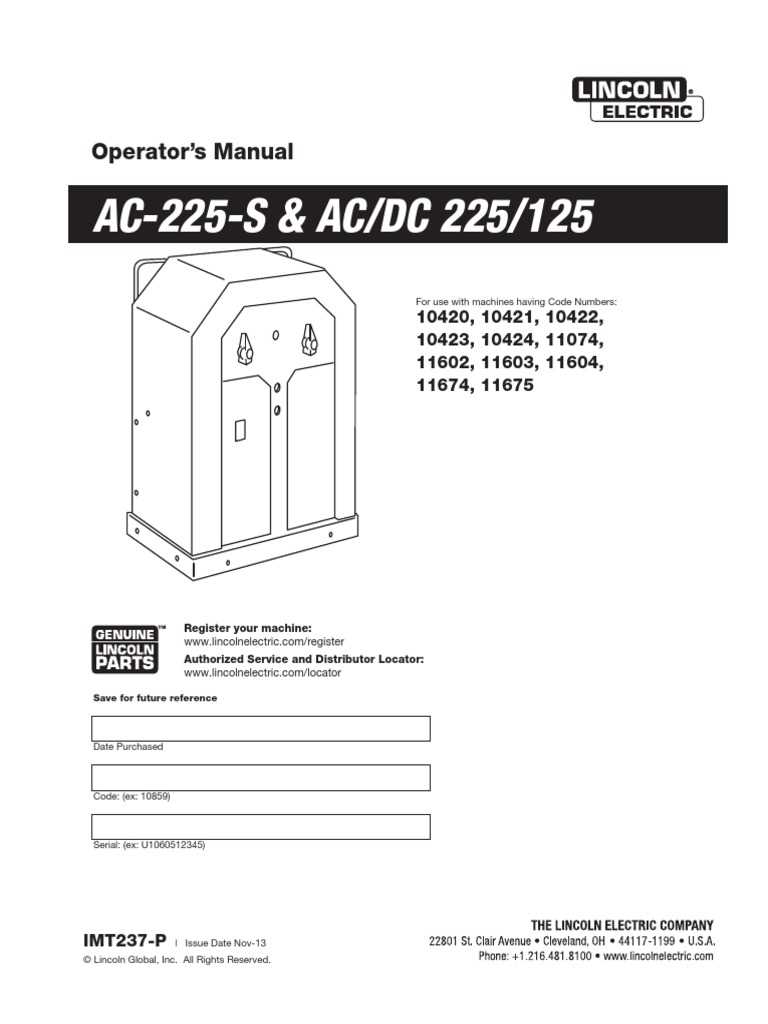

In the realm of welding machinery, comprehending the intricate relationships between various elements is vital for optimal functionality. Each component plays a crucial role, ensuring the equipment operates smoothly and efficiently. A clear visual representation can significantly aid in grasping these interconnections.

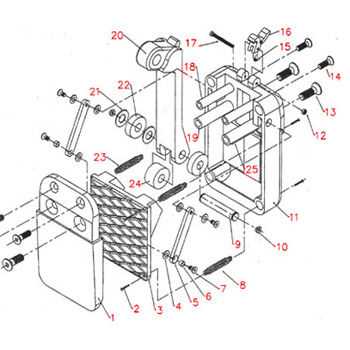

Analyzing the layout of a welder’s internals allows users to identify necessary replacements and upgrades with confidence. This knowledge not only enhances maintenance practices but also extends the lifespan of the equipment. With a comprehensive overview, operators can address issues proactively.

Furthermore, a well-structured reference can serve as an invaluable tool for both novices and seasoned professionals. By diving deep into the specifics, one can uncover the ultimate insights needed to enhance performance and achieve superior results in welding tasks.

Understanding Lincoln AC 225 Components

Familiarizing oneself with the various elements of a welding machine is crucial for both effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, enabling users to achieve desired results in their projects. By comprehensively understanding these parts, one can troubleshoot issues more efficiently and enhance the longevity of the equipment.

