In the world of construction and renovation, having a reliable cutting tool is essential for achieving precision and efficiency. This article explores the various elements that make up a specific model of a powerful saw, focusing on their functions and how they contribute to overall performance.

Familiarizing yourself with the structure of this equipment allows users to grasp the intricacies of its operation. Each component plays a vital role, ensuring that the tool not only meets high standards of quality but also maintains safety during use.

Whether you are a professional or a DIY enthusiast, understanding the layout of these parts can enhance your maintenance skills and improve your overall experience with the device. Knowledge of how each section interacts can lead to better troubleshooting and more effective usage.

This section provides a comprehensive overview of a specific cutting tool renowned for its performance and durability. Understanding the essential components of this equipment is crucial for both maintenance and effective operation. Each element plays a vital role in the functionality and reliability of the tool, making familiarity with these parts important for users and technicians alike.

Key Features of the Equipment

- Robust construction designed for heavy-duty applications

- Advanced safety mechanisms to enhance user protection

- Efficient power management for optimal performance

Importance of Understanding Components

Knowing the individual parts and their functions is essential for effective troubleshooting and maintenance. This understanding aids in:

- Identifying issues quickly

- Ensuring proper reassembly after repairs

- Maximizing the lifespan of the tool

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details of the tool, highlighting its performance and operational capabilities. Understanding these elements is crucial for users to maximize efficiency and ensure proper handling.

The model is designed with a robust engine that delivers exceptional power, making it suitable for various demanding applications. Its lightweight construction allows for easy maneuverability, while the ergonomic design ensures user comfort during extended use.

Additionally, the equipment features advanced safety mechanisms to protect the operator and enhance overall reliability. The compatibility with various accessories further expands its versatility, enabling users to tailor the tool to their specific needs.

Overall, this tool exemplifies a blend of strength, user-friendly features, and adaptability, making it an ideal choice for professionals in the construction and renovation sectors.

