Table saws are essential tools for woodworking enthusiasts and professionals alike. They consist of various elements that work together to ensure precision and efficiency during cutting tasks. Having a clear overview of these components is crucial for both maintenance and troubleshooting, enabling users to keep their equipment in optimal condition.

In this section, we will explore the intricate layout of a specific model, highlighting the key features and functionalities of each segment. By familiarizing yourself with the various parts, you can enhance your understanding of how the saw operates and identify any issues that may arise. Whether you’re a seasoned user or just starting out, this knowledge will empower you to make informed decisions regarding repairs and upgrades.

Additionally, we will discuss the importance of recognizing each element’s role in the overall performance of the tool. From the cutting mechanism to the support structures, every aspect plays a vital role in achieving accurate and safe results. Understanding these details can greatly improve your woodworking experience and help you achieve your project goals.

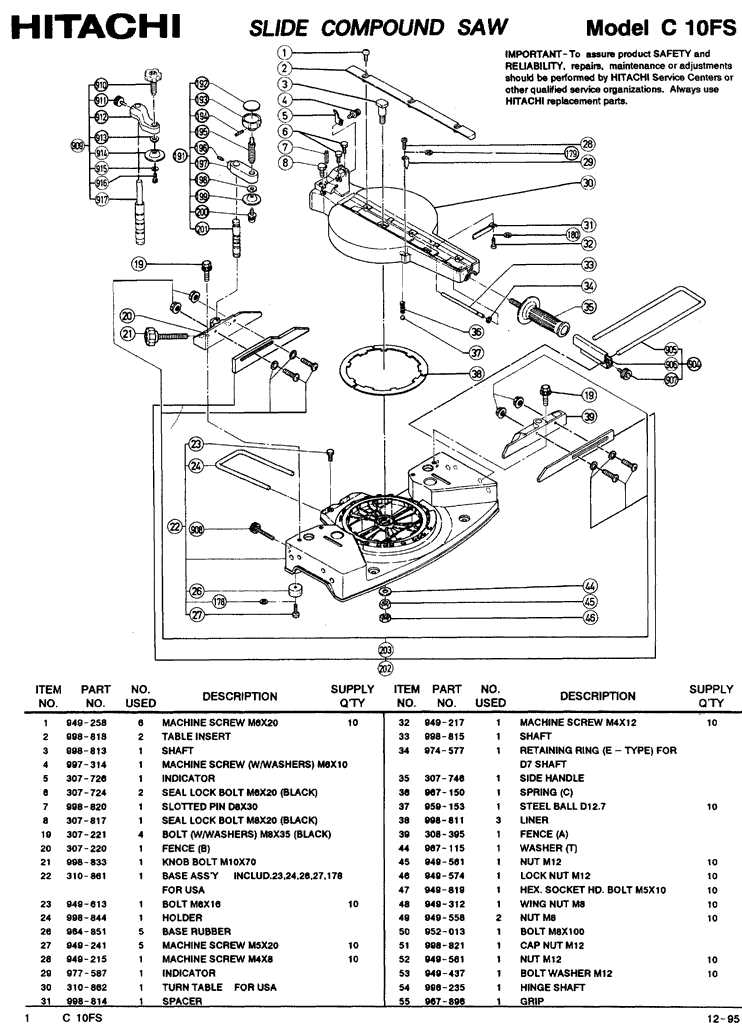

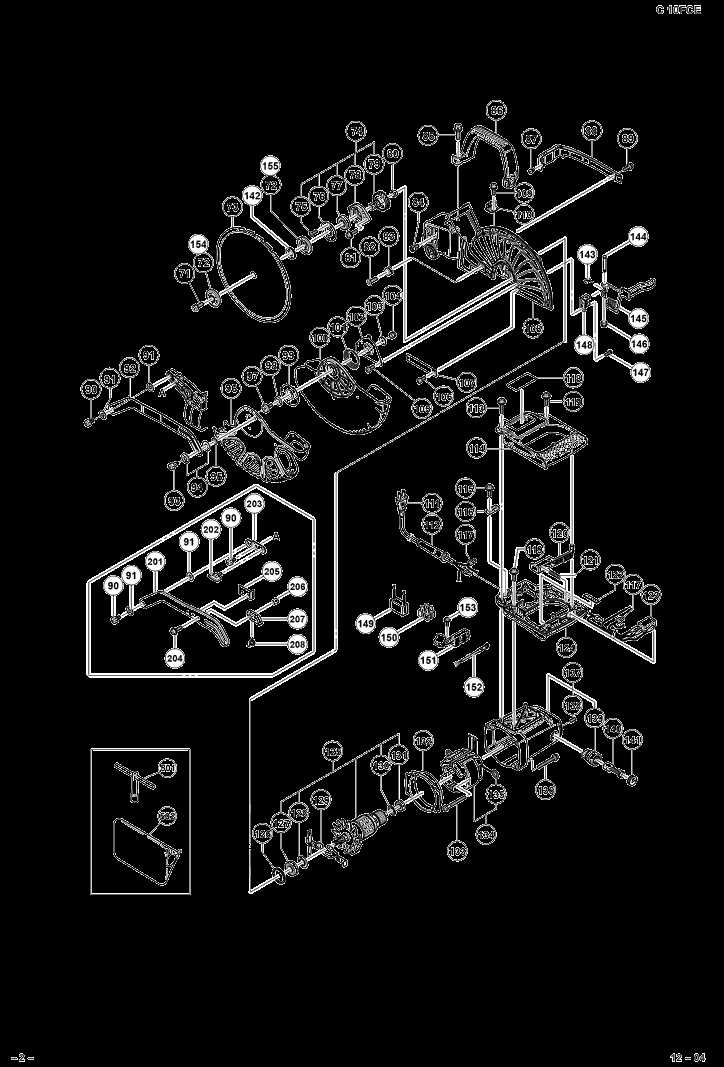

Understanding Hitachi C10FSH Components

The efficient operation of any machinery relies heavily on the various elements that constitute its structure. Each component plays a vital role in ensuring optimal performance, and recognizing their functions can greatly enhance the user’s understanding and ability to troubleshoot issues. This section aims to provide insight into the critical elements of this specific model, focusing on their characteristics and significance in overall functionality.

Key Elements Overview

Familiarity with the essential components allows for better maintenance and operational efficiency. Here are some of the primary elements:

- Motor: The driving force that powers the device, crucial for its operation.

- Base: Provides stability and support, ensuring the unit remains steady during use.

- Table: Serves as the working surface, where materials are placed for cutting or shaping.

- Guard: Enhances safety by protecting the user from moving parts and potential hazards.

- Adjustment Mechanism: Allows for precise changes in settings to accommodate different tasks.

Functionality and Importance

Understanding the functionality of each component aids in maximizing the efficiency of the equipment:

- Each element must work cohesively to achieve desired outcomes.

- Regular inspections and maintenance can prolong the lifespan of individual parts.

- Identifying and addressing issues early can prevent major breakdowns.

By being aware of how each element interacts within the machinery, users can ensure seamless operation and enhance their overall experience.

Importance of Parts Diagrams

