When examining the internal components of a vehicle’s system responsible for holding liquid energy sources, it’s crucial to understand how various elements work together. This section provides insight into the essential components that form the core of this system, allowing the vehicle to operate efficiently and safely.

The complexity of this storage unit lies in the interconnected devices, each playing a pivotal role in maintaining optimal performance. From the containment vessel to various control mechanisms, every piece serves a specific function, ensuring the system operates seamlessly under different conditions.

In the following sections, we will explore how these individual components contribute to the overall functionality of the system. You’ll discover how the internal layout is designed to balance durability, safety, and efficiency, creating a reliable solution for energy storage in automobiles.

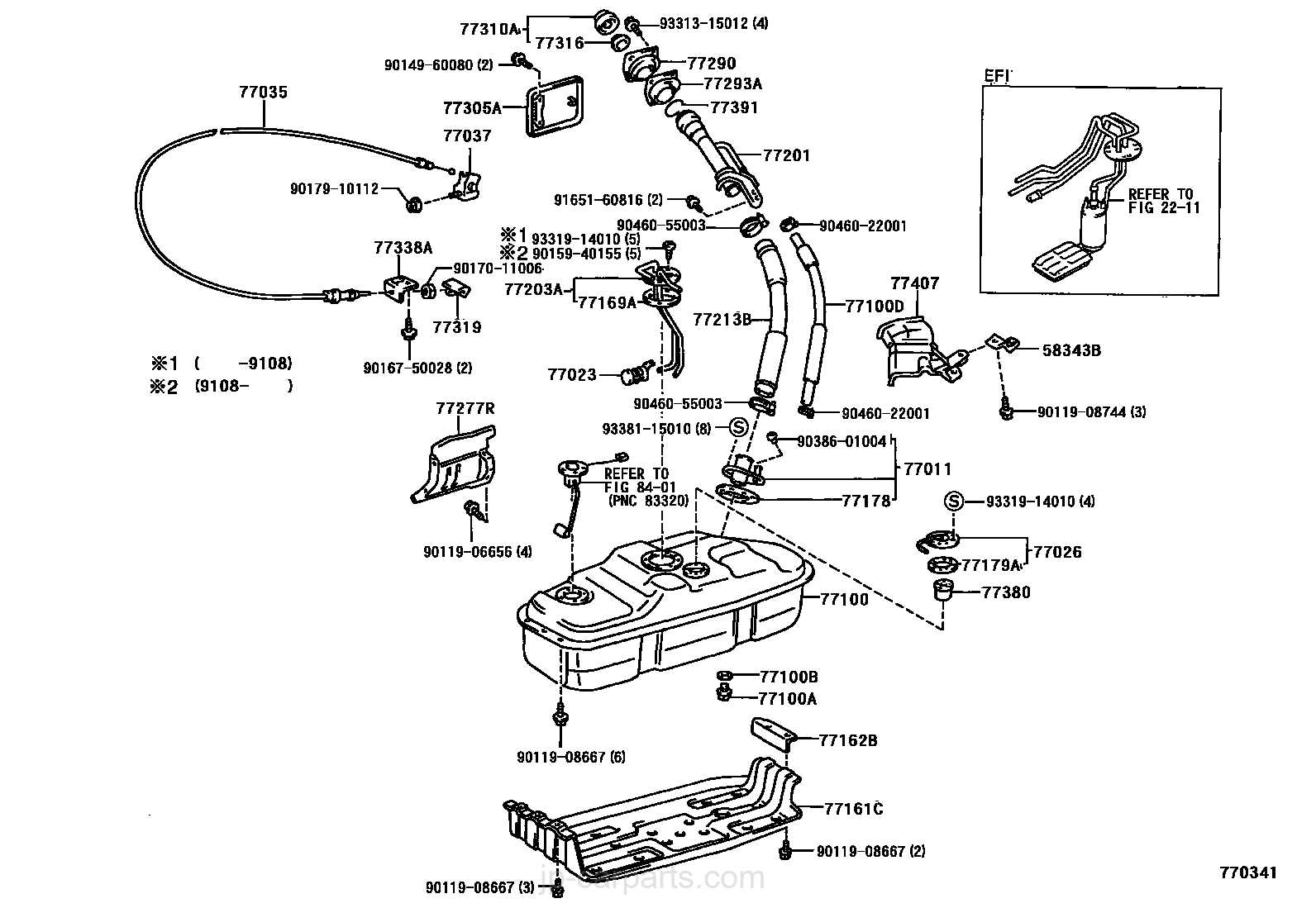

