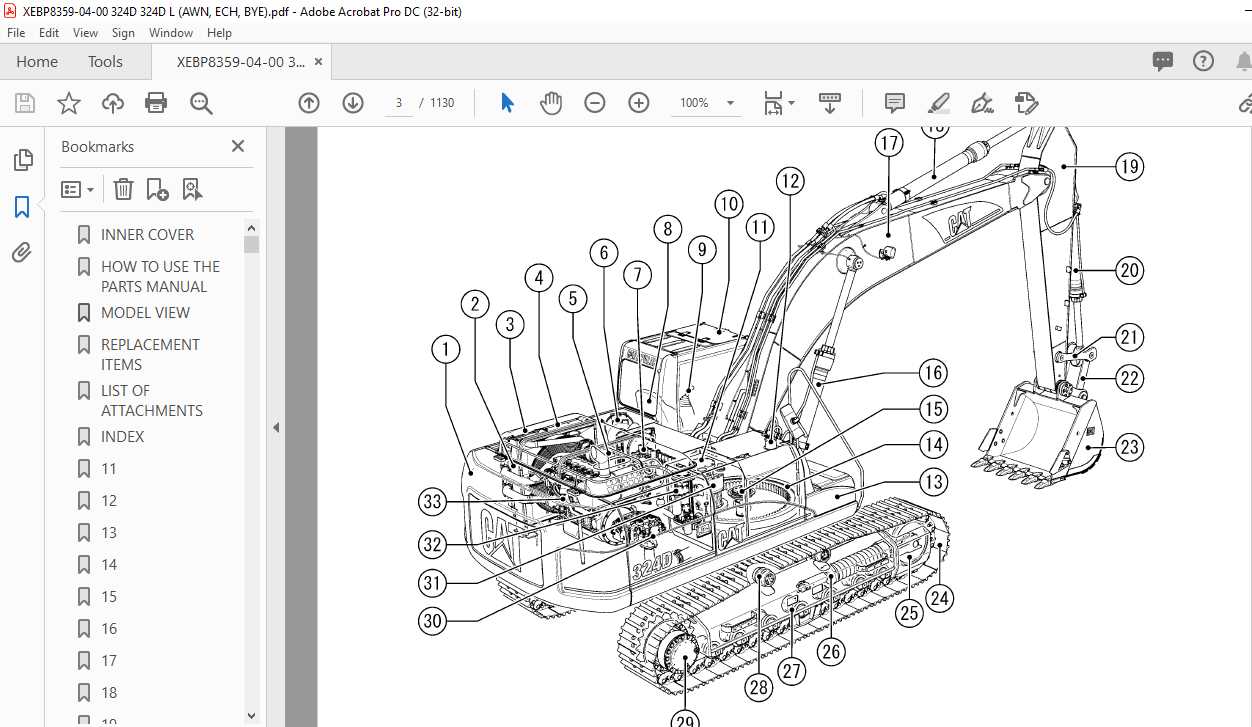

The intricate workings of heavy machinery are crucial to various industries, making knowledge of their internal structures essential for maintenance and operation. Grasping the layout and functionality of these critical elements allows operators and technicians to enhance performance and extend the lifespan of the equipment.

In this section, we will explore a detailed representation of a specific model, focusing on the arrangement and interaction of its various components. Understanding how these elements connect and work together is vital for troubleshooting and optimizing machinery performance.

By delving into this visual guide, readers will gain insights into the configuration of essential systems, ensuring that they are better equipped to handle repairs and maintenance tasks. Knowledge of these components not only aids in efficient operation but also promotes a safer working environment.

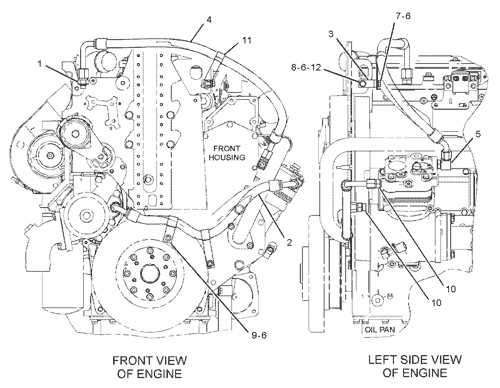

Caterpillar C7 Engine Overview

This section provides an insightful exploration of a robust power unit widely utilized in various applications. Known for its reliability and efficiency, this machine has been engineered to meet the demands of both industrial and commercial sectors.