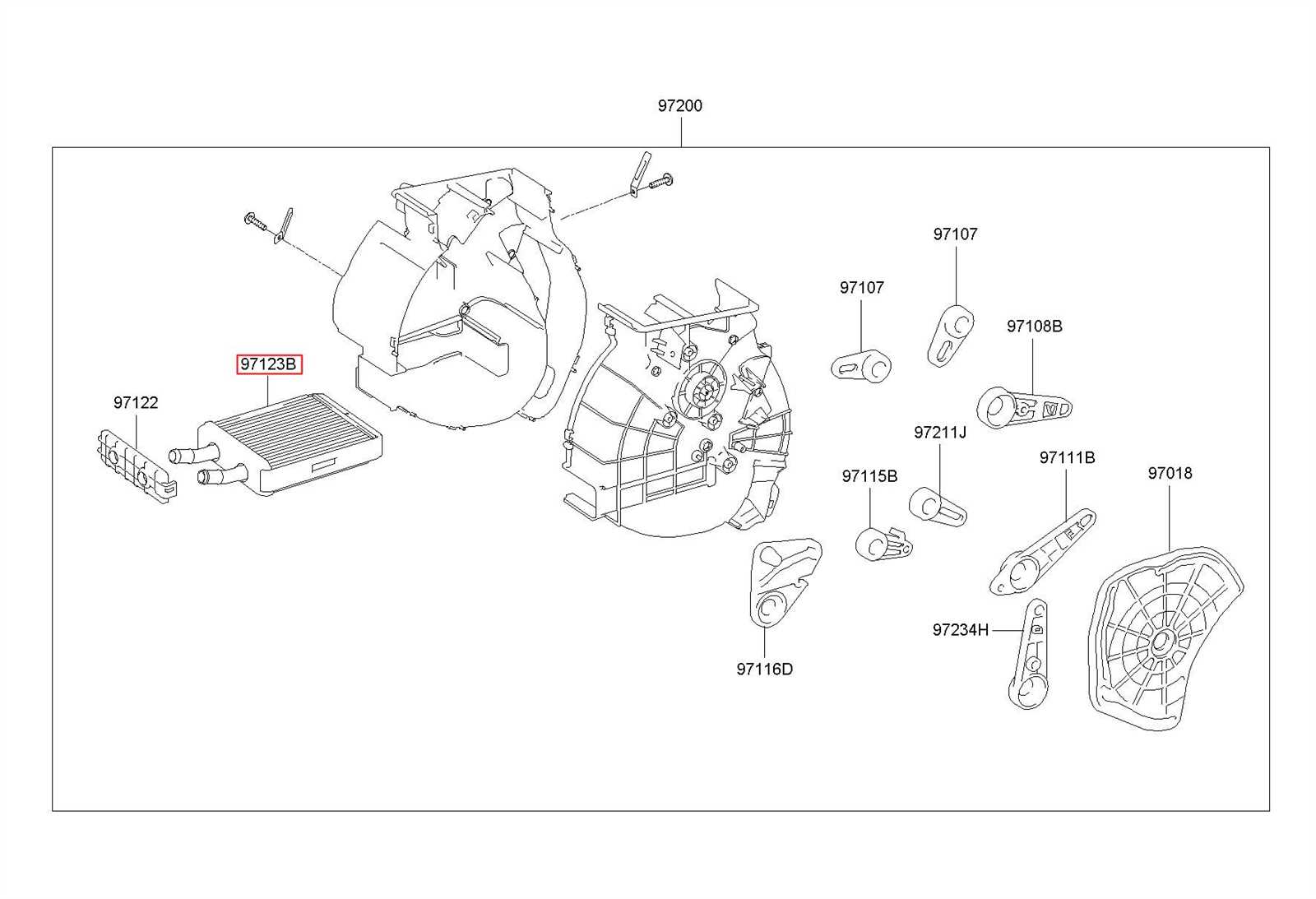

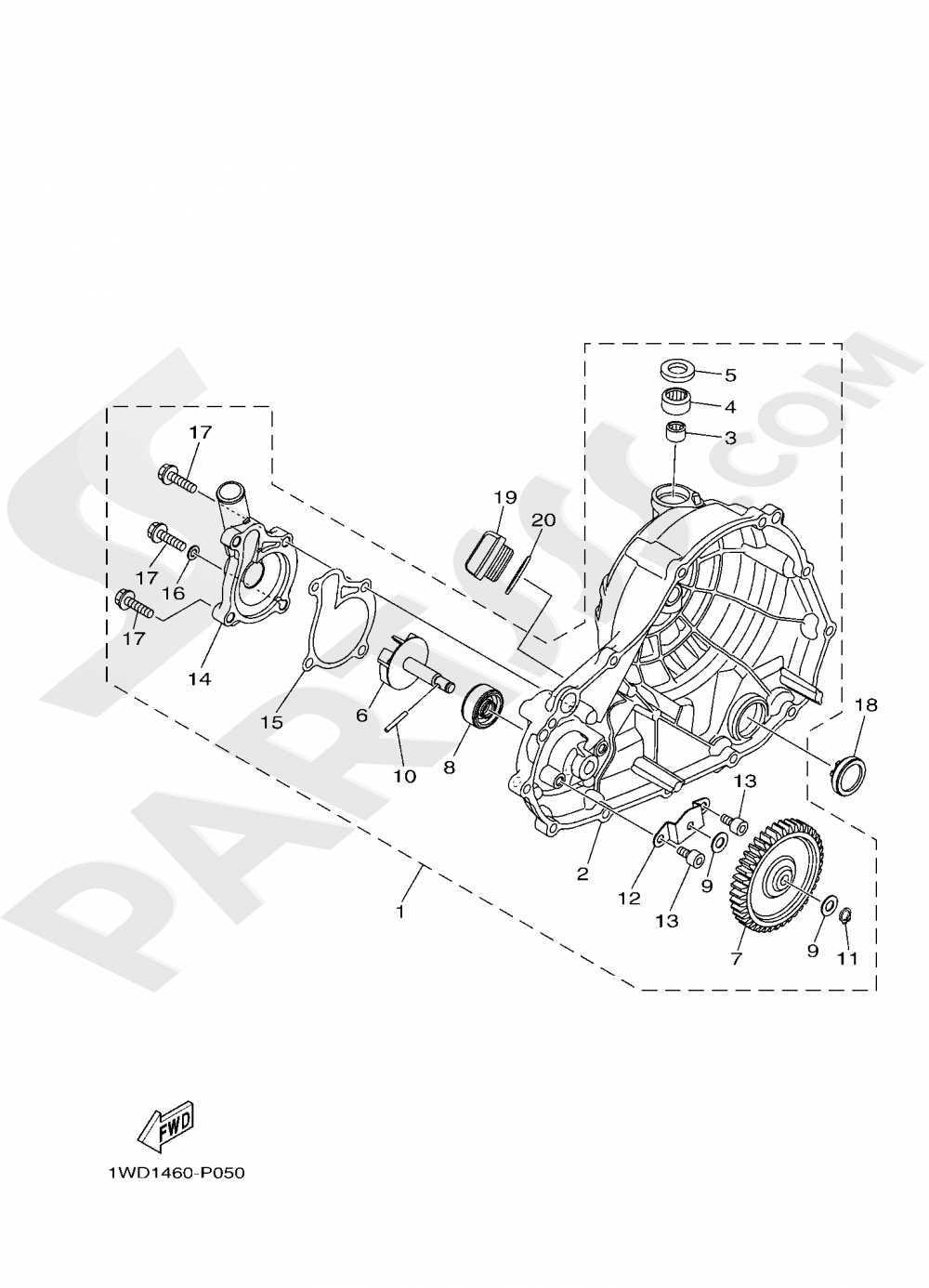

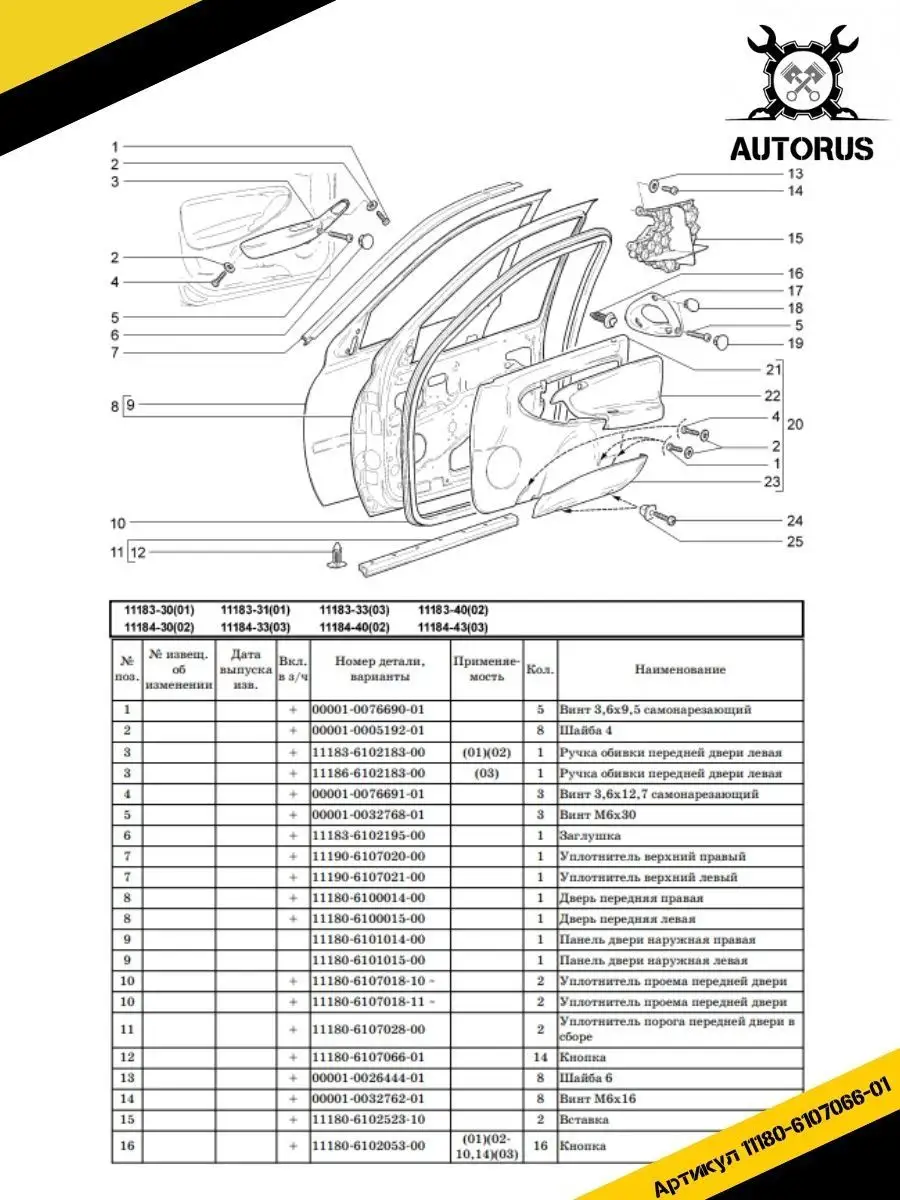

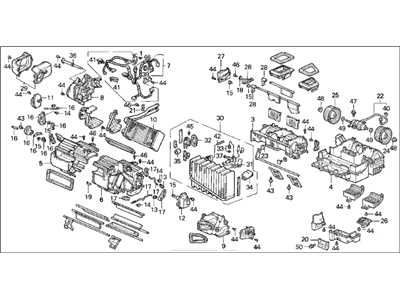

Understanding the Parts Diagram

The illustration of components serves as a vital reference for comprehending the assembly and functionality of machinery. It provides users with a visual representation of individual elements and their interconnections, facilitating easier maintenance and repair processes.

In this section, we will explore the significance of such visual guides, emphasizing their role in identifying each segment’s purpose. Recognizing the layout enables users to troubleshoot issues efficiently and ensures that any replacements or adjustments can be made with confidence. Familiarity with the components not only enhances operational knowledge but also contributes to the overall safety and effectiveness of the equipment.

