In the world of machinery and equipment, comprehending the arrangement of individual elements is crucial for efficient operation and maintenance. Each system consists of various sections that work in harmony, ensuring optimal performance. A clear visual representation aids technicians and enthusiasts alike in identifying parts and their interconnections.

Detailed schematics serve as invaluable tools, offering insight into the configuration of a specific model. By examining these illustrations, users can gain a deeper understanding of how components interact and support one another. Such knowledge not only facilitates troubleshooting but also enhances overall functionality.

Whether you are a seasoned expert or a newcomer, familiarity with these layouts can significantly improve your experience. With the right resources, navigating the intricacies of equipment becomes more accessible, empowering users to take charge of their machinery and extend its lifespan.

Mec 600 JR Overview

This section provides a comprehensive look at a specific model renowned for its efficiency and reliability in various applications. It highlights the essential features, functionalities, and overall design philosophy that make this equipment a preferred choice among users. Understanding these elements is crucial for anyone considering its use or maintenance.

The unit is designed with precision engineering, ensuring optimal performance and durability. Its robust construction is complemented by user-friendly controls, allowing for seamless operation in diverse settings. Additionally, the model incorporates innovative technology that enhances its capabilities, making it suitable for both novice and experienced operators.

| Feature | Description |

|---|---|

| Design | Compact and lightweight, facilitating easy transport and setup. |

| Efficiency | Engineered for high productivity with minimal energy consumption. |

| Durability | Constructed from high-quality materials, ensuring long-lasting performance. |

| User Interface | Intuitive controls that simplify operation and reduce learning curve. |

| Versatility | Adaptable for a range of tasks, making it ideal for various users. |

In summary, this equipment stands out due to its well-thought-out design and practical features, providing significant advantages to its users across multiple applications.

Understanding Parts Functionality

Every component within a mechanical system plays a crucial role in ensuring optimal performance and efficiency. By grasping the unique roles of each element, one can better appreciate how they contribute to the overall operation. This comprehension not only aids in maintenance but also enhances troubleshooting capabilities.

Components serve specific purposes, often working in harmony with others to achieve desired outcomes. For instance, some parts may be responsible for generating power, while others facilitate movement or provide support. Recognizing these functions allows users to identify potential issues early and implement effective solutions.

Moreover, understanding how various elements interact can illuminate the intricacies of design and engineering. Each piece is engineered to perform under specific conditions, and a failure in one area can disrupt the entire system. Knowledge of these relationships empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to improved functionality and longevity.

Importance of Accurate Diagrams

Precise illustrations are crucial in various fields, serving as vital tools for understanding complex systems. They provide clarity, enhance communication, and streamline processes, making it easier for individuals to grasp intricate concepts and components.

Enhancing Understanding

Clear visual representations allow users to:

- Quickly identify essential elements

- Visualize relationships between components

- Facilitate learning and retention of information

Improving Efficiency

Accurate visuals lead to:

- Reduced errors in assembly or maintenance

- Faster troubleshooting and repairs

- Better collaboration among team members

Common Issues with Mec 600 JR

When dealing with various machinery and equipment, certain problems tend to arise frequently. Understanding these issues can help users maintain their devices more effectively and prevent operational disruptions. Below are some of the most prevalent concerns associated with this particular model.

- Jamming: One of the most common problems users face is jamming, often caused by improper alignment or debris buildup.

- Inconsistent Performance: Variability in output can result from worn components or inadequate lubrication, leading to unreliable operation.

- Electrical Failures: Malfunctions in the electrical system may occur, affecting the machine’s responsiveness and functionality.

- Material Feed Issues: Problems with material feeding can lead to inefficiencies, often linked to miscalibration or blockages.

To address these issues, regular maintenance and careful operation are crucial. Users should familiarize themselves with the equipment’s specifications to mitigate risks and enhance longevity.