Specifications of this powerhouse include a remarkable displacement, delivering impressive torque and horsepower. Designed with advanced technology, it features a sophisticated fuel management system that optimizes performance while minimizing emissions.

In terms of durability, this model is built to withstand harsh conditions, ensuring longevity and consistent operation. Routine maintenance and servicing are essential to prolong its lifespan and maintain peak functionality.

With a focus on user-friendliness, this unit incorporates intuitive controls and accessible maintenance points, making it a preferred choice among operators. Overall, its versatility and robust design make it an invaluable asset across a range of industries.

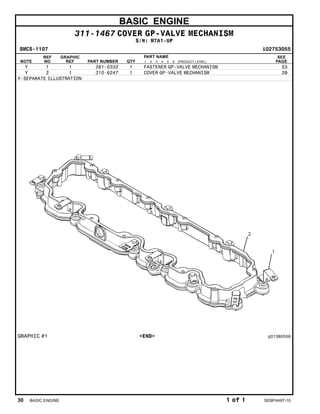

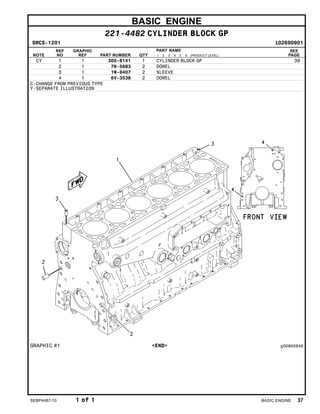

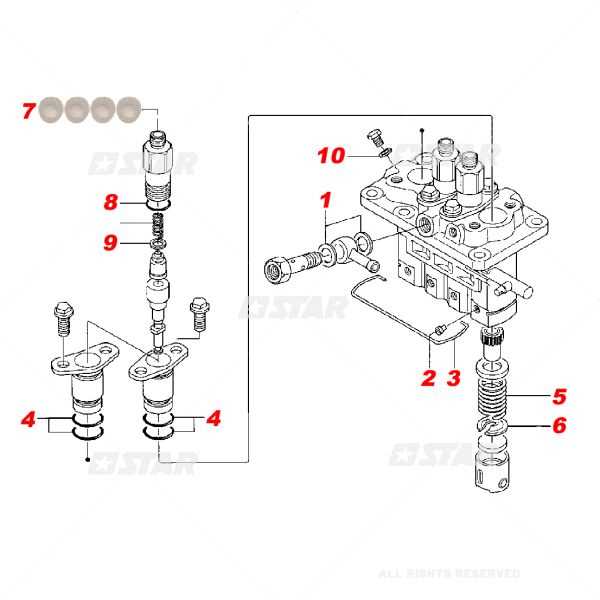

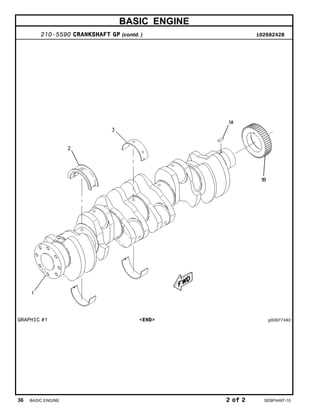

Key Components of the C7 Engine

The heart of any powerful machine lies in its core elements, each meticulously designed to ensure optimal performance and reliability. Understanding these essential features is crucial for anyone looking to grasp the intricacies of high-performance systems.

Here are the primary elements that contribute to the effectiveness of this particular unit:

- Fuel System: Responsible for delivering the right amount of fuel to the combustion chamber for efficient operation.

- Air Intake: Facilitates the entry of clean air, crucial for combustion and overall performance.

- Turbocharger: Enhances power output by forcing extra air into the combustion chamber, improving efficiency.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

- Lubrication System: Reduces friction between moving components, promoting smooth operation and reducing wear.

- Exhaust System: Directs exhaust gases away from the unit, minimizing back pressure and maximizing efficiency.

Each of these components plays a vital role in the overall functionality and performance, contributing to the seamless operation and durability of the machinery.

