When it comes to maintaining a well-kept lawn, the equipment used plays a significant role in the overall performance and efficiency of the task. A closer look at the various components that come together to make up a precision cutting machine can help you understand its functionality and how each element contributes to a flawless result.

Knowing how each section interacts with the others is crucial, whether you’re looking to troubleshoot, replace worn-out components, or simply want a better understanding of the device’s internal structure. Proper maintenance ensures optimal performance and extends the lifespan of the equipment.

In this guide, we will delve into the essential components of a cutting tool, highlighting their purpose and how they work together. Whether you are a DIY enthusiast or a professional, familiarizing yourself with these key parts can enhance your overall experience with lawn care equipment.

Understanding Reel Mower Components

When it comes to maintaining a traditional grass-cutting tool, it’s essential to familiarize yourself with the key elements that make it function efficiently. These components work together to ensure precision and smooth operation, offering a clean and consistent cut. Each part plays a vital role, from the cutting mechanism to the handle system, contributing to the overall effectiveness of the device.

The cutting mechanism is driven by a series of blades arranged in a circular motion, allowing for efficient grass trimming. The wheel assembly supports the entire structure, providing stability and enabling easy maneuverability across different terrains. Additionally, the handle section ensures comfort and control, facilitating effortless use during operation.

Understanding these core elements helps you appreciate the craftsmanship behind the tool and maintain it for optimal performance. Regular inspection and proper care of each part ensure longevity and a flawless cutting experience every time it’s used.

