Exploring the inner workings of gardening machinery unveils the intricate relationships between various elements that contribute to its efficient operation. Each component plays a crucial role, ensuring that the equipment performs optimally, whether it’s for preparing soil or managing vegetation. Grasping the layout and functionality of these parts enhances not only the understanding of the device but also aids in its maintenance and repair.

Mechanisms within the cultivator are designed to work in harmony, facilitating the desired results with minimal effort. By dissecting the arrangement of these components, users can gain insights into the device’s performance, troubleshooting issues, and ultimately extending its lifespan. The knowledge of how each section interacts offers practical benefits, making gardening tasks more manageable and effective.

In this discussion, we will delve into the various assemblies that constitute this vital gardening tool. Emphasizing clarity, we will illustrate the connections and functions of these elements, ensuring that both novice and experienced users can benefit from this exploration. Understanding the fundamental structure not only enriches one’s knowledge but also empowers users to handle their equipment with confidence.

Understanding Earthquake Tiller Mechanics

Gaining insight into the mechanisms that drive garden cultivators enhances our ability to utilize these machines effectively. These devices rely on a series of interconnected components that work harmoniously to achieve optimal soil preparation. Recognizing how these elements function together can greatly improve performance and maintenance.

Key Components and Their Functions

- Engine: Provides the power necessary for operation, converting fuel into mechanical energy.

