When it comes to optimizing the performance of your construction equipment, having a clear grasp of its internal structure is essential. Each element plays a crucial role in ensuring the overall functionality and efficiency of the machine. This knowledge not only aids in maintenance but also enhances troubleshooting capabilities, allowing users to address issues more effectively.

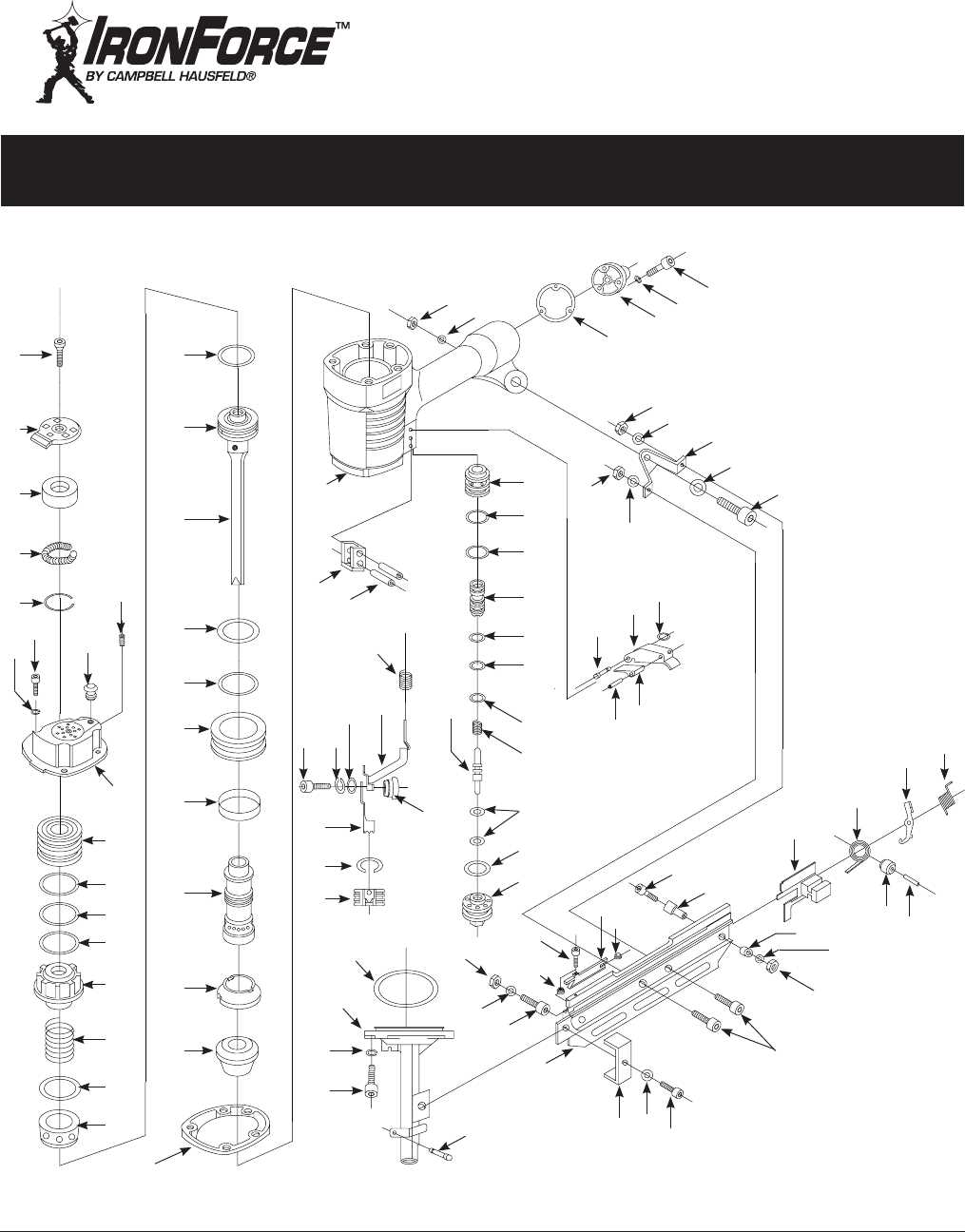

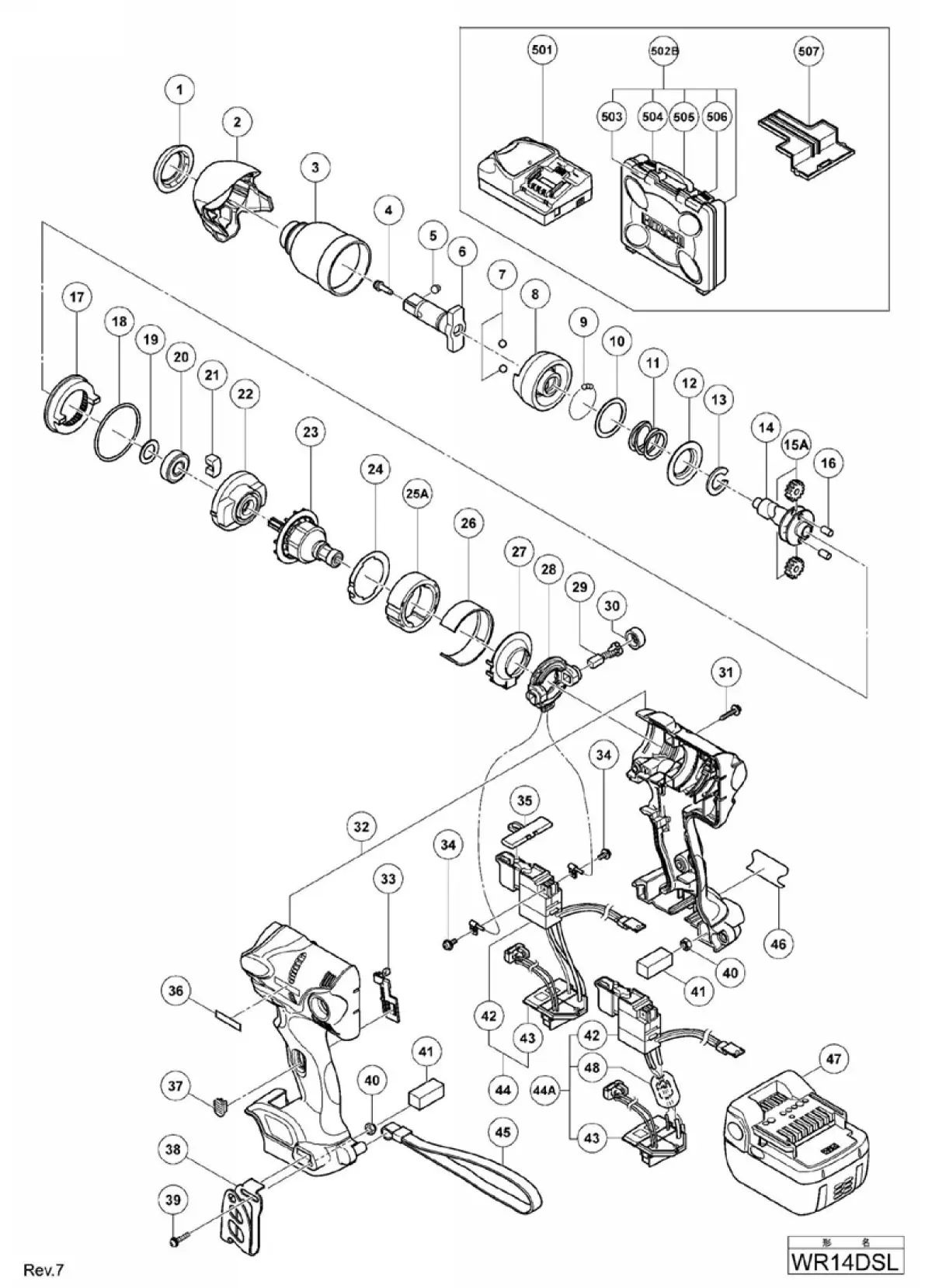

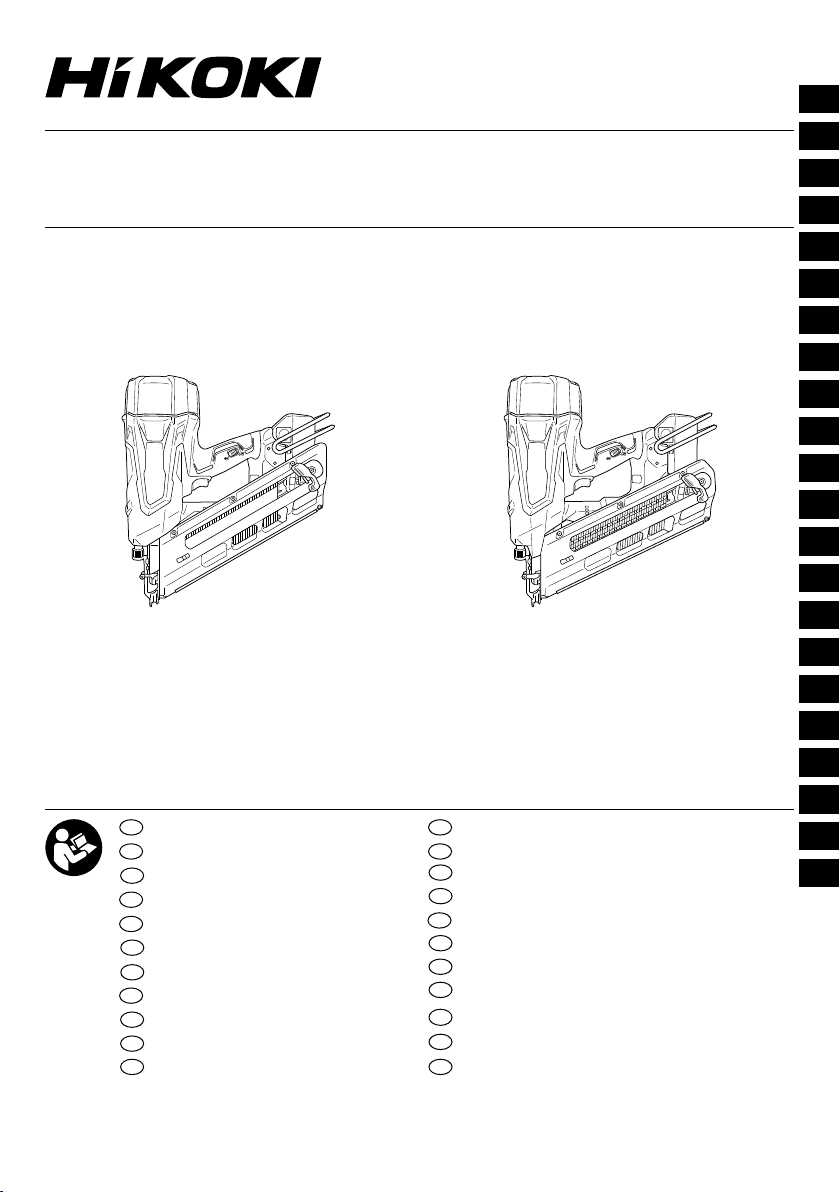

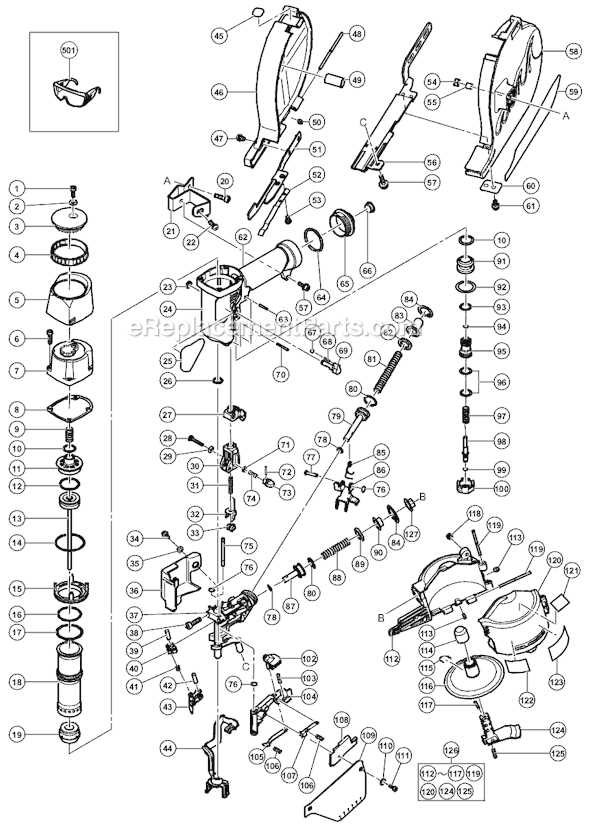

Visual aids serve as invaluable resources, providing a comprehensive overview of the various elements within your device. By familiarizing yourself with these illustrations, you can easily identify components, understand their interrelations, and ensure that everything is functioning as intended. Whether you are a seasoned professional or a DIY enthusiast, this insight is key to maximizing the longevity and reliability of your equipment.