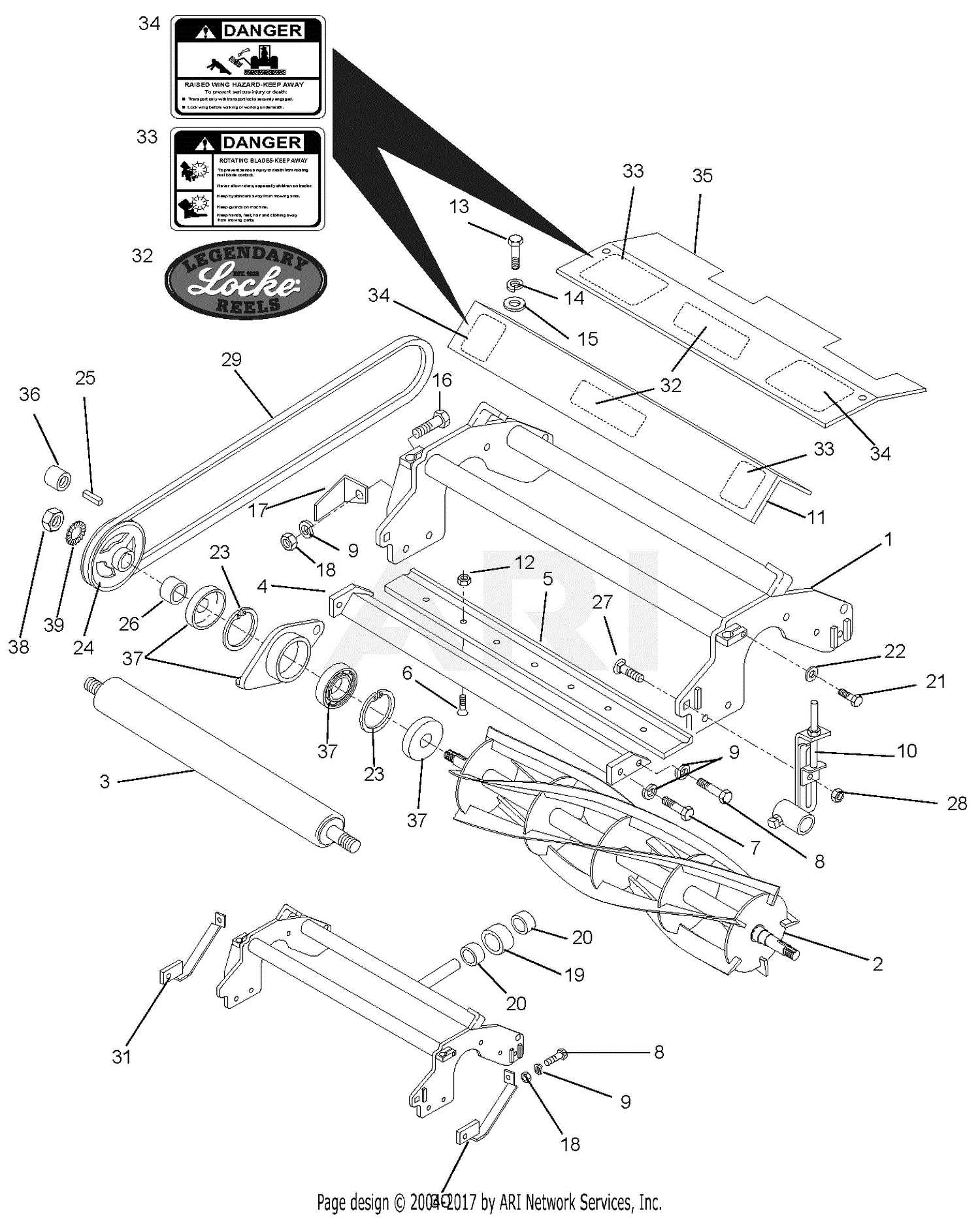

Key Parts of a Reel Mower

The essential components of a grass cutting tool work in unison to deliver precise and efficient results. These crucial elements play distinct roles, ensuring that the machine operates smoothly and provides a clean cut with minimal effort. Understanding each element’s function can help optimize maintenance and usage.

