When maintaining a high-performance lawn mower, it’s crucial to have a clear understanding of the individual parts that make up the machine. Each component plays a specific role, ensuring smooth operation and long-lasting durability. A well-constructed lawn mower consists of various elements, from the engine to the cutting mechanism, and knowing how they fit together can help with troubleshooting and repairs.

Familiarizing yourself with the internal mechanisms is essential for both regular upkeep and any necessary replacements. By understanding the design and function of each piece, you can easily identify where issues may arise and address them with confidence. This knowledge not only improves the longevity of your mower but also ensures optimal performance during every use.

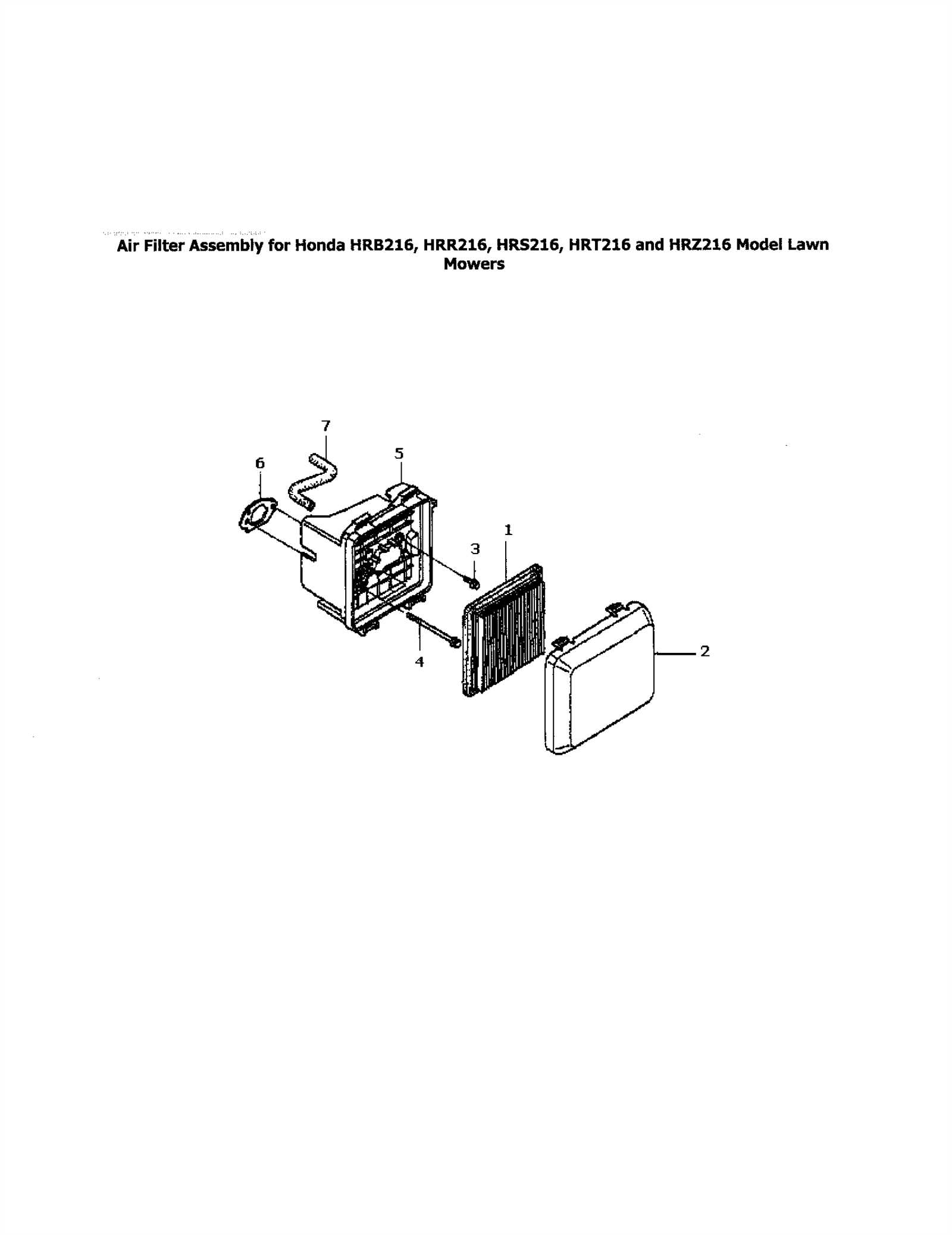

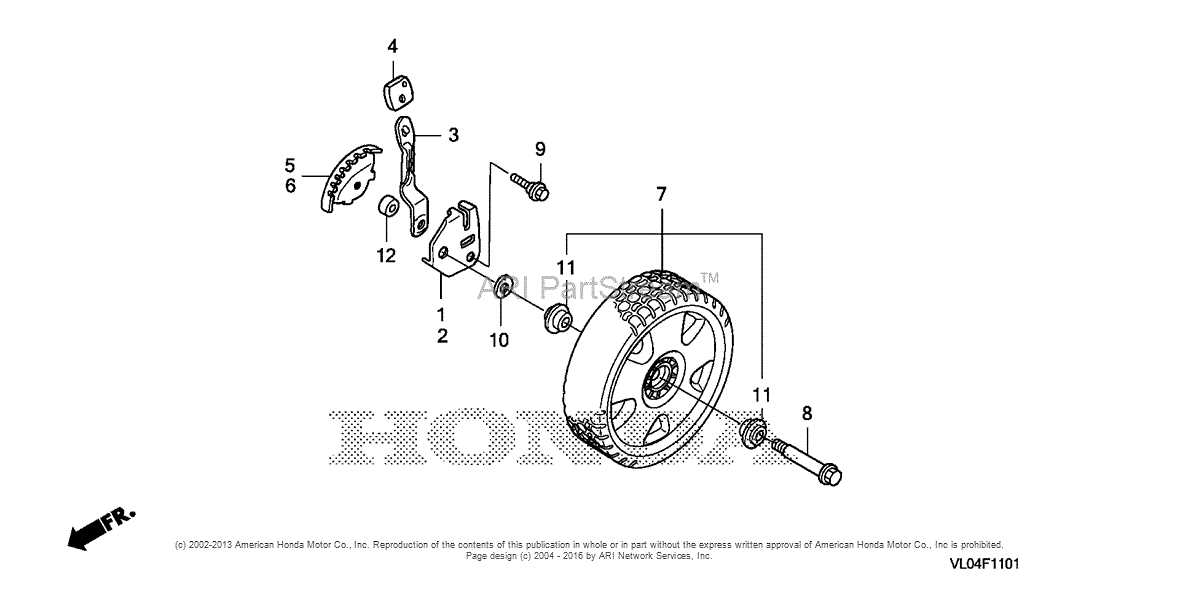

For those seeking to repair or replace specific parts, having a comprehensive visual reference of all the major components is an invaluable tool. Whether you’re dealing with wear and tear or upgrading certain elements, understanding the layout and connection of each part allows for a smoother repair process and reduces the risk of improper installation.

Understanding Honda HRR2163TDA Components

When it comes to maintaining a lawnmower, understanding the essential components that make up the machine is crucial for its optimal performance and longevity. Each element plays a specific role in ensuring the mower runs smoothly and effectively. Whether it’s the cutting mechanism, propulsion system, or control features, familiarity with how these parts work together allows for proper care and troubleshooting when necessary.

Key System Elements

Here are some of the most important systems that contribute to the overall functionality of the equipment:

- Engine: Powers the machine and drives the cutting mechanism.

- Cutting Deck: Contains the blades that trim the grass and ensures uniformity.

- Wheels: Provide mobility and determine the ease of maneuverability across various terrains.

- Handlebars: Allow the user to guide and control the direction of movement.

- Grass Bag or Discharge Chute: Collects or expels the cut grass, depending on the configuration.

