question is a crucial element in modern agricultural machinery, enabling efficient attachment and operation of various implements. This system facilitates seamless connection between the tractor and the tools, ensuring stability and control during use.

Key components of this setup include arms that allow for adjustable positioning, a top link for balance, and various mounting options for implements. Together, these features enhance the functionality and versatility of farming equipment.

By exploring the working principles of this system, one can appreciate how it contributes to productivity in agricultural practices. Understanding its design can lead to better maintenance and improved performance of equipment.

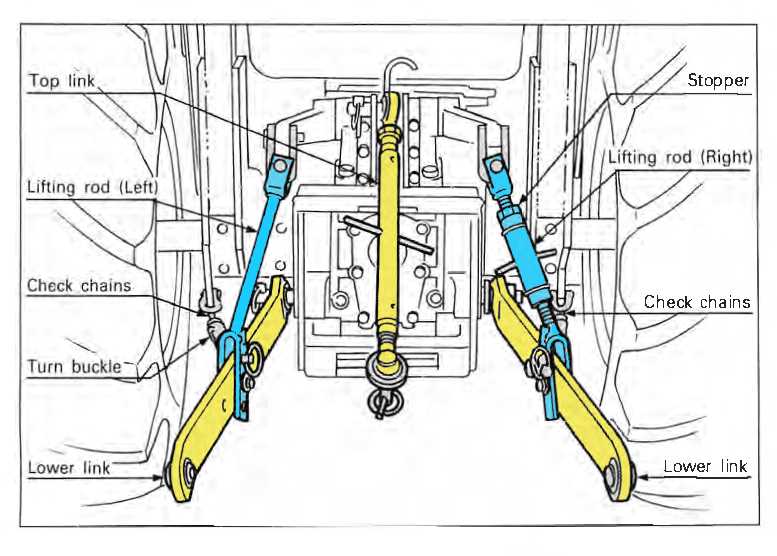

Key Components of the Hitch System

The functionality of a towing mechanism relies on several critical elements that work in harmony to ensure stability and efficiency. Understanding these essential components can enhance both performance and safety in various applications.

Upper Link: This element connects the implement to the towing vehicle, allowing for vertical movement and adjustment, crucial for achieving the correct angle during operation.

Lower Links: These are vital for attaching the implement securely and maintaining balance while in use. They provide the necessary support and alignment for optimal operation.

Lift Arm: The lift arm plays a pivotal role in raising and lowering the implement, facilitating ease of use and adaptability to different terrains.

Draft Arms: Serving as an integral part of the structure, draft arms help in transmitting forces between the implement and the towing vehicle, ensuring stability under load.

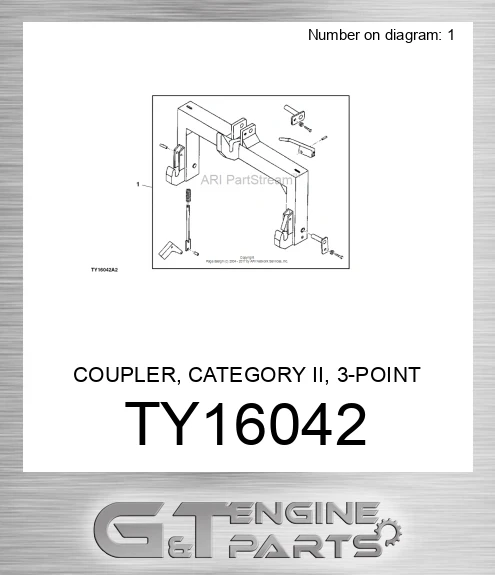

Quick Hitch: This feature enhances efficiency by allowing rapid attachment and detachment of implements, streamlining workflows and reducing downtime.

Benefits of a Three Point Hitch

The use of a versatile coupling mechanism in agricultural machinery provides numerous advantages that enhance both efficiency and functionality. This design allows for easy attachment and detachment of implements, streamlining various tasks while ensuring optimal performance.

