The intricate workings of a vehicle’s transmission system play a vital role in its overall performance. This collection of mechanisms operates seamlessly to ensure that power generated by the engine is effectively transferred to the wheels. Gaining insight into these components is essential for anyone interested in automotive engineering or maintenance.

Each element within this system serves a specific function, contributing to the smooth operation of the vehicle. From the engagement mechanisms to the various levers and springs, understanding how these elements interact can illuminate the complexities of automotive design. Knowledge of these intricacies not only aids in troubleshooting but also enhances the appreciation for engineering ingenuity.

Exploring the layout and functionality of these essential components allows for a deeper understanding of their roles in the vehicle’s dynamics. Such familiarity can empower drivers and mechanics alike to make informed decisions regarding repairs and modifications, ultimately leading to a more efficient and enjoyable driving experience.

Understanding Clutch Components

Grasping the intricacies of a vehicle’s engagement system is essential for both maintenance and performance. This system is crucial for the effective transfer of power from the engine to the transmission, allowing for smooth operation and control. Each element plays a significant role in ensuring functionality and reliability.

Key Elements of the Engagement System

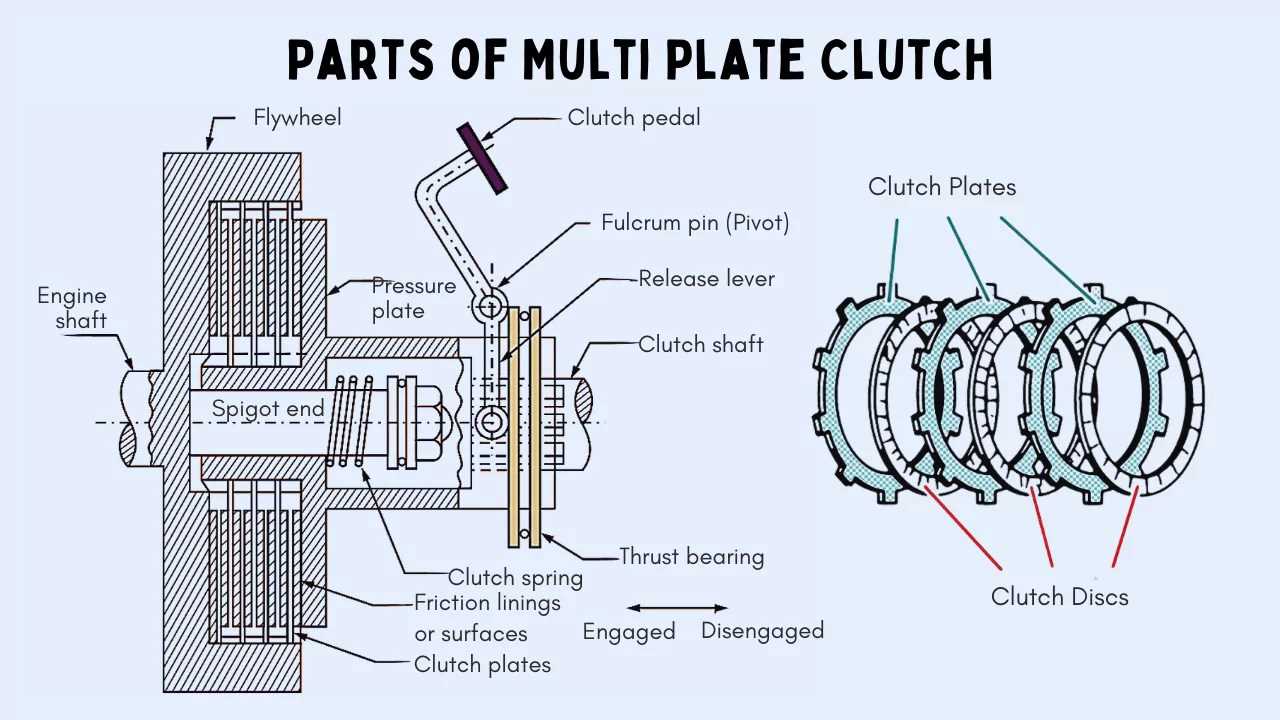

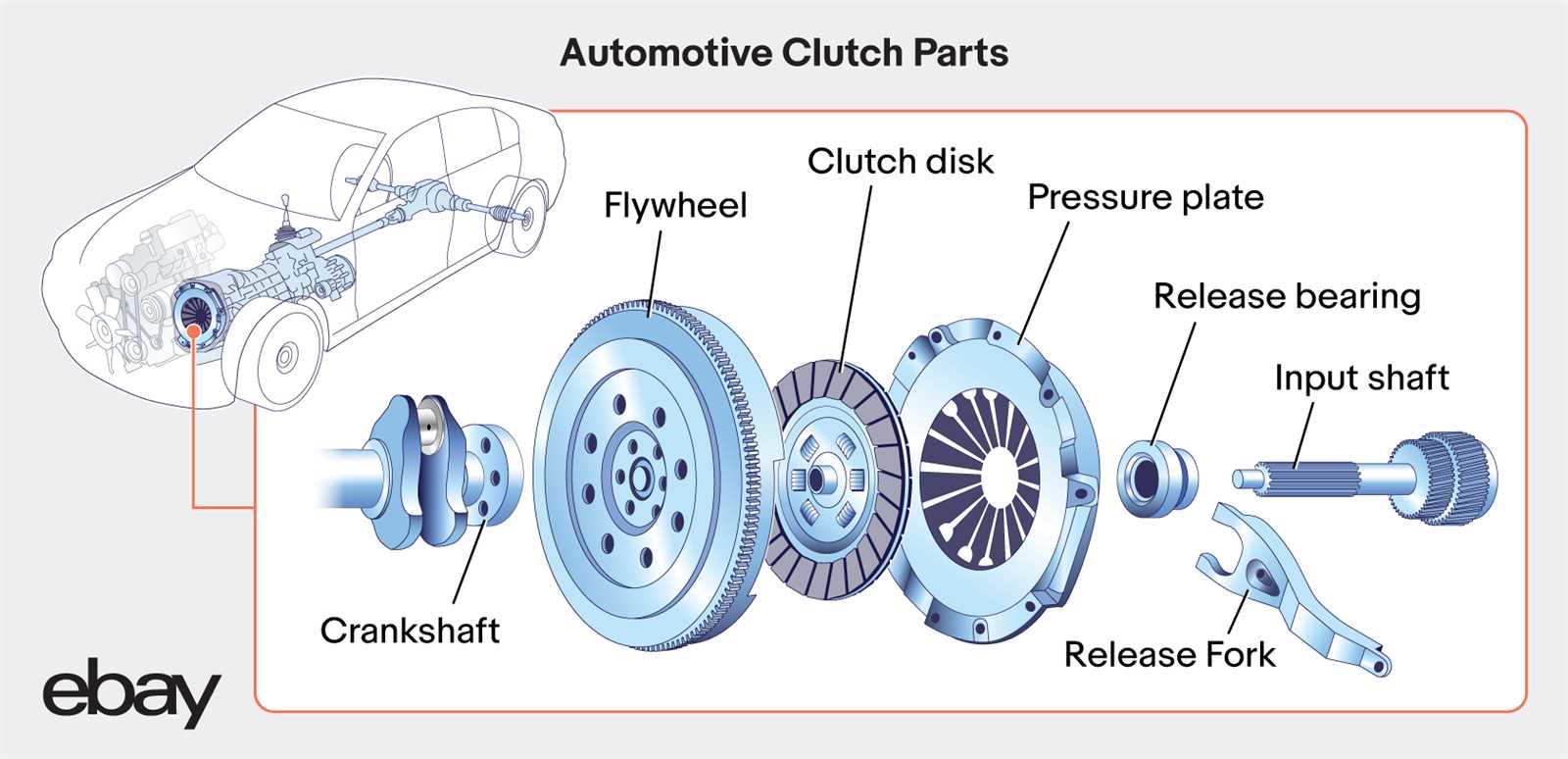

- Friction Disc: This component enables the connection between the engine and the transmission, facilitating power transfer.