Main Components

- Transformer: Converts electrical energy into usable welding current.

- Control Panel: Provides access to settings and adjustments for different welding tasks.

- Electrode Holder: Secures the electrode and conducts current during welding.

- Ground Clamp: Establishes a return path for the electrical circuit, ensuring safety and efficiency.

Additional Parts

- Circuit Breaker: Protects the machine from overloads and electrical faults.

- Cooling System: Prevents overheating during prolonged use, maintaining performance standards.

- Welding Leads: Connect the machine to the workpiece and facilitate the flow of current.

Understanding these components and their functions will empower users to maximize their equipment’s capabilities, leading to improved results and enhanced user experience.

Essential Parts for Effective Operation

To ensure optimal functionality of any welding equipment, understanding the critical components involved is vital. Each element plays a significant role in maintaining performance and enhancing user experience. By familiarizing oneself with these fundamental elements, operators can achieve better results and extend the lifespan of their equipment.

The following table outlines the key components necessary for the effective operation of welding systems:

| Component | Description |

|---|---|

| Power Source | Provides the necessary electrical energy to create the welding arc. |

| Electrode Holder | Holds the welding electrode securely, allowing for precise manipulation during the process. |

| Ground Clamp | Establishes a secure connection to the workpiece, ensuring safety and effective current flow. |

| Cables | Conduct electricity between the power source and the electrode holder, facilitating smooth operation. |

| Cooling System | Prevents overheating of the equipment by dissipating heat generated during operation. |

By prioritizing the maintenance and proper usage of these vital components, operators can significantly enhance the performance and reliability of their welding apparatus.

Common Issues and Solutions

Understanding the common problems that can arise with welding machines is crucial for maintaining their efficiency and ensuring optimal performance. This section will explore frequent challenges encountered by users and provide effective remedies to address these issues.

Electrical Problems

Electrical malfunctions are among the most prevalent issues. These can stem from faulty connections, worn-out components, or inadequate power supply. Identifying the source of the problem is essential for effective troubleshooting.

| Issue | Solution |

|---|---|

| Inconsistent Power Supply | Check the power source and connections. Ensure the voltage matches the machine’s requirements. |

| Flickering Display | Inspect wiring for damage and replace any frayed or corroded cables. |

Performance Issues

Performance-related concerns can significantly impact productivity. These may include poor arc stability or difficulty in maintaining a consistent weld quality. Recognizing the root causes is vital for implementing effective solutions.

| Issue | Solution |

|---|---|

| Poor Arc Stability | Adjust the settings and ensure the correct electrode is being used for the material. |

| Inconsistent Weld Quality | Clean the workpieces thoroughly and check for proper gas flow if applicable. |

Maintenance Tips for Longevity

To ensure the extended lifespan of your equipment, regular upkeep and attention to detail are essential. Implementing a structured maintenance routine can significantly reduce wear and enhance performance, allowing for seamless operation over time.

Begin with routine inspections to identify any signs of wear or potential issues early on. Keeping components clean and free from debris will also prevent unnecessary strain. Lubrication of moving parts is crucial to reduce friction and improve efficiency.

Additionally, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures. Using quality replacement components when necessary will contribute to optimal functionality and reliability. Finally, maintaining a clean workspace can prevent contamination and damage to sensitive parts.

