Understanding the various elements that contribute to the efficiency of modern cutting equipment is crucial for both professionals and hobbyists. Whether you’re engaged in maintenance or seeking replacements, having a clear breakdown of individual sections and their functions can make a significant difference in the performance and longevity of your tool.

In this guide, we will delve into the core mechanisms that drive optimal functionality, highlighting the essential segments that require regular attention. By familiarizing yourself with these details, you can ensure smoother operation and more efficient usage.

Each component plays a vital role in maintaining the overall health of your machine, and being equipped with knowledge about these segments can help prevent common issues. Our goal is to provide a clear and detailed view, so you can keep your equipment in top shape for years to come.

Overview of Husqvarna 550XP Components

The mechanical system under discussion is known for its robust construction and efficient performance, tailored to meet the needs of professionals and enthusiasts alike. It incorporates an intricate design where each element plays a crucial role in ensuring smooth operation, power delivery, and precision during tasks. Understanding how these elements interconnect can greatly improve the efficiency and longevity of the tool.

Engine Assembly

The heart of this machine lies in its highly efficient motor unit. This core element is engineered to deliver optimal power while maintaining fuel efficiency. Key aspects of the motor’s design include advanced cooling mechanisms and high-speed functionality, all working together to maximize operational performance under challenging conditions.

Control and Maneuverability Components

For optimal handling, the equipment features ergonomically designed control mechanisms that ensure user comfort and safety. These components, including strategically placed levers and grips, are crafted to provide responsive control, allowing the operator to maintain precise direction and speed during use. Attention to these details enhances

Key Engine Parts and Their Roles

In any powerful cutting machine, understanding the primary components of the motor is essential for proper maintenance and performance. These elements work in harmony to ensure smooth operation, fuel efficiency, and durability. Each component plays a specific role in driving the system, contributing to the overall functionality and reliability of the device.

Piston: The piston is crucial for converting fuel energy into mechanical motion. It moves within the cylinder, creating the necessary pressure to drive the system forward.

Cylinder: The cylinder forms the combustion chamber where fuel is ignited. It must maintain the correct balance of heat and pressure to optimize engine performance.

Crankshaft: The crankshaft translates the linear motion of the piston into rotational force. This rotation is what powers the cutting mechanism, delivering efficient energy transfer.

Carburetor: Responsible for mixing air and fuel, the carburetor ensures

Understanding the Chain Brake System

The chain brake is a crucial component for enhancing the safety and control of a chainsaw. Its primary function is to halt the movement of the chain in certain conditions, significantly reducing the risk of injury. This system is designed to react swiftly in the event of sudden force or contact, providing operators with an additional layer of protection during use.

How the Chain Brake Works

At the core of the system is a mechanism that activates when triggered by abrupt movements or force. This trigger can be manual or automatic, depending on the situation. When engaged, the brake applies tension, immediately stopping the motion of the chain. This feature is especially effective in preventing accidents caused by kickback.

Key Components of the Brake System

The brake consists of several important elements that work in tandem to ensure proper operation. These include a lever, tension spring, and a band that grips the clutch drum when activated. Each of these parts must function seamlessly to guarantee that the brake system performs reliably in

Fuel and Air System Maintenance

Proper upkeep of the fuel and air systems is crucial for ensuring optimal engine performance and longevity. These components work together to supply the engine with the right mixture for combustion, making it essential to regularly inspect and maintain them to avoid any potential issues.

To maintain the fuel system, it is important to periodically check the filters and lines for blockages or wear. Replacing clogged filters and ensuring the lines are free of debris can prevent interruptions in fuel flow and help the engine run smoothly.

The air system requires similar attention. Clean or replace air filters when they become dirty, as this helps in maintaining the correct air intake levels. Ensuring the airflow remains unobstructed contributes to a balanced combustion process, reducing the strain on the engine and enhancing efficiency.