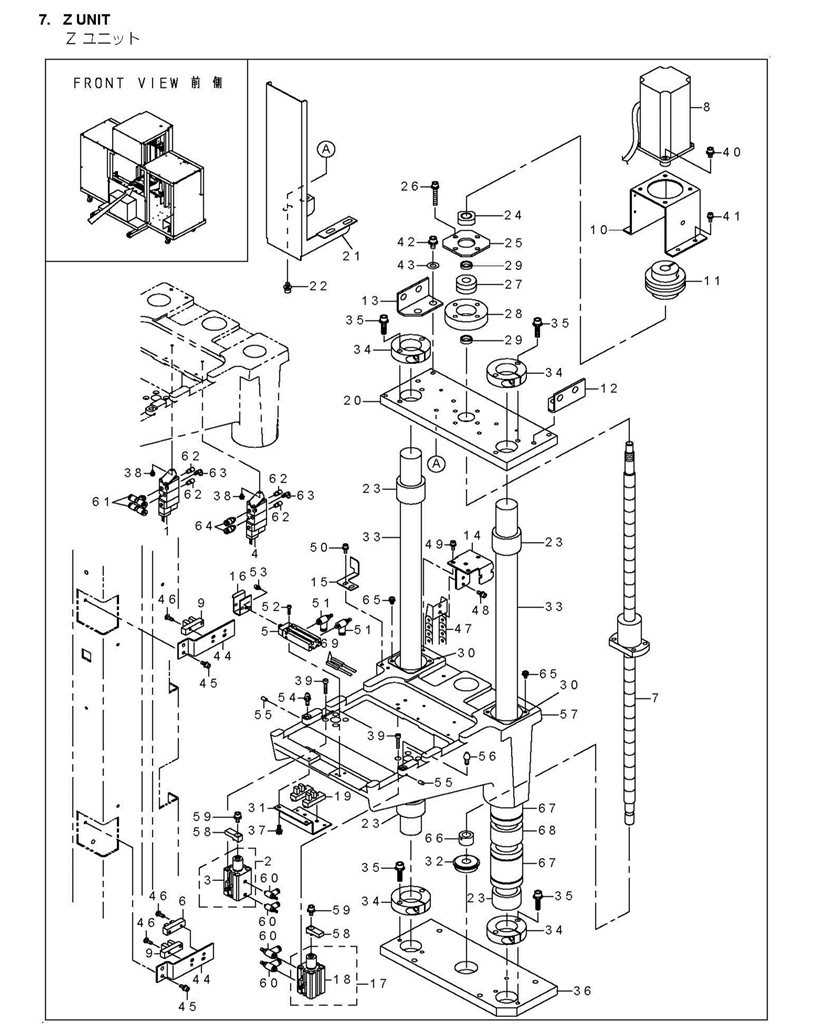

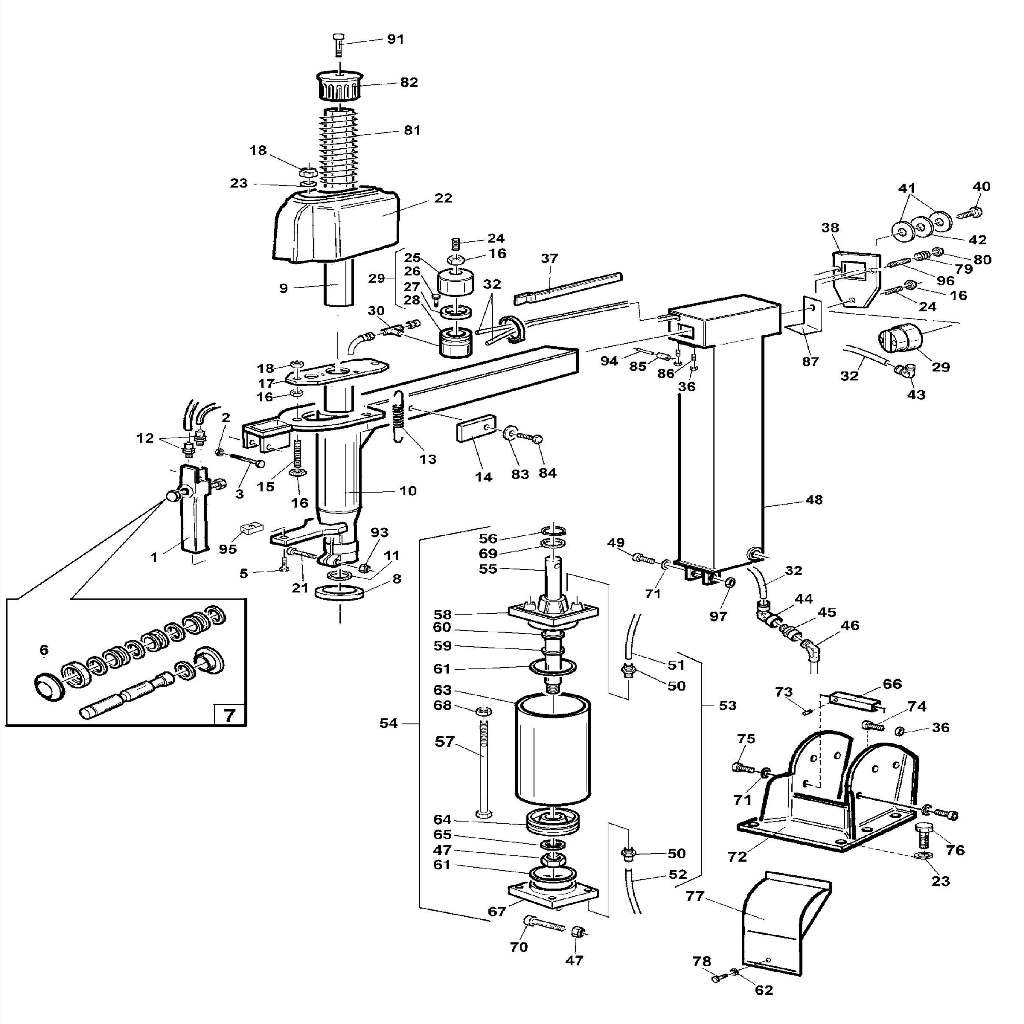

How to Interpret Parts Diagram

Understanding visual representations of components is crucial for effective assembly and maintenance. These illustrations serve as guides, simplifying the identification and organization of various elements. Familiarizing yourself with these visuals can enhance your overall experience with machinery and equipment.

Key Elements of the Illustration

Begin by noting the labeling system used within the representation. Each part is typically assigned a unique identifier, often accompanied by a description. Pay attention to the numbers or letters associated with each section, as these will help you locate specific items easily. Additionally, look for any accompanying notes or symbols that provide further context or instructions.

