When it comes to maintaining and optimizing the performance of your watercraft, having a clear understanding of its mechanical assemblies is crucial. Each element plays a vital role in the overall functionality of the system, ensuring smooth operation on the water. Knowledge of these components not only aids in effective troubleshooting but also enhances the ability to perform necessary repairs and upgrades.

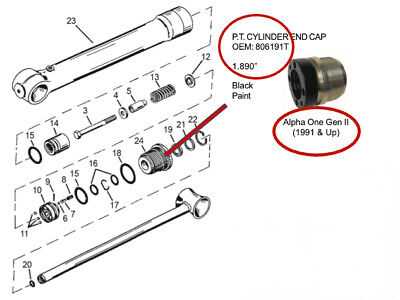

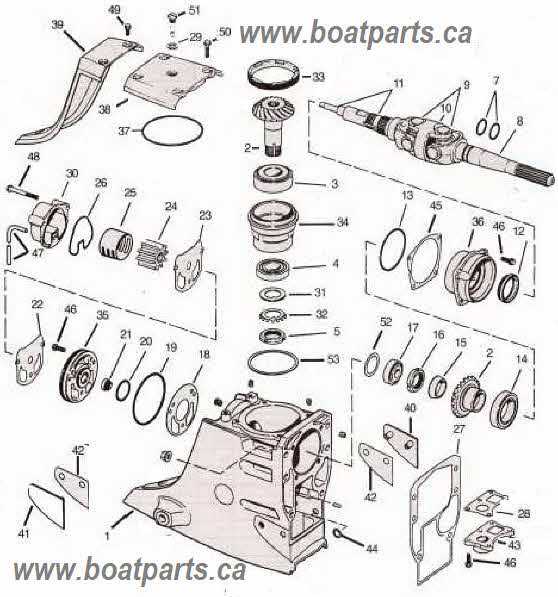

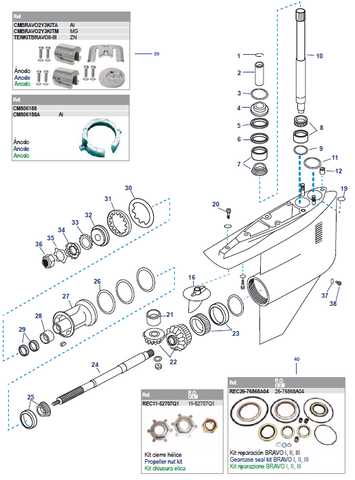

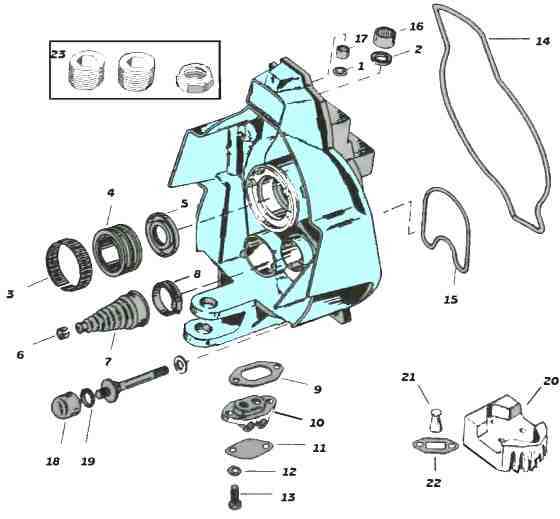

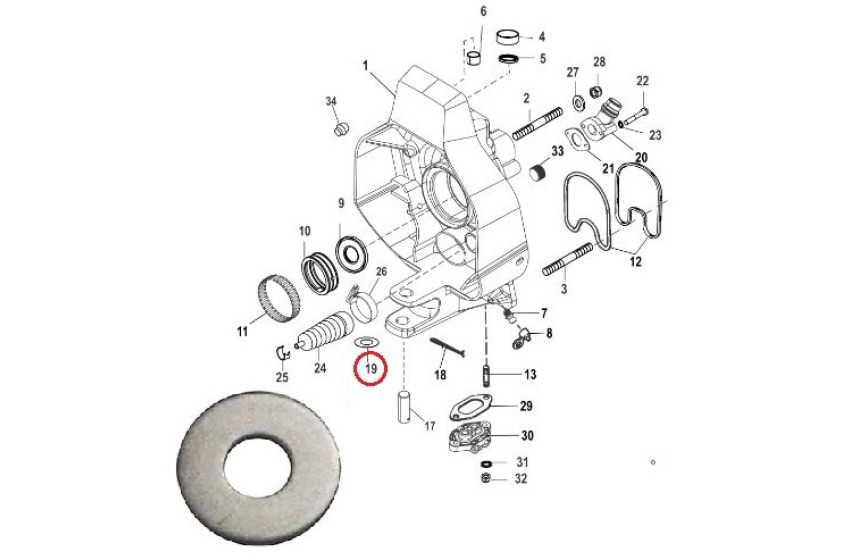

