When it comes to maintaining and repairing your off-road vehicle, having a comprehensive understanding of its various elements is essential. Each component plays a vital role in ensuring optimal performance and reliability during your adventures. With a clear representation of these parts, you can more easily identify issues and make informed decisions about maintenance and upgrades.

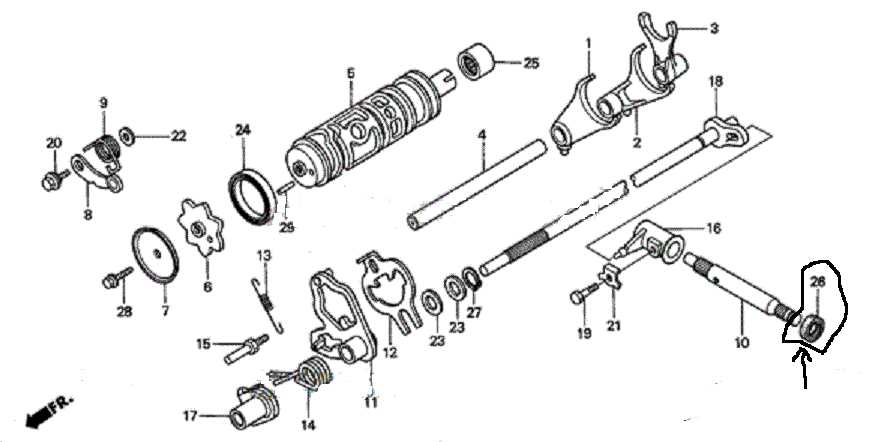

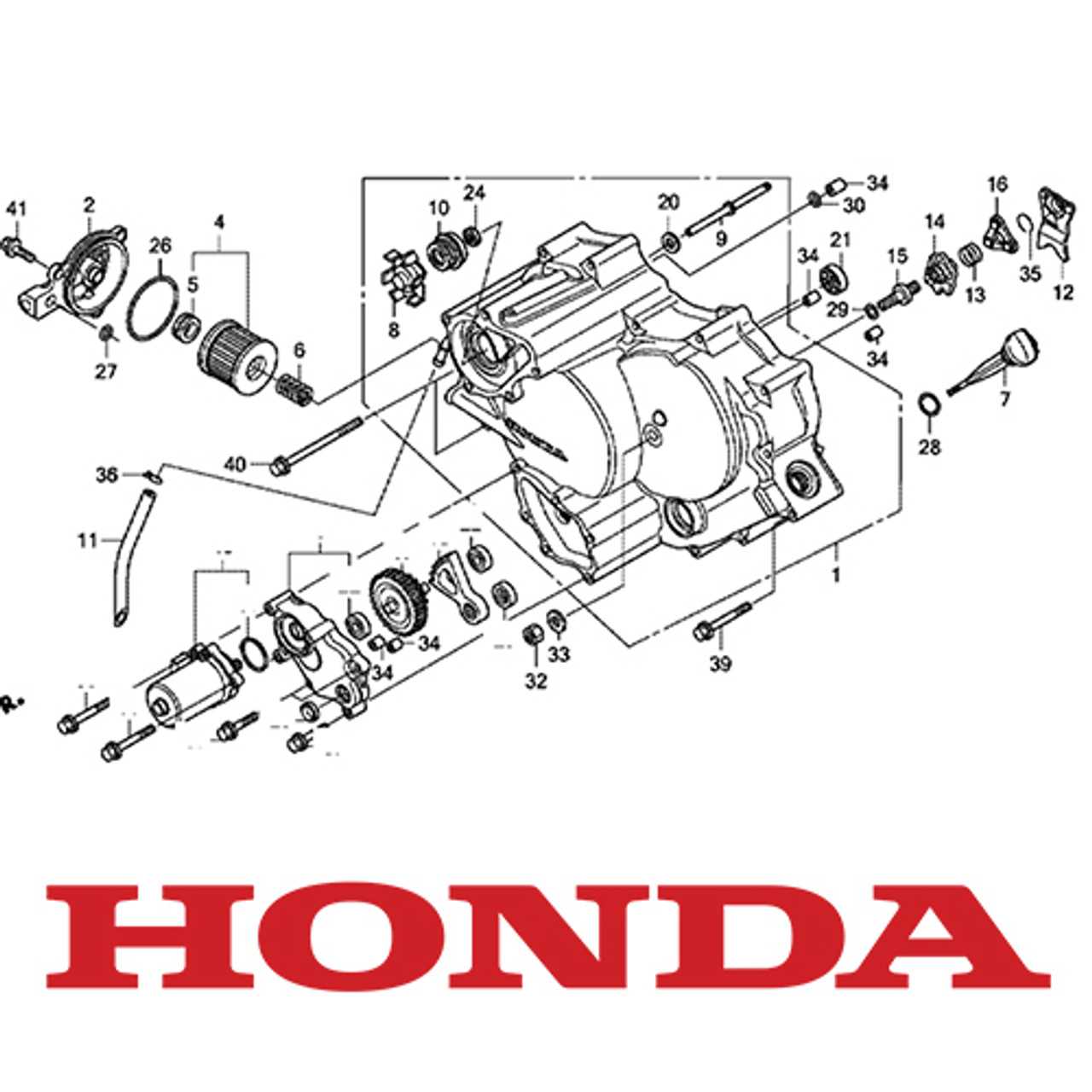

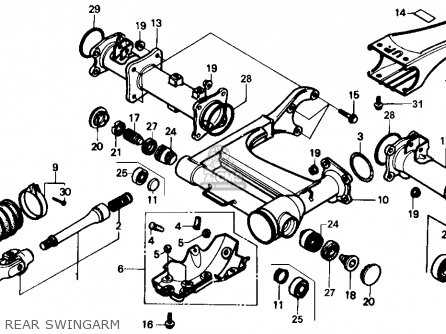

Visual aids serve as invaluable tools in this process, offering detailed insights into the assembly and arrangement of different elements. By examining these illustrations, you can familiarize yourself with the intricate workings of your machine. This knowledge not only enhances your troubleshooting skills but also empowers you to carry out repairs with confidence.

In the following sections, we will explore the specifics of these illustrations, focusing on the functionality and interrelationships of each segment. By the end of this guide, you will be better equipped to navigate the complexities of your vehicle’s structure, ensuring that you can enjoy every ride with peace of mind.

Understanding Honda Foreman Components

Grasping the intricacies of a vehicle’s structure is essential for maintaining its performance and ensuring longevity. Each element plays a crucial role in the overall functionality, contributing to a seamless driving experience. A comprehensive understanding of these components can empower users to make informed decisions regarding repairs and upgrades.

Key Elements to Consider

- Engine: The powerhouse of the machine, responsible for converting fuel into motion.

- Transmission: Facilitates gear shifts and ensures smooth acceleration.

- Suspension: Enhances ride quality and stability over various terrains.

- Brakes: Essential for safety, allowing for controlled stopping.

- Electrical System: Powers all electronic components and ensures proper functioning.

Maintenance Tips

- Regularly check and change fluids to keep the engine running smoothly.

- Inspect the braking system frequently to ensure optimal performance.

- Clean or replace air filters to maintain engine efficiency.

- Examine the suspension for wear to avoid handling issues.

- Stay updated with electrical components to prevent unexpected failures.