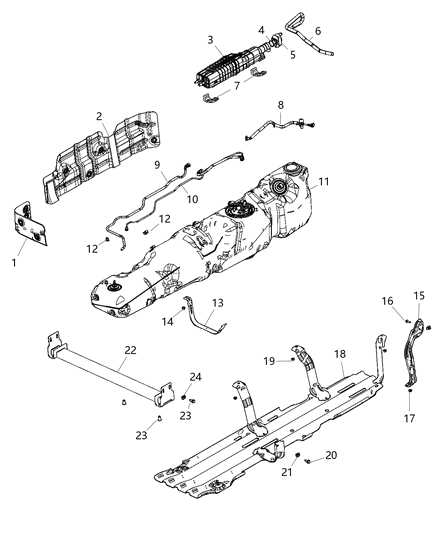

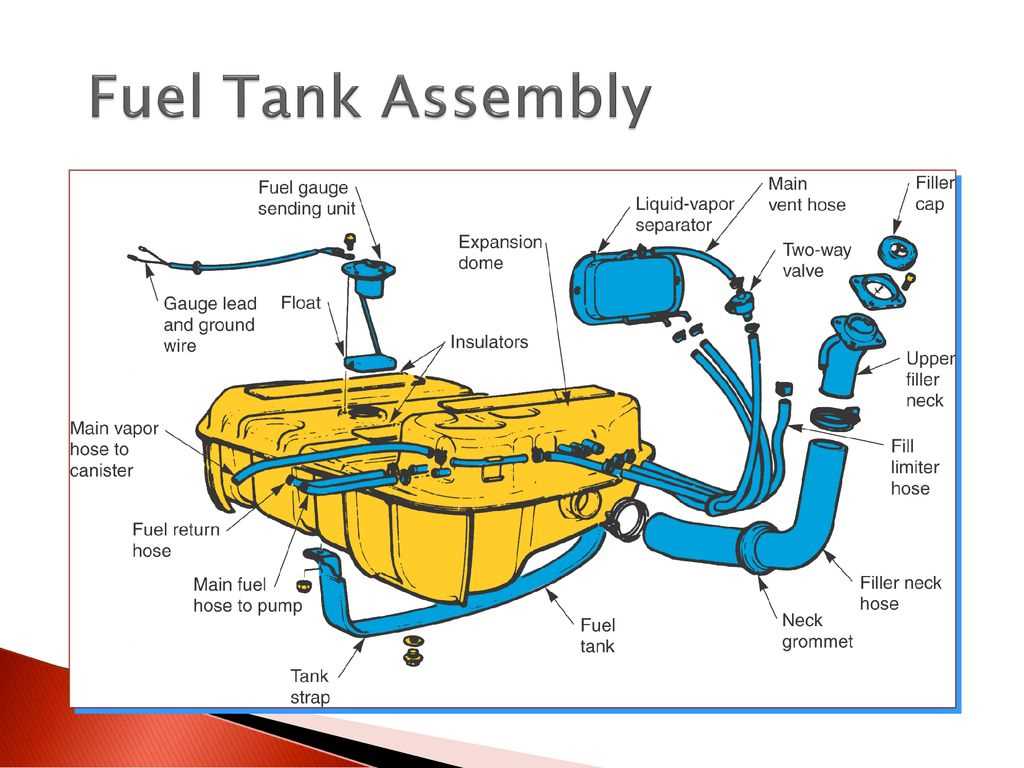

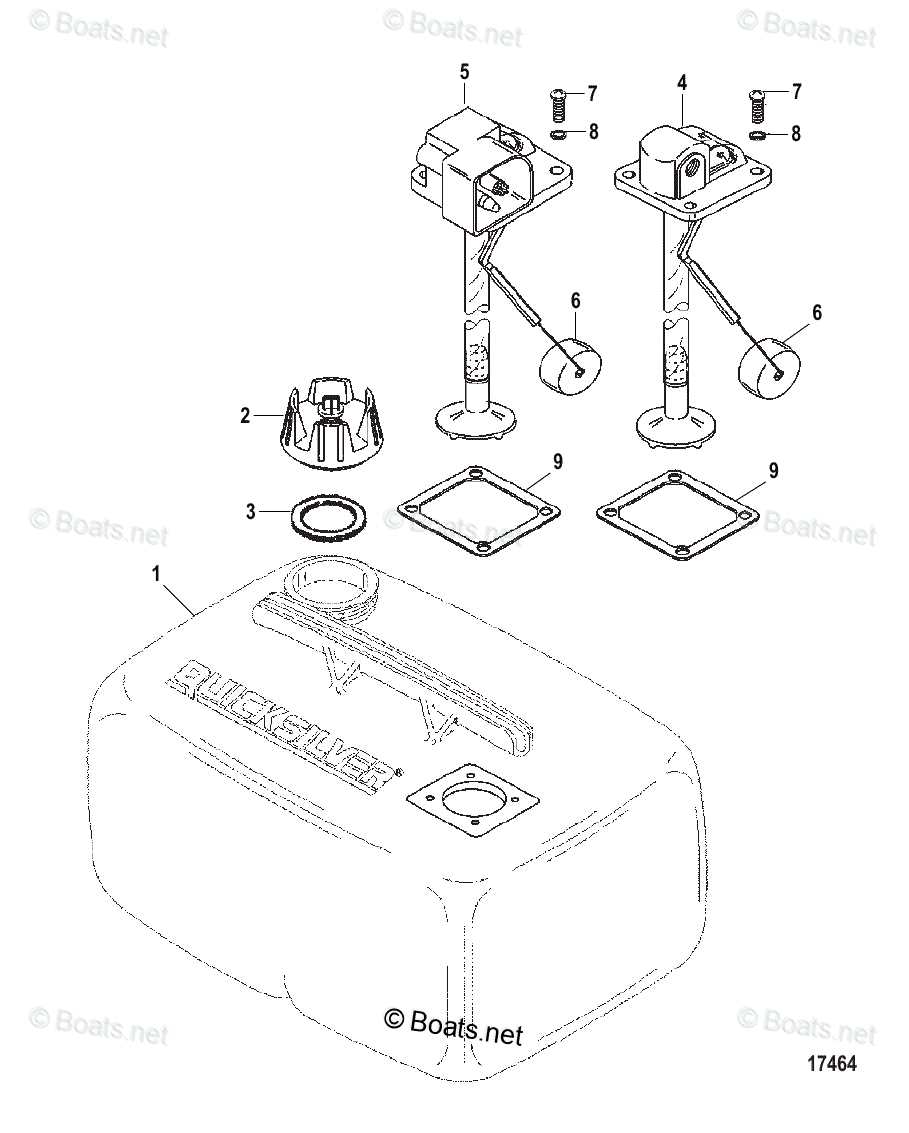

Fuel Tank Components Overview

The storage system in a vehicle plays a crucial role in ensuring proper operation by holding and delivering essential liquids. Various interconnected mechanisms work together to control, measure, and transport these fluids efficiently. Understanding the different elements involved helps maintain the system and avoid potential issues.