Understanding the layout of components in machinery is crucial for effective maintenance and repair. These visual representations provide users with essential insights into the assembly and functionality of various elements. By utilizing such illustrations, technicians can quickly identify and address issues, ensuring optimal performance and longevity of the equipment.

Enhanced Troubleshooting

Clear visual guides enable users to locate specific components swiftly, reducing downtime during repairs. When issues arise, having an organized view of the arrangement facilitates efficient diagnostics, allowing technicians to focus their efforts where they are most needed. This targeted approach minimizes guesswork and streamlines the problem-solving process.

Facilitating Replacement and Upgrades

Illustrative layouts serve as a valuable reference when it comes to replacing worn or outdated elements. With a comprehensive understanding of the configuration, users can select appropriate substitutes or enhancements that fit seamlessly into the existing system. This knowledge not only supports effective upgrades but also helps maintain compatibility across various machinery models.

Common Issues with Hitachi Tools

When it comes to power equipment, certain challenges frequently arise that can impact performance and efficiency. Understanding these common problems can aid in both prevention and resolution, ensuring that tools function optimally.

One prevalent issue is the deterioration of electrical connections, which can lead to intermittent power loss or complete failure. Regular inspections can help identify corrosion or loose connections before they become serious problems.

Another concern is wear and tear on moving components. Over time, parts such as gears and bearings may experience degradation, resulting in unusual noises or decreased functionality. Proper lubrication and timely replacements are essential for maintaining peak performance.

Lastly, overheating is a significant issue that can stem from various factors, including prolonged use or inadequate ventilation. Ensuring that tools are used within recommended limits and keeping air passages clear can help mitigate this risk.

Identifying Essential Spare Parts

Understanding the critical components of your equipment is essential for maintaining its optimal functionality. Recognizing which elements may require replacement over time can significantly enhance the longevity and performance of the machinery. This section provides insights into identifying key components that should be kept in stock to ensure seamless operation.

- Motor: The driving force of the machine, responsible for power transmission.

- Bearing: Essential for reducing friction between moving parts, ensuring smooth operation.

- Blade: A vital component that directly impacts cutting efficiency and quality.

- Switch: Controls the power supply, making it critical for safe operation.