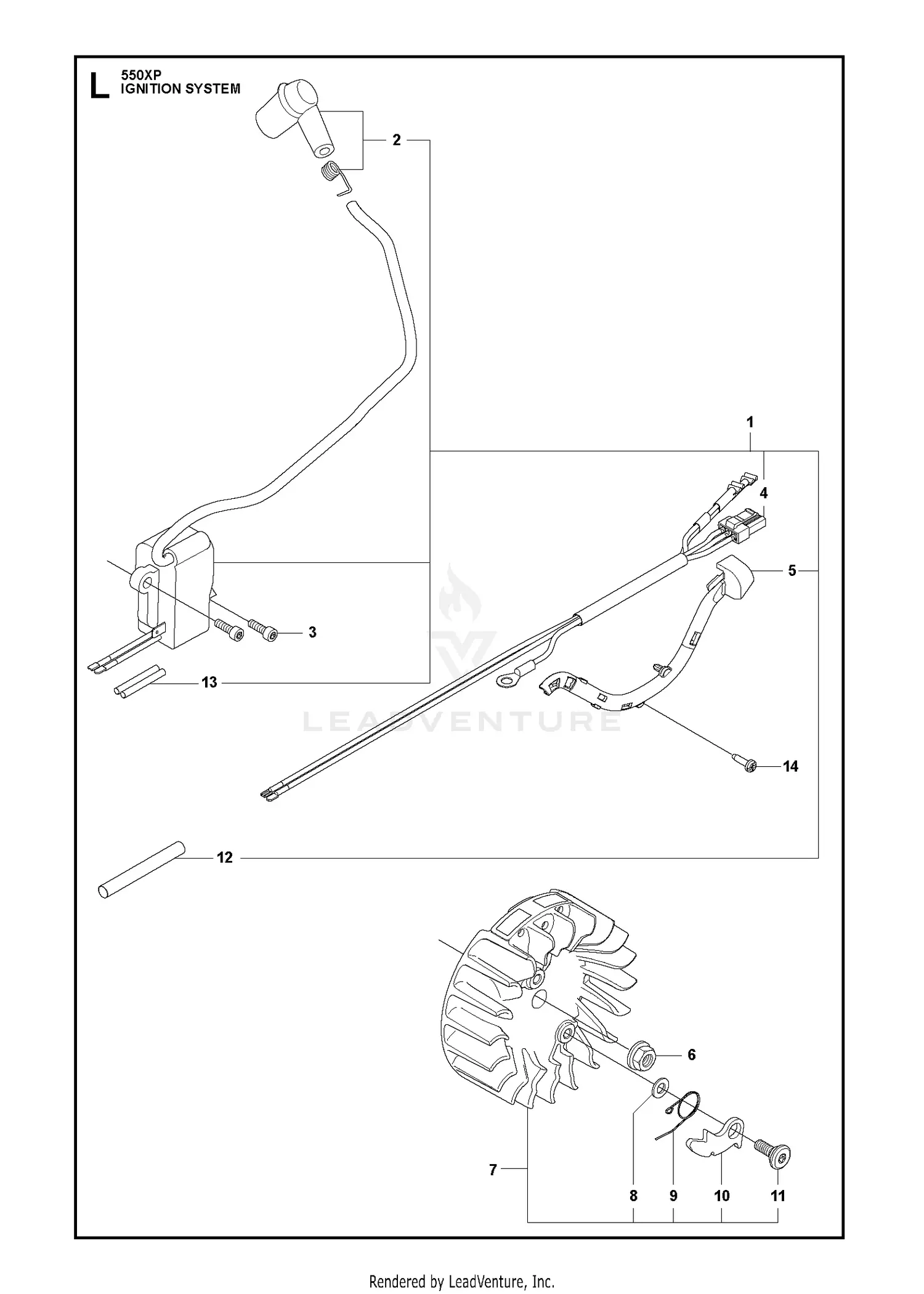

Guide to Ignition Module Layout

The ignition system is a crucial component that plays a key role in starting and maintaining engine performance. This guide outlines the layout of the ignition module, explaining how various elements within the system work together to provide efficient combustion and power generation.

| Component | Function |

|---|---|

| Coil Assembly | Transforms electrical energy into a high-voltage charge needed for spark generation. |

| Flywheel | Generates the magnetic field necessary for triggering the ignition sequence. |

| Spark Plug Lead | Transfers the high-voltage charge from the coil to the spark plug. |

| Control Circuit | Regulates the timing and frequency of the ignition spark based on engine speed and conditions. |

Mount

Exhaust System Design and PlacementThe exhaust system plays a critical role in the overall performance and efficiency of a machine. Its design and location significantly influence the engine’s output and the emissions produced. Proper engineering ensures that gases are expelled efficiently, minimizing back pressure and optimizing airflow. This section delves into the key aspects of exhaust system architecture and the strategic considerations for positioning components to enhance functionality. Key Design ConsiderationsWhen designing an exhaust system, several factors must be considered, including material selection, diameter of the piping, and muffler type. Durability is essential; therefore, materials that can withstand high temperatures and resist corrosion are typically favored. The diameter of the exhaust pipe directly affects the velocity of gas flow, which can enhance engine efficiency. Additionally, the choice of muffler impacts not only noise levels but also the overall performance of the system. Optimal Placement for EfficiencyPlacement of the exhaust components is crucial for optimal performance. Positioning the exhaust outlet away from critical engine components can prevent heat buildup and reduce the risk of damage. Furthermore, routing the system to minimize bends and turns helps maintain a smooth flow of gases, reducing turbulence and improving overall efficiency. Proper alignment and secure mounting are also vital to prevent vibrations that could lead to premature wear and tear. Analyzing the Clutch Assembly Structure