Main Elements and Their Functions

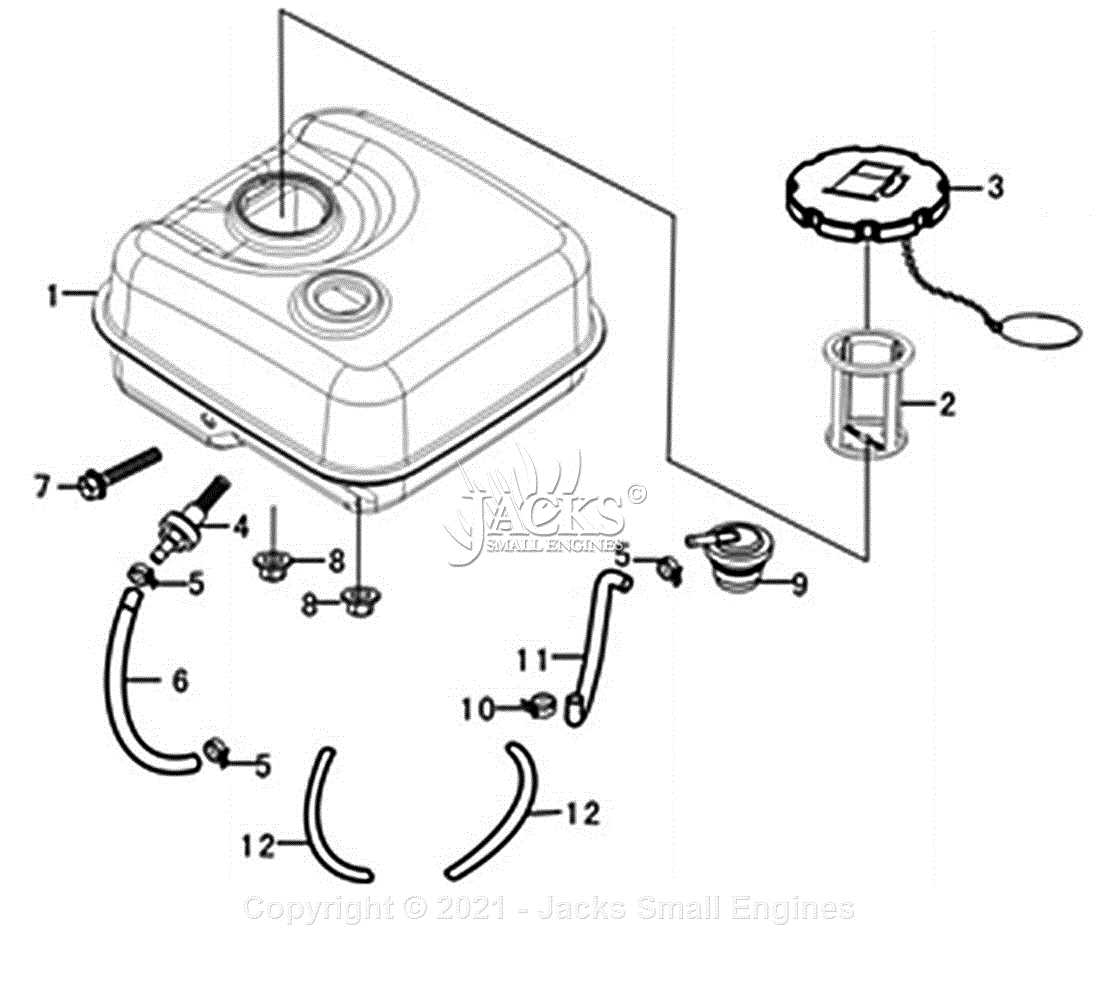

- Reservoir Body: The central container designed to store the necessary liquids safely and securely.

- Piping and Connections: Tubes that transfer the fluid from the container to the engine and other relevant areas.

- Ventilation Mechanism: A system responsible for regulating pressure and preventing vacuum build-up within the container.

- Measurement Units: Devices like gauges that monitor the level of liquid inside, providing real-time information.

Safety and Control Features

- Protective Layers:

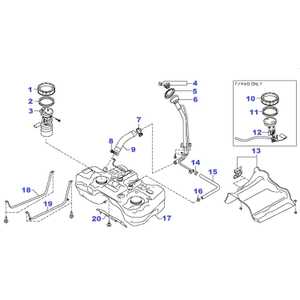

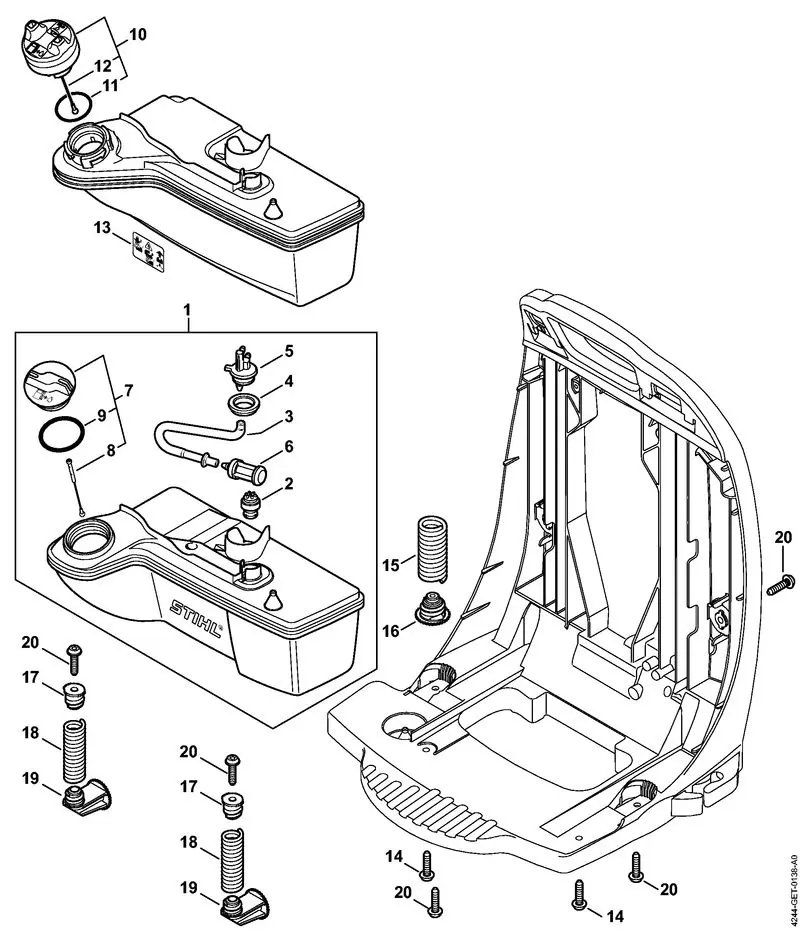

Main Structure of a Fuel Tank

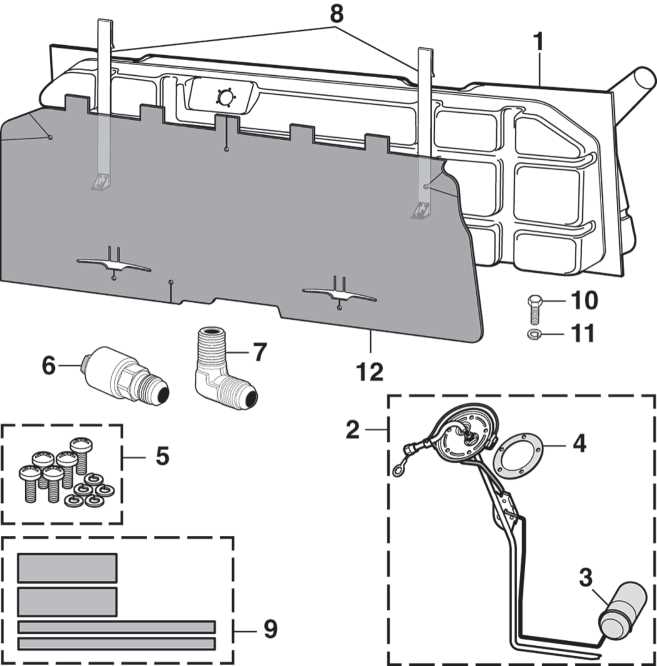

The essential assembly responsible for storing and delivering energy liquids to the engine is designed with several interconnected components. These elements work together to ensure the safe containment and smooth transportation of the necessary fluids, while maintaining proper pressure and integrity of the system.

Outer Shell and Internal Sections

The external casing forms the core frame of the system, crafted from durable materials to withstand various environmental conditions. Inside, the internal sections help direct the flow and manage the levels of liquid, preventing excessive movement or pressure buildup.

Support Components and Safety Features

Additional support elements, such as brackets and mounts, ensure that the container remains securely in place, while various safety mechanisms, including vent systems and overflow protection, prevent leaks and manage pressure regulation effectively.

