The intricate design of mechanical systems involves various elements that work together to achieve functionality. A comprehensive exploration of these components reveals their interconnections and the roles they play in ensuring optimal performance. By grasping how each piece contributes to the whole, one can appreciate the elegance of engineering solutions.

In this section, we will delve into a detailed overview of these vital elements. Each component is meticulously crafted to fulfill specific tasks, ultimately enhancing the efficiency and reliability of the entire system. Understanding these parts allows for a greater insight into maintenance, troubleshooting, and innovation.

Ultimately, the examination of these essential components not only enriches our technical knowledge but also fosters an appreciation for the complexity behind seemingly simple mechanisms. By studying their configurations and functions, we can unlock new possibilities in design and application.

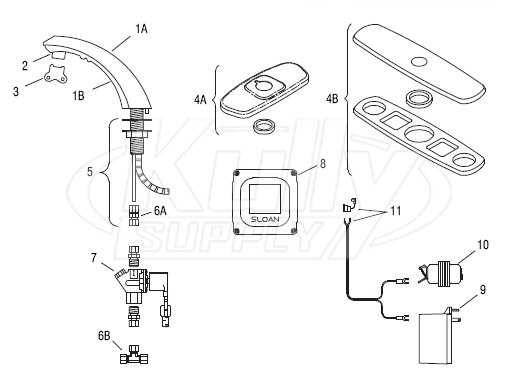

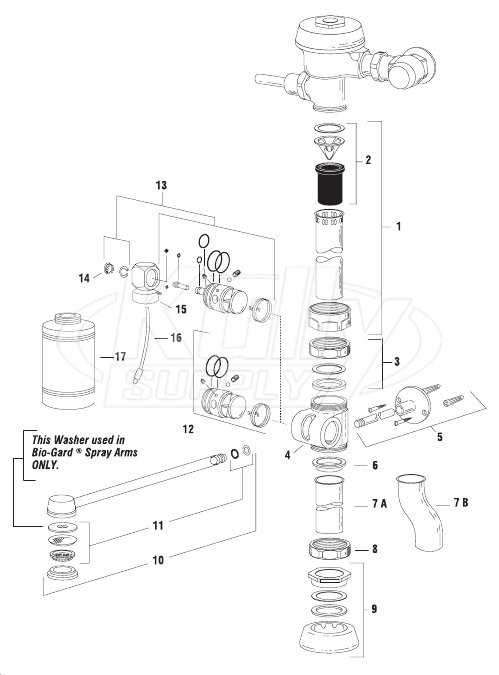

Understanding the Sloan Parts Diagram

This section explores the visual representation that illustrates the components and relationships within a complex system. By breaking down these elements, we can gain insights into how each piece interacts and contributes to the overall functionality.

Grasping the layout is crucial for anyone looking to optimize or troubleshoot the system. Each element serves a distinct purpose, and recognizing these roles can lead to a deeper comprehension of the entire framework.

Diving deeper into this representation allows for enhanced problem-solving abilities. Understanding how to navigate this intricate blueprint is the ultimate step towards effective management and improvement of the system.

Key Components of the Diagram

The layout highlights crucial elements that make up the system, each playing a specific role in its operation. By examining these interconnected units, one can understand the functionality and interaction between various elements, which ensures smooth performance.

Valves: These control the flow of liquid or gas through the system, regulating the amount and direction based on the requirements of the setup.

Connectors: These components serve as essential junctions, linking different elements together. Their proper alignment and positioning are key for maintaining overall system integrity.

Seals: These ensure that the system remains leak-free, providing a tight fit between different sections and preventing any unwanted escape of materials.

Actuators: These are mechanical devices that enable movement or action within the system. They respond to external commands or conditions, allowing for adjustments in performance.

Fasteners: These hold the entire structure together, ensuring that all units remain securely in place

Importance in Mechanical Design

In mechanical engineering, every element within a system must be carefully planned to ensure efficiency, durability, and functionality. The accuracy and clarity of structural layouts play a key role in preventing costly errors and enhancing the overall performance of devices. A well-organized system ensures that components are easily understood and can be replaced or modified when needed.

Key Benefits

- Enhances the reliability and longevity of systems.

- Reduces downtime through efficient troubleshooting and repairs.

- Improves the overall safety and usability of equipment.

Impact on Manufacturing

During production, clear mechanical design contributes to smoother assembly processes, allowing manufacturers to follow precise guidelines. This level of precision reduces material waste and optimizes production time, while maintaining the required quality standards.