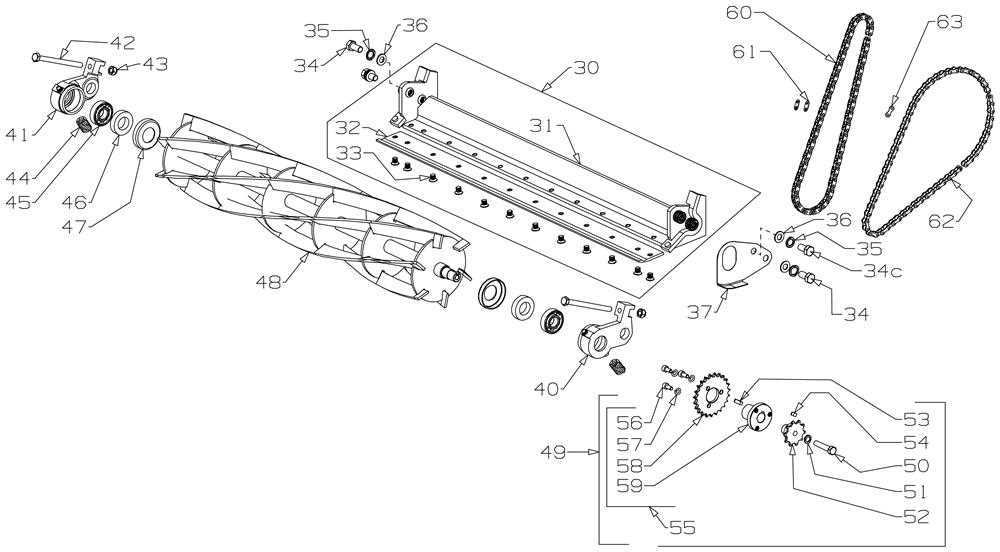

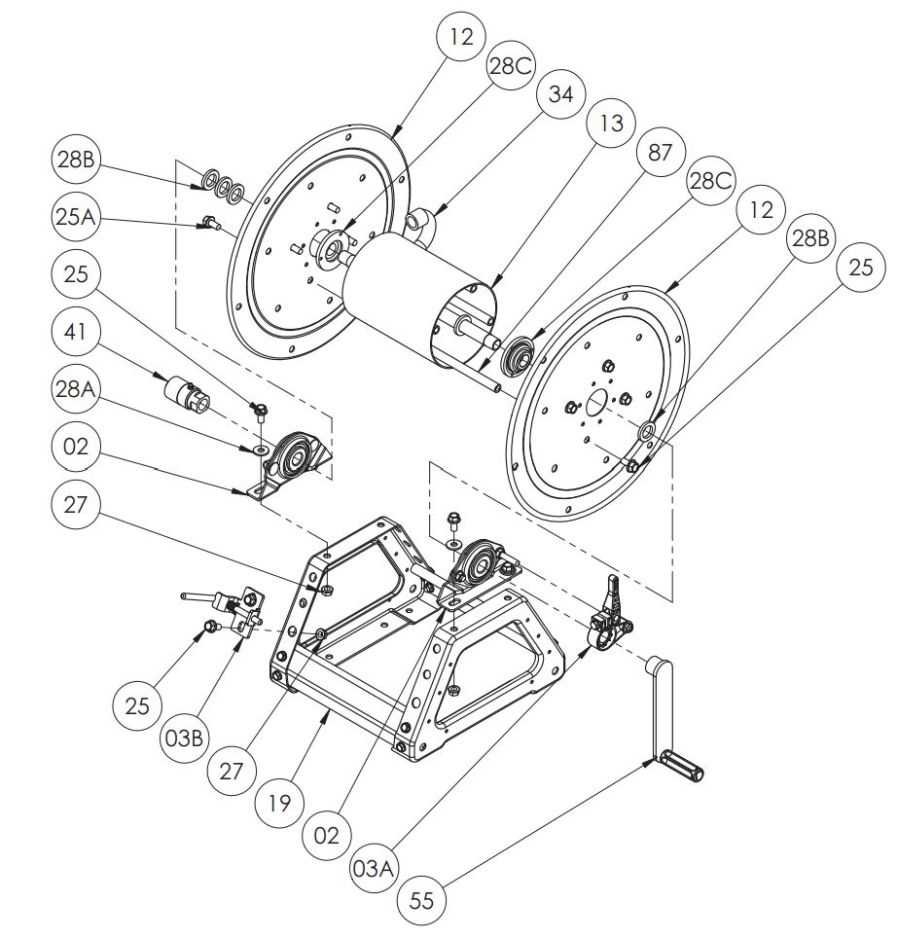

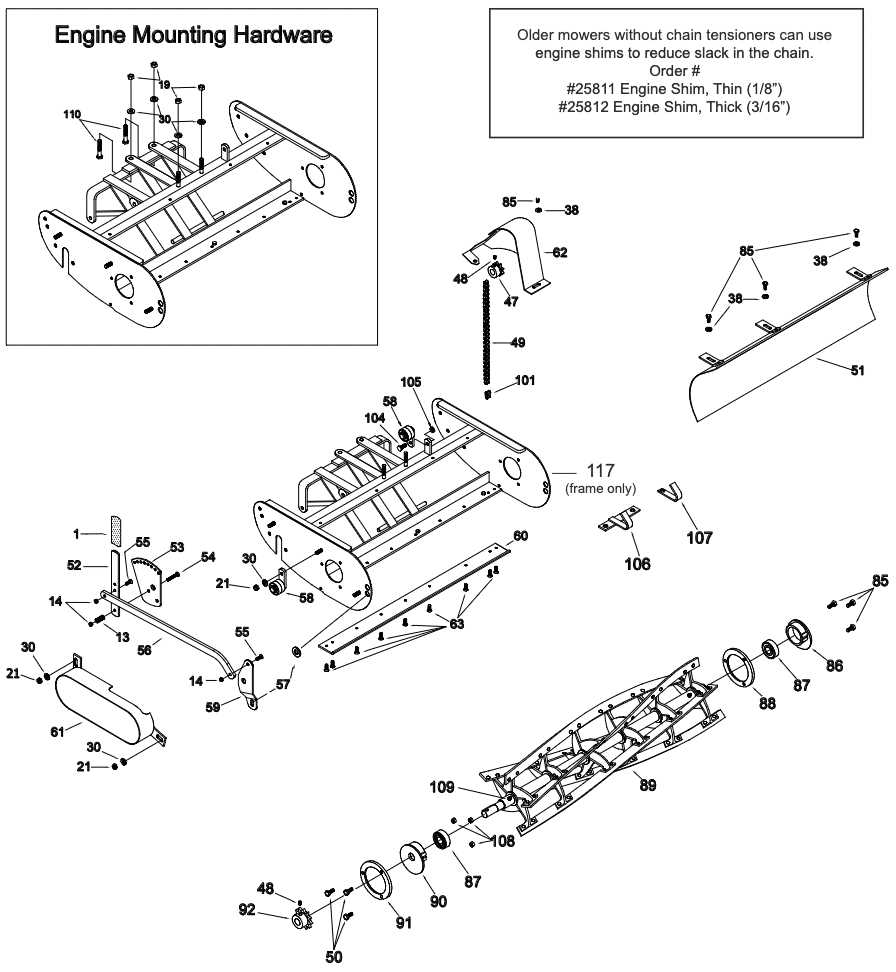

The cutting mechanism consists of a set of rotating blades that perform the primary task of trimming the grass. This system is driven by a set of gears or other mechanical connections that transmit motion from the wheels to the blades. The alignment of these blades is crucial for achieving an even and consistent cut.