Increased Stability

One of the primary benefits of this mechanism is its ability to maintain stability during operation. The design ensures that attachments are securely fastened, minimizing the risk of unintentional disengagement. This stability is crucial for tasks that require precision, such as plowing or lifting heavy loads.

Enhanced Maneuverability

Another significant advantage is the improved maneuverability it offers. This system allows operators to navigate tight spaces and complex terrain with ease. The capability to adjust the height and angle of implements enhances overall control, making it simpler to perform various agricultural tasks efficiently. The adaptability provided by this mechanism supports a wide range of equipment, enabling farmers to optimize their operations.

Common Applications in Agriculture

In modern farming, various tools and equipment are essential for enhancing productivity and efficiency. These mechanisms facilitate the attachment of implements, allowing farmers to perform multiple tasks with ease. Understanding their applications can significantly improve operational workflows in agricultural settings.

Enhancing Soil Preparation

One of the primary uses of these devices is in soil preparation. Farmers attach plows, cultivators, and harrows to prepare the ground for planting. This process ensures optimal soil conditions, enhancing crop growth and yield.

Efficient Crop Management

Additionally, these connections play a crucial role in crop management. Implements such as seeders and sprayers can be easily connected, allowing for precise planting and effective pest control. This flexibility contributes to more sustainable and productive farming practices.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the service life of your agricultural equipment. A consistent maintenance routine not only prevents unexpected breakdowns but also ensures that each component operates at peak performance. Understanding how to care for these systems effectively can significantly boost their durability and reliability.

Regular Lubrication

One of the most crucial steps in equipment care is consistent lubrication. Applying the appropriate lubricant to moving connections reduces friction and minimizes wear over time. It’s important to follow the manufacturer’s guidelines on lubrication intervals to keep everything running smoothly.

Inspection and Cleaning

Frequent inspections are key to identifying potential issues before they become major problems. Check all connections and mechanical links for signs of wear or corrosion. Regular cleaning also plays a vital role in preventing debris buildup, which can lead to operational inefficiencies or damage to the components.

How to Troubleshoot Issues

Identifying the root cause of mechanical malfunctions can be a straightforward task if approached systematically. By understanding the most common symptoms and their potential sources, you can efficiently diagnose the problem and apply the necessary solution.

Step-by-Step Inspection

Start with a visual check to spot any visible damage or misalignments. Look closely at the connections, joints, and moving components. If you detect anything unusual, note it down for further examination.

Common Faults and Their Solutions

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Unresponsive Mechanism | Loose or damaged connections | Tighten bolts and replace any worn-out parts |

| Unexpected Noises | Lack of lubrication | Apply appropriate grease or oil to reduce friction |

| Irregular Movements | Alignment issues | Adjust the settings to ensure all components are in sync |

Comparison with Other Hitch Types

Various attachment systems in agricultural and industrial machinery offer distinct functionalities, each designed to meet specific needs. Understanding the differences between these systems helps to identify their most suitable applications.

Fixed Connection Systems

Fixed connection systems are generally simpler in design and offer a straightforward method for attaching equipment. While they provide a stable and rigid link, they often lack the flexibility required for adjusting the angle or height of the connected implement. This rigidity can be a limiting factor when maneuvering in uneven terrains or adjusting to varying operational conditions.

Adjustable Linkage Variants

Adjustable linkage variants allow for greater control over the positioning of the connected tools. These systems often include mechanisms that enable the operator to fine-tune the equipment’s alignment, enhancing versatility and precision in tasks. Such flexibility is particularly useful when engaging with tasks that require precise control, such as plowing or cultivating fields of varying density.

Choosing the Right Hitch for Your Needs

When selecting the appropriate attachment for your equipment, it’s important to consider various factors to ensure compatibility and efficiency. Understanding the specific requirements of your tasks, as well as the capabilities of your machinery, will help in making the best choice. A well-suited tool can significantly improve the performance of your vehicle, making it more versatile and effective for a range of applications.