Understanding Relationships and Functions

Next, examine how the components relate to one another. The arrangement often indicates how parts interact within the system. Identifying these connections is essential for troubleshooting and repairs. Recognizing the function of each component can also provide insights into the overall operation of the machinery, allowing for more informed decisions during maintenance or replacement processes.

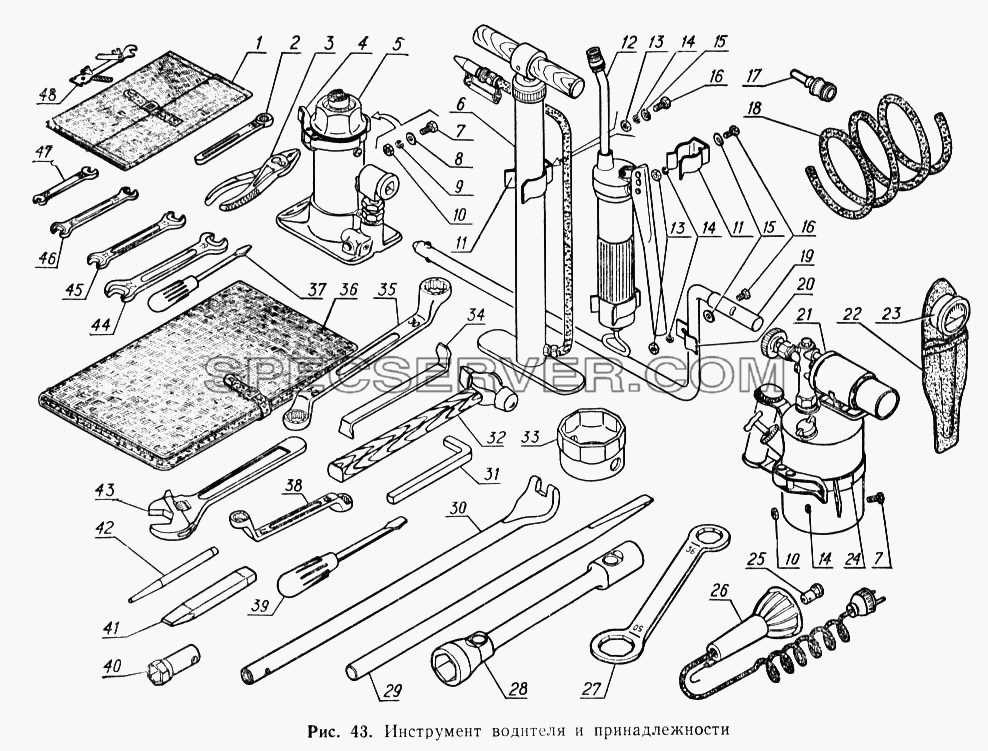

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. Each task requires specific implements that not only enhance efficiency but also ensure safety during the process. Whether you are a professional or a hobbyist, equipping yourself with quality tools can make all the difference in achieving successful outcomes.

