The functionality of any mowing machine relies heavily on its intricate network of elements working in harmony. A thorough comprehension of these components not only enhances operational efficiency but also extends the lifespan of the equipment. By exploring the individual sections of the machine, operators can ensure optimal performance and reduce maintenance issues.

In this guide, we will explore a visual representation of the essential parts, detailing their roles and interconnections. This knowledge empowers users to tackle repairs with confidence and to select the appropriate replacements when necessary. Delving into the specifics will ultimately lead to a better understanding of the equipment’s capabilities.

Additionally, recognizing the significance of each part allows for informed decision-making during service and upgrades. A proactive approach to maintenance will not only enhance the reliability of your mower but also contribute to a more satisfying mowing experience. Ultimately, this knowledge serves as a valuable resource for both novice and experienced operators alike.

Overview and Features

This section provides a comprehensive look at a well-engineered machine designed for efficient lawn care and maintenance. With a focus on performance and user-friendly design, this equipment stands out in its class, catering to both residential and commercial users. Its robust construction and innovative features make it a reliable choice for tackling various landscaping tasks.

Key Characteristics

The equipment boasts several essential attributes that enhance its functionality and ease of use. From a powerful engine to advanced cutting technology, it is built to deliver superior results in diverse conditions.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a high-performance engine that ensures efficient operation and longevity. |

| Cutting Width | A wide cutting deck allows for quick and effective mowing, reducing overall maintenance time. |

| Operator Comfort | Designed with ergonomic seating and controls for a comfortable experience during extended use. |

| Durability | Constructed with high-quality materials to withstand rigorous use and adverse weather conditions. |

Benefits

The combination of innovative design and powerful features makes this machine an excellent investment for those seeking efficiency and reliability in lawn care. Its ability to handle various tasks effortlessly contributes to a more enjoyable and productive landscaping experience.

