Understanding the detailed layout of essential elements in complex kitchen equipment is crucial for efficient operation and maintenance. Knowing the specific components and how they interconnect allows for a better grasp of functionality and troubleshooting.

Each mechanical unit relies on a well-structured assembly of individual pieces. Recognizing how these components work together ensures smoother performance and faster repairs in case of issues. Identifying the role of every element is a vital step for anyone looking to enhance their expertise in this area.

In this section, we will break down the structure of the equipment into its core mechanical units, highlighting their relationships and contributions to overall functionality. This knowledge helps to streamline the maintenance process and ensures long-term durability.

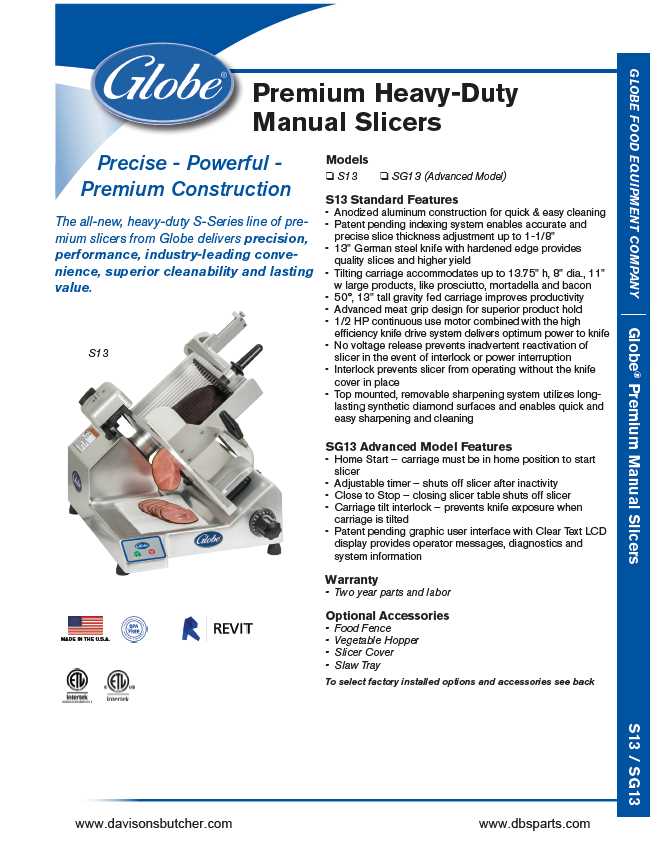

Understanding the Components of a Globe Slicer

Efficient food preparation tools are built with precision and a variety of elements working together. Each element is designed to ensure smooth functionality, safety, and high-quality results. To maintain peak performance, it’s crucial to familiarize yourself with the main components and their roles within the machine.

- Blade Assembly: The primary cutting mechanism, responsible for the precision and thickness of slices.

- Adjustable Thickness Knob: Allows for control over the thickness of each slice, providing flexibility for different food types.

- Food Carriage: Holds the item securely during the cutting process, ensuring safety and consistent results.

- Safety Guard: A crucial feature to protect the user from the sharp edge during operation

How a Food Cutter Operates Efficiently

To ensure smooth operation, food cutting machines rely on precision engineering that optimizes the slicing process. With proper maintenance and settings, these devices are capable of producing consistent results, enhancing productivity in any kitchen environment.

Key Features for Effective Performance

- Precision control for adjustable thickness

- Powerful motor ensuring consistent cutting speed

- Safety mechanisms to protect the operator during use

Steps to Maximize Cutting Efficiency

- Adjust the blade settings based on the desired thickness of the slices.

- Ensure the machine is clean and free of debris before starting.

- Position the food item securely to minimize movement during slicing.

- Engage the motor and guide the item carefully to maintain even cuts.

Identifying Key Parts in a Slicer Diagram

Understanding the essential components in cutting equipment is critical for proper usage and maintenance. Each element plays a specific role in the overall function, ensuring efficiency and precision during operation.

Blade Mechanism: The circular blade is central to the machine’s cutting ability. It needs regular sharpening and maintenance to maintain smooth, accurate cuts.

Adjustment Knob: This control allows for changing the thickness of slices. Precise adjustment is key for achieving the desired cut consistency.

Safety Guard: An important feature designed to protect the user from accidental contact with the blade. Regular inspection ensures it remains secure and functional.

Feeding System: The tray or carriage guides food toward the blade, ensuring an even slice. It operates with a sliding or automatic movement, depending on the model.

Maintenance Tips for Cutting Blades

Proper care of your machine’s cutting components ensures their longevity and sharpness. Regular upkeep reduces wear, improves performance, and guarantees safety during operation. Routine tasks like cleaning and inspecting the edges help prevent dullness and maintain efficient cutting capabilities.