An additional mechanism supports the smooth operation of the cutting system by providing stability and controlling movement. This often includes the handles and the drive assembly, which allows the user to control the speed and direction of the cutting action. The guide system ensures that the tool maintains proper alignment during use, preventing uneven trimming.

The structure’s frame and wheels also contribute to the overall efficiency. The wheels support the device’s movement and are often adjustable to control cutting height. These components must be durable to withstand regular use and ensure a steady performance on different types of terrain.

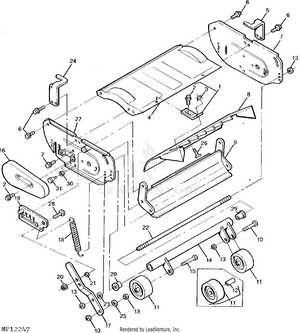

How the Cutting Mechanism Works

At the heart of any grass-trimming tool, the cutting mechanism is designed to efficiently slice through vegetation, ensuring a clean and precise finish. This system operates through the coordinated movement of various components, each playing a vital role in achieving an even cut. Understanding how these parts interact is key to maintaining performance and longevity.

The mechanism consists of two primary elements: a rotating blade and a stationary surface. The rotating blade moves at a high speed, while the stationary surface provides a solid base for the cutting action. The two surfaces meet, and the grass is “scissored” between them, resulting in a sharp and tidy cut.

- Rotating Blade: This component spins rapidly, driving the cutting action. It works much like a pair of scissors, where the blade cuts the grass against the stationary surface.

- Stationary Surface: Positioned close to the rotating blade, this part ensures the grass is held in place while the blade performs the cut. Its proximity to the rotating element is crucial for an accurate and clean trim.

- Handle and Gear Mechanism: These components control the motion of the rotating blade, allowing the user to adjust speed and efficiency during operation. The gear system translates manual effort into rotational force.

Each piece must be maintained and aligned properly to ensure the cutting action remains smooth. Regular cleaning and occasional sharpening are essential to maintain optimal performance.

Importance of the Grass Reel Blade

The cutting mechanism plays a crucial role in achieving a neat and precise finish when maintaining your lawn. It directly impacts the overall performance of the equipment, ensuring that the grass is trimmed evenly and without causing any damage to the blades. A well-designed cutting system makes the task more efficient, minimizing the effort needed to achieve a clean, uniform appearance.

Here are a few reasons why the cutting blade is essential:

- Efficiency: The blade’s ability to slice through the grass effortlessly reduces the time spent on the task, making the process quicker and more efficient.

- Precision: A sharp, properly aligned blade ensures a clean cut, promoting healthy grass growth and enhancing the appearance of the lawn.

- Durability: High-quality blades are designed to withstand the repetitive stresses of cutting, maintaining their sharpness over longer periods.

- Reduced Stress: With the right blade, the stress on the engine is minimized, allowing it to run more smoothly and extend its lifespan.

Maintaining the blade’s condition is essential for keeping the equipment in optimal working order. Regular sharpening and proper alignment can make a significant difference in performance.