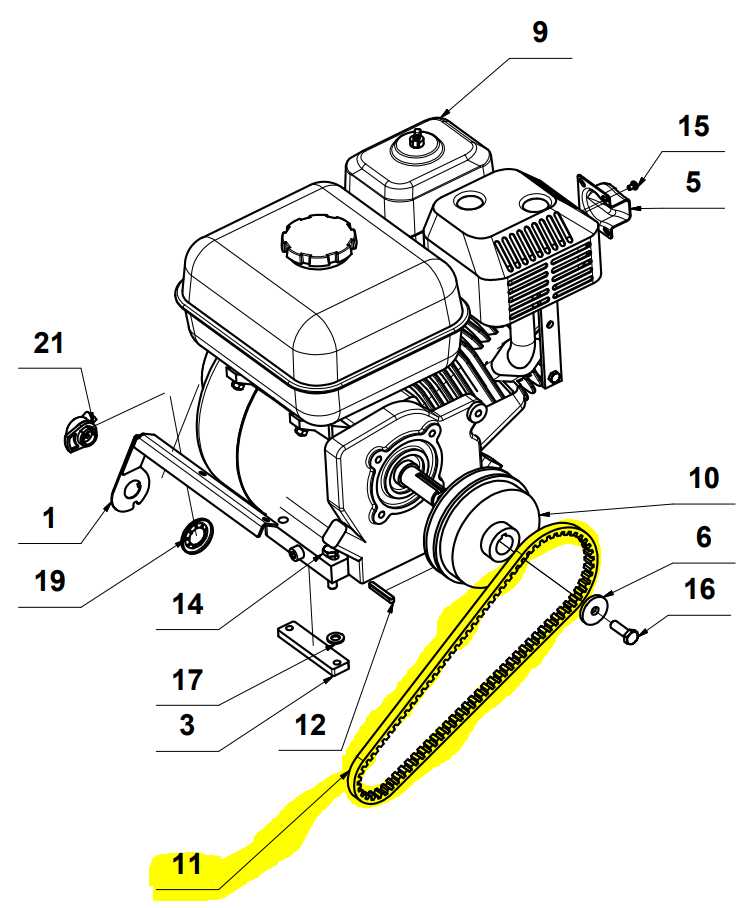

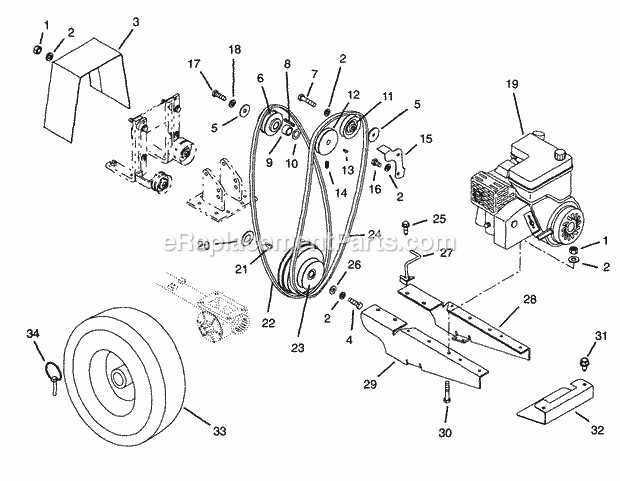

- Transmission: Transfers power from the engine to the working elements, allowing for variable speed adjustments.

- Blades: Designed to break up and aerate the soil, these sharp elements are crucial for effective tilling.

- Chassis: The framework that supports all other components, ensuring stability and durability during operation.

Operational Mechanisms

- When the engine starts, it creates rotational force.

- This force is transmitted through the transmission system to the working blades.

- As the blades rotate, they penetrate the soil, breaking it apart and mixing in organic material.

- The operator can adjust the speed and depth of tilling by manipulating the controls, optimizing the process for different soil conditions.

Understanding these mechanics not only aids in the effective use of the machine but also promotes better maintenance practices, ensuring longevity and reliability in the field.

Essential Components of Tiller Systems

The functionality of cultivation machinery relies on several crucial elements that work in harmony to enhance soil preparation and management. Understanding these components is key to optimizing performance and maintenance.

Key Elements

Each component plays a specific role, contributing to the overall efficiency and effectiveness of the equipment. Here’s a closer look at the primary parts:

| Component | Function |

|---|---|

| Drive Mechanism | Transfers power to the working tools for effective operation. |

| Working Tools | Engages the soil, breaking it up and aerating for better growth. |

| Frame | Provides structural support and stability during use. |

| Controls | Allows the operator to adjust speed and direction for precision. |

Maintenance Considerations

Regular upkeep of these essential components is vital for ensuring longevity and optimal performance. Timely inspections can prevent larger issues and enhance productivity.