Common Components and Their Functions

This section explores the essential elements found in cutting tools and their respective roles. Understanding these components helps in the effective operation and maintenance of the equipment.

Main Parts

- Blade: The primary tool for cutting, available in various sizes and types for different materials.

- Motor: Provides the necessary power to drive the blade, influencing performance and efficiency.

- Handle: Designed for user comfort and control, ensuring stability during operation.

- Guard: A safety feature that protects the user from debris and accidental contact with the blade.

Supporting Elements

- Base Plate: Stabilizes the tool, allowing for precise cuts and enhancing balance.

- Cooling System: Prevents overheating, prolonging the lifespan of the motor and blade.

- Switch: Enables quick activation and deactivation of the tool for user safety.

Maintenance Tips for Longevity

Proper upkeep of machinery is crucial for ensuring its extended functionality and performance. By implementing regular maintenance routines, operators can prevent premature wear and address potential issues before they escalate. This section outlines essential strategies to enhance the lifespan of your equipment.

Regular Cleaning and Inspection

Routine cleaning and inspection of the machinery components are vital for identifying wear and tear. Keeping surfaces free of debris not only improves efficiency but also minimizes the risk of damage to internal mechanisms. Ensure that all moving parts are accessible and check for any signs of wear during regular inspections.

Lubrication and Fluid Levels

Maintaining appropriate lubrication levels is essential for smooth operation. Ensure that all lubricated parts are adequately serviced to reduce friction and heat build-up. Additionally, regularly checking fluid levels in hydraulic systems is necessary to avoid operational failures.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Cleaning | After each use | Remove dust and debris |

| Inspection | Weekly | Check for wear and damage |

| Lubrication | Monthly | Ensure all moving parts are lubricated |

| Fluid Level Check | Monthly | Maintain hydraulic fluid levels |

Identifying Replacement Parts

Understanding the various components of your equipment is crucial for effective maintenance and repair. Recognizing the specific elements that may require substitution can significantly enhance the longevity and performance of the machine. This section aims to provide guidance on how to identify these essential components and ensure proper replacements when necessary.

Common Components to Check

Begin by familiarizing yourself with the most frequently used elements. This includes cutting tools, filters, and drive belts. Regular inspection of these parts can help you spot wear and tear early, preventing potential breakdowns.

Resources for Identification

Utilize manufacturer manuals and online resources to locate detailed information regarding the various components of your equipment. Visual aids such as images or schematics can be particularly helpful in recognizing different items. Additionally, consulting with experienced technicians can provide insights into the most common replacement requirements.

Assembly Instructions for Components

Understanding the assembly of individual elements is crucial for achieving optimal performance and functionality. This section provides a step-by-step guide to effectively combine the various components involved in the process.

Follow these instructions to ensure proper assembly:

- Gather Required Tools:

- Screwdriver

- Wrench

- Measuring tape

- Prepare Components:

- Inspect each element for any damage or defects.

- Ensure that all pieces are clean and free of debris.

- Begin Assembly:

- Start with the base component and secure it firmly.

- Attach subsequent elements in the specified order.

- Ensure all fasteners are tightened to the manufacturer’s specifications.

- Final Check:

- Review the assembly for any loose parts.

- Perform a functionality test to confirm everything is operating correctly.

By adhering to these instructions, you will ensure a secure and efficient assembly of all components involved.

Safety Precautions During Use

Ensuring safety during operation is crucial to prevent accidents and injuries. Proper precautions help maintain a secure working environment and enhance the effectiveness of the task at hand. This section outlines essential guidelines to follow for safe usage of the equipment.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection.

- Inspect the equipment before each use to identify any signs of wear or damage.

- Ensure the working area is clean and free from any obstacles that could cause tripping or accidents.

- Read and understand the manufacturer’s instructions before operating the equipment.

Operational Safety Tips

- Keep hands and other body parts away from moving components during operation.

- Never bypass safety features or remove protective guards.

- Maintain a firm grip and stable stance while using the equipment.

- Be aware of your surroundings and ensure that no one is within the danger zone.

Where to Find Official Resources

Accessing accurate and reliable documentation is crucial for effective maintenance and operation of machinery. Various platforms offer official materials that can aid in understanding the components and functions of your equipment.

To locate these resources, consider the following options:

| Resource Type | Description | Access Method |

|---|---|---|

| Manufacturer Website | The primary source for manuals, schematics, and service guides. | Visit the official site and navigate to the support section. |

| Customer Service | Direct assistance for inquiries about products and services. | Contact via phone or online chat for personalized help. |

| Authorized Dealers | Local distributors often provide access to official documents and support. | Visit or call your nearest authorized dealer for assistance. |

| Online Forums | Community-driven platforms may host discussions and shared resources. | Join relevant forums to connect with other users and share information. |