By familiarizing oneself with these core elements and adhering to maintenance practices, users can enhance the reliability and durability of their vehicles, ensuring they are always ready for the next adventure.

Importance of Parts Diagrams

Understanding the intricate details of a machine is crucial for effective maintenance and repair. Visual representations that illustrate the various components of equipment play a significant role in ensuring users can identify and manage each element efficiently. These resources serve as essential guides, aiding technicians in their work and helping owners grasp the mechanics behind their devices.

Enhancing Repair Efficiency

When it comes to fixing or replacing components, having a clear visual reference streamlines the process. It allows individuals to quickly locate specific pieces, reducing the time spent searching for information. Moreover, accurate depictions help minimize the risk of errors, ensuring that replacements fit properly and function as intended.

Facilitating Knowledge and Understanding

Beyond just repairs, visual aids provide valuable insights into how machinery operates. By examining the layout and relationships between different elements, users can deepen their comprehension of the overall system. This understanding not only empowers them to tackle minor issues independently but also fosters a greater appreciation for the technology at hand.

Common Issues with Honda Foreman

Many users of all-terrain vehicles encounter specific challenges that can affect performance and reliability. Understanding these frequent problems can help owners maintain their machines and ensure a smoother riding experience. This section highlights some of the most prevalent issues that operators may face.

Engine Performance Problems

One of the primary concerns for users is engine efficiency. Issues such as poor acceleration, stalling, or difficulty starting can stem from various factors. Regularly checking the fuel system, including filters and injectors, is essential. Routine maintenance can prevent these complications from arising.

Transmission and Drive System Issues

Another common area of concern involves the transmission and drive mechanisms. Users may notice unusual noises, slipping gears, or difficulty shifting. These problems can often be traced back to wear and tear or insufficient lubrication. Timely inspections and servicing are crucial to address these challenges effectively.

