In any aquatic management system, a comprehensive grasp of its fundamental elements is essential for ensuring efficient operation. These components work in harmony to maintain cleanliness and enhance the overall experience, reflecting the intricacies involved in their design and functionality.

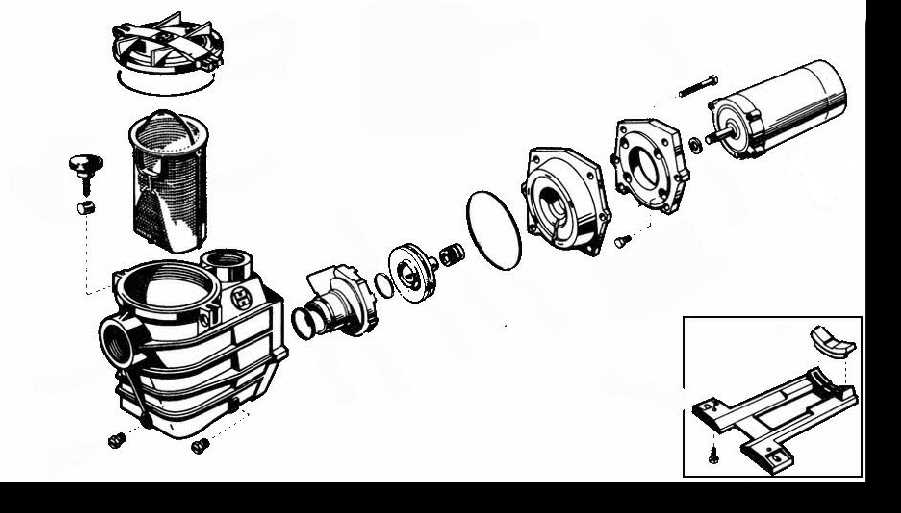

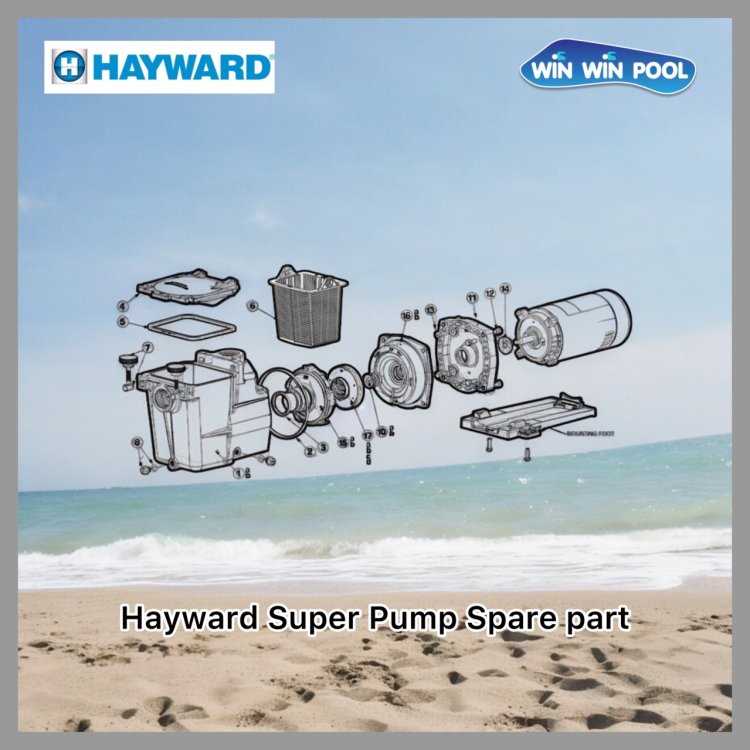

Visual representation of these integral units can greatly aid in identifying their roles and interconnections. By exploring these illustrations, one can better appreciate how each segment contributes to the system’s ultimate performance.

For those seeking to enhance their knowledge, delving into the specifics of these components not only fosters a deeper understanding but also empowers users to troubleshoot and optimize their setup effectively. The synergy among these elements is key to achieving peak efficiency and longevity.