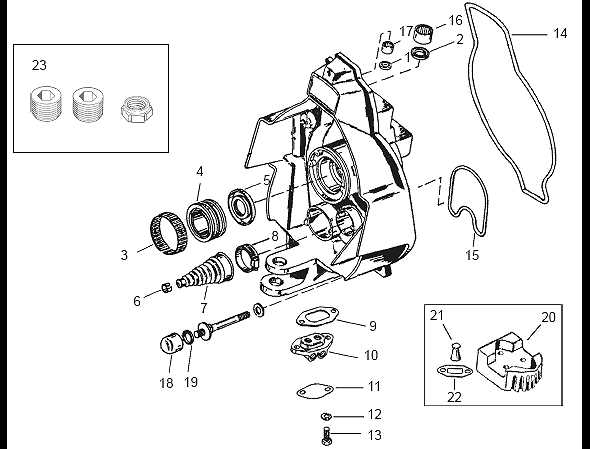

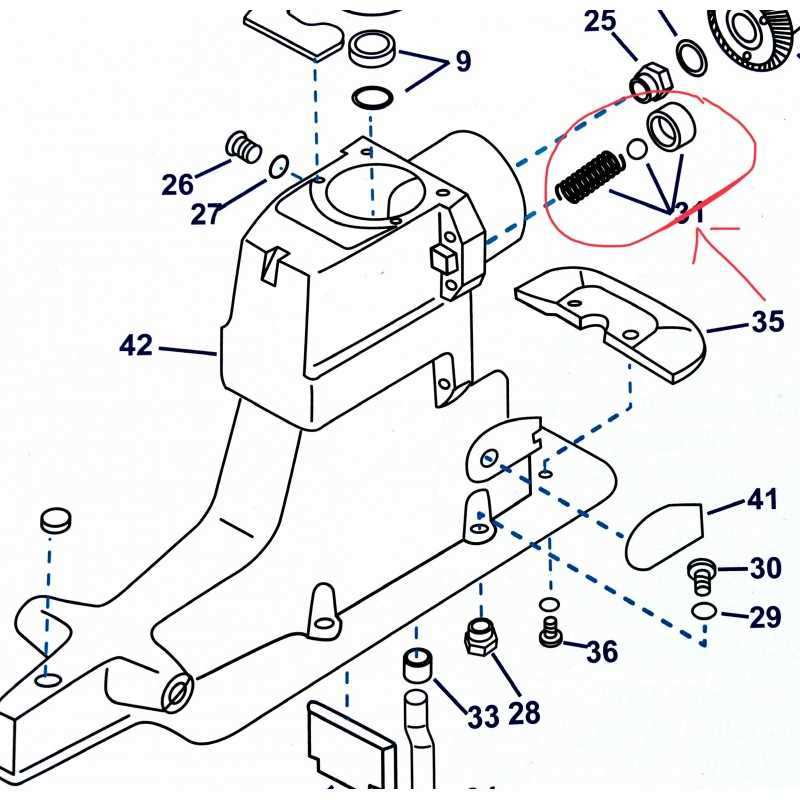

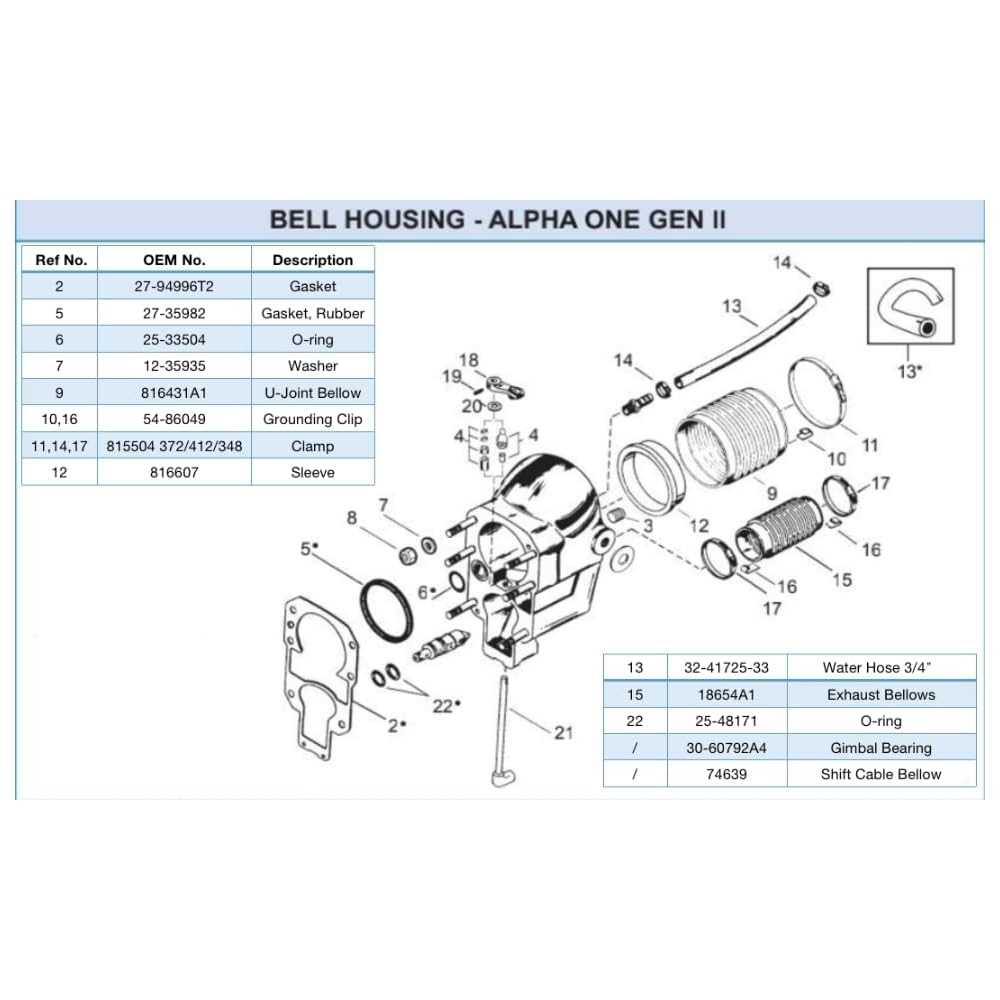

Visual aids can be invaluable for enthusiasts and technicians alike. A comprehensive illustration of the various elements involved in the propulsion system provides a reference point for identification and analysis. These visuals help to demystify complex arrangements, making it easier to grasp how each part interacts with the others.

Moreover, being familiar with the nomenclature and layout of these components empowers owners to engage in informed discussions with service professionals. This understanding fosters confidence when seeking advice or making decisions regarding maintenance strategies. Ultimately, a solid grasp of the underlying mechanics will lead to better care of your vessel, prolonging its lifespan and enhancing your enjoyment on the water.

Understanding Mercruiser Alpha One Gen 2

The marine propulsion system in question is a critical component for ensuring optimal performance and reliability in watercraft. It integrates various elements that contribute to the efficient operation of boats, providing both power and maneuverability. Grasping the intricacies of this system is essential for maintenance, repair, and enhancement of your vessel.