1. Screwdrivers: A diverse set of screwdrivers is fundamental. Flathead and Phillips variations in multiple sizes enable you to tackle a range of fasteners with ease. Ensure they have ergonomic grips for comfort during extended use.

2. Wrenches: An adjustable wrench and a set of combination wrenches allow for flexibility when working with nuts and bolts of various dimensions. Look for options that provide a solid grip to prevent slipping.

3. Pliers: Needle-nose and slip-joint pliers are versatile tools essential for gripping, twisting, and cutting. Their ability to reach tight spaces makes them indispensable during intricate repairs.

4. Multimeter: This instrument is vital for diagnosing electrical issues. It measures voltage, current, and resistance, enabling you to pinpoint faults efficiently.

5. Safety Gear: Always prioritize safety with protective eyewear and gloves. These items safeguard against potential hazards, ensuring a secure working environment.

By investing in these essential implements, you prepare yourself to tackle various repair challenges effectively and safely.

Maintenance Tips for Longevity

Ensuring the long-term performance of your equipment requires regular attention and care. By adopting a proactive approach to upkeep, you can significantly extend its lifespan and maintain optimal functionality. Here are essential practices to keep in mind.

Regular Cleaning

Keeping components free from dirt and debris is crucial. Accumulated grime can lead to wear and tear over time. Use appropriate cleaning solutions and tools to gently remove contaminants, ensuring that no damage occurs during the process. Regular maintenance will not only enhance performance but also prevent unexpected failures.

Periodic Inspections

Conducting routine checks allows you to identify potential issues before they escalate. Pay close attention to moving parts and connections, looking for signs of wear or irregularities. Early detection can save time and resources, helping you avoid costly repairs. Remember to refer to your manual for specific inspection intervals and recommendations.

Implementing these strategies will help you achieve a more reliable operation and maximize the longevity of your equipment. Prioritizing care today ensures a better-performing tomorrow.

Where to Source Replacement Parts

Finding the right components for your equipment can often be a challenge. Various options are available for sourcing these essentials, ensuring that your machinery continues to operate efficiently. Understanding where to look and what to consider can make a significant difference in the maintenance process.

Online Retailers: A multitude of online platforms specialize in aftermarket and OEM offerings. Websites dedicated to equipment parts often provide a comprehensive selection, along with detailed specifications to help you make informed decisions.

Local Dealers: Engaging with local distributors can provide you with access to original components. Establishing a relationship with a dealer can also yield benefits such as personalized service and expert advice tailored to your needs.

Manufacturer’s Website: Directly visiting the manufacturer’s official website is another reliable approach. They typically have a section for ordering components, ensuring that you receive genuine items that fit your model perfectly.

Salvage Yards: For those looking to save on costs, salvage yards can be a treasure trove of usable components. While this option may require more effort in terms of searching, it can lead to significant savings and unique finds.

Forums and Community Groups: Engaging with online forums or community groups dedicated to your type of equipment can provide valuable insights. Members often share recommendations for where to find components, as well as tips for installation and maintenance.

By exploring these various avenues, you can effectively locate the necessary items to keep your machinery in peak condition.

User Experiences and Feedback

This section explores the impressions and evaluations shared by users regarding their interactions with the equipment. Gathering insights from various individuals can reveal the strengths and weaknesses of the system, helping others make informed decisions.

- Many users appreciate the ease of operation, highlighting intuitive controls and quick setup.

- Some have noted durability and reliability, emphasizing long-term use without significant issues.

- On the other hand, a few users reported challenges with specific components, suggesting improvements could be made.

- Overall satisfaction tends to correlate with the quality of customer support received.

- Feedback often highlights the importance of user manuals for better understanding.

- Regular updates based on user input have significantly enhanced functionality.

Engaging with these experiences can provide valuable perspectives for potential users, encouraging a deeper understanding of the system’s ultimate capabilities.