Understanding Hayward Pool Pump Components

Gaining insight into the various elements of a water circulation system is essential for maintaining its efficiency and longevity. Each component plays a crucial role in ensuring optimal operation and performance. Familiarity with these elements enables better troubleshooting and enhances overall functionality.

The central element often includes a motor that drives the mechanism, converting electrical energy into mechanical energy. This is typically paired with an impeller, which facilitates the movement of liquid through the system. A well-designed casing surrounds these parts, providing both protection and structural integrity.

Additionally, filters are integrated to remove debris, ensuring that the liquid remains clean and clear. Valves and seals are critical for controlling flow and preventing leaks, which can significantly impact performance. Regular maintenance of these components is vital to prolonging the lifespan and effectiveness of the entire system.

Understanding the interconnectivity of these elements allows for more informed decisions regarding repairs and upgrades. Knowledge of each component’s function empowers users to optimize their water management systems for better efficiency and performance.

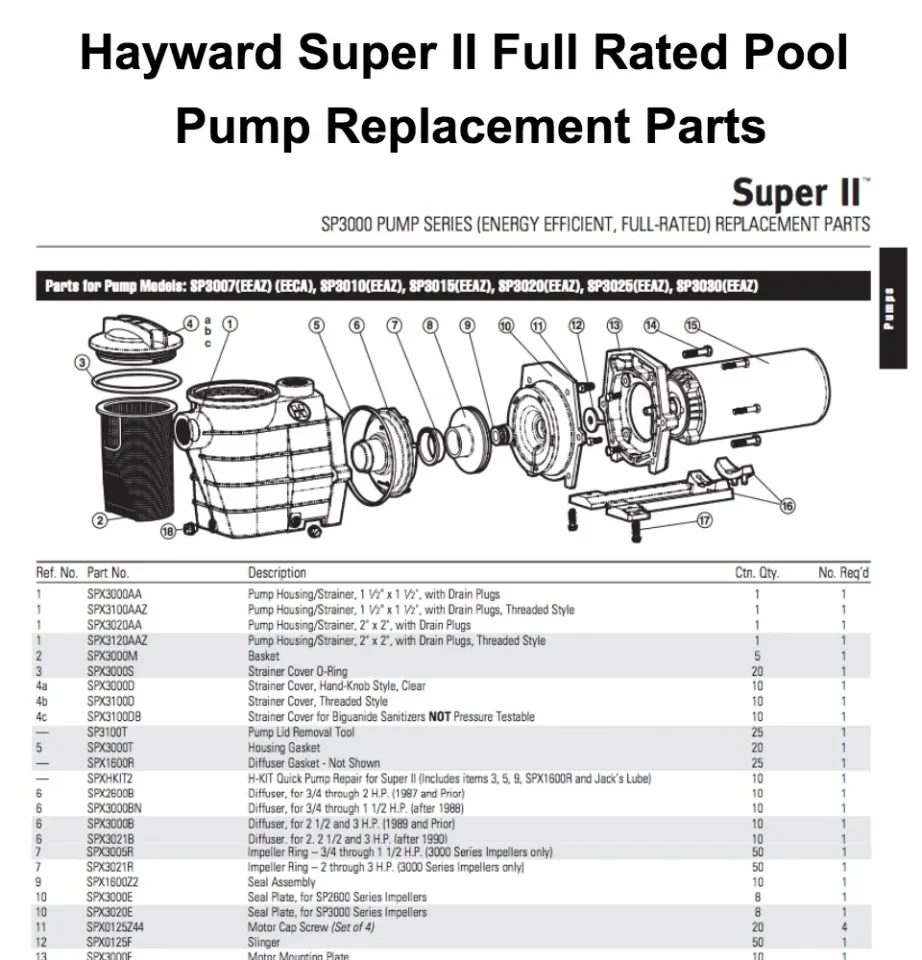

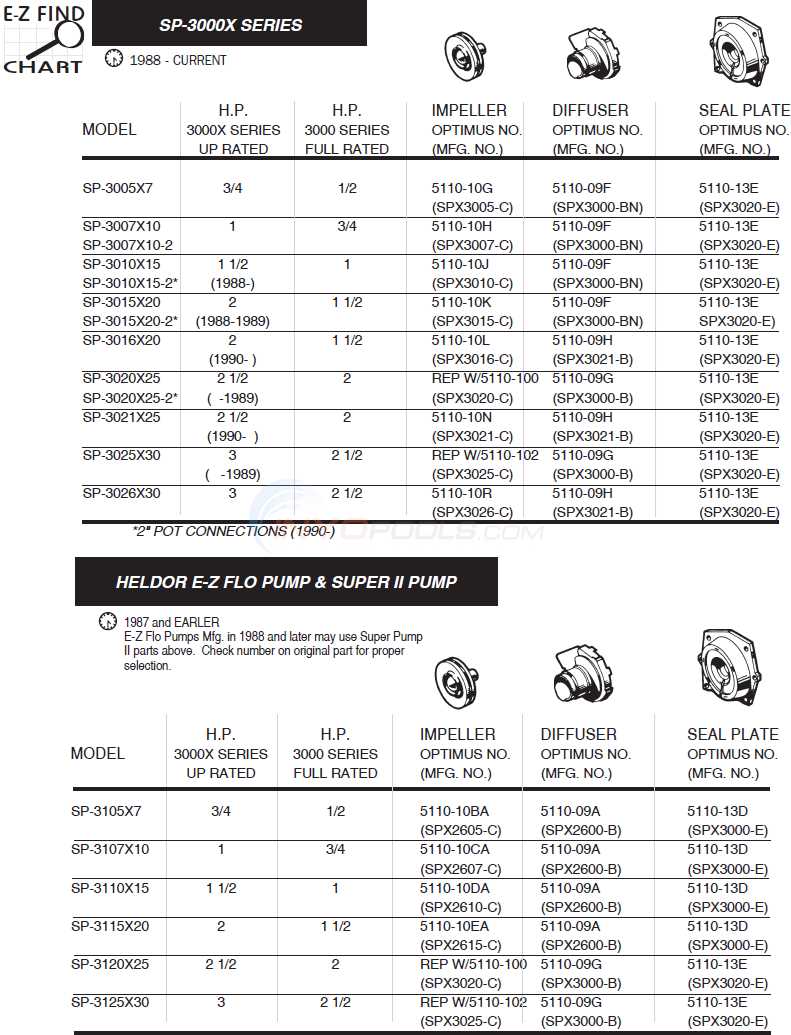

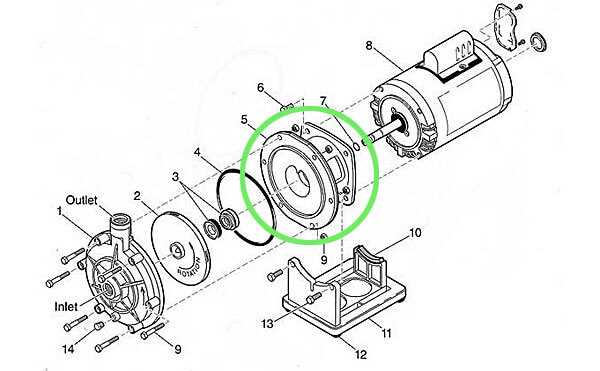

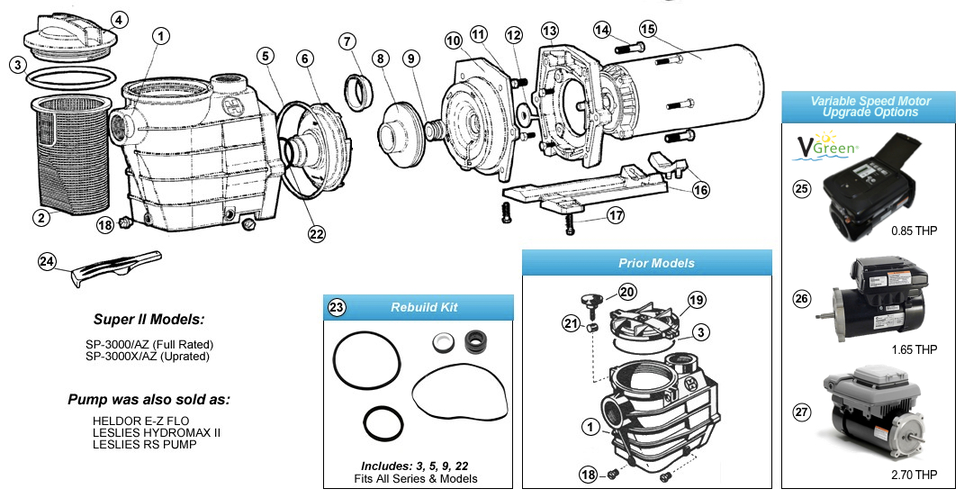

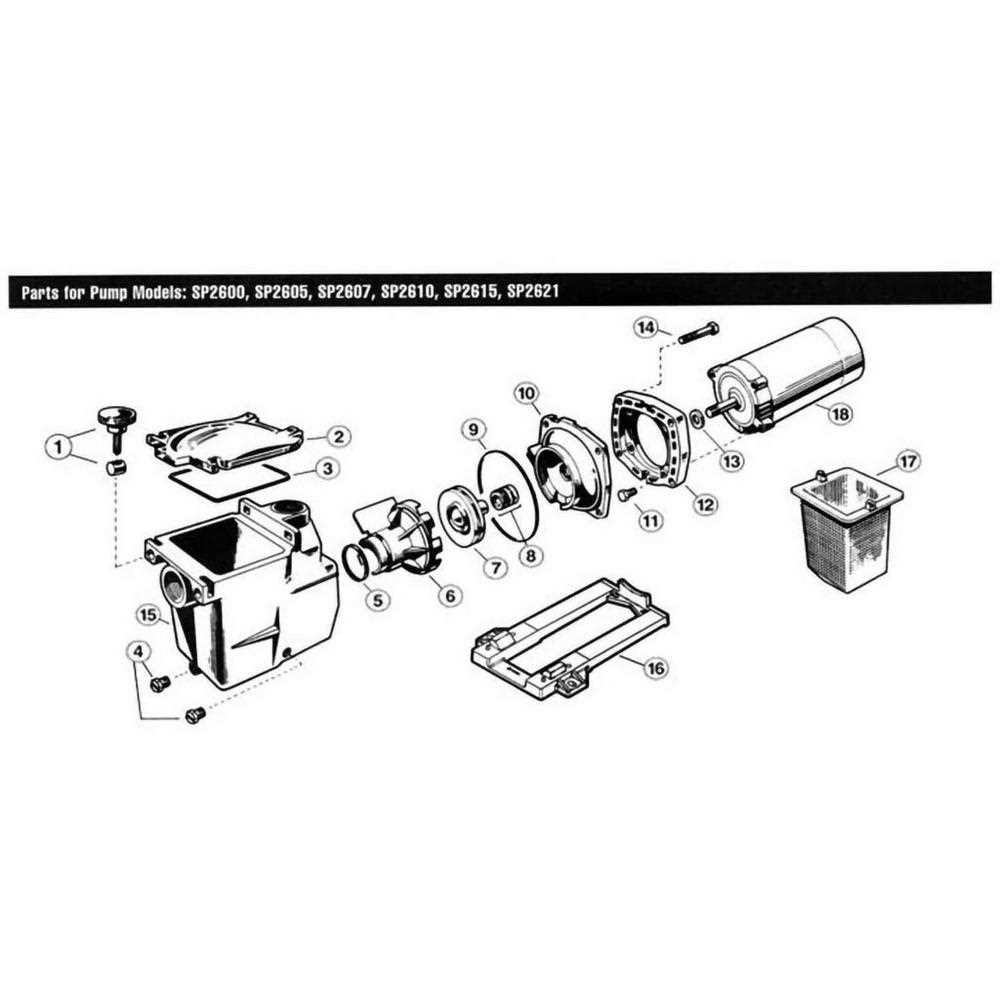

Common Parts in Hayward Pumps

This section explores the essential components found in various models of circulation systems, emphasizing their roles and functionalities. Understanding these elements is crucial for maintenance and efficient operation.

Key Components

- Motor: The driving force behind the entire system, providing the necessary energy for operation.

- Impeller: This component facilitates the movement of fluid, ensuring proper circulation throughout the system.

- Strainer Basket: A protective element that collects debris and prevents clogging, enhancing performance.

- Volute: A casing that helps direct flow from the impeller to the discharge pipe, optimizing efficiency.

Additional Elements

- Seal Plate: Provides a barrier to prevent leakage between the motor and wet end.

- Diffuser: Works in conjunction with the impeller to guide the flow and increase pressure.

- Base Assembly: The foundational support that holds all components in place and minimizes vibrations.

Each of these elements plays a vital role in ensuring the smooth operation and longevity of the system, making regular inspection and maintenance essential for optimal performance.