- Pressure Plate: It applies force to the friction disc, ensuring a secure connection during operation.

- Release Bearing: This part disengages the friction disc when the driver operates the pedal, allowing for smooth gear changes.

- Flywheel: This element stores rotational energy and helps maintain engine momentum.

Importance of Each Component

- The friction disc’s material quality directly affects durability and performance.

- A well-functioning pressure plate is vital for effective engagement.

- The release bearing’s condition impacts the ease of shifting gears.

- The flywheel’s balance is crucial for overall engine performance and vibration control.

Understanding each of these components and their functions can lead to improved maintenance practices and enhanced vehicle performance.

How Clutch Systems Operate

The mechanism responsible for engaging and disengaging power between the engine and the drivetrain is crucial for smooth vehicle operation. This system allows for seamless transitions during acceleration and deceleration.

- When the driver presses the pedal, a series of components work together to separate the rotating elements.

- This action interrupts the connection, enabling gear shifts without grinding.

- Upon releasing the pedal, the connection is re-established, allowing for efficient power transfer.

Understanding the sequence of events enhances appreciation for the engineering behind this essential system. Key components include:

- Pressure plate

- Friction disc

- Release bearing

Each component plays a vital role in achieving the ultimate functionality, ensuring the vehicle operates smoothly across various driving conditions.