Components of this system work together seamlessly, from the drive unit to the propeller, each playing a vital role. Recognizing how these parts interact can significantly improve both your understanding and handling of the overall mechanism. The functionality of the assembly can impact everything from acceleration to fuel efficiency, making it crucial for boat owners and enthusiasts to be well-versed in its operation.

When exploring the various elements, one can observe that attention to detail in each component’s design contributes to the overall efficiency. Regular maintenance and an awareness of potential wear and tear can extend the lifespan of the system and enhance your boating experience. Familiarity with the specific arrangements and specifications allows for informed decisions regarding repairs or upgrades.

In conclusion, comprehending the complexities of this propulsion system is not only beneficial for troubleshooting but also enhances the overall enjoyment of navigating the waters. By investing time in learning about the interrelated components and their functions, boat owners can ensure that their vessels remain in peak condition.

Key Components of Alpha One Gen 2

This section explores the essential elements that comprise the drive system, highlighting their functions and significance in overall performance. Understanding these components is crucial for maintenance and repair, ensuring that the system operates efficiently and reliably.

Drive Unit

The drive unit serves as the central hub, connecting the engine to the propulsion system. Its design allows for smooth transmission of power, while also providing the necessary angle adjustments for optimal thrust and maneuverability. Regular inspection of seals and lubrication is vital to prevent water ingress and ensure longevity.

Propeller

The propeller is a key element that converts rotational energy into forward motion. Available in various pitches and diameters, selecting the right propeller is crucial for achieving desired speed and handling characteristics. Maintenance involves checking for damage and ensuring proper alignment with the drive unit.

Importance of Parts Diagrams

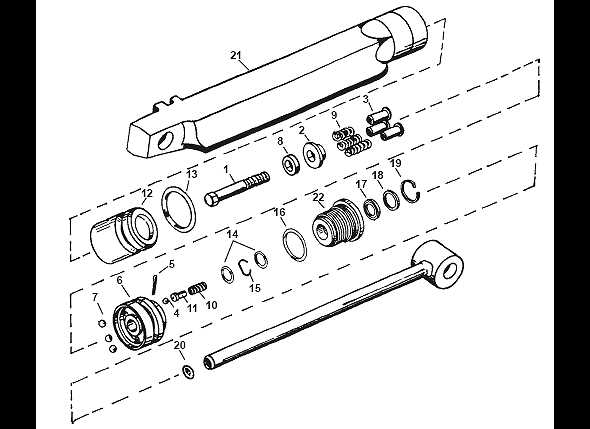

Visual representations of components play a crucial role in understanding the intricacies of mechanical systems. They provide a clear overview, allowing individuals to grasp how each element fits into the larger framework, ultimately enhancing maintenance and repair processes.

Enhanced Understanding

- Clarifies complex assemblies.

- Shows the relationship between various elements.

- Facilitates better troubleshooting.

Efficiency in Repairs

- Streamlines the identification of required components.

- Minimizes the risk of incorrect part installation.

- Reduces downtime during maintenance activities.

How to Interpret the Diagram

Understanding a visual representation of components can enhance your ability to maintain and repair your marine engine efficiently. Familiarity with the layout and symbols used in these illustrations allows for quicker identification of parts and their relationships, ultimately leading to more effective troubleshooting and assembly.

Familiarizing with Symbols

Each symbol and label in the illustration serves a specific purpose. Take the time to learn what each icon represents, as this knowledge will aid in navigating through the complexities of the engine’s structure. Pay attention to legends or keys that may accompany the representation, as they often provide essential insights.

Recognizing Component Relationships

Look for connections and flow paths within the visual guide. Understanding how components interact can provide clues about potential issues and their resolutions. Focus on the arrangement and grouping of elements to grasp how systems are integrated within the overall framework.

Common Replacement Parts Needed

When maintaining your marine engine, certain components often require attention due to wear and tear. Understanding which elements are most commonly replaced can help you ensure optimal performance and longevity of your vessel.

Gear Lube is essential for the smooth operation of the drive system. Regularly checking and changing the lubricant can prevent significant damage and maintain efficiency.