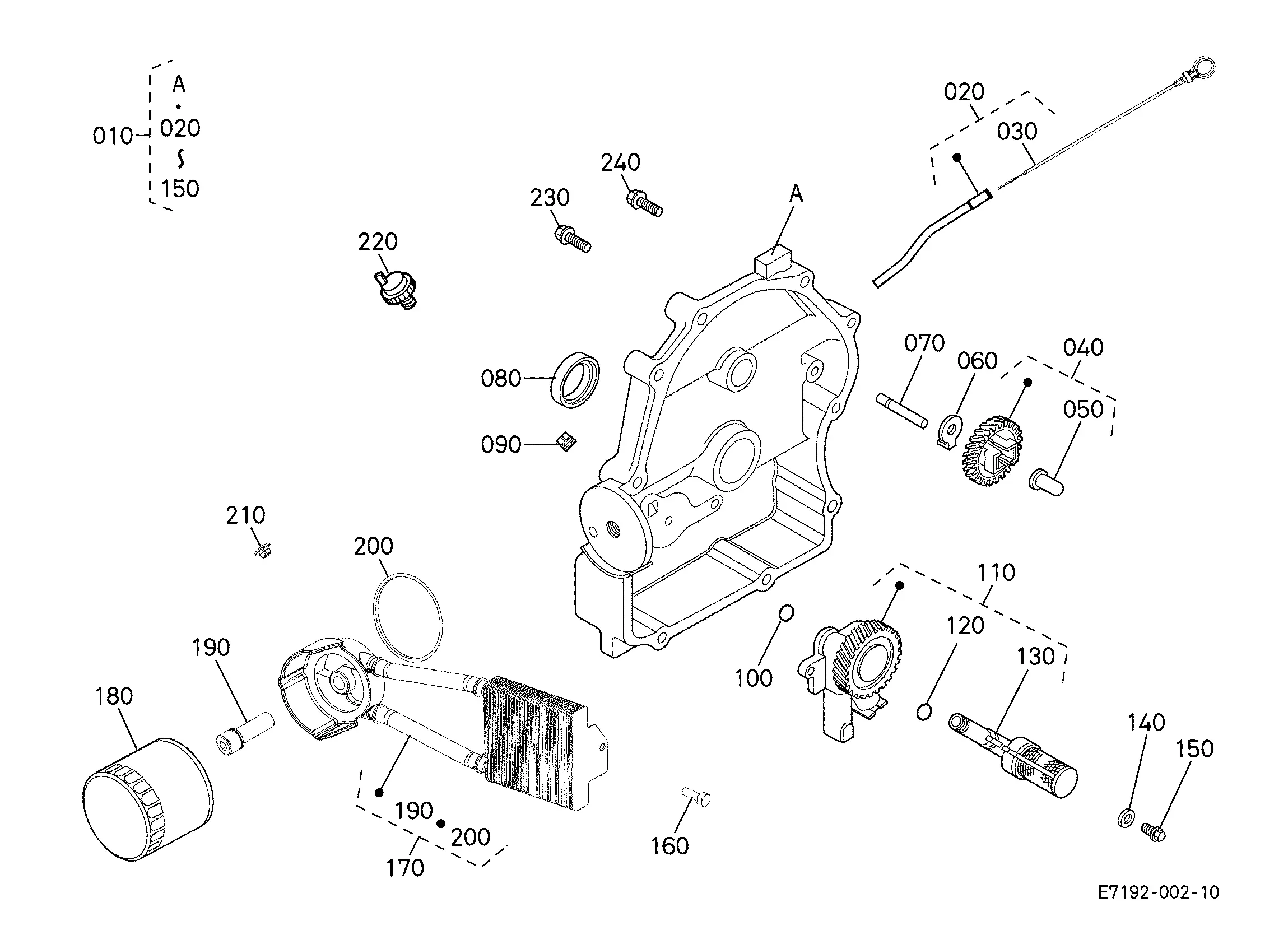

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations serve as essential tools for technicians and enthusiasts alike, simplifying the identification and organization of various elements.

Benefits of Visual Guides

- Enhances clarity in complex assemblies.

- Facilitates efficient troubleshooting and repairs.

- Promotes proper maintenance practices.

Utilization in Maintenance

- Streamlines the repair process by providing clear references.

- Ensures that all necessary components are accounted for.

- Aids in ordering the correct replacements when needed.

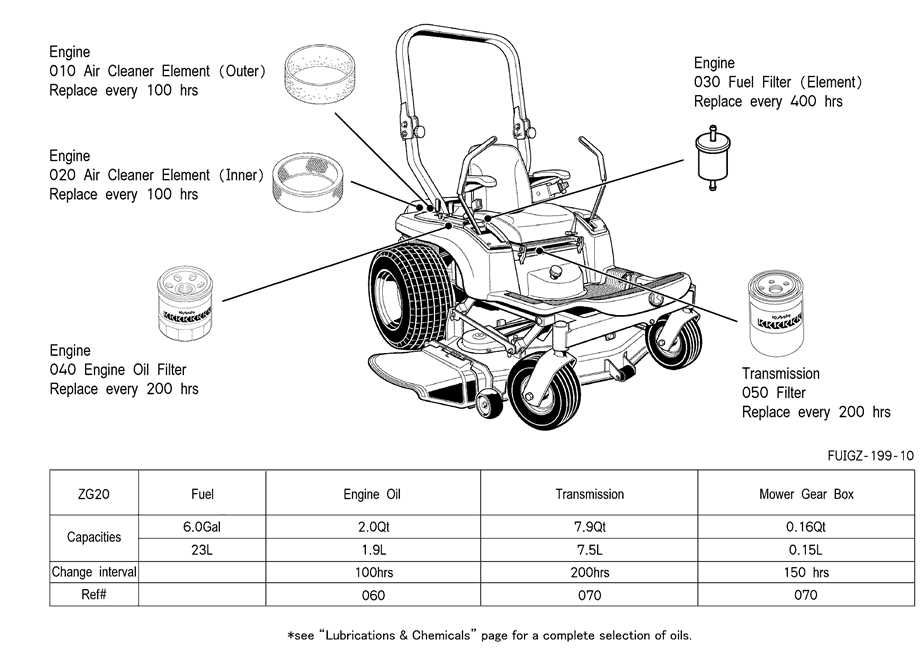

Common Issues with ZG20 Components

When operating a specialized lawn care machine, various components may experience issues over time, impacting performance and reliability. Understanding these common problems can help users maintain optimal functionality and extend the lifespan of their equipment.

Electrical Failures: One prevalent concern involves the electrical system. Users often encounter malfunctions due to faulty wiring, corroded connections, or defective batteries. Regular inspections can prevent unexpected shutdowns and ensure smooth operation.

Hydraulic Leaks: Another frequent issue is hydraulic fluid leaks, which can stem from worn seals or damaged hoses. These leaks not only reduce efficiency but can also pose safety risks. Prompt detection and replacement of affected components are crucial for maintaining proper functionality.

Engine Performance: Users may notice reduced power or unusual noises from the engine. These symptoms can indicate issues such as clogged air filters or fuel system problems. Regular maintenance, including filter replacements, is essential to keep the engine running smoothly.

Cutting Deck Problems: The cutting deck may experience challenges like uneven cutting or failure to engage properly. This can be attributed to dull blades, misalignment, or issues with the drive belt. Routine sharpening and alignment checks can significantly enhance performance.

Addressing these common challenges not only improves the efficiency of the machine but also helps in avoiding costly repairs in the future. Regular maintenance and vigilance are key to ensuring a trouble-free experience with your equipment.