Importance of Clutch Maintenance

Regular upkeep of the transmission system is essential for optimal vehicle performance and longevity. Neglecting this aspect can lead to significant issues that affect drivability and safety.

Proper care ensures smooth operation and helps in identifying potential problems before they escalate. Frequent inspections can reveal wear and tear that may compromise the efficiency of the mechanism.

Timely maintenance not only enhances performance but also saves costs in the long run. By investing in routine checks, drivers can avoid expensive repairs and enjoy a more reliable driving experience.

Identifying Common Clutch Problems

Recognizing issues in the transmission system is crucial for ensuring smooth vehicle operation. Various signs can indicate underlying troubles that need attention, ranging from performance issues to unusual noises. Understanding these symptoms can help in early diagnosis and prevention of further damage.

Common Symptoms of Issues

- Slipping Engagement: A noticeable lack of responsiveness when accelerating, often felt as a delay in power transfer.

- Noisy Operation: Unusual sounds such as grinding or rattling during gear shifts may suggest mechanical wear.

- Difficulty in Shifting: Resistance or stiffness when changing gears can indicate problems in the system.

- Vibrations: Excessive shaking during acceleration may point to imbalance or misalignment.

Potential Causes

- Wear and Tear: Over time, components can degrade, affecting overall performance.

- Fluid Leaks: Insufficient hydraulic fluid can lead to ineffective operation.

- Misalignment: Incorrect positioning of components can cause operational inefficiencies.

- Faulty Mechanisms: Defective springs or linkages may impair functionality.

By being aware of these common issues and their symptoms, vehicle owners can take proactive steps toward maintenance and repair, ensuring a reliable driving experience.