Common Applications in Engineering

In the field of engineering, various mechanical and electronic components are utilized to optimize system functionality. These components are often designed to ensure efficient operation in a wide range of settings, from construction to automation. The integration of these elements into different systems helps to address specific challenges in energy consumption, environmental sustainability, and performance enhancement.

Infrastructure Development

In infrastructure projects, these mechanical elements are frequently employed to support fluid dynamics, energy management, and structural stability. Their use is critical in ensuring that large-scale operations run smoothly, reducing downtime and promoting safety standards. Engineers rely on these components to maintain precision and consistency in system operation, ultimately improving the longevity of the infrastructure.

Industrial Automation

In industrial environments, these systems contribute to the automation of processes, increasing both productivity and accuracy. By incorporating components that facilitate efficient control of machinery, engineers can create solutions that respond dynamically to operational needs. This level of automation allows industries to optimize workflow, minimize manual intervention, and enhance overall production capabilities.

Step-by-Step Creation Process

Understanding the sequence for building components requires following a structured approach. The aim is to ensure that each piece fits perfectly within the overall framework, enabling smooth functionality. This process involves working through several stages, carefully aligning each element to guarantee compatibility and efficiency.

Initial Planning

The first phase involves outlining the structure. A clear blueprint of the intended setup is crucial to ensure all elements are accounted for. During this stage, focus on aligning the dimensions and positioning key connections for future assembly.

Assembly and Adjustment

Once the groundwork is established, the next step is to begin putting the pieces together. This is a delicate phase, requiring precision and attention to detail to ensure everything aligns as intended. If adjustments are necessary, make them early to avoid complications during later stages.

| Step | Description | Tools Required |

|---|---|---|

| 1 | Design

Analyzing Diagrams for Efficiency

Understanding visual representations of components is essential for optimizing functionality. Such illustrations provide a comprehensive overview, facilitating better comprehension of intricate systems. By dissecting these visuals, one can identify areas for enhancement and streamline processes. To achieve maximum effectiveness, consider the following aspects:

By focusing on these key points, one can significantly enhance the utility of visual schematics, making them a powerful tool for analysis and improvement. Challenges in Diagram InterpretationUnderstanding visual representations of complex systems can pose significant difficulties for users. These illustrations often contain various elements that require careful analysis to derive meaningful insights. The inherent intricacies and the potential for misinterpretation can lead to confusion, especially for those unfamiliar with the underlying concepts. One major challenge lies in the diverse symbols and notations employed, which may vary across different contexts. This inconsistency can hinder effective communication, as users might struggle to grasp the intended meanings. Additionally, the absence of standardized legends or key references may further complicate the interpretation process, leaving individuals uncertain about how to proceed. Furthermore, the complexity of the relationships depicted within these visuals can overwhelm users. Elements may be interconnected in ways that are not immediately obvious, necessitating a deeper understanding of the system as a whole. As a result, those attempting to analyze such representations must invest time and effort into unraveling these connections, which can be both time-consuming and frustrating. Best Practices for UsageTo maximize the effectiveness and longevity of essential components, it is crucial to follow certain guidelines during operation and maintenance. Adhering to these recommendations ensures optimal functionality while minimizing the risk of damage or malfunction. Regular Maintenance: Establish a consistent routine for inspections and upkeep. This helps identify potential issues before they escalate and ensures all elements function smoothly. Cleanliness is vital; ensure that all areas are free from debris and contaminants. Proper Installation: Ensure components are installed according to manufacturer specifications. This includes verifying compatibility and secure connections. Any deviations can lead to inefficiencies or failures. Training and Education: Equip users with the necessary knowledge to operate equipment effectively. Proper training reduces the likelihood of mistakes and enhances overall productivity. Utilize Resources: Make use of available resources, such as manuals and technical support, to gain a better understanding of operational requirements. These resources can provide valuable insights into best practices and troubleshooting techniques. Monitor Performance: Regularly assess the performance of the system to identify any irregularities. Early detection of issues can prevent costly repairs and downtime. Future Trends in Diagram DevelopmentThe evolution of visual representation techniques is poised for significant advancements. As technology progresses, the methodologies for illustrating complex systems and relationships are becoming increasingly sophisticated. Innovations in software, along with a focus on user experience, are expected to redefine how these representations are created and utilized across various fields. Integration of Artificial IntelligenceOne of the most notable trends is the incorporation of artificial intelligence in the creation and analysis of visual representations. This integration offers several benefits:

Collaborative PlatformsThe rise of collaborative tools is another significant trend. These platforms facilitate real-time teamwork, enabling users to contribute and modify visual content collectively. Key features include:

|