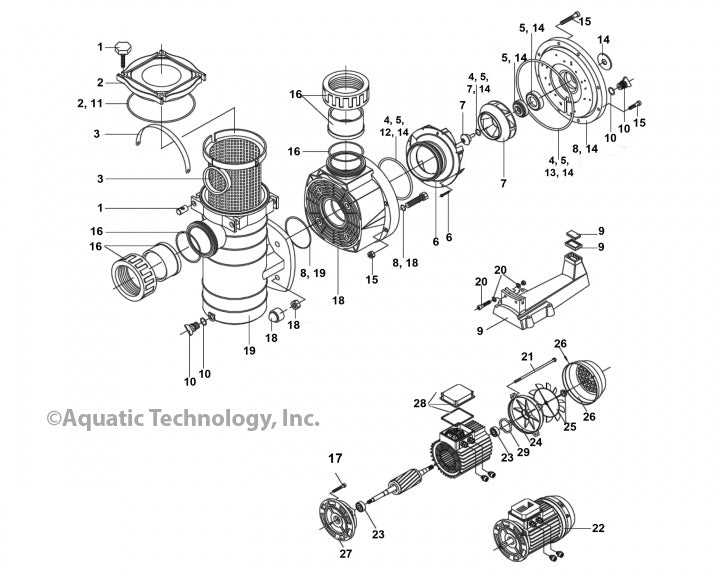

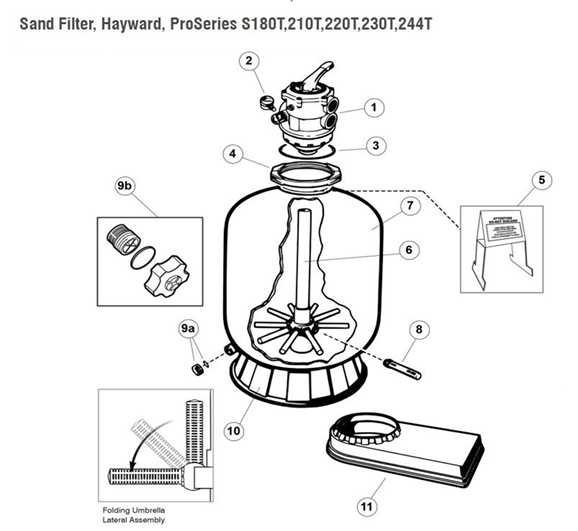

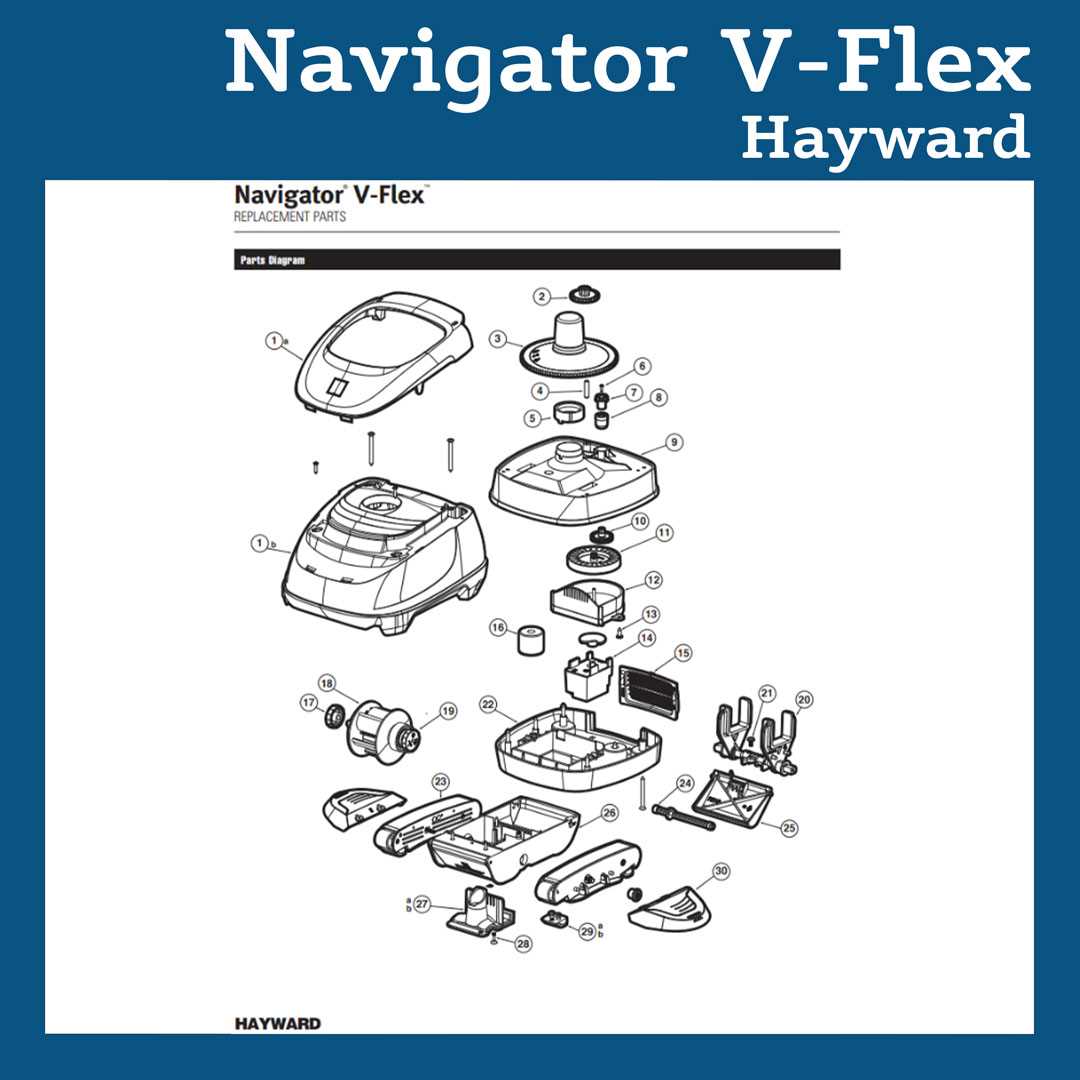

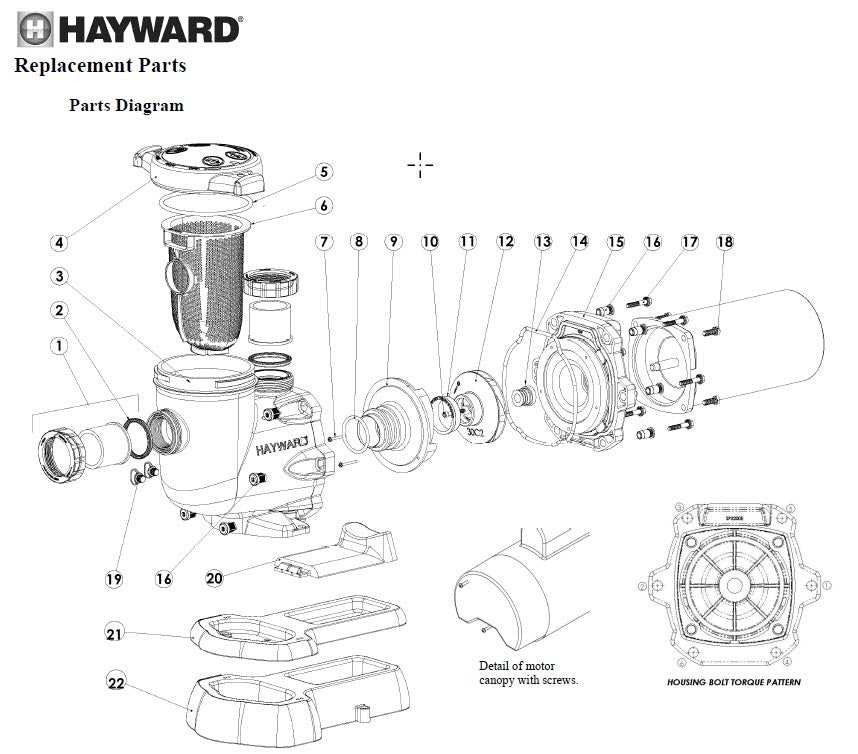

How to Read Pump Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and troubleshoot machinery. These visual guides provide essential information about the components and their relationships within a system. By familiarizing yourself with the symbols and layout, you can efficiently identify issues and perform repairs.

Key Elements of Technical Illustrations

- Symbols: Each element in the illustration is represented by specific symbols. Knowing what these symbols stand for is crucial for interpretation.

- Labels: Annotations often accompany symbols, clarifying their function or specifying particular details. Pay close attention to these labels for a better understanding.