Where to Find Official Diagrams

Finding accurate schematics for machinery can be essential for maintenance and repairs. Whether you’re troubleshooting an issue or performing routine service, having access to reliable visuals can greatly enhance your understanding and efficiency. Below are some key sources where you can locate authentic representations of components.

Manufacturer’s Website

The primary source for authentic visuals is the official site of the manufacturer. These platforms often provide downloadable manuals and interactive resources, making it easier to navigate the specific model you’re working with. Look for sections dedicated to support or resources, where diagrams are typically categorized by model year and type.

Authorized Dealers and Service Centers

Another excellent resource is your local authorized dealers or service centers. They often have access to proprietary information and can provide printed materials or digital files upon request. Additionally, technicians at these centers can offer valuable insights based on their experience, further aiding your repair efforts.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components can significantly enhance the performance and longevity of your vehicle. These parts are specifically designed to meet the rigorous standards set by the manufacturer, ensuring compatibility and reliability. By opting for such components, you invest in quality and peace of mind, knowing that you are using parts that have been tested and approved for your model.

Quality Assurance

One of the main advantages of using original components is the assurance of quality. These parts undergo stringent testing processes, which guarantees their durability and effectiveness. Unlike generic alternatives, OEM components are crafted to fit precisely and function optimally within your vehicle’s system, reducing the likelihood of premature wear and tear.

Enhanced Performance

Utilizing original manufacturer components can lead to improved performance. These parts are engineered to work seamlessly with other systems, providing enhanced efficiency and reliability. This can result in better fuel economy, smoother operation, and overall improved handling, which are crucial for maintaining the driving experience you expect from your vehicle.

Maintenance Tips for Your Foreman

Regular upkeep is essential for optimal performance and longevity of your vehicle. By adhering to a structured maintenance routine, you can prevent issues and enhance the overall driving experience.

| Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 100 hours | Use high-quality lubricant for better protection. |

| Air Filter Cleaning | Every 50 hours | Ensure it’s free from dirt for optimal airflow. |

| Tire Pressure Check | Monthly | Maintain recommended PSI for stability. |

| Brake Inspection | Every 200 hours | Check pads and fluid regularly for safety. |

| Battery Maintenance | Monthly | Clean terminals and check for corrosion. |

DIY Repairs: A Guide

Engaging in do-it-yourself repairs can be both rewarding and cost-effective. With the right approach and resources, individuals can tackle various maintenance tasks, enhancing their skills while ensuring their equipment operates efficiently. This guide will provide you with essential steps and tips for successful repairs.

Before starting any repair, it’s crucial to gather the necessary tools and materials. Having everything on hand will streamline the process and minimize interruptions. Here’s a list of common items you may need:

- Wrenches and sockets

- Screwdrivers (various types)

- Pliers

- Jack and jack stands

- Replacement components

- Safety gear (gloves, goggles)

Next, understanding the structure of your equipment is vital. Consulting reference materials or guides can help identify components and their functions. Consider the following steps for effective repairs:

- Assessment: Identify the issue and determine what needs fixing or replacing.

- Preparation: Ensure you have the right tools and components before beginning.

- Disassembly: Carefully take apart the necessary sections, keeping track of screws and small parts.

- Repair or Replace: Fix the damaged areas or install new components as needed.

- Reassembly: Put everything back together in reverse order, ensuring all parts fit correctly.

- Testing: Once reassembled, test the equipment to confirm that the issue has been resolved.

Remember to take safety precautions throughout the process. Working with machinery can pose risks, so always prioritize your well-being by wearing protective gear and following best practices.

Finally, documenting your repairs can be beneficial for future reference. Keeping a record of what was done and any parts replaced will aid in ongoing maintenance and troubleshooting down the line.

Upgrades to Enhance Performance

Improving the capabilities of your all-terrain vehicle can lead to a more exhilarating experience and greater efficiency in challenging environments. By focusing on key components, you can significantly boost power, handling, and overall functionality.

One of the primary areas to consider is the exhaust system. Upgrading to a high-performance exhaust can improve airflow, leading to better engine efficiency and a more aggressive sound. Additionally, enhancing the air intake system allows for increased air flow, which can further elevate engine performance.

Suspension modifications can also play a crucial role in handling and comfort. Installing premium shocks and springs can provide improved stability and control over rough terrain, allowing for a smoother ride. Coupled with larger, more aggressive tires, these upgrades can enhance traction and grip, making it easier to tackle difficult obstacles.

Finally, considering electronic enhancements such as performance tuning chips can optimize engine management. This can result in better throttle response and increased horsepower, ensuring that your vehicle performs at its peak under various conditions.