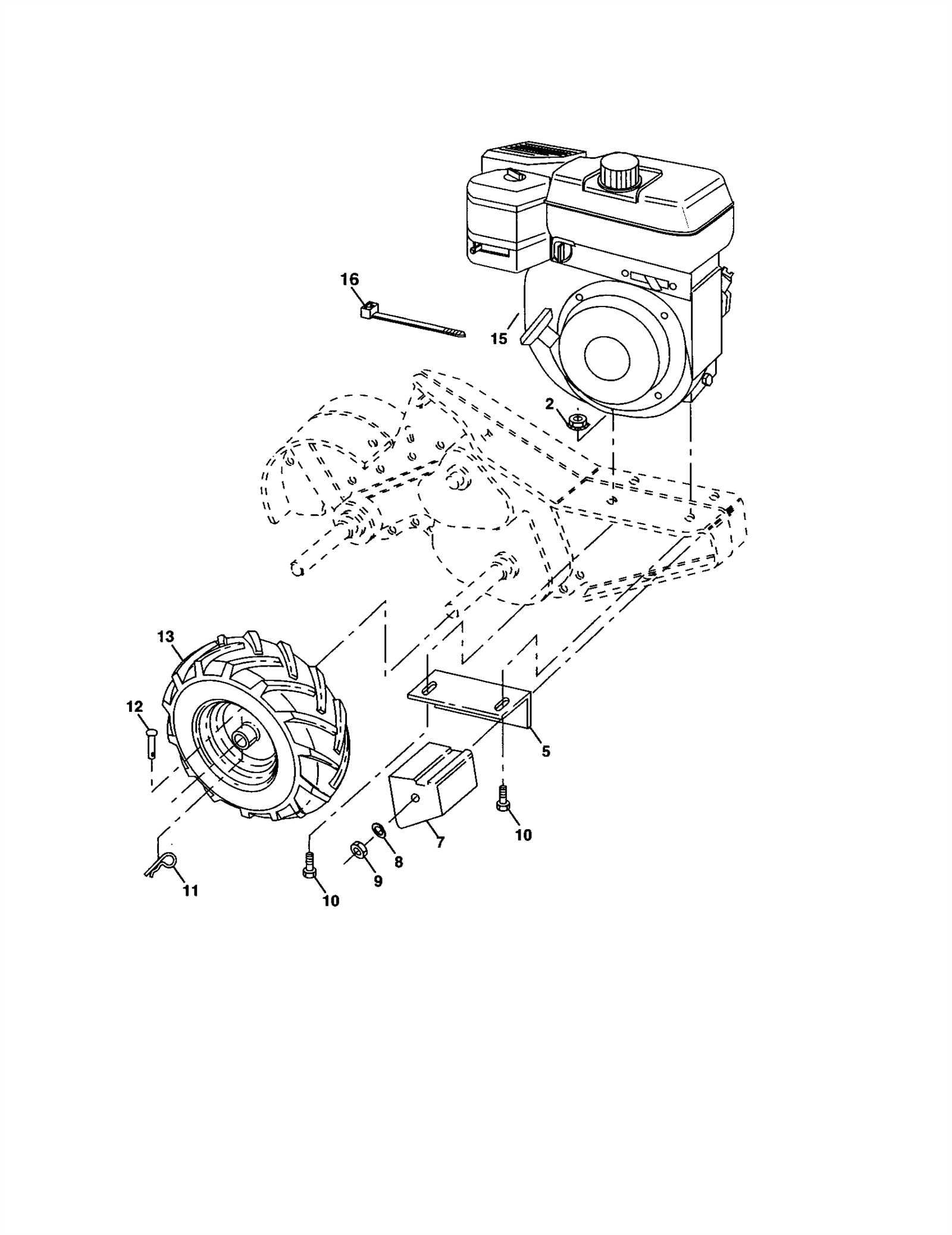

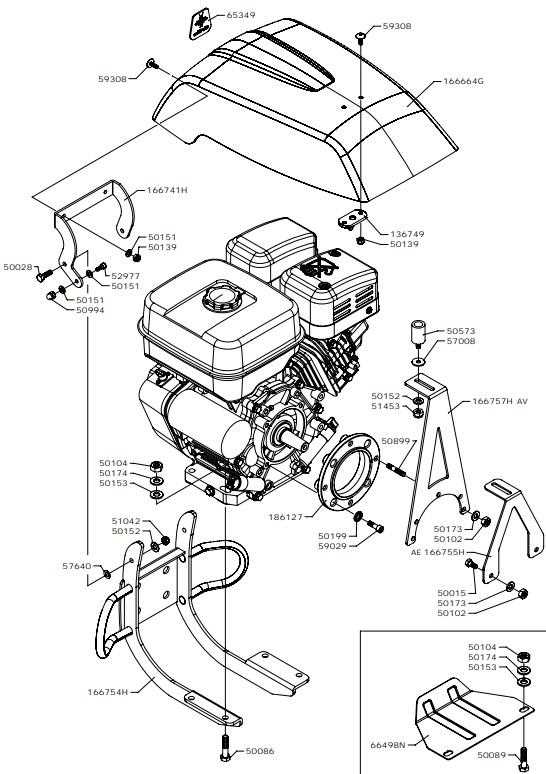

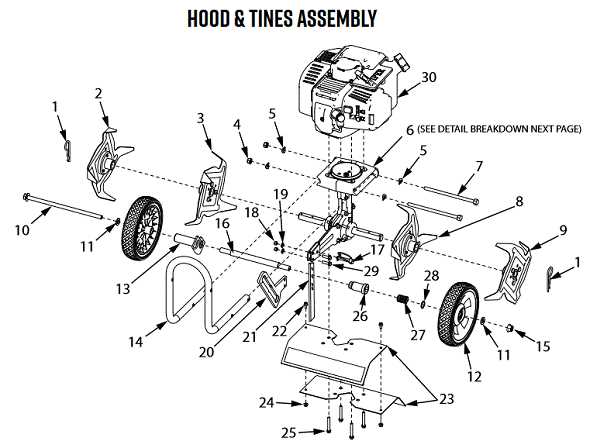

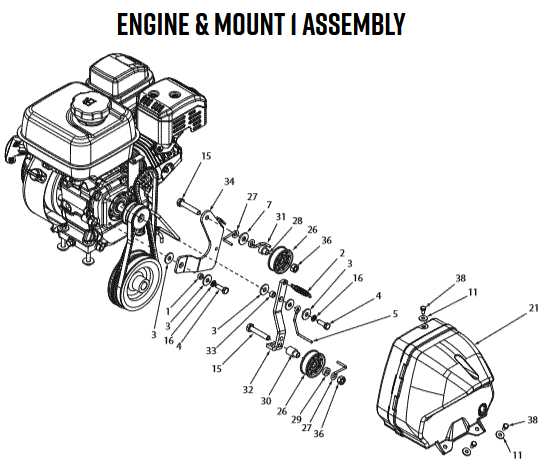

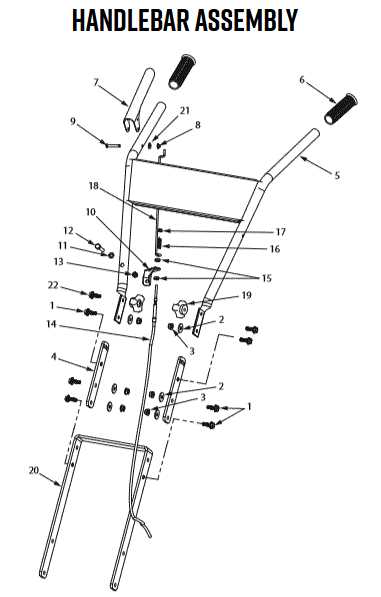

How to Interpret Tiller Diagrams

Understanding technical illustrations is essential for effective maintenance and operation of gardening machinery. These visual aids provide crucial insights into the assembly and functionality of various components, enabling users to troubleshoot issues and perform repairs more efficiently.

First, familiarize yourself with the symbols and labels used in the illustration. Each element typically represents a specific component or function, so knowing what they signify is vital for accurate interpretation.

Next, pay attention to the layout and organization of the information. Components are often arranged in a logical sequence, showing how they connect and interact with one another, which can guide you in the assembly or disassembly process.

Lastly, consult the accompanying documentation for detailed descriptions and instructions related to the illustration. This can enhance your understanding and ensure you are equipped with the ultimate knowledge to manage the equipment effectively.

Common Issues with Tiller Parts

When working with soil cultivation tools, various challenges may arise due to component wear and tear or improper maintenance. Understanding these common problems can help users maintain their equipment effectively and ensure optimal performance.

Frequent Problems

- Wear of Blades: Over time, blades can become dull or damaged, affecting their ability to penetrate the soil.

- Engine Difficulties: Issues such as starting problems or irregular operation can arise, often linked to fuel supply or ignition components.

- Transmission Failures: Difficulty in shifting gears or a complete loss of movement can occur, typically due to worn-out belts or gears.

- Vibration and Noise: Excessive vibrations or unusual sounds may indicate loose or damaged parts, requiring immediate attention.

Maintenance Tips

- Regularly inspect and sharpen cutting edges to ensure efficient operation.

- Check fuel lines and filters for clogs and replace them as needed.

- Lubricate moving parts according to the manufacturer’s guidelines to reduce friction.

- Store the equipment in a dry place to prevent rust and corrosion.

Maintenance Tips for Your Tiller

Proper care and regular upkeep are essential for ensuring the longevity and efficiency of your gardening equipment. By following a few straightforward guidelines, you can keep your machine in excellent working condition, making your gardening tasks more enjoyable and effective.

