When dealing with maintenance or upgrades, it is essential to have a clear view of how each element of your off-road vehicle fits together. The arrangement of the various mechanical parts is vital for both the performance and durability of the machine. Whether you’re conducting repairs or simply trying to familiarize yourself with the setup, recognizing how each component interacts is key to ensuring everything runs smoothly.

Examining individual components allows users to get a deeper understanding of the internal workings of their machine. Visual breakdowns of mechanical systems not only help during assembly or disassembly but also aid in identifying potential issues. By using this approach, anyone from beginners to experienced enthusiasts can efficiently maintain their equipment.

Polaris Trailblazer 250 Parts Overview

Understanding the essential components of a well-known ATV model can help ensure smooth operation and maintenance. This section provides an overview of the key elements that make up the vehicle, highlighting the critical systems and their functions.

Engine and Transmission

The motor and gear system are at the heart of the vehicle, providing the power and control needed for various terrains. The engine operates with a mix of mechanical and electronic systems, ensuring efficient performance, while the transmission allows for seamless shifting between speeds.

Suspension and Steering

The suspension system absorbs shocks from rough terrain, providing a comfortable ride, while the steering assembly ensures precise control. Together, they enable stable handling and adaptability on different surfaces, from smooth roads to off-road trails.

| Component | Function |

|---|---|

| Braking System | Stops or slows the vehicle safely using hydraulic pressure. |

| Fuel System | Supplies and regulates fuel for the engine to maintain consistent power. |

| Cooling Mechanism | Prevents the engine from overheating by dissipating heat efficiently. |

Engine Components and Layout

Exploring the inner workings of an off-road vehicle reveals a complex system of interconnected parts and mechanisms. This section delves into the intricate arrangement and functionality of the power unit, highlighting key components that ensure optimal performance and reliability in challenging terrain.

The heart of the vehicle, known as the powerplant, incorporates various vital elements that collectively drive its capability. Examining the internal combustion system provides insight into how fuel is transformed into mechanical energy, powering the vehicle forward with efficiency. Supporting this primary function are auxiliary systems that regulate temperature, lubrication, and airflow, crucial for maintaining operational integrity.

Each component within the engine bay plays a distinct role in the overall operation, from pistons and cylinders to valves and camshafts. Their precise arrangement within the engine block ensures optimal performance and durability, capable of withstanding the rigors of off-road environments. Understanding the layout and interaction of these components provides enthusiasts and technicians alike with a deeper appreciation of the engineering complexity involved.

Efforts to enhance efficiency and durability continue to drive innovation in engine design, with advancements in materials and manufacturing techniques pushing boundaries. Engineers strive to balance power output with fuel economy and environmental considerations, reflecting ongoing improvements in the field of off-road vehicle engineering.

