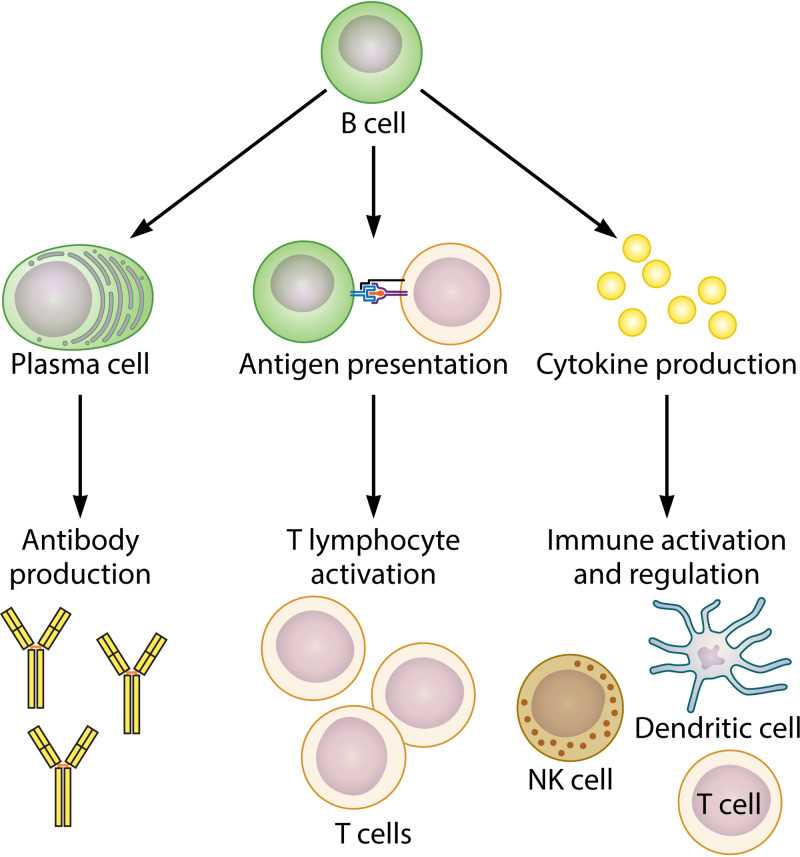

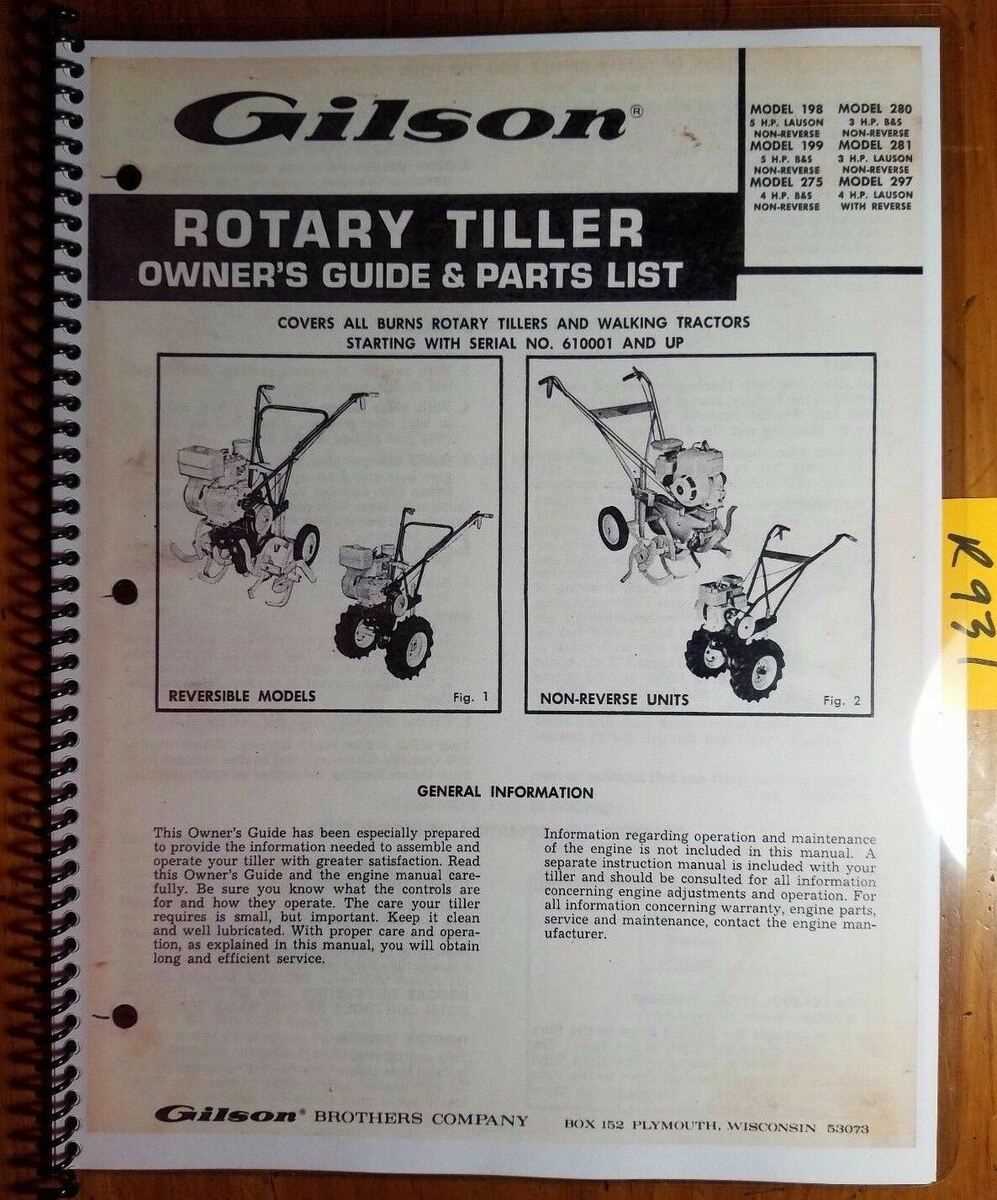

When it comes to maintaining and repairing garden machinery, having a clear understanding of the various components is essential. This section aims to provide insight into the intricate layout of parts that make up these essential tools for cultivating soil.

Visual representations can greatly enhance comprehension, allowing users to identify and locate each element with ease. By examining detailed illustrations, you can quickly grasp how different sections interconnect, ultimately facilitating more efficient repairs and upgrades.

Whether you are a seasoned gardener or a novice, familiarizing yourself with the assembly of these implements will empower you to tackle maintenance tasks confidently. A thorough exploration of these components can lead to a deeper appreciation for the machinery that aids in our gardening endeavors.

Understanding Gilson 1580 Tiller Components

Grasping the essential elements of agricultural machinery is crucial for effective maintenance and operation. Familiarity with various components enhances performance and longevity, allowing users to tackle tasks with confidence. This section delves into the primary constituents of a specific cultivation device, providing insights into their functions and interconnections.

Each element plays a pivotal role in the overall functionality, contributing to the seamless operation of the machine. Understanding these parts not only aids in troubleshooting but also empowers operators to perform necessary repairs and upgrades efficiently.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, converting fuel into mechanical energy. |

| Transmission | Facilitates the transfer of power from the engine to the working components, ensuring appropriate speed and torque. |

| Blade Assembly | Responsible for tilling the soil, featuring sharp edges designed for efficient breaking and aeration. |

| Handlebars | Provide control and maneuverability, allowing the operator to guide the equipment with ease. |

| Wheels | Support the entire structure, aiding in mobility and stability during operation. |