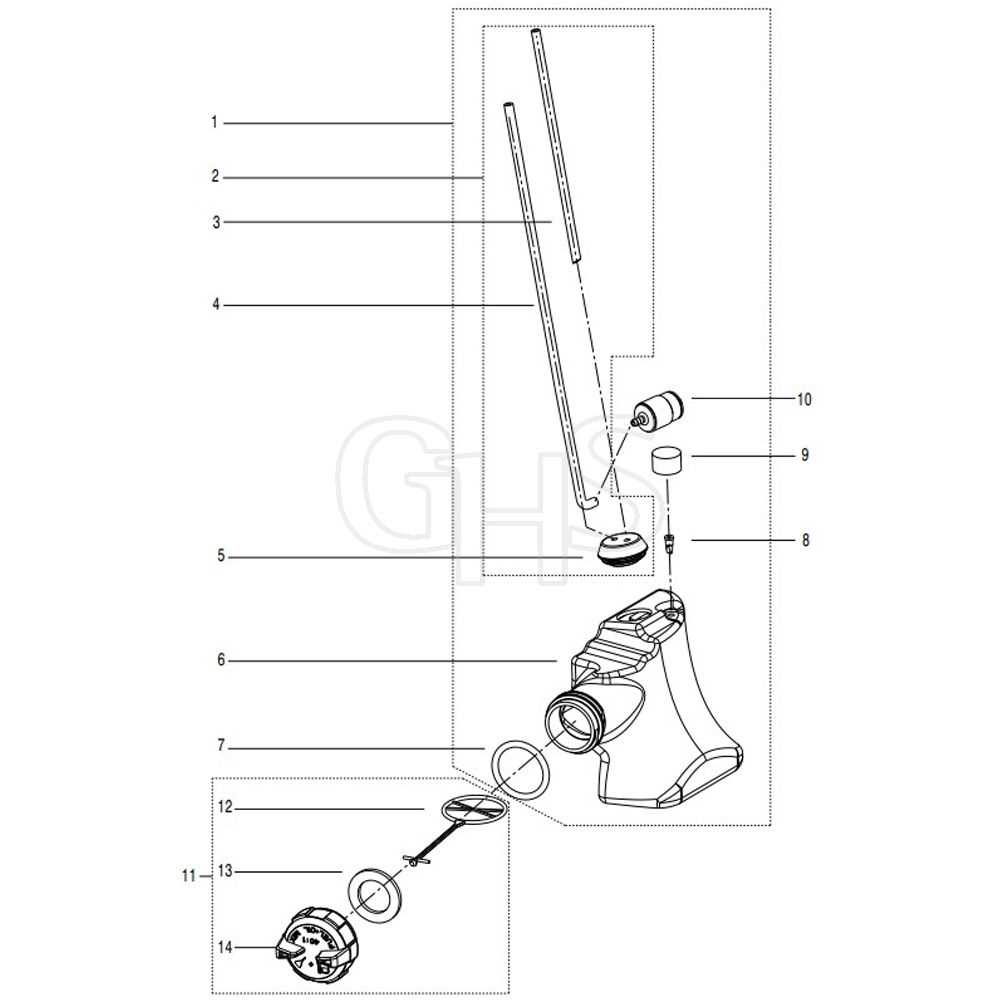

Fuel Pump and Its Functions

The component responsible for transferring liquid from the reservoir to the engine is vital for ensuring smooth operation and optimal performance. This part plays a key role in delivering the necessary substance that powers the vehicle’s internal processes, ensuring continuous motion and efficiency.

Main Purpose of the Pump

The primary function of this mechanism is to move the liquid at the right pressure to meet the demands of the engine. It ensures that the flow is consistent, and the required quantity reaches the system as needed for combustion and energy generation.

Additional Features of the Pump

- Ensures steady circulation without interruptions.

- Regulates the amount needed during various driving conditions.

- Prevents vapor lock, maintaining constant pressure in the lines.

