Understanding how various elements of an outdoor heating system work together is essential for ensuring its efficient operation. Each component plays a critical role in maintaining consistent temperatures and delivering reliable performance. A detailed look at the assembly of these parts helps identify potential issues and enhances the ability to carry out maintenance and repairs effectively.

This guide will walk you through the configuration of essential mechanisms within your water heating system. By recognizing the function of each segment, you can optimize your unit’s functionality, ensuring it runs smoothly throughout the seasons. Whether you’re troubleshooting or simply maintaining your setup, this structured approach will provide clarity.

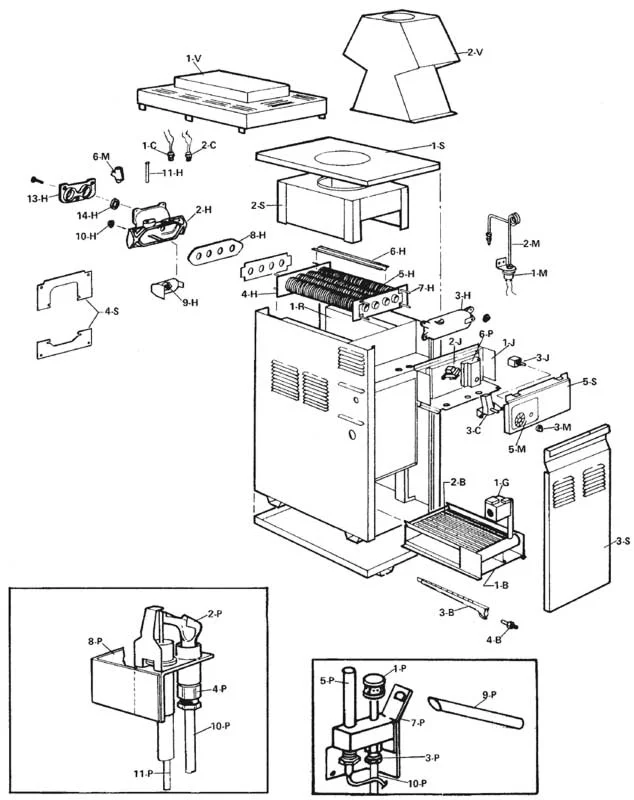

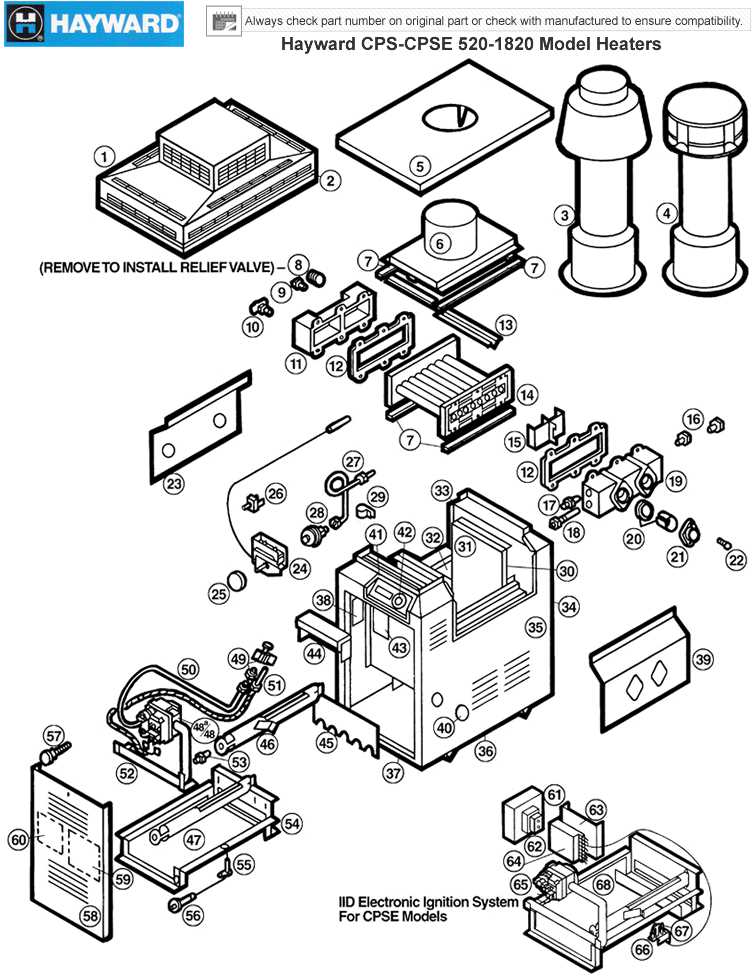

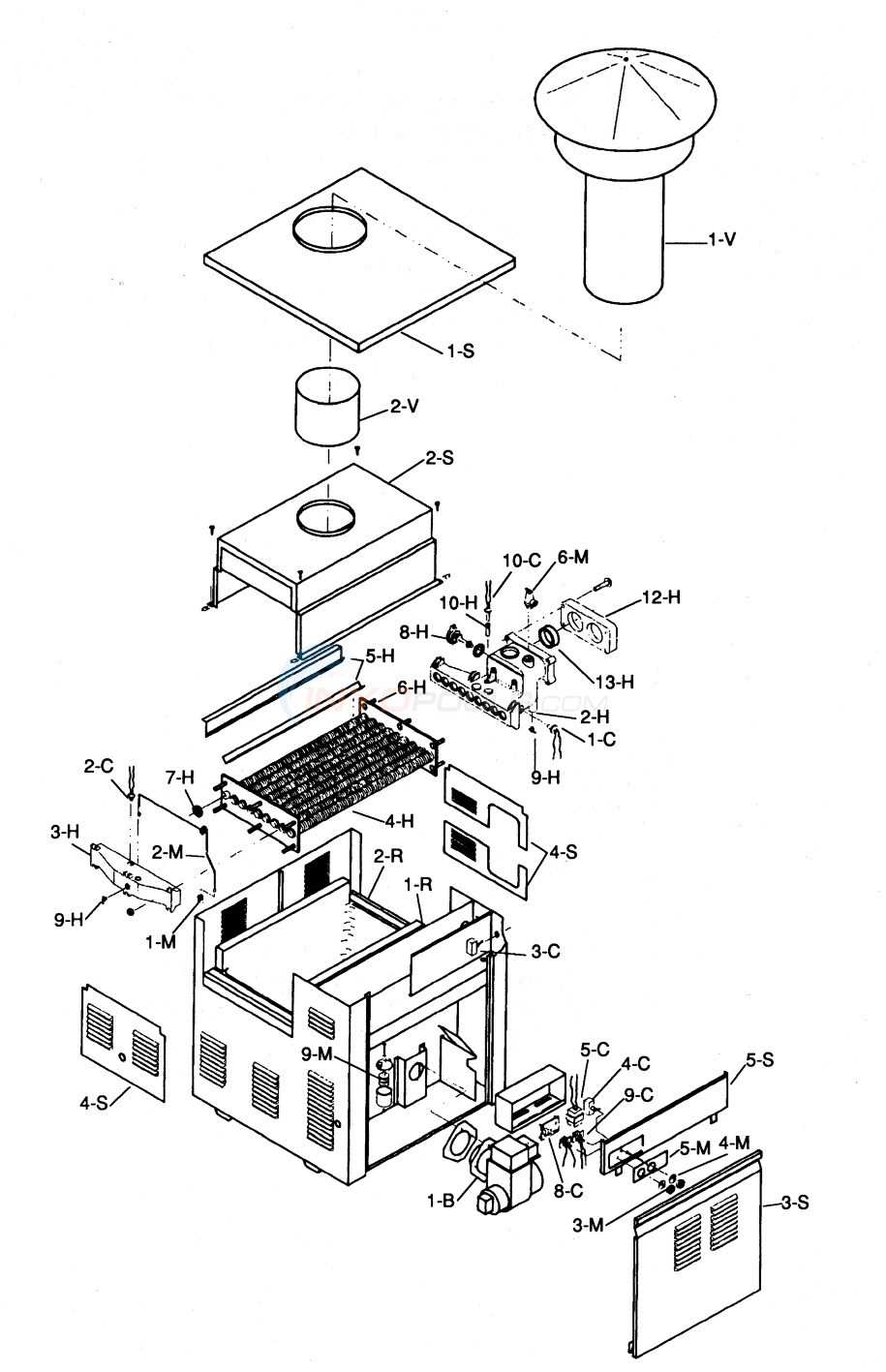