Regular Cleaning and Inspection

It is important to clean the blades thoroughly after each use. Residue buildup can lead to rusting and reduced cutting precision. Inspect the edges regularly to identify any nicks or damage that may need attention.

Sharpening and Alignment

Keeping the cutting surface sharp is crucial for maintaining smooth operation. Use appropriate tools to sharpen the blade at regular intervals. Also, ensure that the alignment of the cutting edge is precise to prevent uneven slices and excessive wear.

Exploring the Motor System of a Slicer

The motor mechanism is a vital component of any food preparation equipment, ensuring seamless operation and efficiency. Understanding its design and functionality is essential for maintaining optimal performance and avoiding potential issues.

The motor system typically comprises several key elements that work together to drive the machine’s cutting mechanism. These components include an electric motor, a belt or gear system for transmission, and various connectors that facilitate smooth movement and control. Below is an overview of the primary elements:

Component Function Electric Motor Provides the main power source, converting electrical energy into mechanical motion. Belt or Gear System Transfers the motor’s energy to the cutting mechanism, ensuring smooth operation. Connectors Link various parts of the motor system, allowing coordinated movement and control. Cleaning and Replacing Slicer Components

Proper maintenance of any cutting equipment involves regular cleaning and occasional replacement of various components to ensure efficiency and safety. Following a systematic approach helps extend the lifespan of the machine and guarantees that it operates at peak performance.

Here’s how to clean and replace key elements of your device:

- Unplug the equipment: Always disconnect the machine from the power source before performing any maintenance tasks to avoid accidents.

- Remove detachable parts: Disassemble removable sections carefully. Pay attention to smaller elements that may need extra care when handling or cleaning.

- Clean thoroughly: Wash all removable sections using warm soapy water. Use a non-abrasive cloth to prevent scratching surfaces.

- Inspect for wear: While cleaning, check each component for signs of wear or damage. Replace any worn or defective elements promptly.

- Reassemble properly: Once cleaning and inspections are complete, reassemble all parts securely. Make sure every section is in its correct place to avoid operational issues.

Regular maintenance not only keeps

Safety Features in Modern Food Cutting Equipment

When it comes to handling food preparation machinery, safety is a key priority. Modern designs prioritize user protection through innovative features that help minimize risks during operation. These safety mechanisms are implemented to ensure that both efficiency and security go hand in hand.

Protective Shields and Guards

One of the most important safety elements in these machines is the use of protective barriers. These shields are designed to cover sharp edges and prevent accidental contact during use. They also help reduce the chance of injury when the equipment is being cleaned or maintained.

- Non-removable guards to prevent unintended exposure to blades

- Clear barriers for visibility while maintaining protection

- Automatic shutdown mechanisms when guards are improperly positioned

Non-Slip and Stability Features

Ensuring the equipment stays stable during operation is another key safety measure. These devices often come with non-slip feet or stabilizing mechanisms to prevent accidental movement while cutting, thus avoiding potential hazards.

- Rubberized feet to enhance grip on various surfaces

Common Issues with Slicer Parts

Mechanical food cutting devices are essential in many kitchens, but over time, certain components may begin to wear down or malfunction. Regular maintenance can help prevent these problems, but it’s important to be aware of the most frequent issues that arise.

Wear and Tear of Blades

Blades are often subjected to extensive use, and over time, they may dull or become damaged. This can result in uneven cuts or require more force during operation. Sharpening the blade or replacing it when necessary is essential to maintain performance.

Problems with Motor Functionality

The motor is a crucial component, and when it experiences issues, the device might struggle to operate at full capacity. Common signs of motor problems include unusual noises or inconsistent speed. Regular checks and timely servicing can help keep the motor running smoothly.

Guide to Lubricating Moving Parts

Ensuring the smooth operation of mechanical devices is essential for their longevity and performance. Proper lubrication of moving components plays a critical role in reducing friction, preventing wear, and maintaining efficiency. This section provides insights into effective lubrication practices to enhance the functionality of your equipment.

Choosing the Right Lubricant

Selecting an appropriate lubricant is vital. Consider factors such as viscosity, temperature range, and compatibility with materials. Greases are ideal for applications requiring long-lasting protection, while oils may be preferable for high-speed components. Always refer to the manufacturer’s recommendations to ensure optimal results.

Application Techniques

Applying lubricant correctly can significantly impact performance. Use a clean cloth to remove old lubricant before application. Apply the new lubricant in the recommended areas, ensuring it penetrates moving parts adequately. Regular checks and maintenance schedules will help in identifying areas needing attention, prolonging the lifespan of your machinery.