Impellers are vital for water circulation and cooling. A worn or damaged impeller can lead to overheating, making it crucial to replace this component periodically.

Gaskets play a critical role in sealing various engine parts. Over time, these can degrade, leading to leaks. Keeping a fresh supply of gaskets on hand can save you from unexpected issues.

Hoses and Belts are also common replacements. Exposure to water and varying temperatures can cause them to crack or wear out, so regular inspections are recommended.

Lastly, Filters, including fuel and oil filters, need to be changed regularly to ensure clean operation and prevent contaminants from entering critical systems.

By being aware of these commonly replaced components, you can better prepare for maintenance and keep your engine running smoothly.

Maintenance Tips for Longevity

Ensuring the durability of your marine engine requires regular attention and care. By adhering to a consistent maintenance schedule, you can prevent potential issues and extend the life of your equipment significantly.

Regular Inspections

Routine checks are essential for identifying wear and tear early. Inspect components such as seals, hoses, and electrical connections frequently to catch any problems before they escalate.

Fluid Management

Maintaining proper fluid levels is crucial. Change the oil and other fluids according to the manufacturer’s recommendations to ensure optimal performance and reduce friction and wear.

Identifying Issues Through Diagrams

Understanding mechanical systems can be daunting, but visual representations play a crucial role in diagnosing problems. By utilizing detailed illustrations, one can pinpoint discrepancies, assess component relationships, and streamline troubleshooting processes. These visuals serve as a roadmap, guiding users through complex structures and highlighting areas that may require attention.

Visual aids simplify the identification of faults by allowing users to see how parts interact and function together. When a malfunction occurs, these resources enable users to compare normal operations against problematic scenarios, facilitating quicker resolutions. Moreover, diagrams enhance communication among technicians and enthusiasts alike, ensuring everyone has a clear understanding of the system in question.

Ultimately, leveraging these illustrative tools fosters a more efficient approach to maintenance and repair. As one delves deeper into the specifics, the clarity provided by these representations can significantly reduce guesswork and lead to more effective solutions.

Where to Find Quality Parts

Finding reliable components for your marine engine can significantly enhance performance and longevity. High-quality materials are essential for ensuring optimal functionality and safety on the water. Here are some effective strategies to locate the best options available.

- Authorized Dealers: Visit authorized retailers or dealerships that specialize in marine equipment. They often provide genuine components with manufacturer warranties.

- Online Marketplaces: Utilize reputable online platforms that specialize in marine supplies. Look for sellers with positive reviews and ratings to ensure credibility.

- Local Marine Supply Stores: Explore local shops that cater to boat enthusiasts. These stores often have knowledgeable staff who can guide you in choosing the right items.

- Boat Shows and Expos: Attend marine exhibitions and trade shows. These events provide an opportunity to connect with vendors and discover new products.

- Forums and Community Groups: Join online forums and social media groups focused on boating. Members frequently share recommendations and experiences regarding various suppliers.

By employing these methods, you can ensure that you obtain durable and efficient components for your vessel, contributing to a safer and more enjoyable experience on the water.

DIY Repairs: A Step-by-Step Guide

Engaging in do-it-yourself repairs can be a rewarding experience that saves time and money. This guide is designed to help you navigate through common maintenance tasks with clarity and confidence. By following these steps, you can address issues effectively and enhance the longevity of your equipment.

Preparation and Tools

Before starting any repair, gather the necessary tools and materials. A well-equipped workspace can significantly impact your efficiency. Ensure you have a quality toolkit, including wrenches, screwdrivers, and pliers. Additionally, keep safety gear like gloves and goggles nearby to protect yourself during the process.

Step-by-Step Process

Begin with a thorough assessment of the situation. Identify the problem and refer to manuals or online resources for guidance. Document the steps you take, and if applicable, label any components you remove. This will simplify reassembly later on. Follow each step carefully, making adjustments as necessary. Once repairs are completed, conduct a test to ensure everything operates smoothly.

With patience and practice, tackling repairs independently can become a valuable skill that not only enhances your knowledge but also builds confidence in maintaining your equipment.