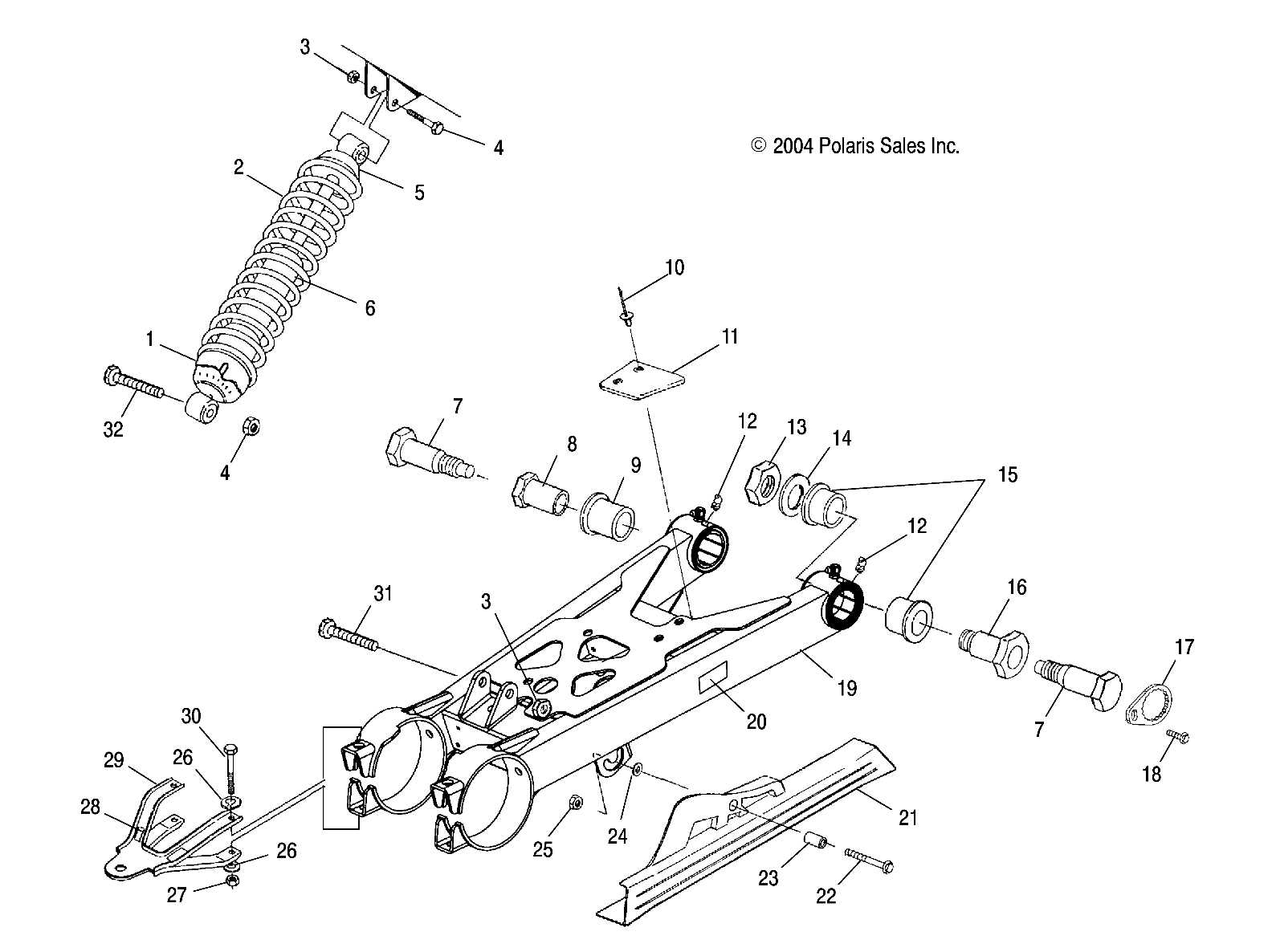

Suspension System Breakdown

The suspension of this vehicle is a complex network of components that work together to ensure optimal handling and comfort on various terrains. It consists of interconnected parts that absorb shocks and vibrations, enhancing stability and control during operation.

Key Components

Within the suspension setup, essential elements include components that manage the vehicle’s ability to react to rough terrain and handle diverse driving conditions. These elements work in tandem to ensure stability and provide an optimal level of comfort for the rider.

Braking System Parts and Function

The braking system of an off-road vehicle is crucial for ensuring control, safety, and stability during operation. Its primary function is to reduce the speed of the vehicle or bring it to a complete stop when necessary. The system works through the application of friction, converting kinetic energy into heat, which slows down or halts the movement. Proper maintenance and understanding of the components involved are essential for efficient and reliable braking performance.

Each component of the braking system plays a specific role in the process. The brake pads apply pressure to the rotors, creating friction that slows the wheels. The brake calipers house the pads and force them against the rotors when the brake lever or pedal is engaged. The brake fluid, housed in the master cylinder, transmits force from the lever to the calipers. In some cases, a brake line connects the components, allowing the hydraulic force to travel effectively. All these parts work together to provide responsive stopping power.

Maintaining the condition of each element is vital. Over time, components like the brake pads and fluid can wear down or degrade, reducing braking efficiency. Regular checks and replacements ensure the vehicle can stop effectively when needed, preventing accidents and enhancing performance in challenging terrains.

Electrical Wiring and Key Components

The efficient functioning of any all-terrain vehicle relies heavily on its electrical system. This system includes a network of wiring, connectors, and essential components that work together to provide power and control various functions. Understanding the intricacies of the electrical setup is crucial for maintenance and troubleshooting, ensuring that every ride is safe and enjoyable.

Wiring Harness and Connections

The wiring harness serves as the backbone of the electrical system, facilitating communication between different parts of the vehicle. Proper connections are vital to prevent electrical failures. Regular inspection of the harness and connectors can help identify wear or corrosion, which could lead to malfunction.