How to Identify Kubota Parts

Identifying components for your machinery can significantly enhance maintenance and repair processes. A clear understanding of each element’s role and compatibility ensures that your equipment operates efficiently and reliably. This guide offers insights into recognizing essential components and their specifications.

Start with the Model Number: Each machine typically has a designated model number, which serves as a reference for finding the correct elements. This number can often be found on the chassis or within the user manual.

Consult the Manual: The owner’s manual is an invaluable resource. It often includes a comprehensive list of all necessary components, along with diagrams that illustrate their locations and functions. Referencing this document can save time and prevent errors.

Use Online Resources: Numerous websites provide detailed catalogs and resources to assist in identifying machine components. Utilizing these tools can simplify the search process and ensure accurate selection.

Check Manufacturer Specifications: Official specifications from the manufacturer can clarify which elements are compatible with your machinery. This information is crucial for ensuring longevity and optimal performance.

Join Online Communities: Engaging with fellow enthusiasts and professionals in forums or social media groups can provide insights and tips. Sharing experiences can lead to discovering resources and advice that might not be readily available.

Take Photos: When in doubt, taking clear photos of the components can help when consulting experts or seeking assistance. Visual references can make identification easier and more accurate.

Maintenance Tips for ZG20 Owners

Regular upkeep is essential for ensuring optimal performance and longevity of your mowing equipment. Implementing a systematic maintenance routine can prevent common issues and enhance efficiency. Here are some key practices to keep in mind.

Routine Inspections

Conduct thorough inspections before each use. Check fluid levels, tire pressure, and overall condition. Early detection of wear can save time and costly repairs later.

Cleaning and Care

Keep the machine clean by removing grass clippings and debris after use. Regularly check and replace air filters to maintain airflow and engine efficiency, contributing to a well-functioning machine.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process with the right resources. Whether you are looking for genuine or aftermarket items, various avenues can help you acquire what you need to keep your equipment running smoothly.

Authorized Dealers

One of the most reliable sources for obtaining essential components is through authorized dealers. These vendors often provide original equipment that meets quality standards, ensuring compatibility and longevity.

Online Marketplaces

The internet has transformed how users find and purchase components. Numerous online platforms offer a vast selection of items, often at competitive prices. Be sure to read reviews and check seller ratings to ensure a positive purchasing experience.

| Source | Advantages | Disadvantages |

|---|---|---|

| Authorized Dealers | Genuine products, expert advice | Higher prices |

| Online Marketplaces | Wide selection, competitive pricing | Variable quality, potential shipping delays |

| Local Repair Shops | Personalized service, quick access | Limited inventory |

| Salvage Yards | Cost-effective, unique finds | Uncertain condition, time-consuming |

Understanding Kubota Parts Terminology

When dealing with machinery, familiarizing oneself with the specific terminology related to components is essential. Clear comprehension of the language used in manuals and repair guides enables users to effectively communicate their needs and understand the requirements for maintenance and replacement. This section aims to shed light on the common terms and definitions that one may encounter in the context of mechanical assemblies.

Components refer to the individual pieces that come together to form a functional unit. Each part plays a distinct role in the overall operation, and knowing the name and purpose of each element can greatly aid in troubleshooting and repairs.

Assembly denotes a collection of components that are put together to perform a specific function. Understanding how various assemblies interact can provide insight into the machine’s performance and help in diagnosing issues that may arise.

Service Intervals indicate the recommended timelines for maintenance tasks. Recognizing these intervals is crucial for ensuring that machinery operates efficiently and prolonging its lifespan.

Specifications are the detailed descriptions of dimensions, materials, and performance criteria for each element. Being aware of these details can assist users in selecting the appropriate replacements or upgrades.

By mastering this terminology, individuals can enhance their understanding of machinery and improve their maintenance skills, leading to more efficient operation and longevity of equipment.

Upgrades and Modifications for Performance

Enhancing the efficiency and capabilities of your machinery can lead to significant improvements in performance. By implementing specific modifications and upgrades, users can achieve greater power output, increased durability, and enhanced handling characteristics. These enhancements not only optimize operational effectiveness but also contribute to an overall improved user experience.

One of the most effective upgrades involves the installation of a high-performance air intake system, which can boost engine efficiency by allowing for better airflow. Additionally, upgrading the exhaust system can help in reducing back pressure, leading to improved horsepower and torque. Consider also adjusting the fuel delivery system for better combustion efficiency.

Moreover, incorporating advanced suspension components can enhance stability and handling, making the equipment more responsive and easier to control in various conditions. Wheel and tire upgrades can also play a crucial role, providing better traction and grip, which is essential for challenging terrains.

Finally, regular maintenance and tuning are vital for sustaining performance improvements over time. Keeping all systems in optimal condition ensures that the benefits of upgrades are fully realized, allowing for peak performance throughout the equipment’s lifespan.