- Connections: Arrows and lines indicate how different components are interconnected. This helps visualize the flow of energy or liquid within the system.

Tips for Effective Reading

- Start with the Legend: Always check the legend or key provided with the illustration. It explains the symbols and terms used.

- Follow the Flow: Trace the pathways indicated by arrows to understand how the system operates.

- Cross-Reference: Use supplementary manuals or guides to enhance your comprehension of the components depicted.

With practice, reading these illustrations will become a valuable skill, allowing for improved maintenance and quicker problem-solving. Equip yourself with this knowledge for more efficient operation and upkeep of your machinery.

Importance of Regular Maintenance

Benefits of Consistent Upkeep

- Prolongs lifespan of equipment

- Improves overall efficiency

- Reduces risk of unexpected failures

- Enhances safety for users

Key Maintenance Practices

- Routine inspections

- Cleaning components regularly

- Checking for wear and tear

- Replacing damaged parts promptly

Identifying Faulty Pump Parts

Recognizing malfunctioning components is essential for maintaining optimal functionality in any water circulation system. Understanding the common indicators of issues can prevent further damage and ensure efficient operation. By closely observing performance and listening for unusual sounds, users can effectively diagnose problems before they escalate.

Common Symptoms of Malfunction

There are several signs that may indicate a component is not operating correctly. Reduced flow rate is often the first noticeable symptom, suggesting blockages or wear. Additionally, unusual noises such as grinding or squealing may point to issues with bearings or seals. Users should also pay attention to any vibrations that differ from the norm, as they can signify misalignment or damaged parts.