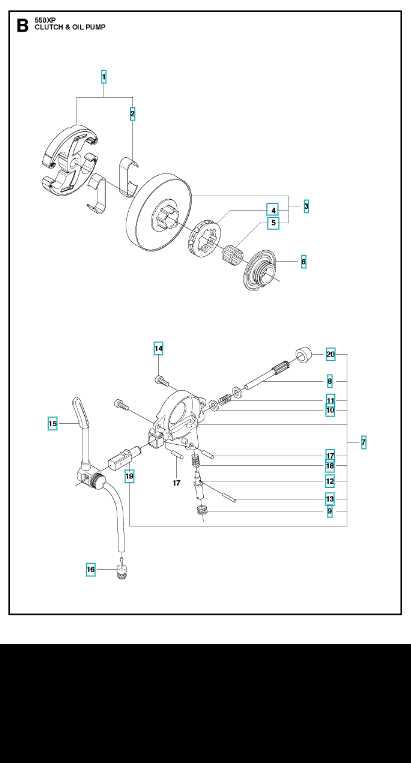

The clutch assembly plays a crucial role in the functionality of various outdoor power equipment. It serves as a vital component that enables the transfer of power from the engine to the cutting tools, allowing for efficient operation. Understanding its structure is essential for proper maintenance and troubleshooting. Components of the Clutch Assembly The assembly typically consists of several key parts, including the clutch drum, shoes, springs, and the drive mechanism. Each component has a specific function that contributes to the overall performance. The clutch drum houses the shoes and serves as the connection point for the drive system. The shoes engage and disengage to control the power transfer, while the springs ensure the shoes return to their resting position when not engaged. Functionality and Maintenance Proper functioning of the clutch assembly is essential for optimal performance. Regular inspection and maintenance can prevent wear and tear, ensuring that the components operate smoothly. Replacing worn-out parts, adjusting the tension of the springs, and keeping the assembly clean are vital practices for maintaining the efficiency of this mechanism. In summary, a thorough understanding of the clutch assembly structure and its components can greatly enhance the longevity and reliability of outdoor power equipment. By paying attention to these details, operators can ensure their machines perform at their best. Proper Lubrication and Oil Parts FunctionEffective lubrication is crucial for the optimal performance of any machinery. Ensuring that all moving components receive adequate oil not only prolongs the lifespan of the equipment but also enhances efficiency and reduces the risk of malfunctions. The right lubricant acts as a barrier against wear and tear, preventing metal-to-metal contact and minimizing friction. Oil plays a vital role in the functioning of various elements within mechanical systems. It aids in dissipating heat generated during operation, ensuring that components remain at a safe temperature. Moreover, the lubrication process helps in preventing corrosion and provides a sealing effect that can keep contaminants at bay. Regular maintenance and timely oil changes are essential to maintain the fluidity and effectiveness of the lubricant, which in turn safeguards the functionality of the machinery. Understanding the specific lubrication requirements for each component is necessary for ensuring longevity. Components such as bearings, gears, and chains have unique needs that must be addressed to maintain smooth operation. Following the manufacturer’s recommendations regarding the type and frequency of lubrication can significantly impact overall performance. Replacing and Repairing External CoversMaintaining the integrity of the outer casing of your equipment is essential for ensuring optimal performance and longevity. The external covers serve not only as a protective shield against environmental elements but also contribute to the overall aesthetics of the machine. Over time, wear and tear may necessitate either replacement or repair to keep the unit in top condition. When addressing issues with the external covers, it’s important to first assess the extent of damage. Minor scratches or dents may be repairable with the right tools and materials, while significant cracks or breaks could require complete replacement. Before beginning any work, ensure you have the appropriate replacement parts or repair kits on hand, along with the necessary tools for disassembly and reassembly. To start, disconnect the power source and remove any components that obstruct access to the outer covers. Carefully detach the damaged parts by unscrewing or unclipping them, taking note of their placement for easier reinstallation. If opting for repairs, clean the damaged area thoroughly and apply adhesive or filler as needed, following the manufacturer’s instructions. For replacements, align the new cover with the mounting points and secure it in place with screws or clips. Once the covers are in place, reassemble any components that were removed and conduct a thorough inspection to ensure everything is securely fastened. Regular maintenance and timely repairs will help maintain the functionality and appearance of your equipment, ensuring it continues to serve you well for years to come. |