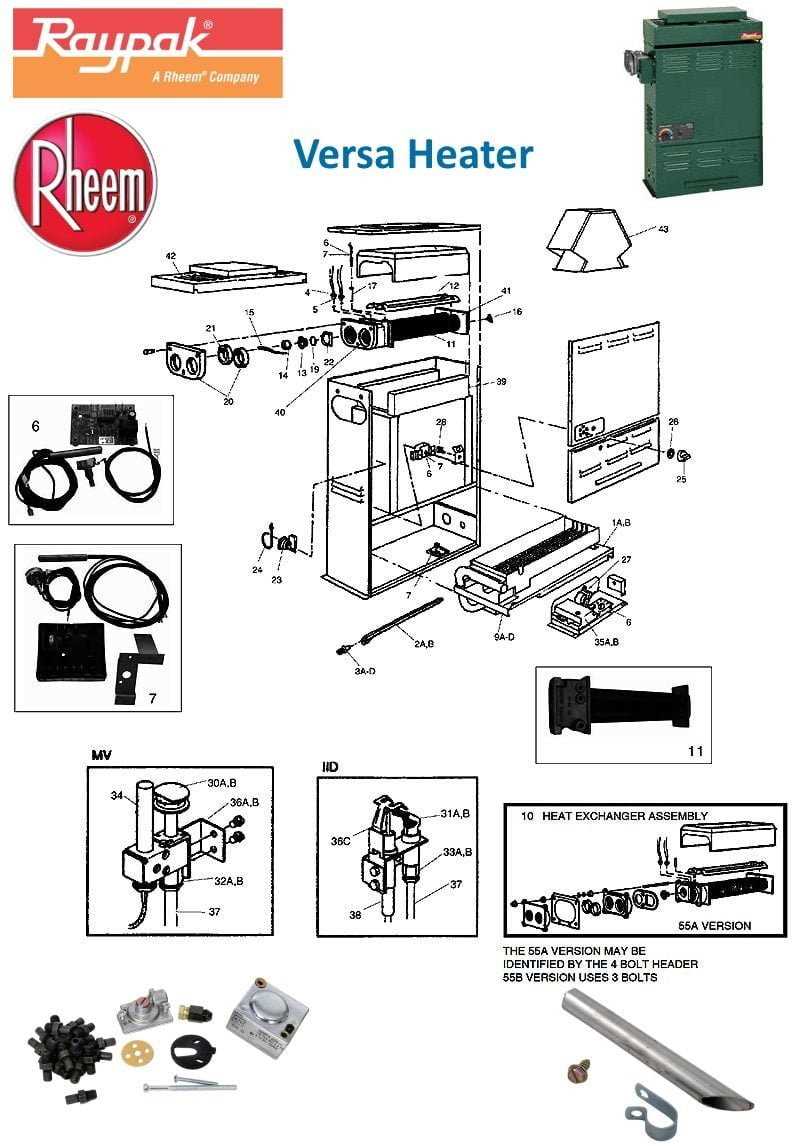

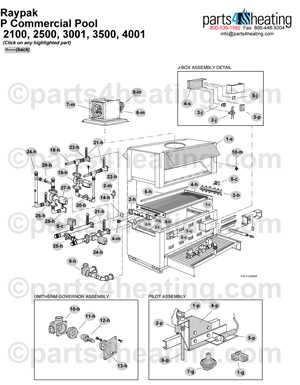

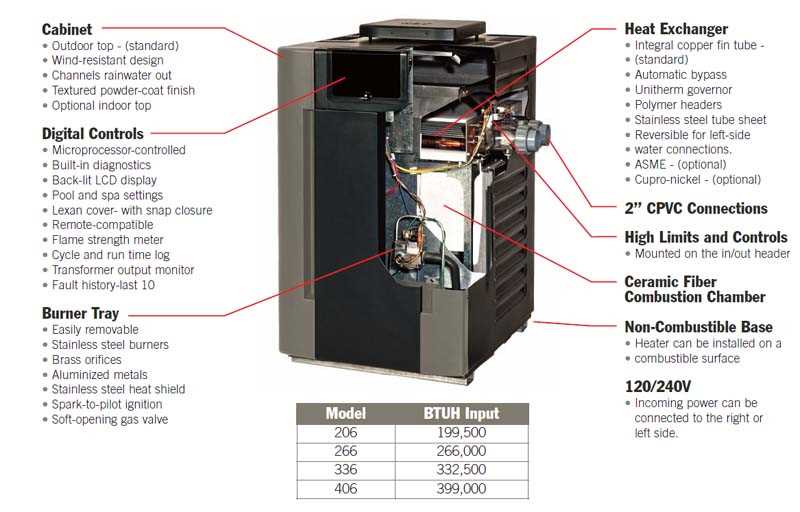

Essential Components of a Rheem Pool Heater

The proper functioning of any aquatic heating system relies on a combination of carefully designed mechanisms that work together to regulate and maintain water temperature. These systems include multiple key elements that ensure consistent operation, efficient performance, and long-term durability.