Consider the Weight and Power

One of the main aspects to evaluate is the weight capacity and power output of your equipment. The selected attachment must handle the load without straining the machinery, ensuring long-term durability and performance. Overloading or choosing an unsuitable option can lead to wear and tear, impacting overall efficiency.

Evaluate Your Work Environment

The terrain and environment where the equipment will be used also play a critical role in the decision-making process. Whether working on soft ground, rugged landscapes, or in confined spaces, choosing the right attachment ensures smooth operation and maximizes productivity for your

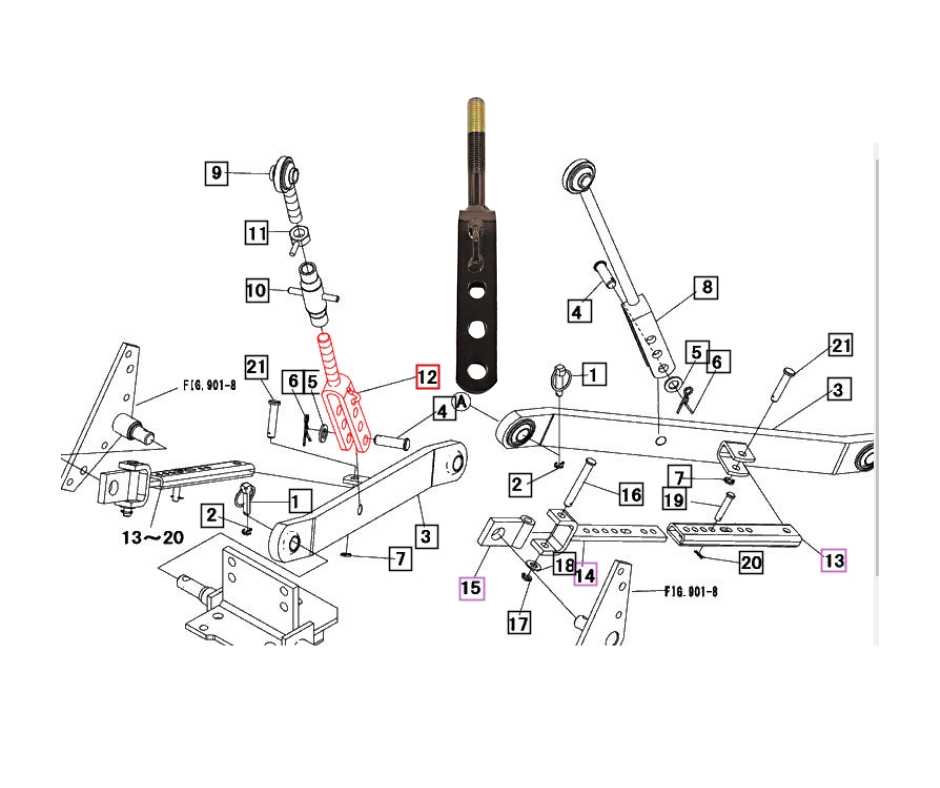

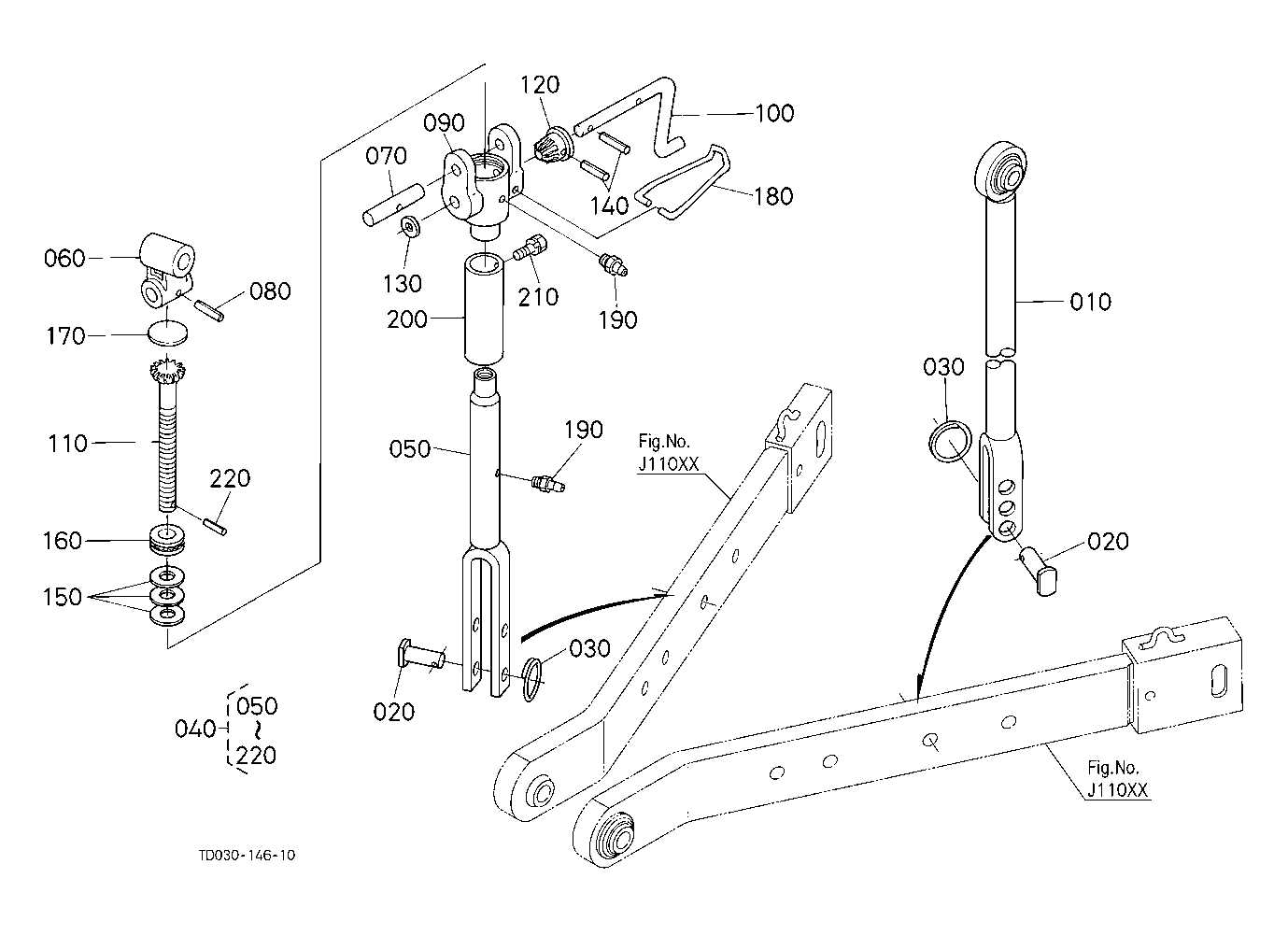

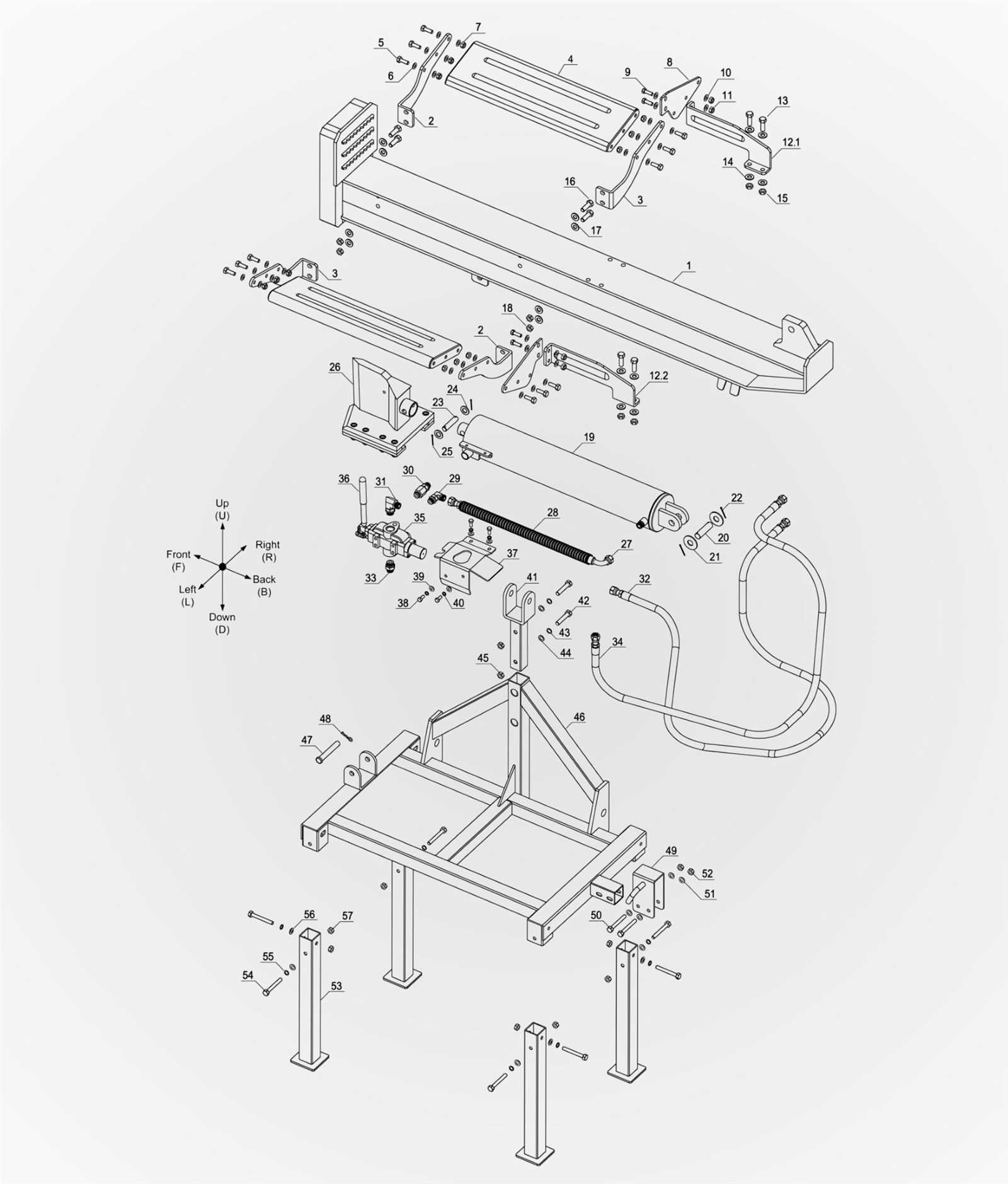

Visual Guide: Parts Diagram Explained

This section provides a detailed overview of the key elements within the illustrated setup, aiming to offer a clearer understanding of its interconnected components. The focus is on describing each element’s role, how they function together, and their significance in the overall mechanism.

- Core Components: These are the essential units that drive the entire mechanism, ensuring proper alignment and stability during operations.

- Supporting Structures: Highlighting the secondary units that enhance the functionality, these elements provide additional support and reinforce the main framework.

- Connectors and Linkages: These crucial parts bind the system together, allowing for smooth movement and efficient control.

- Adjustment Mechanisms: Tools that enable fine-tuning and precision, critical for adapting the configuration to various tasks.

- Safety Features: Important safeguards built into the setup to prevent malfunction and ensure user protection during use.

Understanding how these components interact is vital for maximizing the efficiency and reliability of the entire system, as it allows for better maintenance and performance optimization.