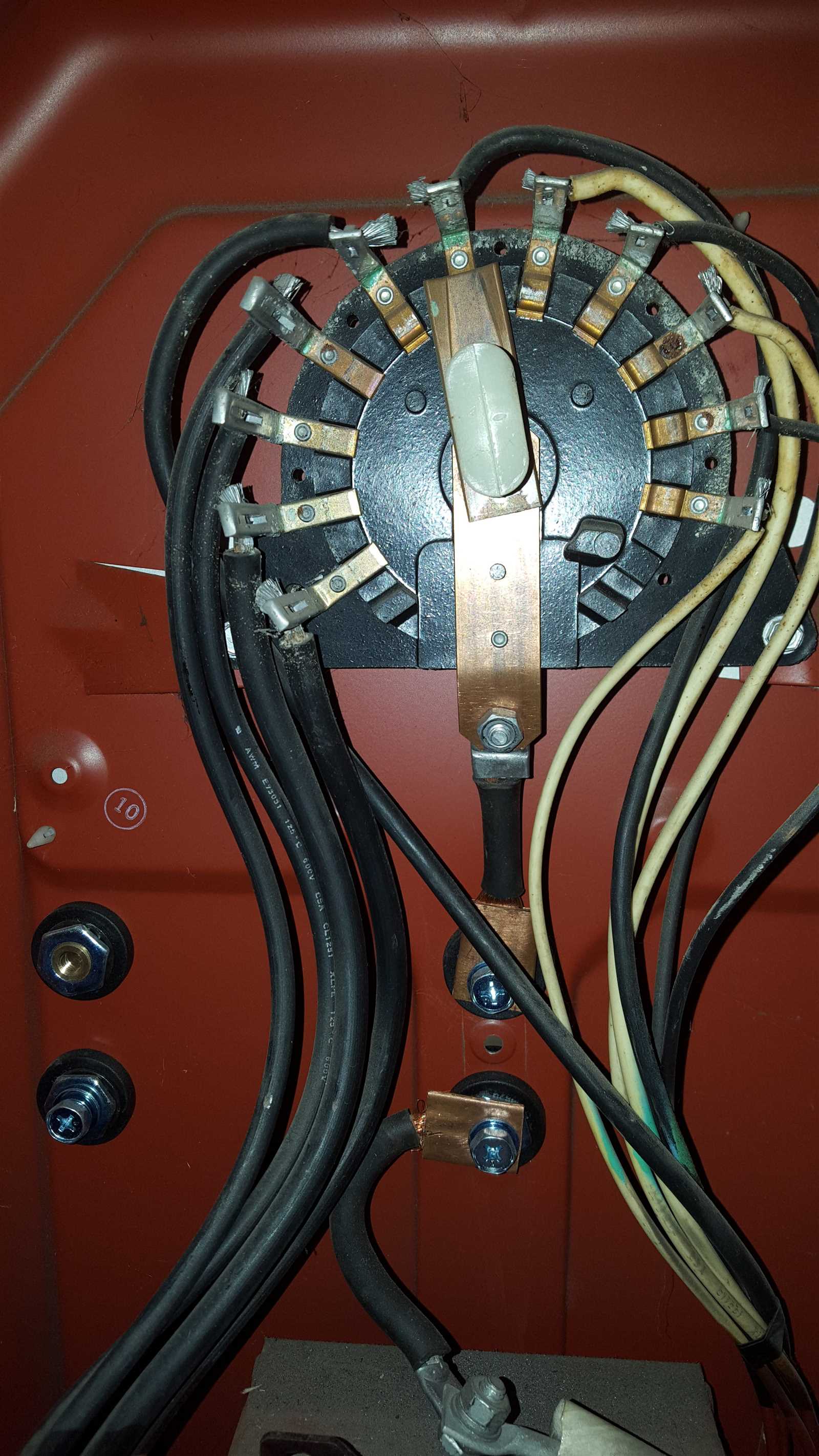

Wiring Diagram Overview Explained

Understanding the intricate connections within an electrical system is crucial for effective troubleshooting and maintenance. A comprehensive illustration serves as a visual guide, mapping out how components interconnect and function together. This clarity helps users identify potential issues and make informed adjustments or repairs.

Key Components and Their Functions

Every electrical blueprint highlights essential elements, such as power sources, connectors, and operational parts. Recognizing each component’s role is vital for grasping the overall functionality. It allows users to pinpoint where current flows, how circuits are completed, and which areas may require attention.