Heating Mechanism

The core element responsible for raising water temperature is the combustion or heating system. It typically utilizes gas or electricity to produce the necessary heat, which is then transferred to the water passing through the device.

Control and Safety Features

Understanding the Internal Structure

To grasp the functionality of a heating system, it’s important to familiarize yourself with its internal components and how they work together. The internal structure is a complex network of parts that ensures efficient operation and seamless performance.

Here are the key elements involved:

- Control Panel: The main interface for monitoring and adjusting the settings, allowing you to regulate temperature and other essential functions.

- Burner Assembly: Responsible for generating heat, this component converts fuel into energy through combustion.

- Heat Exchanger: A critical element that transfers the heat generated by the burner into the water flowing through the system.

- Ignition System: This system initiates the combustion process, ensuring the burner ignites safely and reliably.

- Safety Features: Various mechanisms are built into the system to prevent overheating, gas leaks,

Key Features of Heat Exchangers

Heat exchangers play a crucial role in transferring thermal energy between two mediums, ensuring efficient temperature regulation. Their design and function contribute to maintaining optimal performance in various systems.

- Durability: Modern heat exchangers are built to withstand harsh conditions, ensuring longevity and consistent efficiency.

- High Efficiency: Advanced models maximize the transfer of thermal energy, minimizing energy loss and improving overall system performance.

- Corrosion Resistance: Many heat exchangers are designed using materials that resist corrosion, extending the lifespan and reliability of the unit.

- Compact Design: Some heat exchangers offer a compact form, allowing for easier integration into various systems without sacrificing performance.

- Easy Maintenance: Simplified access to components allows for easier upkeep, reducing downtime and maintenance costs.

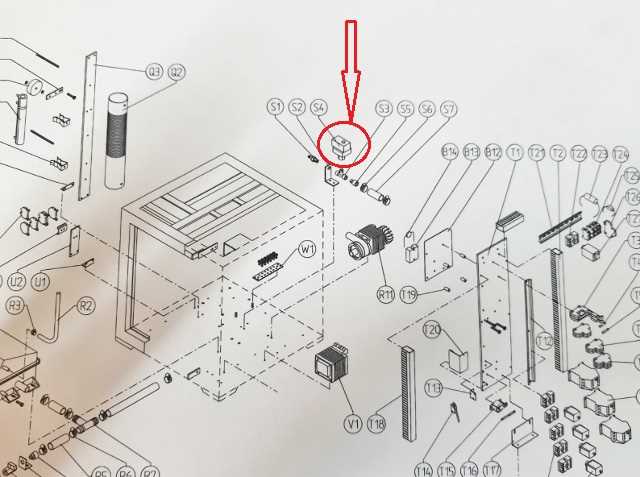

Identifying Control Panel Elements

Understanding the different components on the control panel is essential for effective operation and maintenance. The layout may include various buttons, indicators, and displays, each serving a distinct purpose to ensure smooth functionality.

Main Buttons and Their Functions

The control panel typically includes several primary buttons, each designated for a specific task. These buttons may be responsible for adjusting settings, turning the system on or off, or switching between modes. Knowing the function of each button helps in managing operations efficiently.

Indicator Lights and Displays

Indicator lights and displays are crucial for providing real-time feedback about the system’s performance. Lights may signal when a function is active, while displays can show temperatures, settings, or error messages. Understanding these signals can assist in troubleshooting and optimizing usage.

Element Purpose Circulation System Breakdown

The circulation system is essential for maintaining the consistent flow of water, ensuring even distribution of heat and chemicals throughout the water. Understanding how each element functions within the system allows for efficient troubleshooting and maintenance. By analyzing the system’s various components, one can better grasp how water is pumped, filtered, and returned, ensuring optimal performance.

Key elements of this system include the pump, filters, and valves. Each of these works in unison to keep the water clean and at a stable temperature. Proper management of this system prevents blockages, promotes efficiency, and extends the lifespan of equipment.

Valve Assembly and Functions

The valve assembly plays a critical role in managing the flow of fluid within a system, ensuring optimal performance and efficiency. Understanding its components and their functions is essential for maintaining a well-functioning unit.