Essential Electrical Components

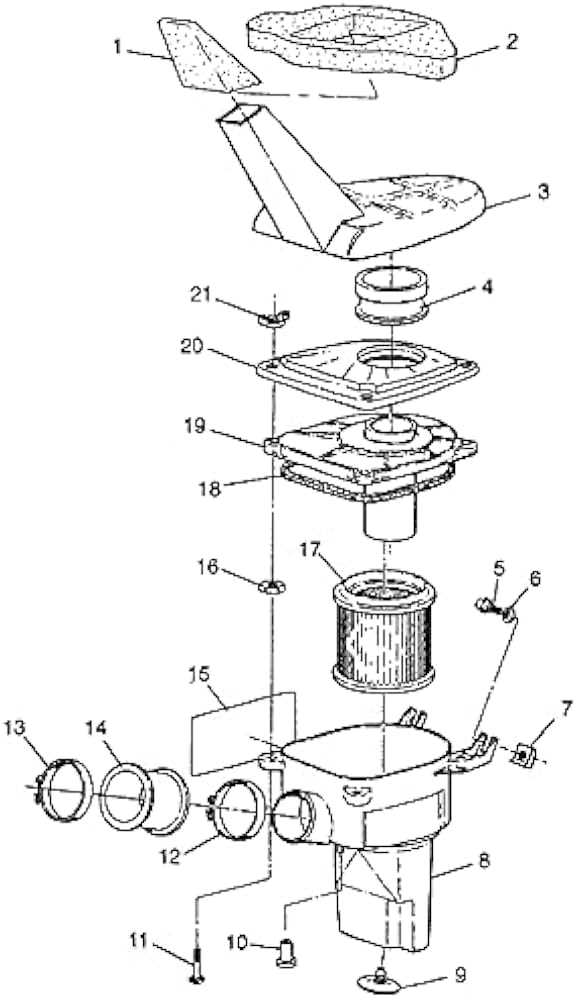

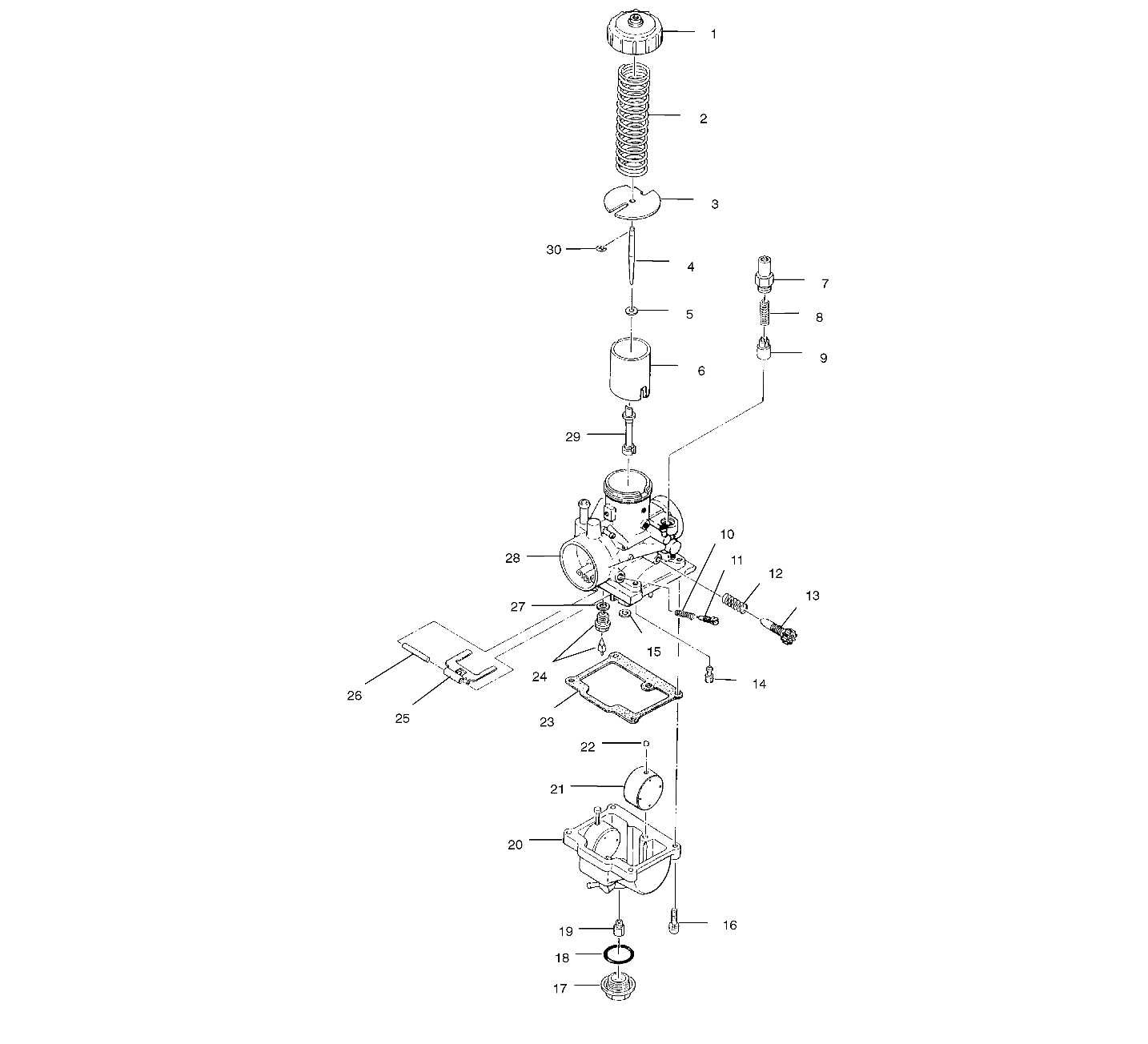

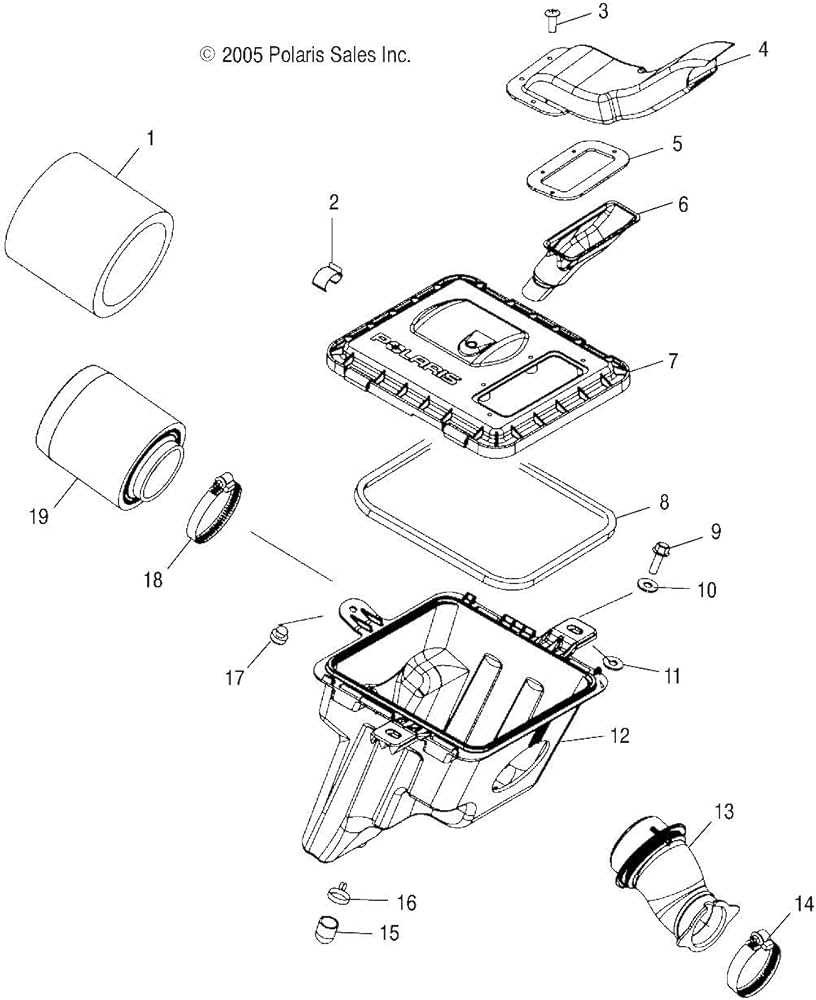

Fuel System Parts and Flow

The fuel system is a crucial component of any vehicle, responsible for delivering the right amount of fuel to the engine for optimal performance. Understanding the various elements and their interactions within this system can help in diagnosing issues and ensuring smooth operation.