- Regular Cleaning: After each use, clean the exterior and any attachments to remove soil and debris. This prevents buildup that can affect performance.

- Inspect Components: Routinely check all parts for wear and damage. Look for cracks, rust, or other signs of deterioration.

- Change Oil: Follow the manufacturer’s recommendations for oil changes. Fresh oil reduces friction and enhances performance.

- Sharpen Blades: Keep blades sharp for optimal efficiency. Dull blades can tear plants rather than cutting them cleanly.

- Check Fuel System: Inspect fuel lines and filters for blockages or leaks. Use fresh fuel to avoid starting issues.

By implementing these maintenance practices, you can extend the life of your equipment and ensure it operates at peak performance whenever you need it.

Choosing Quality Replacement Parts

When it comes to maintaining and enhancing the performance of your outdoor machinery, selecting high-grade components is essential. Quality replacements not only ensure longevity but also improve functionality, allowing your equipment to operate at its best. Understanding the importance of sourcing reliable items can save time and money in the long run.

First and foremost, consider the manufacturer’s reputation. Established brands often provide durable alternatives that meet stringent quality standards. Researching customer reviews and ratings can help gauge the reliability of different options available in the market.

Additionally, it is crucial to evaluate the materials used in the alternatives. High-quality substances typically result in better performance and resistance to wear and tear. Checking for certifications or specifications can also offer insights into the reliability of the components.

Lastly, purchasing from reputable suppliers ensures that you receive authentic items. Avoiding counterfeit or subpar alternatives can make a significant difference in the overall efficiency of your machinery. By making informed decisions, you can maintain the effectiveness of your equipment for years to come.

DIY Repairs: Tools You Need

When tackling home repairs, having the right tools at your disposal is essential for a successful outcome. Whether you are fixing equipment or conducting routine maintenance, the following items will enhance your efficiency and effectiveness.

Essential Hand Tools

- Wrenches – Adjustable and fixed for loosening and tightening.

- Screwdrivers – Various types including flathead and Phillips for different fasteners.

- Hammer – A versatile tool for driving nails and fitting parts together.

- Pliers – Useful for gripping, twisting, and cutting wire.

Power Tools

- Drill – Ideal for creating holes and driving screws quickly.

- Saw – Electric or manual for cutting through various materials.

- Multitool – A compact device with various functions, perfect for tight spaces.

Equipping yourself with these fundamental tools will empower you to handle a range of repair tasks effectively. Remember to prioritize safety by using protective gear as needed.

Comparing Different Tiller Models

When selecting a cultivation tool, it’s essential to evaluate various models to identify the one that best suits your gardening needs. Different designs and features cater to diverse soil conditions and user preferences, making it crucial to understand the distinctions between them.

| Model | Engine Power | Working Width | Weight | Price Range |

|---|---|---|---|---|

| Model A | 5 HP | 18 inches | 75 lbs | $300 – $400 |

| Model B | 6 HP | 20 inches | 85 lbs | $400 – $500 |

| Model C | 4 HP | 16 inches | 70 lbs | $250 – $350 |

| Model D | 7 HP | 22 inches | 90 lbs | $500 – $600 |

Understanding these specifications will help you make an informed decision based on your specific gardening tasks, whether you need a lightweight option for small plots or a robust machine for larger areas.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is paramount to prevent accidents and injuries. Following specific guidelines can help create a secure work environment and protect both the technician and the equipment involved.

Essential Safety Measures

Before starting any repair, it is crucial to gather all necessary tools and equipment, checking their condition beforehand. Wear appropriate personal protective gear, including gloves and goggles, to safeguard against potential hazards.

Work Environment Setup

Maintain a clean and organized workspace to minimize risks. Ensure that the area is well-lit and free from clutter, and keep emergency equipment accessible.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Use gloves, goggles, and masks as needed. |

| Tool Inspection | Check tools for damage before use. |

| Clean Workspace | Remove obstacles and ensure proper lighting. |

| Emergency Preparedness | Have first aid kits and fire extinguishers nearby. |