Typically, the valve assembly comprises several key elements, each contributing to its overall operation:

- Inlet Valve: Controls the entry of fluid into the system, allowing for precise regulation of flow rates.

- Outlet Valve: Manages the discharge of fluid, ensuring that excess is released appropriately.

- Check Valve: Prevents backflow, maintaining a unidirectional flow and protecting the system from pressure fluctuations.

- Pressure Relief Valve: Ensures safety by releasing pressure when it exceeds a predetermined limit, preventing damage to the assembly.

- Actuator: Facilitates automatic control of the valves, allowing for responsive adjustments based on system demands.

Proper maintenance of the valve assembly is vital for effective operation. Regular inspections and timely replacements of worn components help avoid disruptions and ensure longevity. Understanding each part’s function aids in troubleshooting and optimizing system performance.

Maintenance of Ignition Systems

Regular upkeep of ignition systems is crucial for ensuring reliable performance and longevity. This involves inspecting various components, cleaning, and replacing parts as necessary to maintain optimal functionality. Proper attention to these systems can prevent malfunctions and extend the overall life of the equipment.

Key areas to focus on during maintenance include the ignition electrode, wiring connections, and control module. These elements play a significant role in the ignition process, and any issues with them can lead to poor performance or failures. Below is a table outlining the main components and recommended maintenance tasks:

Component Maintenance Task Frequency Ignition Electrode Clean or replace if worn Annually Wiring Connections Inspect for wear or damage Every six months Control Module Check for error codes and reset As needed Gas Supply Ensure proper pressure and connections Quarterly By adhering to a scheduled maintenance plan, users can significantly improve the efficiency and reliability of ignition systems, reducing the likelihood of unexpected failures and ensuring smooth operation.

Flow Sensor Operation and Maintenance

The flow sensor is a vital component in ensuring the efficient functioning of your system. Its primary role is to monitor the movement of liquid, providing essential feedback for optimal performance. Regular maintenance and understanding of its operation can lead to enhanced reliability and longevity of the entire setup.

Understanding the operation of the flow sensor involves recognizing how it detects fluid movement and communicates this data to the control unit. This information is crucial for maintaining the desired performance level. Key aspects include:

- Fluid Detection: The sensor measures the velocity of the liquid, which allows for accurate flow rate assessments.

- Signal Transmission: It relays the data to the system controller, enabling it to make necessary adjustments.

- Calibration: Proper calibration ensures accurate readings, which is essential for effective operation.

To maintain the flow sensor in optimal condition, consider the following maintenance tips:

- Regular Inspection: Frequently check for any signs of wear or damage, as this can affect performance.

- Cleaning: Remove any debris or buildup that may hinder fluid flow or sensor accuracy.

- Check Connections: Ensure that all electrical and fluid connections are secure and free of leaks.

- Calibration Checks: Periodically verify that the sensor is calibrated correctly to ensure accurate readings.

By following these guidelines, you can ensure that the flow sensor operates effectively, contributing to the overall efficiency and reliability of your system.

Troubleshooting Common Part Failures

When dealing with common malfunctions in heating systems, understanding the potential issues can significantly aid in diagnosing and resolving problems. Many components can experience wear and tear over time, leading to inefficiencies or failures that may disrupt operation. Identifying these components and their common issues is essential for effective maintenance.

1. Power Supply Issues: One of the most frequent causes of system failure is an inadequate power supply. Ensure that the unit is receiving the proper voltage, and check for any tripped breakers or blown fuses that may need replacing.

2. Thermostat Malfunctions: A malfunctioning thermostat can lead to improper temperature regulation. Verify that the thermostat is calibrated correctly and is functioning as intended. If it appears faulty, consider replacing it to restore proper functionality.

3. Sensor Failures: Temperature and pressure sensors are crucial for the correct operation of the system. If these sensors are not providing accurate readings, they may need cleaning or replacement. Regular inspections can help catch these issues early.

4. Corrosion and Leaks: Over time, corrosion can lead to leaks in various components, affecting efficiency and performance. Regularly inspect the system for signs of corrosion or water accumulation, and address any leaks promptly to prevent further damage.

5. Ignition Problems: Issues with ignition can stem from faulty ignitors or gas supply problems. If the system fails to ignite, check the ignitor for damage and ensure that gas is reaching the unit without obstructions.

By familiarizing yourself with these common issues and their solutions, maintaining an efficient and reliable heating system becomes a more manageable task.