- Belt: Connects different parts, transmitting power from the motor to the cutting element.

By ensuring these crucial components are readily available, operators can minimize downtime and maintain productivity. Regular assessments of these elements will help in identifying potential wear and facilitate timely replacements.

Maintenance Tips for C10FSH Model

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular attention to specific components can prevent breakdowns and enhance functionality, making maintenance a key aspect of ownership. Implementing a structured approach will help you keep your device in peak condition.

Regular Cleaning

Cleaning the exterior and interior surfaces is crucial. Dust and debris can accumulate over time, affecting both the appearance and efficiency of the machine. Utilize a soft cloth and appropriate cleaning solutions to maintain cleanliness without causing damage. Ensure that air vents and cooling systems remain free from obstructions.

Routine Inspections

Conduct routine inspections to identify potential issues before they escalate. Pay close attention to moving parts, electrical connections, and any signs of wear or fatigue. If you notice any irregularities, address them promptly to avoid costly repairs. Additionally, consulting the user manual for specific inspection points can provide further guidance.

How to Use the Diagram Effectively

Utilizing a visual representation of components can significantly enhance understanding and troubleshooting processes. This section aims to guide you on maximizing the benefits of such illustrations.

When engaging with the visual guide, consider the following steps:

- Familiarize yourself with the layout: Understand the arrangement of elements to navigate the illustration effortlessly.

- Identify key components: Recognize critical parts and their functions to build a foundational knowledge of the assembly.

- Refer to the legend: If available, use the legend to decode symbols or color codes that clarify component types or statuses.

In addition to these steps, keep the following tips in mind:

- Cross-reference with manuals or specifications to validate information.

- Make notes on the illustration for quick reference during maintenance or assembly tasks.

- Practice identifying components on the actual unit using the visual guide to reinforce learning.

By following these strategies, you can effectively utilize the visual representation, leading to improved accuracy and efficiency in your work.

Replacing Worn Out Components

Maintaining optimal performance of machinery often requires the timely replacement of deteriorating elements. Identifying these worn components is crucial for ensuring the longevity and efficiency of the equipment. By replacing faulty parts, users can prevent further damage and costly repairs, while also enhancing overall functionality.

Identifying Signs of Wear

Regular inspections can help in recognizing indicators of degradation. Look for unusual noises, vibrations, or reduced efficiency, as these may signal that certain elements need attention. Pay close attention to any visible damage, such as cracks or excessive wear, as these can directly impact performance.

Steps for Replacement

When it comes time to replace a worn component, begin by gathering the necessary tools and new parts. Ensure the equipment is powered off and secured to prevent accidents. Carefully remove the damaged piece, taking note of its orientation and connections. Install the new part by reversing the removal process, ensuring that all connections are secure. Finally, conduct a thorough test to confirm that everything operates smoothly.

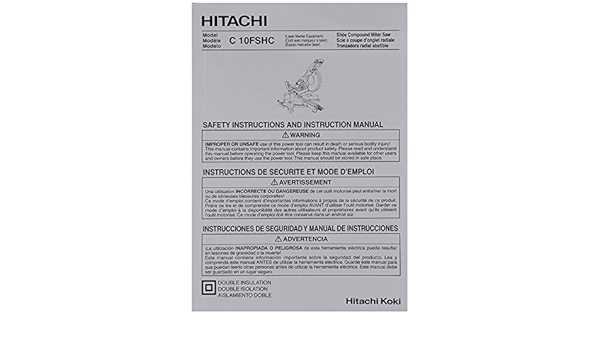

Safety Precautions During Repairs

When undertaking maintenance or service tasks on any machinery, adhering to safety measures is paramount to ensure both personal protection and the longevity of the equipment. Proper precautions can prevent accidents and enhance the effectiveness of the repair process.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks, to safeguard against debris and chemicals.

- Disconnect the power source before starting any repairs to eliminate the risk of electric shock or accidental activation of the device.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust that may be released during the repair process.

- Keep a first aid kit readily available in case of minor injuries.

- Use the right tools for the job, as improper tools can lead to injuries or damage to components.

Before beginning any work, familiarize yourself with the machinery’s specifications and follow the manufacturer’s guidelines to ensure safe practices throughout the repair process.

- Be cautious of sharp edges and moving parts that could cause injury during disassembly and reassembly.

- Ensure that all components are securely fastened to avoid accidental dislodgement during operation.

- Never rush through repairs; take your time to follow each step methodically to avoid mistakes.

- Stay organized by keeping your workspace clean and labeling any parts removed during the process.

By adhering to these guidelines, you can ensure a safer repair experience and maintain the equipment’s efficiency and reliability.