This mechanism is crucial for the vehicle’s efficiency

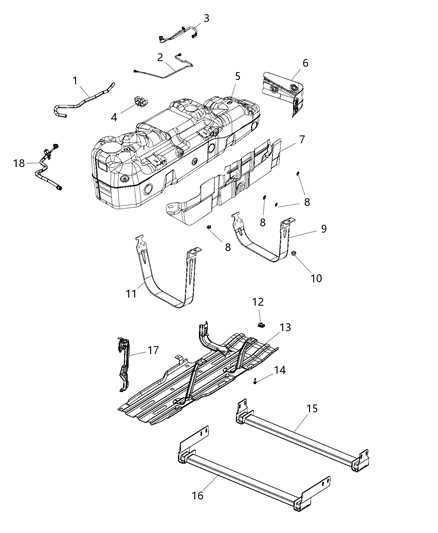

Understanding Fuel Tank Valves

Valves play a crucial role in controlling the flow and maintaining the balance of liquids within a container. These components ensure proper management of pressure and regulate the entry or release of gases and liquids. By controlling these processes, they contribute to the safe and efficient operation of the entire system.

There are different types of valves, each designed for specific tasks. Some manage the flow of vapors, while others handle liquid circulation. Certain valves are pressure-sensitive, automatically adjusting to changes in the environment to prevent overpressure or vacuum formation. Understanding how each type functions is essential for ensuring smooth and safe operations.

Proper maintenance of these components is important to avoid malfunctions that could lead to performance issues or safety hazards. Regular inspections can help detect early signs of wear or damage, preventing more significant problems from arising.