How Each Component Interacts

Understanding how these systems interact is essential for diagnosing any issues or optimizing performance:

- The engine drives the cutting deck, ensuring blades rotate at high speed.

- Wheels allow easy navigation over the lawn, with the cutting height adjustable based on the terrain.

- The handlebar controls the movement of the mower, while the grass collection system handles disposal.

- Proper maintenance and timely replacements of worn-out parts help prevent breakdowns and extend the life of the equipment.

Importance of Accurate Parts Diagrams

Precise visual representations play a crucial role in the maintenance and repair of machinery. They serve as essential tools for understanding how components fit and function together, enabling users to efficiently locate and identify each element. This clarity is vital for ensuring proper assembly and disassembly, which ultimately impacts the overall performance and longevity of the equipment.

Moreover, having an accurate reference can significantly reduce the risk of errors during repairs. Technicians and hobbyists alike benefit from clear illustrations that outline each part’s relationship to others, fostering a more intuitive grasp of the system’s workings. This not only streamlines the repair process but also enhances safety by minimizing the likelihood of incorrect installations.

In summary, well-crafted visual guides are indispensable for anyone involved in the upkeep of mechanical devices, ensuring that operations proceed smoothly and efficiently.

Common Issues with Lawn Mower Parts

Maintaining a healthy cutting machine is crucial for optimal performance. Various components can face challenges over time, leading to decreased efficiency and potential malfunctions. Understanding these common issues can help users troubleshoot effectively.

Frequent Problems

- Blades: Dull or damaged blades can result in uneven cuts.

- Fuel System: Clogged filters and stale fuel can hinder engine performance.

- Wheels: Worn-out wheels may cause difficulty in maneuvering.

- Belt: A frayed or broken belt can prevent proper operation.

Maintenance Tips

- Regularly inspect and sharpen blades.

- Replace fuel and clean filters as needed.

- Check wheels for wear and ensure they are securely attached.

- Examine belts for signs of damage and replace if necessary.

Step-by-Step Repair Process

This section outlines a detailed approach to restoring a lawn mower, ensuring optimal performance. Following these steps will help diagnose issues and replace necessary components effectively.

Preparation

- Gather tools: wrenches, screwdrivers, and replacement parts.

- Find a clean, well-lit workspace.

- Review the user manual for specific guidelines.

Repair Steps

- Turn off the mower and disconnect the spark plug to prevent accidental starts.

- Inspect the blades for damage and sharpen or replace if needed.

- Check the fuel system for leaks or blockages.

- Examine the air filter and clean or replace it as necessary.

- Reassemble the mower, ensuring all components are secured properly.

- Reconnect the spark plug and perform a test run to confirm repairs.

Where to Find Replacement Parts

Finding suitable components for your machinery is crucial for maintaining optimal performance. Various sources can provide the necessary elements to keep your equipment running smoothly.

Online Retailers: Numerous websites specialize in offering a wide selection of items. These platforms often have user-friendly interfaces and detailed descriptions, making it easy to locate what you need.

Local Dealerships: Visiting authorized sellers can yield original components that guarantee compatibility and quality. Staff at these locations can offer valuable insights and recommendations.

Salvage Yards: Exploring salvage or recycling facilities can be a cost-effective option. Here, you may discover gently used items that are still in good condition, offering significant savings.

Community Forums: Engaging with online communities can provide leads on where to find rare or hard-to-find components. Enthusiasts often share their experiences and tips for sourcing specific items.

Manufacturer Websites: Checking the official website of the brand can lead you to authorized distributors and inventory. This ensures you are purchasing legitimate and high-quality replacements.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures the highest level of quality and compatibility for your machinery. These items are specifically designed to fit and function seamlessly, enhancing the overall performance and longevity of your equipment.

One major advantage of choosing OEM components is their reliability. They undergo rigorous testing to meet stringent standards, reducing the risk of malfunctions. Additionally, using these authentic parts often helps maintain warranties, safeguarding your investment.