Key Components of the Fuel System

- Fuel Tank: Stores fuel until needed.

- Fuel Pump: Transports fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Injector: Sprays the fuel into the engine’s combustion chamber in a fine mist.

- Fuel Lines: Connect the tank, pump, filter, and injector, facilitating the flow of fuel.

Flow of Fuel

- The fuel is drawn from the tank by the fuel pump.

- The fuel passes through the fuel filter, where contaminants are removed.

- Clean fuel travels through the fuel lines to the fuel injector.

- The injector atomizes the fuel and delivers it into the combustion chamber.

- After combustion, exhaust gases are expelled, completing the cycle.

Understanding these components and their function can greatly aid in maintaining the efficiency and reliability of the engine’s fuel delivery system.

Transmission and Drive Chain Components

The transmission and drive chain system is essential for the effective transfer of power from the engine to the wheels. This intricate network of parts ensures smooth acceleration and deceleration while providing the necessary torque for various terrains. Understanding the components involved helps in maintaining optimal performance and addressing potential issues promptly.

Transmission: The heart of the power delivery system, the transmission is responsible for regulating the gear ratios. It allows the operator to change speeds, facilitating control in different driving conditions. Key elements include the gears, clutch mechanism, and shift linkage, all working harmoniously to provide seamless transitions.

Drive Chain: This component links the transmission to the wheels, transmitting rotational force effectively. A well-maintained drive chain ensures that energy is efficiently converted into motion. Important parts of the drive chain include sprockets, chain links, and tensioners. Regular inspection and lubrication of these elements are crucial to avoid wear and ensure longevity.

Conclusion: An understanding of the transmission and drive chain components enhances the ability to troubleshoot and maintain the vehicle. Regular maintenance of these systems is vital for optimal performance and longevity, ultimately leading to a smoother and more enjoyable riding experience.

Frame and Body Structure Details

The frame and body structure of an all-terrain vehicle (ATV) are essential elements that ensure durability, stability, and performance. These components serve as the foundation for the vehicle’s design, providing support to the engine, suspension, and other key parts. The overall construction affects handling, comfort, and safety, while the materials used in the frame construction contribute to the vehicle’s weight and resistance to wear and tear in various environments.

Frame Construction

The frame is typically made of steel or aluminum, materials chosen for their strength and ability to withstand the rigors of off-road riding. A robust frame design absorbs shocks and vibrations, preventing damage to other components. The shape and layout of the frame are critical for maintaining balance and ensuring the vehicle can navigate uneven terrain effectively. Reinforced areas around the engine and suspension mount points provide additional stability where needed.

Body Panels and Guards

The body panels and guards provide protection for the rider and critical components, such as the engine and exhaust system. These parts are often made from lightweight yet durable materials, including high-density plastics and composite materials. They help shield against debris and minor impacts while contributing to the overall aesthetic of the vehicle. Additionally, specific guards are installed to protect the frame from rocks, mud, and other elements encountered during off-road adventures.

| Component | Material | Purpose |

|---|---|---|

| Frame | Steel/Aluminum | Structural support, shock absorption, durability |

| Body Panels | High-density plastic/Composite | Protection from debris, aesthetics |

| Guards | Plastic/Aluminum | Protection of vital components from damage |

Handlebar Controls and Instruments

The handlebar area serves as the primary interface for operators, enabling essential communication between the rider and the machine. This section highlights the various controls and instruments located in this crucial zone, focusing on their functions and importance for safe and efficient operation.

| Control/Instrument | Function |

|---|---|

| Throttle | Regulates engine power and speed by controlling fuel intake. |

| Brakes | Ensures safety by allowing the operator to reduce speed or come to a stop. |

| Clutch Lever | Engages or disengages the engine from the transmission for smooth shifting. |

| Headlight Switch | Controls the illumination of the front lights for visibility during low-light conditions. |

| Ignition Key | Activates the electrical system and engine start function. |

| Speedometer | Displays current speed, aiding the operator in maintaining safe travel rates. |

| Fuel Gauge | Indicates remaining fuel level, ensuring the rider can monitor consumption. |

Understanding the functions of these controls and instruments enhances the riding experience and promotes safety on various terrains. Familiarity with each component is vital for both novice and experienced operators.