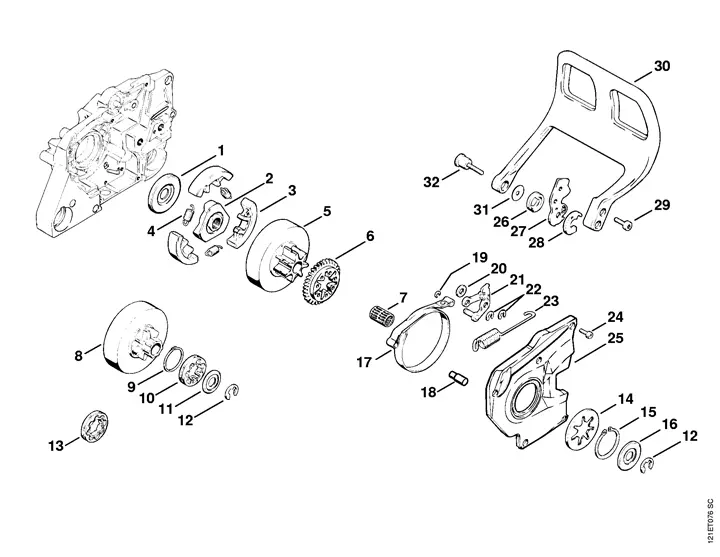

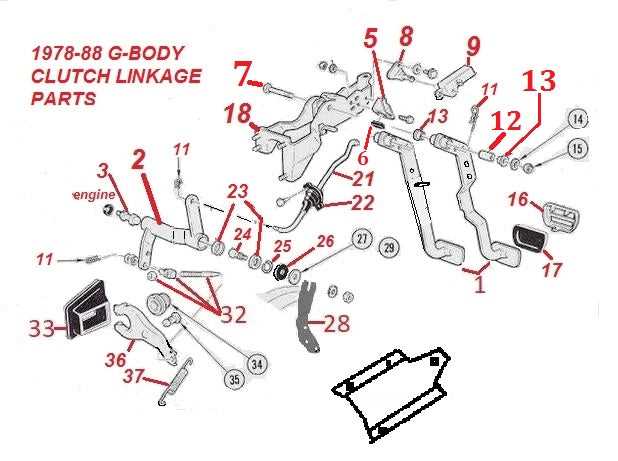

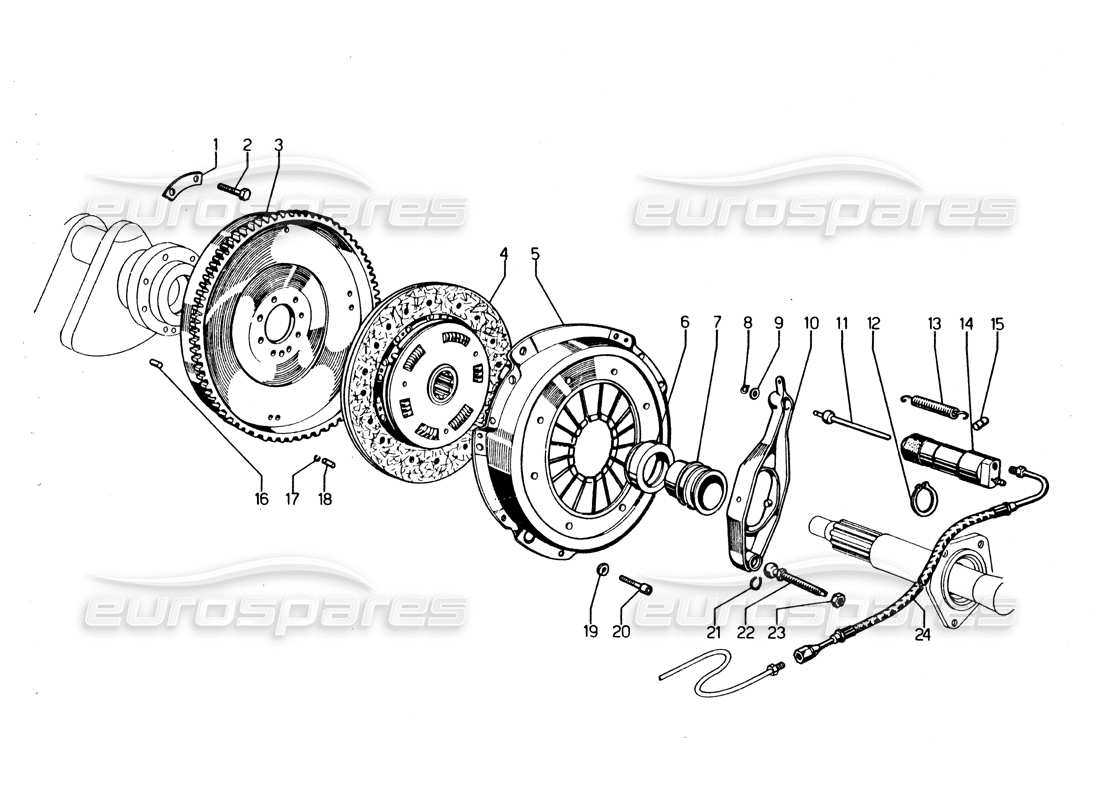

Diagram of Clutch Assembly

The mechanism responsible for engaging and disengaging power in vehicles is a complex system composed of interconnected components. Understanding its structure helps in identifying how energy is transferred smoothly between the engine and the transmission. Proper alignment of the key elements ensures effective functionality and longevity.

At the heart of this system are several critical sections, each playing a specific role in maintaining the balance between motion and control. The proper functioning of each piece is crucial for smooth transitions during gear shifts. These elements work together to provide the necessary force, allowing the smooth transfer of motion.

Included in the setup are elements designed to absorb and distribute forces evenly, ensuring that the overall mechanism operates without excessive wear. Each section is engineered to withstand high levels of stress, providing durability and precision in operation.

Choosing Quality Replacement Parts

When it’s time to replace worn components in a vehicle, ensuring the right quality is critical for performance and durability. Opting for premium alternatives helps maintain smooth operation and extends the lifespan of the entire system. It is essential to prioritize reliable materials and trusted manufacturers to avoid potential issues down the road.

Quality certification is a key factor to consider. Make sure that the products you choose meet industry standards and are tested for reliability. Certifications indicate that the components have undergone rigorous testing and adhere to specific guidelines for safety and performance.

Additionally, check compatibility with your vehicle’s model. Parts must align with the technical specifications of your system to ensure proper function. Always verify that the selected items are designed to work seamlessly with the original setup.

Clutch Types and Their Uses

Mechanical systems often rely on specialized components to manage and transfer power efficiently. These mechanisms are designed to engage and disengage power from one part of a machine to another, ensuring smooth operation and control over various processes. Different types of these systems have been developed to serve specific purposes in a range of applications.

| Type | Common Uses |

|---|---|

| Friction-Based | Ideal for vehicles and machinery, ensuring gradual engagement for smooth transitions. |

| Centrifugal | Used in small engines and scooters, relying on rotational force to automatically engage when speed increases. |

| Hydraulic | Found in heavy machinery, providing enhanced control and reliability in high-torque environments.

DIY Clutch Repair Tips

Maintaining smooth operation of your vehicle’s drivetrain requires attention to key components that wear out over time. Addressing issues early can prevent costly repairs and extend the lifespan of the entire system. This guide provides essential advice for tackling common problems yourself. Tools and PreparationBefore beginning any mechanical work, it’s vital to gather the necessary tools and ensure the vehicle is properly supported. A well-prepared workspace will make the task easier and safer. Here are some basic steps to follow:

Step-by-Step TroubleshootingOnce the area is accessible, diagnosing the problem becomes straightforward. Key signs to look for include grinding noises, difficulty in shifting, or unusual vibrations during operation. Here’s a general troubleshooting checklist: |