Another benefit is the assurance of precise engineering. Original parts retain the integrity of the original design, promoting optimal operation and efficiency. This precision ultimately leads to better fuel efficiency and lower operational costs over time.

Moreover, sourcing genuine components contributes to a more sustainable approach. By ensuring durability and reducing the need for frequent replacements, you not only save money but also minimize waste. Investing in high-quality items is a step toward responsible maintenance.

Tools Required for Maintenance

Performing regular maintenance on outdoor equipment ensures longevity and smooth operation. To keep the machine in optimal working condition, certain tools are essential. Having the right set of instruments can help make the job easier and more efficient, allowing for timely servicing and repair.

Basic Tools

- Wrench Set – Different sizes are needed for various bolts and nuts.

- Socket Set – A versatile tool for tightening or loosening fasteners.

- Phillips and Flathead Screwdrivers – For removing screws from different areas of the unit.

- Spark Plug Socket – To remove and replace spark plugs safely.

- Oil Filter Wrench – For proper removal and installation of the oil filter.

Additional Tools

- Torque Wrench – Ensures bolts are tightened to the correct specifications.

- Grease Gun – To apply grease to moving parts that require lubrication.

- Fuel Stabilizer – Helps maintain the fuel system during long periods of inactivity.

- Cleaning Brush – To remove dirt and debris from filters and other components.

Equipped with these tools, you can confidently carry out routine tasks such as oil changes, spark plug replacement, air filter cleaning, and more. Proper maintenance not only improves performance but also extends the life of your equipment.

Safety Tips During Repairs

When performing maintenance or repairs on outdoor equipment, ensuring safety is a top priority. Proper precautions can prevent injuries, protect the machine, and guarantee a smooth repair process. Adhering to safety guidelines is essential, whether you’re working on a lawnmower, generator, or other similar devices. Always follow recommended procedures and use the right tools to avoid accidents and unnecessary risks.

Protect Yourself with Appropriate Gear

Before starting any repair task, it’s important to equip yourself with the necessary protective gear. Gloves, safety goggles, and sturdy footwear are a minimum requirement. Gloves will protect your hands from sharp edges or debris, while goggles safeguard your eyes from small particles or liquids. Non-slip footwear ensures stability, especially when working in damp or uneven environments.

Work in a Safe and Organized Environment

Keep your workspace clean and well-lit to prevent accidents. Ensure that all tools are in good condition and are properly stored when not in use. An organized environment will help you avoid misplacing items and reduce the risk of tripping or stumbling over tools and materials. Always have a stable surface to work on to prevent any slips or falls.

| Safety Measure | Explanation |

|---|---|

| Wear protective gloves | Protects hands from sharp objects, chemicals, and debris |

| Use safety goggles | Prevents injury from flying debris and chemicals |

| Ensure proper ventilation | Prevents inhalation of harmful fumes and gases |

| Turn off power sources | Reduces the risk of electrical shock or accidental activation |

In addition to personal safety, always make sure the equipment is turned off or disconnected from any power source before starting any work. This step reduces the risk of electrical shocks or unintended machine activation during repairs. If you’re unsure about any aspect of the repair process, consult the manual or reach out to a professional to ensure you are following all safety protocols.

Maintaining Your Honda Lawn Mower

Proper upkeep of your lawn care equipment is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also ensures a pristine cut and a healthy yard. Understanding key maintenance practices will help you keep your machine running smoothly throughout the season.

Start by regularly checking the oil level and replacing it as needed. Clean or replace the air filter to ensure proper airflow, and inspect the spark plug for any signs of wear. Keeping the blades sharp is crucial; dull blades can damage grass and lead to a lackluster appearance. Additionally, cleaning the mower deck after each use prevents buildup that can affect performance.

Seasonal tune-ups are important; check the fuel system and ensure that the fuel is fresh. Inspect the wheels and drive system for any signs of wear, and keep the wheels free from debris. Lastly, store the equipment in a dry place during off-seasons to protect it from the elements, ensuring it’s ready for action when needed.