By recognizing these essential components, users can better appreciate how each part contributes to the machine’s overall functionality, ultimately leading to more effective agricultural practices.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair. These illustrations serve as essential guides, enabling users to identify and locate specific elements quickly. Accurate visuals facilitate streamlined processes, reducing the likelihood of errors during assembly or replacement.

Enhanced Understanding

Clear depictions foster a deeper comprehension of machinery. Users can easily grasp the interrelations between various elements, ensuring that they approach repairs with confidence and knowledge. This understanding ultimately leads to improved performance and longevity of the equipment.

Efficient Repairs

When issues arise, having reliable visuals at hand speeds up the troubleshooting process. Users can quickly pinpoint the necessary components and procure the correct replacements, minimizing downtime. This efficiency not only saves time but also resources, contributing to overall productivity.

| Benefits | Description |

|---|---|

| Quick Identification | Facilitates the rapid location of components needed for repairs. |

| Reduced Errors | Minimizes mistakes during assembly and replacement processes. |

| Informed Decisions | Empowers users to make knowledgeable choices regarding maintenance. |

Common Issues with Tiller Parts

Maintaining agricultural equipment often reveals various challenges that can impact performance and efficiency. Understanding these common complications is crucial for effective troubleshooting and ensuring longevity.

Wear and Tear: Over time, components may experience significant degradation due to regular usage. This can lead to diminished effectiveness and the need for timely replacements.

Improper Alignment: Misalignment of essential elements can cause uneven operation, resulting in inadequate soil cultivation. Regular checks can help identify and rectify such issues early.

Clogging: Debris accumulation can obstruct functionality, particularly in mechanisms designed for soil disruption. Regular cleaning and maintenance can prevent these disruptions.

Fluid Leaks: Hydraulic systems are susceptible to leaks, which can severely impact operational capabilities. Monitoring fluid levels and inspecting seals can help mitigate this problem.