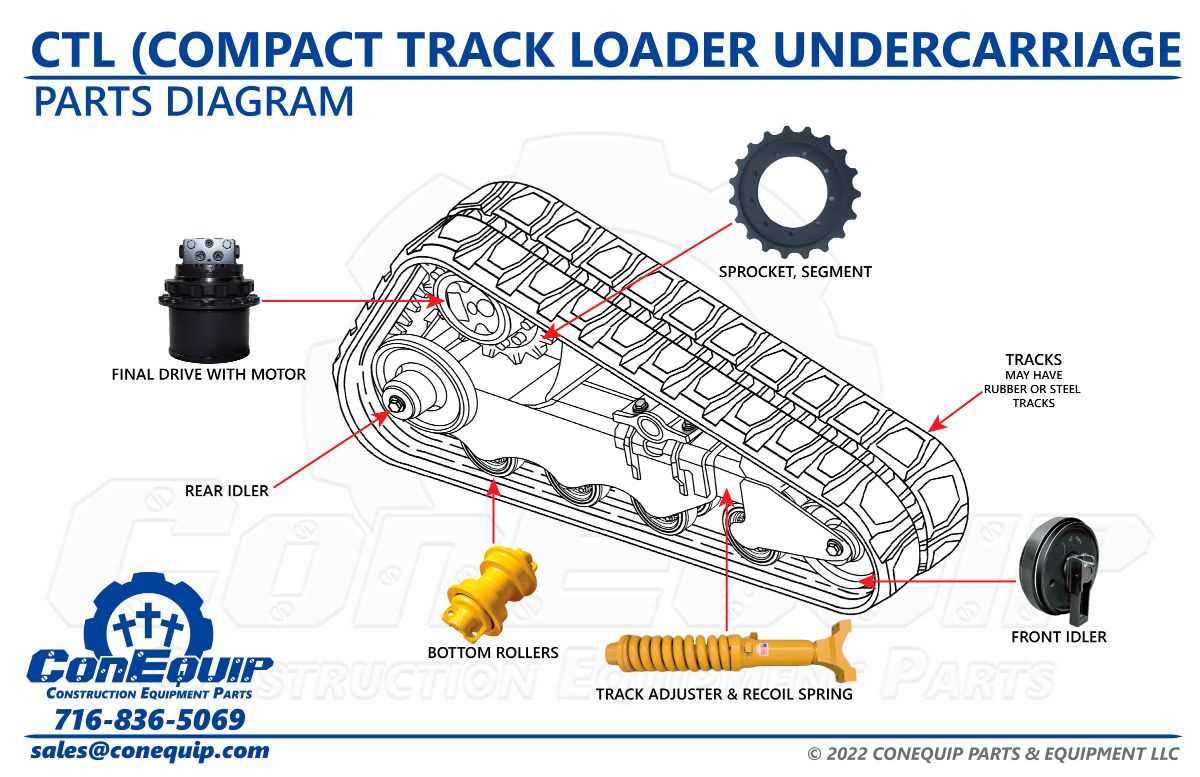

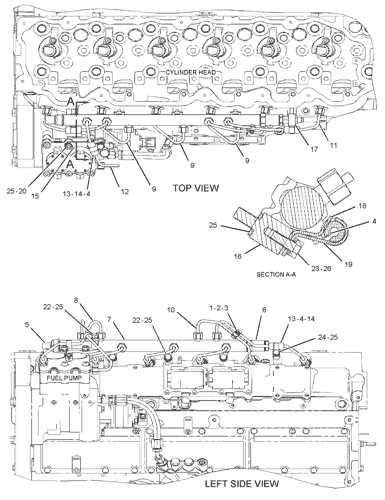

Understanding the Parts Diagram

Grasping the intricacies of mechanical illustrations is essential for anyone involved in maintenance or repair tasks. These visual representations serve as a roadmap, guiding users through the complex structure of various components.

Key elements of such visual guides include:

- Labels: Each section is clearly marked to identify specific elements.

- Connections: Arrows often depict how different components interact with one another.

- Legend: A key or legend explains symbols and colors used throughout the illustration.

By familiarizing oneself with these features, individuals can:

- Identify components and their functions more effectively.

- Trace systems to diagnose issues accurately.

- Understand assembly and disassembly processes with ease.

Ultimately, a well-constructed visual representation not only enhances comprehension but also improves the efficiency of maintenance activities.

Common Issues with C7 Parts

When dealing with a specific type of machinery, various components may present challenges that can affect performance and reliability. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the unit.

Frequent Malfunctions

One of the most prevalent issues involves overheating, often caused by inadequate cooling systems or blocked airflow. Additionally, wear and tear on critical components can lead to decreased efficiency. Regular inspections can mitigate these concerns and ensure smooth operation.