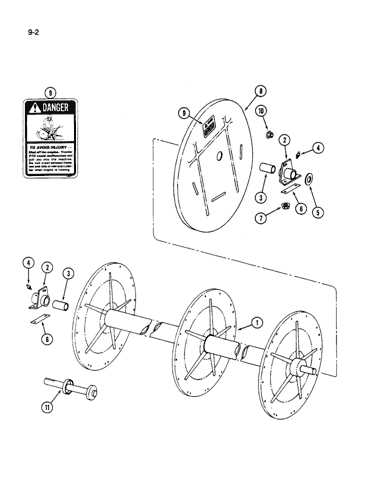

Wheel and Handle Assembly Explained

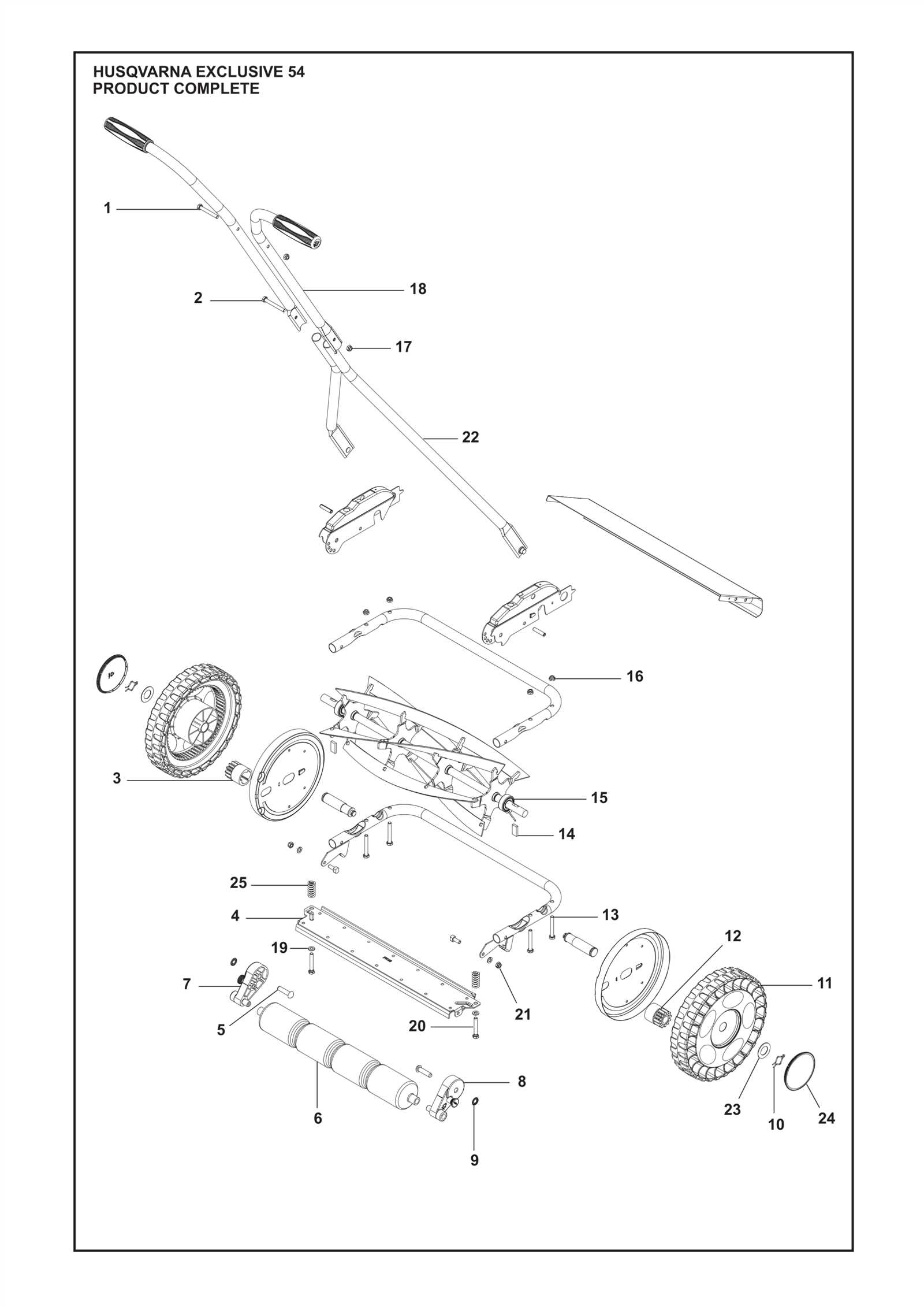

The assembly of the rolling mechanism and control structure plays a crucial role in ensuring smooth operation and maneuverability of the equipment. This section focuses on the key components that connect the wheels to the handles, enabling effortless movement and ease of use during operation. Understanding the configuration and maintenance of these elements is essential for the proper functionality of the machine.

Key Components of the Rolling Mechanism

The rolling mechanism includes the wheels and the associated mounting system. These parts are designed to support the weight of the equipment while ensuring it can move smoothly across various surfaces. Regular inspection of the wheels, axles, and brackets helps maintain optimal performance.