Wear of Bearings: Bearings are critical for smooth movement. If they become worn, it can lead to increased friction and potential breakdowns, necessitating prompt attention.

Addressing these issues proactively ensures optimal performance and extends the lifespan of the equipment, making regular maintenance a vital practice.

How to Locate Replacement Parts

Finding suitable components for your outdoor machinery can be a straightforward process when you know where to look. Whether you need to replace a worn-out piece or upgrade for better performance, having a clear strategy will save you time and effort.

Start by consulting the manufacturer’s manual, which often contains essential information on compatible components and specifications. If the manual is unavailable, visiting the official website can provide valuable resources, including part numbers and descriptions. Additionally, reputable online retailers specialize in outdoor equipment and may offer searchable catalogs for easy navigation.

For a more hands-on approach, consider visiting local repair shops or authorized dealers. They often have access to the latest inventory and can assist in identifying the exact components you require. Don’t hesitate to ask questions–knowledgeable staff can offer insights and recommendations based on their experience.

Another effective method is to connect with online forums or community groups dedicated to outdoor equipment. Members often share their experiences and can suggest reliable sources for obtaining the necessary items. This collaborative approach not only aids in your search but also fosters a sense of community among enthusiasts.

In summary, leveraging multiple resources–manuals, official websites, local dealers, and online communities–will enhance your ability to locate the right components efficiently. Take your time to research and ensure you select high-quality items to maintain the performance of your equipment.

Tools Needed for Tiller Maintenance

Proper upkeep of your gardening equipment is essential for optimal performance and longevity. A variety of implements and devices are required to ensure that your machinery remains in top shape, facilitating efficient operation during use.

Essential Implements

Several basic tools are crucial for routine maintenance tasks. These include items for cleaning, inspection, and minor repairs, ensuring all components function seamlessly.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening or loosening bolts and nuts. |

| Screwdriver | Essential for adjusting screws and fittings. |

| Grease Gun | To apply lubrication to moving parts. |

| Cleaning Brush | For removing dirt and debris from surfaces. |

| Oil Can | To maintain proper lubrication of mechanisms. |

Advanced Maintenance Tools

In addition to basic implements, more specialized tools may be necessary for deeper maintenance tasks, allowing you to delve into repairs and replacements that enhance performance.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your garden machinery to optimal condition. Following a methodical process ensures efficiency and precision, allowing you to tackle repairs with confidence.

Preparation

- Gather all necessary tools and replacement components.

- Ensure the working area is clean and well-lit.

- Refer to the manual for specific instructions related to your model.

Repair Process

- Disconnect the power source to avoid accidents.

- Remove any coverings or casings carefully.

- Inspect each component for wear and damage.

- Replace any faulty parts with compatible replacements.

- Reassemble the unit, ensuring all connections are secure.

- Test the equipment to confirm proper functionality.

By adhering to this structured guide, you can enhance the longevity and performance of your machinery.

Preventive Measures for Tiller Longevity

Ensuring the durability of agricultural equipment involves a combination of regular maintenance, careful operation, and appropriate storage practices. By implementing strategic measures, users can significantly extend the lifespan and efficiency of their machinery.

Regular Maintenance Checks

Routine inspections play a crucial role in identifying potential issues before they escalate. Key components should be checked frequently to maintain optimal performance.

| Component | Maintenance Action |

|---|---|

| Engine | Change oil and filter regularly. |

| Blades | Sharpen or replace as needed. |

| Fuel System | Inspect for leaks and clean filters. |

| Tires | Check pressure and tread wear. |

Proper Storage Techniques

Storing equipment in a dry, protected area prevents rust and damage from environmental factors. Covering machinery and ensuring it’s clean can further enhance longevity.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their maintenance, offering insights to help users navigate their options effectively. Understanding these aspects can enhance the performance and longevity of your equipment.

What should I consider when replacing components?

When looking to replace elements, consider compatibility, quality, and the specific needs of your machinery. It’s vital to ensure that new items match the specifications required for optimal functionality.

How can I identify the right components?

Identification can be achieved by consulting manuals, checking model numbers, or seeking expert advice. Resources such as schematics or forums can also provide valuable guidance in the selection process.

Where to Find Expert Advice

Seeking knowledgeable guidance is crucial for effective maintenance and repair of outdoor machinery. Identifying the right resources can enhance your understanding and ensure optimal performance.

- Online Forums: Engage with communities of enthusiasts and professionals who share valuable insights and troubleshooting tips.

- Manufacturer Websites: Visit official sites for detailed manuals and recommendations tailored to specific models.

- Local Repair Shops: Consult with experienced technicians who can offer hands-on advice and solutions based on their expertise.

- Instructional Videos: Explore platforms like YouTube for visual guides that break down complex tasks into manageable steps.

- Trade Shows: Attend events to connect with experts and learn about the latest technologies and techniques in the industry.