Visual Inspection Techniques

Conducting a thorough visual examination is vital in identifying defective elements. Look for cracks, leaks, or signs of corrosion on the exterior of components. Inspect seals and gaskets for wear and tear, as these areas are common points of failure. Regular maintenance checks can greatly enhance the longevity of the system and reduce unexpected breakdowns.

Steps for Disassembling a Pump

Disassembling a mechanical device requires careful attention to detail and a methodical approach. Following a systematic procedure not only ensures safety but also facilitates efficient reassembly. This section outlines essential steps to effectively take apart the unit while minimizing the risk of damage to components.

1. Gather Necessary Tools: Start by collecting all the required tools, such as wrenches, screwdrivers, and pliers. Having everything on hand will streamline the disassembly process.

2. Disconnect Power Supply: Before beginning, ensure the device is unplugged or the power source is completely turned off. This precaution prevents accidental activation during disassembly.

3. Remove External Covers: Use the appropriate tools to carefully remove any outer casings. Take note of the screws and their locations, as this will aid in reassembly.

4. Document the Configuration: Before taking apart internal components, consider documenting their arrangement with photos or notes. This reference will be invaluable during reassembly.

5. Detach Components Sequentially: Begin detaching parts from the unit one at a time, starting with the most accessible. Keep track of all fasteners and small pieces, organizing them in labeled containers.

6. Inspect for Wear: As components are removed, inspect them for any signs of wear or damage. This evaluation will inform any necessary replacements during reassembly.

7. Clean Parts: Once disassembled, clean all components thoroughly to remove debris and buildup. This step enhances performance when the device is reassembled.

8. Reassemble Carefully: After inspecting and cleaning, reassemble the device in reverse order of disassembly, following your documentation for guidance.

Replacing Worn-Out Components

Regular maintenance of your equipment is essential for optimal performance and longevity. Over time, certain elements may wear out, affecting efficiency and functionality. Identifying and replacing these components promptly can save you from costly repairs down the line.

Key signs of deterioration include:

- Unusual noises during operation

- Reduced efficiency or performance

- Leaks or visible damage

- Increased energy consumption

When it comes to replacing these components, consider the following steps:

- Turn off and unplug the system.

- Carefully remove the damaged part.

- Install the new component, ensuring proper alignment.

- Test the system to confirm functionality.

By proactively addressing these issues, you can ensure your system operates at its ultimate capacity.

Best Practices for Pump Installation

Proper installation is crucial for ensuring the longevity and efficiency of your equipment. By following best practices, you can optimize performance and reduce maintenance needs, ultimately enhancing the overall system reliability.

1. Select the Right Location: Choose a flat, stable surface that provides adequate drainage and is free from debris. Ensure there’s sufficient space around the unit for maintenance access.

2. Follow Manufacturer Guidelines: Always refer to the provided instructions for installation specifics. Adhering to these recommendations helps prevent operational issues and maintains warranty validity.

3. Secure Connections: Use appropriate fittings and ensure all connections are tight to prevent leaks. Employing high-quality materials can enhance durability.

4. Electrical Safety: Ensure all electrical work complies with local codes. Use a dedicated circuit and ensure proper grounding to prevent electrical hazards.

5. Test the System: After installation, conduct a thorough test to ensure everything operates smoothly. Monitor for unusual sounds or vibrations that may indicate issues.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of maintenance systems. Various resources are available to help you delve deeper into the intricacies of equipment management and functionality.

- Online Forums: Engage with communities where enthusiasts share their knowledge and experiences.

- Instructional Videos: Visual aids can clarify complex concepts through step-by-step demonstrations.

- Manufacturer Websites: Official pages often provide manuals and troubleshooting guides to assist users.

- Books and E-books: Look for literature that covers maintenance strategies and repair techniques in detail.

- Workshops and Webinars: Participate in live sessions to learn from experts and ask questions directly.

Utilizing these resources can provide the ultimate advantage in mastering the care and upkeep of your equipment.