As you delve deeper into the intricacies of your tool, it becomes apparent that recognizing each segment’s purpose is fundamental. This understanding empowers users to execute repairs and replacements with confidence, ultimately leading to better performance and satisfaction in their projects. With the right guidance, anyone can master the essentials of their machinery.

Understanding Hitachi Nail Gun Components

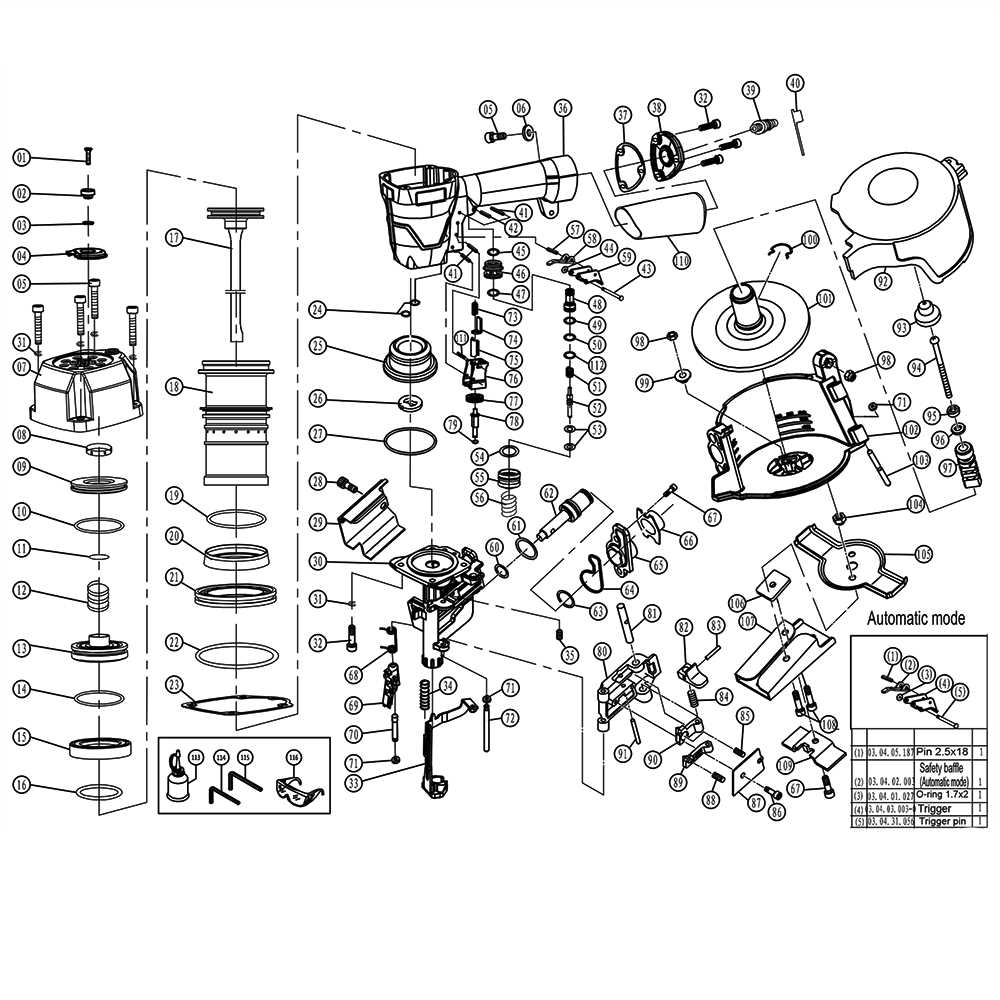

In any tool designed for precision and efficiency, the various elements work in harmony to achieve the desired results. Grasping the functions and interactions of these components is essential for effective operation and maintenance. Each segment contributes to the overall performance, ensuring reliability and durability in demanding tasks.