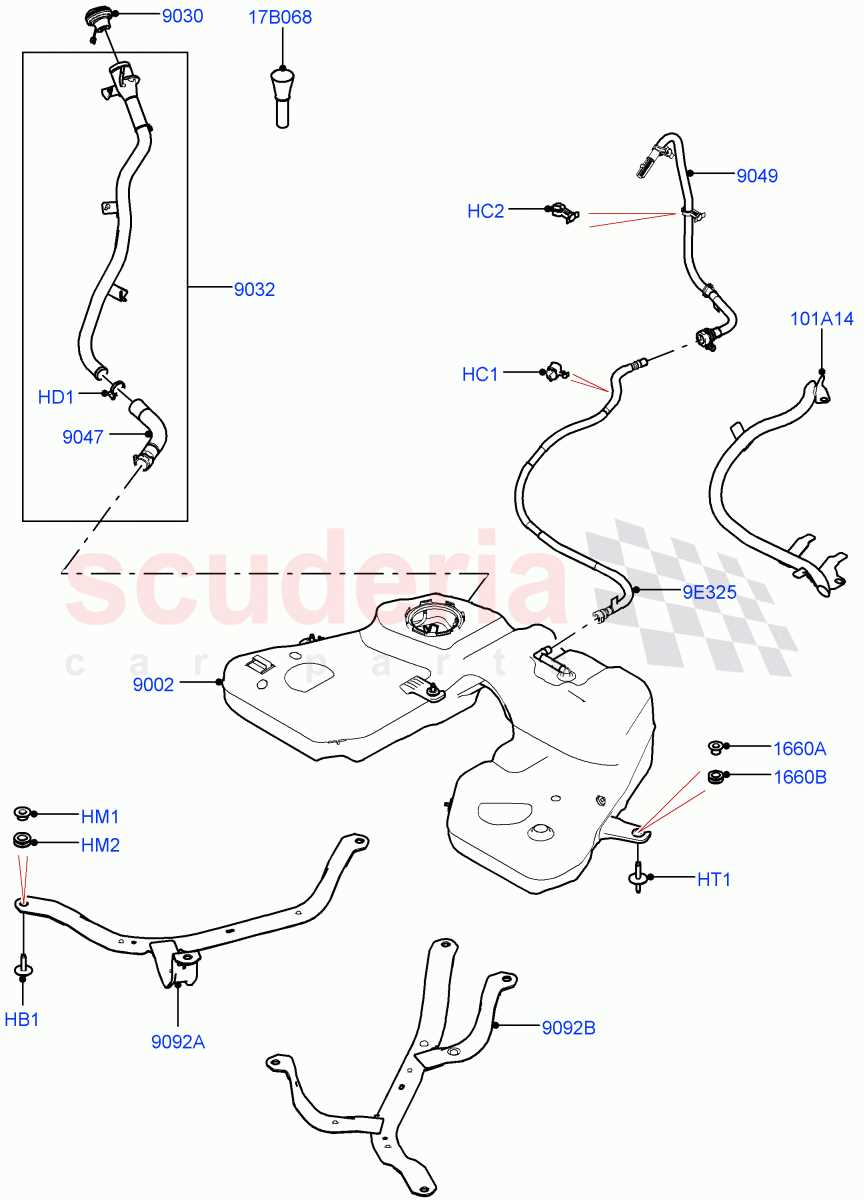

Fuel Lines: Purpose and Importance

The conduits that transport liquid energy play a crucial role in ensuring the smooth operation of any vehicle’s engine system. These pathways are designed to efficiently deliver the necessary substance from one part of the system to another, allowing the motor to perform optimally.

Understanding the significance of these channels is essential for vehicle maintenance. Below are key reasons why their integrity and functionality are vital:

- They maintain the correct flow of liquid energy to the engine, ensuring consistent performance.

- Properly functioning conduits prevent leaks, reducing the risk of fire hazards and environmental harm.

- They help regulate pressure within the system, which is critical for optimal engine efficiency.

- Durable and well-maintained lines extend the lifespan of the engine by preventing damage from improper liquid delivery.

In summary, these pathways are not just simple connectors; they are integral to the safety, efficiency, and longevity of the engine system.

Fuel Filter: Role in the System

In modern combustion engines, the filtration component plays a critical role in ensuring the proper functioning of the entire setup. By preventing unwanted materials from entering key components, it helps maintain efficiency and prolongs the life of the machinery.

Protecting Vital Components

The filtration unit serves as a barrier that captures contaminants like dirt and debris, preventing them from reaching sensitive mechanisms. This protective measure is essential for avoiding costly repairs and maintaining optimal performance.

Ensuring Clean Operation

By filtering out impurities, the system ensures that only clean substances circulate through the engine. This process leads to smoother operations, improved reliability, and a reduced likelihood of unexpected breakdowns, making it a key element in the overall system’s longevity.

Vapor Recovery System Explained

The vapor recovery system is designed to capture emissions that would otherwise escape into the atmosphere. This system ensures that harmful gases are properly managed, enhancing environmental protection and reducing pollution. Its mechanisms prevent the release of vapors during different operational processes, efficiently redirecting them for further use or safe disposal.

Component Function Control Valve Regulates the flow of gases, allowing them to move through the system at appropriate times. Storage Container Collects the vapors and holds them temporarily until they can be processed or neutral Fuel Level Sensors and Indicators

Monitoring the volume of liquid within a storage unit is essential for ensuring optimal performance and preventing malfunctions. Devices that measure and display the quantity of liquid play a critical role in various systems. They provide real-time feedback, allowing users to monitor and control the situation with precision.

Types of Measurement Devices

There are several technologies designed to gauge the volume of liquid. Some operate mechanically, utilizing floats, while others rely on electronic components, such as resistive or capacitive sensors. Each type has its unique advantages, depending on the specific application and environment.

Indicators and Their Importance

Indicators, often located on a control panel or dashboard, interpret data from the measuring devices, converting it into readable information. These displays can be analog or digital, providing accurate and clear information. Having a reliable indicator is vital for ensuring smooth operations and avoiding unexpected issues.

Maintenance Tips for Fuel Tank Parts

Proper care and attention to the essential components of a liquid storage system can significantly enhance its performance and longevity. Regular inspection and upkeep not only prevent unforeseen issues but also ensure optimal functionality, ultimately saving costs on repairs and replacements.

Regular Inspections

Frequent examinations of the system are crucial. Look for any signs of wear, corrosion, or leaks. Early detection of potential problems allows for timely interventions, reducing the risk of more severe damage. Make it a habit to check connections and seals for tightness, as loose fittings can lead to operational inefficiencies.

Cleaning and Protection

Keeping the components clean is vital for maintaining efficiency. Accumulated debris can obstruct functionality and lead to performance issues. Use appropriate cleaning agents to remove any buildup, and consider applying protective coatings to shield against environmental factors. Regular maintenance not only enhances appearance but also extends the lifespan of the system.