Component Failures

Another concern is the failure of seals and gaskets, which can result in leaks and loss of pressure. Moreover, electrical malfunctions can occur due to corrosion or poor connections, impacting overall performance. Addressing these issues promptly is crucial to avoid more extensive repairs.

Maintenance Tips for C7 Engine

Regular upkeep is essential for optimal performance and longevity of any heavy machinery. Proper maintenance routines not only prevent costly repairs but also ensure reliability during operation. Understanding the key aspects of care will help operators keep their equipment running smoothly.

Key Maintenance Practices

Implementing a structured maintenance schedule is crucial. Focus on the following practices:

| Practice | Description |

|---|---|

| Fluid Checks | Regularly inspect and replace oil, coolant, and other essential fluids to ensure efficient functioning. |

| Filter Replacements | Change air and fuel filters at recommended intervals to maintain clean airflow and fuel supply. |

| Visual Inspections | Conduct thorough visual checks for leaks, cracks, and signs of wear to identify issues early. |

| Electrical Systems | Examine wiring and connections for corrosion or damage to prevent electrical failures. |

| Scheduled Servicing | Follow the manufacturer’s recommended service intervals for comprehensive inspections and adjustments. |

Common Issues to Monitor

Being aware of frequent problems can help in early detection. Keep an eye on these issues:

| Issue | Signs |

|---|---|

| Overheating | Check for abnormal temperature readings or warning lights. |

| Unusual Noises | Listen for strange sounds that may indicate mechanical wear or damage. |

| Poor Performance | Notice any loss of power or responsiveness during operation. |

By adhering to these maintenance tips, operators can enhance the efficiency and reliability of their machinery, ensuring it remains in top condition for years to come.

Replacement Parts: What to Consider

When it comes to ensuring the longevity and optimal performance of your machinery, selecting the right components is crucial. Various factors play a significant role in this decision-making process, and understanding them can lead to more efficient operation and cost-effectiveness.

Quality vs. Cost

One of the primary considerations is the balance between quality and price. While it may be tempting to opt for the cheapest options available, investing in high-quality alternatives can prevent frequent breakdowns and costly repairs in the long run. Durability and reliability should always take precedence over short-term savings.

Compatibility and Specifications

Another essential aspect to evaluate is compatibility with your current setup. Ensure that the components meet the specific requirements of your machinery. Always consult the manufacturer’s guidelines to verify that the replacements align perfectly with the original specifications, as this will help maintain performance and safety.

Performance Enhancements for C7 Engines

Optimizing the output and efficiency of a powerful machine requires a strategic approach. By implementing specific modifications and upgrades, enthusiasts can achieve significant improvements in power delivery, fuel economy, and overall performance. This section explores various methods to enhance the capabilities of a high-performance unit.

Upgrades and Modifications

There are several avenues to explore when aiming to boost performance. Key enhancements include upgrading intake and exhaust systems, tuning the control module, and incorporating better fuel delivery mechanisms. Each of these modifications contributes to a more responsive and robust operation.

| Modification | Benefit |

|---|---|

| High-Flow Air Filter | Increases airflow, improving combustion efficiency. |

| Performance Exhaust System | Reduces back pressure, allowing for better gas flow. |

| ECU Tuning | Optimizes fuel maps for enhanced throttle response and power. |

| Upgraded Fuel Injectors | Delivers more fuel, supporting increased power levels. |

Considerations for Optimization

When pursuing enhancements, it’s essential to consider the balance between performance and reliability. Some modifications may strain components if not carefully integrated. It’s advisable to consult with experts or refer to reliable resources to ensure that the chosen upgrades align with the desired outcomes.

Where to Find C7 Engine Parts

Locating the necessary components for your machinery can often seem daunting. However, with the right resources and strategies, you can easily acquire high-quality replacements to ensure optimal performance.

Online Retailers: Numerous online platforms specialize in selling aftermarket and original equipment alternatives. Websites like eBay, Amazon, and specialized machinery parts stores often have extensive inventories. Always check customer reviews to ensure reliability.

Local Distributors: Many cities have authorized dealers and distributors who stock various components. Visiting these locations can provide immediate access to what you need, along with expert advice on installation and compatibility.

Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove. They often have used components that are still in good condition, offering substantial savings.

Forums and Community Groups: Engaging with online communities dedicated to machinery enthusiasts can yield valuable information. Members frequently share leads on where to find specific components, as well as tips for installation and maintenance.

Manufacturer’s Website: Always consider checking the manufacturer’s official website. They may offer direct sales or provide a list of authorized retailers where you can purchase genuine replacements.