The power source is a critical feature that drives the mechanism, providing the necessary force to propel fasteners into different materials. Understanding the type of energy used–whether pneumatic, electric, or battery-operated–can inform users about maintenance and usage practices.

The firing mechanism plays a pivotal role in how the tool delivers fasteners. Different styles of actuation, such as sequential or contact, can significantly affect both speed and accuracy. Familiarity with these mechanisms helps in selecting the right approach for specific projects.

Magazine design influences the efficiency of loading and unloading fasteners. Different configurations allow for varying capacities and ease of use, making it vital to choose a model that aligns with project needs.

Safety features are paramount in ensuring the secure operation of the device. Understanding these elements not only enhances user confidence but also minimizes the risk of accidents. Features such as trigger locks and depth adjustment mechanisms contribute to safer handling.

Lastly, regular maintenance and care are essential for the longevity of any tool. Familiarity with wear components, such as seals and O-rings, will aid users in troubleshooting issues and ensuring peak performance over time. A comprehensive understanding of these fundamental aspects is crucial for anyone looking to utilize this equipment effectively.

Overview of Nail Gun Functionality

This section explores the fundamental workings of a fastening tool designed for efficient assembly tasks. Understanding the mechanics of this equipment is crucial for both users and technicians, as it enhances productivity and ensures safety during operation.

Core Components and Their Roles

The functionality of this tool relies on several key elements, each serving a specific purpose:

- Power Source: This can be pneumatic, electric, or battery-operated, providing the necessary energy to drive fasteners.

- Driving Mechanism: This component is responsible for the propulsion of fasteners into materials, typically using a rapid motion.

- Magazine: This holds the fasteners and feeds them into the driving mechanism, ensuring a continuous supply during operation.

- Trigger System: This initiates the fastening action, allowing for precise control by the operator.

Operation Process

The process of fastening involves several steps:

- Loading the fasteners into the magazine.

- Connecting the power source.

- Aligning the tool to the material surface.

- Pulling the trigger to engage the driving mechanism.

- Releasing the trigger to stop the action, allowing for repositioning.

By understanding these components and their functions, users can effectively utilize the tool for various applications, from construction to furniture assembly.