Interpreting Symbols and Connections

Familiarity with the various symbols used in these illustrations is essential for accurate interpretation. Each symbol represents a different part or type of connection, providing insight into the operational flow of the system. Understanding these representations empowers users to navigate the setup effectively and enhances their ability to solve problems as they arise.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various sources are available that offer quality items suitable for maintenance and repair needs. Understanding these options can save you time and ensure you find the right pieces for optimal performance.

Authorized Dealers

One of the most reliable ways to obtain high-quality components is through authorized dealers. These retailers are certified and often provide original parts that guarantee compatibility and durability. Visiting the manufacturer’s website can help you find a list of trusted sellers in your area.

Online Marketplaces

The internet offers a plethora of online marketplaces where you can search for components. Websites specializing in industrial supplies often have extensive catalogs, including user reviews and ratings that can assist in making informed decisions. Ensure to check the seller’s reputation and return policy before making a purchase.

Remember, when searching for replacements, always verify the specifications to ensure a proper fit. Quality should never be compromised, as it directly impacts the performance and longevity of your equipment.

Upgrading Your Lincoln AC 225

Enhancing your welder can significantly improve its performance and extend its lifespan. Whether you’re a hobbyist or a professional, investing in upgrades can lead to better results and a more enjoyable experience. This section explores various modifications and enhancements that can elevate the capabilities of your equipment.

One of the first areas to consider is the power supply. Upgrading to a higher amperage source can provide more versatility for various welding tasks. Additionally, implementing a more efficient cooling system can prevent overheating during extended use, ensuring consistent performance.

Another important aspect is the welding electrode holder. Choosing a more ergonomic design can enhance comfort and reduce fatigue during longer sessions. Similarly, selecting high-quality cables can improve conductivity and reduce energy loss, leading to more effective welding.

For those looking to expand their skill set, adding a spool gun or a TIG attachment can open up new possibilities for different welding techniques. These additions can make your equipment more versatile and allow you to tackle a wider range of projects with ease.

Finally, don’t overlook the importance of regular maintenance. Upgrading components like the contact tip and nozzle can ensure a cleaner, more efficient welding process. With thoughtful enhancements and proper upkeep, your welder can achieve peak performance for years to come.

Safety Precautions While Using Equipment

Ensuring safety during the operation of machinery is paramount for both the operator and those in proximity. Proper precautions not only minimize the risk of accidents but also enhance overall efficiency and effectiveness in task execution.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear such as gloves, goggles, and helmets to shield against potential hazards.

Familiarization with the equipment is crucial. Operators should thoroughly understand the operational guidelines and safety features before use.

Regular maintenance is vital to ensure the machinery is in optimal condition. Inspect the equipment for any signs of wear or damage before starting.

Keep the work area clear of obstructions to prevent accidents. A tidy space allows for better movement and reduces the chance of tripping or falling.

Finally, always have an emergency plan in place. Knowing the steps to take in case of an incident can significantly reduce response time and potential harm.

Resources for Further Learning

Exploring supplementary materials can significantly enhance your understanding of welding equipment and its components. This section provides a variety of resources that cater to different learning preferences, ensuring that you can deepen your knowledge effectively.

- Books:

- “Welding Essentials” by William L. B. Dutton

- “Modern Welding” by Andrew D. Althouse

- “The Welding Handbook” by the American Welding Society

- Online Courses:

- Coursera – Welding Fundamentals

- edX – Introduction to Welding Processes

- Udemy – Advanced Welding Techniques

- Videos:

- YouTube – Welding Tips and Tricks Channel

- Vimeo – Professional Welding Demonstrations

- Skillshare – Interactive Welding Workshops

- Forums and Communities:

- WeldingWeb – Discussion boards for enthusiasts and professionals

- Reddit – Subreddit r/Welding for sharing experiences and advice

- American Welding Society – Networking and resources for members

Utilizing these resources will provide valuable insights and practical knowledge, empowering you to excel in your welding projects and maintenance tasks.