Handle Configuration and Adjustment

The handles provide the necessary leverage and control for operating the equipment. They are usually adjustable to suit different user preferences and are attached to the body structure in a way that ensures comfort and stability. Proper alignment and tightening of the handle components are essential for safe operation.

| Component | Description | Function |

|---|---|---|

| Wheel | A circular element that supports the equipment and allows movement | Ensures smooth movement across surfaces |

| Axle | A rod that connects the wheels and allows them to rotate | Enables wheel rotation for movement |

| Handle | A bar used to control the direction and operation of the equipment | Provides leverage for maneuvering |

| Bracket | A support structure that holds the wheel assembly in place | Secures wheels to the body of the equipment |

Maintenance Tips for Reel Mowers

Proper care and regular upkeep are essential for ensuring that your lawn care tool operates efficiently and lasts for many years. Regular maintenance helps to avoid unnecessary repairs, enhance performance, and keep the tool in optimal working condition.

- Keep the cutting edges sharp for a clean and precise cut.

- Regularly check for any loose or worn-out components to prevent malfunctions.

- Ensure all moving parts are properly lubricated to reduce friction and wear.

- Inspect wheels and adjust the height settings to achieve an even cutting height.

- Clean the tool thoroughly after every use to prevent grass buildup and rust.

By following these steps, you can extend the life of your tool, improve efficiency, and maintain a beautifully groomed lawn.

Common Issues with Reel Mower Parts

When it comes to maintaining a manual cutting tool, there are several challenges that can arise over time. From the blades not aligning correctly to wear and tear on crucial components, these problems can affect the efficiency and performance of the device. Regular inspection and timely repairs are essential to ensure smooth operation.

Misalignment of Cutting Blades

One of the most frequent issues is the misalignment of the cutting elements. Over time, the blades can shift slightly out of position, resulting in uneven cuts. This can cause frustration and lead to the need for frequent adjustments to maintain precision. Proper alignment is essential to avoid damage and ensure a clean, uniform finish.

Wear and Tear on Moving Components

Another common problem is the deterioration of moving parts due to prolonged use. The friction from constant motion can cause parts like gears and axles to wear down, impacting the overall functionality. Lubricating and replacing worn-out components is crucial for maintaining the device’s effectiveness and extending its lifespan.

Replacing Reel Mower Parts Effectively

Maintaining your equipment in top condition is essential for its optimal performance. Understanding the necessary replacements and how to approach them will help ensure your tool runs smoothly for a long time. This section offers insights into the replacement process, focusing on key components that require periodic attention.

Common Components to Replace

Over time, certain elements of the machine wear out due to regular use. Regularly inspecting these items allows for timely replacement, preventing potential damage to other parts. Below are the common components that often need replacing.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Cutting Blades | Signs of dullness, jagged edges, or cracks | Replace with new blades to maintain cutting efficiency |

| Roller | Uneven or noisy rotation, visible damage | Replace if it fails to roll smoothly or shows wear |

| Handle | Cracks or loosening | Replace or tighten for improved control and safety |

| Adjustment Mechanism | Difficulty adjusting or lack of precision | Replace if the mechanism does not function properly |

Steps for Efficient Replacement

Follow these steps to ensure the replacement process is smooth and effective:

- Start by disconnecting any power source or turning off the device.

- Use the appropriate tools for disassembly, ensuring that bolts and screws are properly removed.

- Carefully remove the worn component, avoiding damage to surrounding parts.

- Install the new component securely, making sure it is aligned correctly.

- Test the tool after assembly to confirm proper operation.

Choosing the Right Parts for Your Mower

Selecting the appropriate components for your lawn equipment is essential for ensuring smooth operation and longevity. Each element plays a key role in the efficiency and performance of the tool, and choosing the correct ones helps avoid future problems. Understanding the specific requirements and compatibility of each item is crucial for maintaining the optimal functioning of the device.

When selecting components, consider the quality, durability, and suitability for your machine. It’s vital to match each item with the specifications outlined by the manufacturer to ensure proper fit and function. Below is a helpful guide to assist you in making informed decisions for the right choice of items.

| Component | Function | Key Considerations |

|---|---|---|

| Blade | Responsible for cutting the grass | Ensure sharpness and correct length for the type of work |

| Handle | Provides control over the equipment | Check for ergonomic design and durability |

| Wheels | Facilitate movement and stability | Choose the right size and tread pattern based on terrain |

| Engine | Powers the equipment | Ensure proper power output and fuel efficiency |