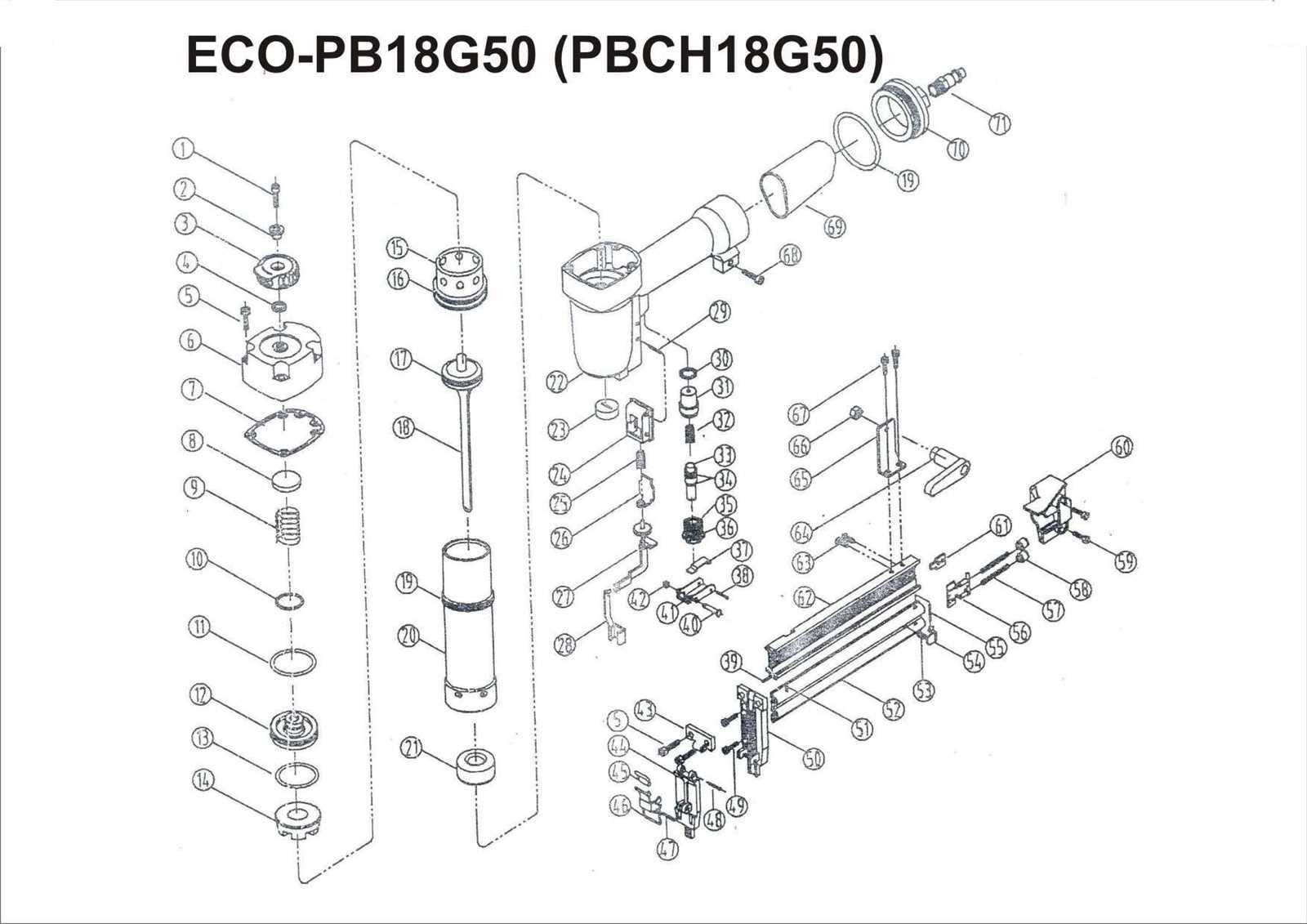

Common Parts of Hitachi Nail Guns

Understanding the essential components of fastening tools is crucial for effective maintenance and repair. These tools consist of various integral elements that contribute to their overall functionality and performance. Familiarity with these components allows users to troubleshoot issues and ensure optimal operation.

One of the primary elements is the housing, which provides structural integrity and protects internal mechanisms. The motor assembly is vital for driving fasteners with precision, while the trigger mechanism allows for user control during operation. Another significant component is the magazine, which holds the fasteners and facilitates smooth feeding into the driving mechanism.

Additionally, the exhaust port plays a role in expelling air, enhancing user comfort during extended use. Safety features, such as the contact element, help prevent accidental discharge, ensuring a secure working environment. Lastly, the depth adjustment mechanism allows for customization of fastening depth, catering to various materials and applications.

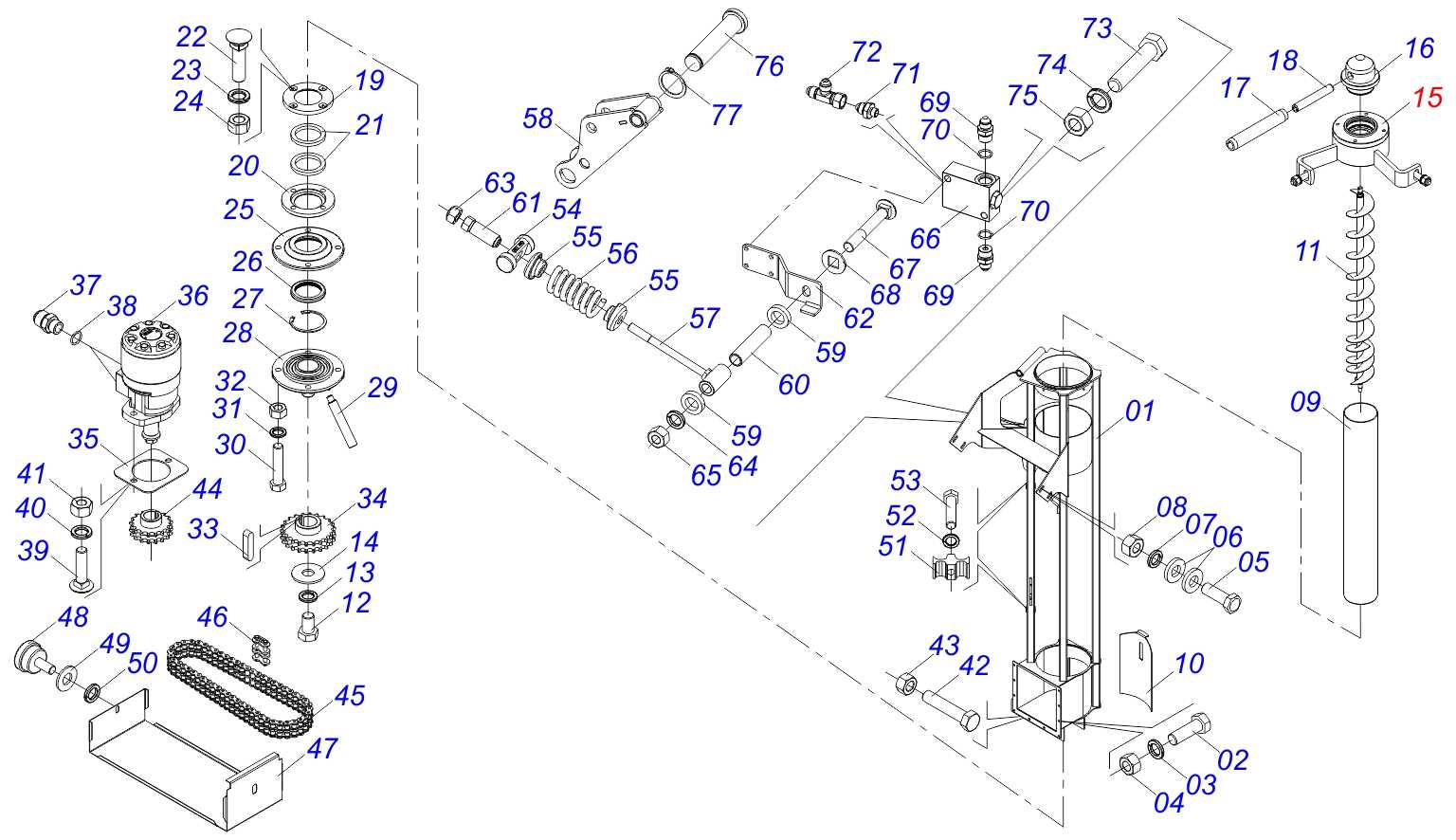

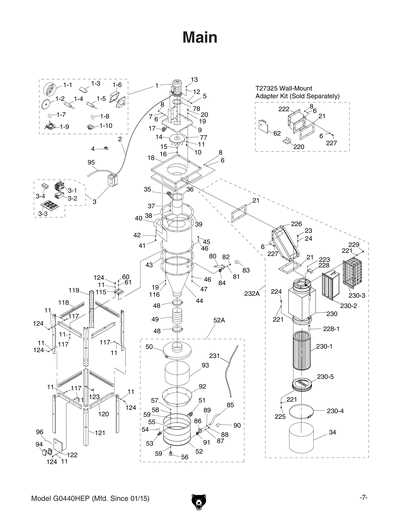

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to maintain and repair equipment. These illustrations provide a clear overview of various elements, helping you identify and locate each section effectively.

Familiarize yourself with the layout first. Usually, the main assembly is depicted in the center, with auxiliary components arranged around it. This arrangement often follows a logical flow, allowing for easier comprehension.

Next, look for labels or numbers corresponding to a list or key. These identifiers are crucial for pinpointing specific items and can guide you in sourcing replacements. Make sure to cross-reference these with a detailed inventory.

Additionally, note the connections between elements. Arrows or lines often indicate how parts interact, providing insights into their functionality. This understanding can be invaluable when troubleshooting issues.

Importance of Proper Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of any mechanical device. Proper care not only enhances efficiency but also minimizes the risk of unexpected failures. A well-maintained tool operates smoothly and safely, ultimately contributing to better results in various applications.

Neglecting maintenance can lead to wear and tear, resulting in decreased functionality and potential hazards. Routine inspections and timely replacements of worn components can prevent minor issues from escalating into major problems. Moreover, maintaining equipment according to manufacturer recommendations fosters reliability and can extend the overall lifespan of the device.

Investing time in regular maintenance not only safeguards your investment but also promotes safety for the user. Understanding the importance of care routines and adhering to them can ensure that the tool remains in peak condition, ready for any task at hand.

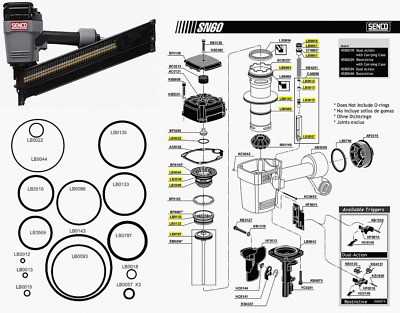

Identifying Replacement Parts Quickly

Understanding how to swiftly recognize components for your tools can significantly enhance your maintenance efficiency. Whether you’re a professional or a DIY enthusiast, knowing where to look and what to seek can save you time and frustration. A structured approach will ensure you find the exact pieces you need without unnecessary delays.

Start by familiarizing yourself with the essential features of your equipment. This includes knowing the model number and any unique characteristics that distinguish it from others. A comprehensive user manual often provides a wealth of information, including diagrams and specifications, which can aid in pinpointing the necessary elements.

| Component Type | Common Issues | Replacement Solution |

|---|---|---|

| Drive Mechanism | Inconsistent operation | Inspect for wear and replace if necessary |

| Trigger Assembly | Sticking or failure to engage | Check for debris and consider a replacement |

| Housing | Cracks or breaks | Look for compatible replacements based on model |

| Power Source | Insufficient charge or malfunction | Test and replace with an approved type |

Utilizing online resources can also streamline the identification process. Many websites offer detailed images and descriptions that can guide you to the correct elements. Additionally, engaging with online forums or communities can provide valuable insights and recommendations from fellow users.

Troubleshooting Common Issues

When working with any type of power tool, it’s essential to identify and resolve frequent challenges to ensure optimal performance. This section will guide you through common problems encountered during operation and provide effective solutions to enhance functionality.

1. Tool Fails to Operate: If the device does not start, check the power source. Ensure that the plug is securely connected and the outlet is functional. Additionally, inspect the trigger mechanism for any blockages or damage.

2. Inconsistent Performance: Variability in operation may indicate issues with airflow or pressure. Verify that the air compressor is set to the appropriate pressure levels and that there are no leaks in the hose or fittings. Cleaning the air intake may also help improve consistency.

3. Jamming: Frequent jams can disrupt workflow significantly. Examine the feeding mechanism for debris or misalignment. Regularly lubricating moving parts can also prevent this issue from recurring.

4. Excessive Noise: If unusual sounds are present during use, it may indicate wear on internal components. Inspect the motor and any moving parts for signs of damage. Addressing these issues promptly can prevent further complications.

5. Misalignment: If results are not as expected, check the alignment of the mechanism. Adjusting the settings or recalibrating the tool may be necessary to achieve precision in application.

By systematically addressing these issues, users can significantly enhance the reliability and efficiency of their equipment, ensuring a smoother operation overall.

Where to Purchase Spare Parts

Finding reliable components for your tools is essential for maintaining their performance and longevity. Whether you’re looking to replace a worn-out piece or upgrade your equipment, knowing where to acquire quality items can make a significant difference.

Authorized Retailers

One of the most dependable sources is authorized retailers. These establishments often carry a full range of original components, ensuring compatibility and quality. They can provide guidance on the specific requirements for your equipment and often have knowledgeable staff who can assist with your inquiries.

Online Marketplaces

Another convenient option is online marketplaces. Websites specializing in tools and equipment usually offer a vast selection of components at competitive prices. When shopping online, ensure that you check customer reviews and ratings to verify the reliability of the seller. Consider looking for warranties or return policies to protect your investment.

Whether you choose to shop in-store or online, always prioritize quality and authenticity to ensure the best performance of your equipment.

Benefits of Genuine Hitachi Parts

Utilizing authentic components for tools ensures optimal performance and longevity. These original items are designed to meet specific standards, enhancing the overall reliability of the equipment.

Enhanced Performance

- Precision Engineering: Original components are crafted to fit perfectly, minimizing the risk of malfunction.

- Consistent Quality: Genuine items undergo rigorous testing, ensuring they meet high-quality benchmarks.

- Improved Efficiency: Using authentic parts helps maintain the tool’s speed and effectiveness during operation.

Long-term Cost Savings

- Reduced Maintenance: Genuine components often require less frequent replacements, leading to lower maintenance costs.

- Increased Lifespan: Quality parts enhance the durability of the equipment, prolonging its usable life.

- Warranty Protection: Many manufacturers provide warranties on genuine items, safeguarding your investment.